Module: 2 Lecture: 6 ACETIC ACID (continued) Module:2

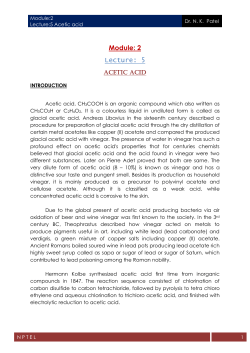

Module:2 Lecture:6 Acetic acid Dr. N. K. Patel Module: 2 Lecture: 6 ACETIC ACID (continued) 3. Ethylene oxidation Raw material Basis: 1000kg of acetic acid by ethylene oxidation Ethylene 470kg Oxygen 530kg Reaction Manufacture process Gas recycle Separator Acetaldehyde recycle to reactor Reactor Ethylene Distillation Palladium catalyst Steam Oxygen Acetic acid Figure: Manufacture of acetic acid by ethylene oxidation Block diagram of manufacturing process Diagram with process equipment NPTEL 1 Module:2 Lecture:6 Acetic acid Dr. N. K. Patel Animation Vapour phase oxidation of ethylene was carried out using palladium supported on alumina as catalyst. Ethylene and oxygen was charged into a reactor in vapour phase. The reaction temperature and pressure was 215 – 2500C and 150 -300psi respectively. Unreacted ethylene from product stream was separated in separator. The crude liquid containing acetaldehyde and acetic acid was separated in a distillation column. Acetaldehyde and ethylene obtained from distillation and separation respectively, where recycled to the process for increasing yield and conversion. 4. Oxidative fermentation Raw material Basis: 1000kg of acetic acid by oxidative fermentation Ethanol 770kg Oxygen 530kg Reaction Manufacture process Dilute ethanol solution Acetobacter Nitrogen Water vapor Cooled water Air Acetic acid still Water Water Fermenter Autoclave Steam Scrubber Acetic acid Figure: Manufacture of acetic acid by oxidative fermentation NPTEL 2 Module:2 Lecture:6 Acetic acid Dr. N. K. Patel Block diagram of manufacturing process Diagram with process equipment Animation Dilute solution of alcohol was first sterilize in autoclave and then charged in to fermenter. Oxygen in the form of air was supplied by bubbling through the solution of alcohol in fermenter. An aerobic bacterium like acetobacter was added into the fermenter for aerobic fermentation. Oxidation of ethanol was carried out at 26 – 360C temperature. Nitrogen was removed from product stream in scrubber, by scrubbing with cooled water. Liquid mixture coming out from bottom of scrubber containing acetic acid and water was separated in acetic acid still. Vinegar of 15% and 20% acetic acid was manufacture in 24hrs and 60hrs process respectively. 5. Anaerobic fermentation Raw material Sugar Anaerobic bacteria (Genus Clostridium) Nitrogen Reaction Manufacture process The species of anaerobic bacteria, including members of the genus clostridium are used which are capable to convert sugars to acetic acid directly, instead of using ethanol. At an actual 85% yield, the anaerobic process offers 60% reduction in raw material. The mechanism of anaerobic fermentation of sugar is quite complex. NPTEL 3 Module:2 Lecture:6 Acetic acid Dr. N. K. Patel Anaerobic Fermentation of sugar was carried out in fermenter. An anaerobic bacterium like clostridium was added to initiate the fermentation process. Nitrogen is supplied by bubbling during the fermentation process. Clostridium Nitrogen Water vapor Sugar Cooled water Nitrogen Acetic acid still Water Water Fermenter Scrubber Steam Acetic acid Figure: Manufacture of acetic acid by anaerobic fermentation Block diagram of manufacturing process Diagram with process equipment Animation The mixture was then charged in to scrubber where it is scrubbed with cooled water to remove excess nitrogen present in system. Mixture coming out from bottom of scrubber contains acetic acid and water which was then separated in acetic acid still. The most important method for producing acetic acid in modern industries is carbonylation of methanol. Engineering aspects Acetaldehyde oxidation process Reactor design The reaction vessel consists principally of aluminum-lines steel vessel fitted with air distributor. Aluminum coils for heating and cooling, inlet and outlet opening and an air distributor. NPTEL 4 Module:2 Lecture:6 Acetic acid Dr. N. K. Patel Alternative purification methods for acetic acid from acetaldehyde have discovered but it has no industrial application. Nitric acid and sodium nitrate were used for oxidation of formic acid and acetaldehyde, but they causes serious corrosion problem. Water Water Air Figure: Rector used in acetaldehyde oxidation Impurities are reduced rather than oxidized by oxidizing agent. The reduction is carried out by passing hydrogen over a metallic catalyst such as nickel or copper turnings. This method is not used because hydrogen can be explosive. Acetaldehyde conversion is 90%. Stainless steel must be used in plant construction. Methanol carbonylation process In carbonylation process, methanol is obtained from synthesis gas, so manufacture of acetic acid without isolating methanol is explored in both vapour and liquid phase. If halide promoted ruthenium catalyst used alcohols are generated. Acetic acid is produced by addition of Ru 3(CO)12. A selective synthesis can be done by using complex metallic catalyst containing rhodium, manganese, iridium and lithium supported on silica. Catalyst activity can be improved by running them in by stages to the optimum operating temperature over prolonged time periods. Ethylene oxidation process NPTEL 5 Module:2 Lecture:6 Acetic acid Dr. N. K. Patel Ethylene concentration Ethylene concentration was kept below 3%. If it above 3% then there is always possibilities of formation of by products viz. acetaldehyde, ethanol etc. There so yield ane acetic acid was lowered. Amount of air The oxygen supply should be kept optimum. If oxygen supply in lesser amount will kill the bacteria.If over-oxidation takes place, acetic acid will convert in to CO2 and H2O; which leads to decrease in acetic acid production. To overcome the problem efficient aeration are used by compressed air and proper mechanical device. PROPERTIES Molecular formula Molecular weight Appearance Odour Boiling point Melting point Density Solubility : C2H4O2 : 60.05gm/mole : Colourless liquid : Pungent : 118-1190C : 16-170C : 1.049gm/cm3 : Miscible with water USES As monomer in the production of vinyl acetate Used in synthesis of wood glue, synthetic fibres, fabrics and cellulose acetate Esters of acetic acid used as solvent in coatings, inks and paints industry 20% of acetic acid is used as solvent in terephthalic acid production As a stop bath in development of photographic films As a household vinegar to clean indoor climbing holds of chalk As solvent for recrystallization to purifyorganic compounds As wart and verruca remover As a food additives NPTEL 6

© Copyright 2026