Microwave inactivation of Ecoli K12

Journal of Food Engineering 116 (2013) 315–323 Contents lists available at SciVerse ScienceDirect Journal of Food Engineering journal homepage: www.elsevier.com/locate/jfoodeng Microwave inactivation of Escherichia coli K12 CIP 54.117 in a gel medium: Experimental and numerical study Mohamad Mazen Hamoud-Agha, Sébastien Curet ⇑, Hélène Simonin, Lionel Boillereaux LUNAM Université, ONIRIS, CNRS, GEPEA, UMR 6144, Site de la Géraudière, Nantes F-44322, France a r t i c l e i n f o Article history: Received 29 July 2012 Received in revised form 30 October 2012 Accepted 26 November 2012 Available online 20 December 2012 Keywords: Microwave pasteurization Thermal inactivation Predictive microbiology Finite element Escherichia coli K12 CIP 54.117 a b s t r a c t This study evaluates the efficiency of the inactivation of Escherichia coli K12, entrapped within calcium alginate gel, by microwave processing compared to a conventional approach i.e. by heating in a water bath. Microbial thermal inactivation equations coupled with heat transfer and Maxwell’s equations are integrated into a 3D Finite Elements model under dynamic heating conditions. Water bath microbial inactivation experimental data are exploited for performing parameter identification of a non-linear microbial model, and the Calcium alginate gel’s dielectric properties were numerically estimated. The coupled model provides a very good fitting to the experimental results. The simulation have shown uneven temperature distribution during microwave heating which may interpret its lower inactivation efficiency comparing to the conventional water bath treatment. This study also demonstrates the reliability of the coupled modeling approach to estimate the efficiency of the microbial inactivation, despite the thermal heterogeneity inherent in the microwave treatment. Ó 2012 Elsevier Ltd. All rights reserved. 1. Introduction Microwave heating is increasingly used for several processes in the food industry e.g. drying, thawing, meat tempering, pasteurization, sterilization and blanching of foods (Tang et al., 2008; Venkatesh and Raghavan, 2004). In fact, there are several advantages of microwave heating compared to conventional heating methods due to the different ways the energy is delivered. In particular, microwave heating can provide a rapid rise in temperature within materials of low thermal conductivity such as food products. Thus, microwave heating reduces the processing time, which may enhance overall food quality (Cinquanta et al., 2010; Guan et al., 2002; Lau and Tang, 2002; Sun et al., 2007). Microwave pasteurization has been tested on several food products, either liquid like fruit juices and milk (Cañumir et al., 2002; Kindle et al., 1996) or solid like meat (Huang and Sites, 2007; Yilmaz et al., 2005) and vegetables (Lau and Tang, 2002). Moreover, microwave heating has been shown to be effective in inactivating both gram positive and gram negative bacteria (Fujikawa et al., 1992; Giuliani et al., 2010; Guan et al., 2003; Zhou et al., 2010). The existence of non-thermal effects of microwaves on microorganisms is subject to debate. On the one hand, several publications suggest that microwave irradiation can cause non-thermal effects (Barnabas et al., 2010; Bohr and Bohr, 2000; Hong et al., 2004; Kozempel et al., 1998) while, on the other hand, some studies have ⇑ Corresponding author. Tel.: +33 2 51 78 54 63; fax: +33 2 51 78 54 67. E-mail address: [email protected] (S. Curet). 0260-8774/$ - see front matter Ó 2012 Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.jfoodeng.2012.11.030 found that microwaves inactivate microorganisms exclusively by heat (Fujikawa et al., 1992; Heddleson and Doores, 1994; Shaman et al., 2007). The most important limiting factor associated with microwave pasteurization is the non-uniform temperature distribution, resulting in hot and cold spots in the heated product. This can lead to the survival of pathogenic microorganisms in the less heated zones, which can be a major obstacle to the widespread development of microwave heating in industrial food pasteurization (Vadivambal and Jayas, 2010). This is particularly critical for solid food products where convection does not occur. For example, a recent study indicates that short time exposures of chicken portions to microwave heating did not eliminate Escherichia coli O157:H7 because of the non-homogeneous heating and wide temperature variations ranging from 66.7 to 92.0 °C (Apostolou et al., 2005). Reliable thermal processing calculations require an understanding of the thermal inactivation kinetics of microorganisms throughout the heating process and in each part of the treated samples. As a result, the microbial inactivation kinetics has to be coupled with the heat transfer phenomena to calculate the survival of bacteria, especially in the microwave non-uniform heating process. These relationships are commonly expressed in terms of mathematical models. To our knowledge, there is a lack of coupled modeling studies to understand the microwave pasteurization process. Inactivation of vegetative bacterial cells, whether due to a thermal or non-thermal food processing technique, can exhibit one of eight shapes (Geeraerd et al., 2005). As a consequence, various 316 M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 Nomenclature a, b dimensions of the wave guide (m) AsymDref asymptotic decimal reduction time (min) critical component represents physiological state of the Cc cells (-) Cp apparent specific heat (J kg1 K1) E electric field intensity (V m1) amplitude of the electric field (V m1) E0 Elocal electric field intensity at every point (V m1) h convective heat transfer coefficient (W m2 K1) H magnetic field intensity (A m1) k thermal conductivity (W m1 K1) kmax specific inactivation rate (min1) L sample length (m) N microbial population (CFU/g) N0 initial microbial population (CFU/g) Nsimul simulated microbial population (CFU/g) Nexp experimental microbial population (CFU/g) volumetric heat generation term (W m3) Qabs r radial distance (m) R radius (m) models have been proposed to describe the non-linear curves (Albert and Mafart, 2005; Geeraerd et al., 2000; Linton et al., 1995; Mafart et al., 2002; Peleg, 1999; Xiong et al., 1999). The dynamic non-linear model (Geeraerd et al., 2000) overcomes the disadvantages of several previous models (Daugthry et al., 1997; Sapru et al., 1992; Whiting, 1993; Xiong et al., 1999). This model has been successfully applied to the inactivation data of different microorganisms under various experimental conditions (Marquenie et al., 2003; Valdramidis et al., 2005; Velliou et al., 2011). Microwave heating can be modeled using two main approaches: Lambert’s law, which assumes an exponential decay of microwave absorbed power as a function of penetration depth within the sample, or a method based on the complete resolution of Maxwell’s equations, which govern the electromagnetic field propagation. In the case of thin samples, i.e. much smaller than the microwave penetration depth, Maxwell’s equations need to be solved (Chen et al., 2008; Curet et al., 2008). Furthermore, for cylindrical geometries, the Lambert’s law approach provides a less accurate temperature distribution during microwave heating compared to the Maxwell’s equations approach (Yang and Gunasekaran, 2004). There is no study which highlights both experimental and numerical data concerning the microbial inactivation in solid matrix during a microwave heating treatment. In this paper, the microbial inactivation effect of microwave heating is compared with a conventional water bath inactivation. Furthermore, in order to interpret the microwave inactivation results, Maxwell’s equations and heat transfer are coupled to microbial inactivation equations, and integrated into a 3D Finite Element model under dynamic heating conditions. 2. Materials and methods 2.1. Culture and preparation of cell suspensions E. coli K12 CIP 54.117 was obtained from the Pasteur Institute, France. The stock culture was kept at 80 °C in Brain Heart Infusion (BHI) broth (Fluka-53286 Sigma–Aldrich, 38297 St. Quentin Fallavier, France) with 30% (v/v) glycerol (104094 Merck, Darmstadt, Germany). A pre-culture was prepared by transferring a loopful of the stock culture into 10 mL Tryptic Soy Broth (TSB) T T0 T1 Tref x, y, z z value temperature (°C) initial temperature of product (°C) ambient temperature (°C) microbial inactivation reference temperature (57 °C) spatial coordinates in the three dimensions (m) thermal resistance constant (°C) Greek letters e complex permittivity (F m1) e0 permittivity of vacuum (8.85 1012 F m1) e0r relative dielectric constant e0r 0 relative dielectric loss factor l magnetic permeability of the material (H m1) l0 magnetic permeability of vacuum (1.256 106 H m1) q density (kg m3) r electrical conductivity (S m1) x pulsation of the microwave radiation (rad s1) (9100461, 30 g/L Biokar, Grosseron, 44819 St. Herblain, France) and incubating it at 30 °C for 24 h on a rotary shaker at 175 rpm (Excella E24, New Brunswick Scientific, Edison, New Jersey, USA). 1 mL of the pre-culture was then subcultured into 100 mL fresh TSB in a 250-mL Erlenmeyer flask in the same conditions for 16 h. Early stationary-phase cultures were harvested by centrifuging the broth culture for 10 min at 8720g at 4 °C (Jouan, GR 20.22, Thermo scientific, 91963 Villebon sur Yvette, France). The pellet was resuspended to approximately 1.5 1010 cells per mL in 20 mL sterile Phosphate Buffered Saline (PBS). 2.2. Calcium alginate gel preparation Calcium alginate (Ca-alginate) gel is widely used as an experimental material in food-related research (Yoo et al., 1996). Two volumes of sterile 3% (w/w) sodium alginate solution (Algogel 3021, Cargill, 78100 St. Germain en laye, France) were mixed with one volume of the cell suspension. By using a 3-mm diameter cutended micropipette, 0.5 mL of this mixture was then flowed gently and constantly into a sterile 1% (w/w) CaCl2 solution. The resulting cylindrical gels were hardened in this solution for 15 min, then washed with sterile PBS to remove excess calcium ions and untrapped cells. The gels were then dried for 10 min inside the laboratory fume hood. The final gels (8 mm diameter, 10 mm height) of 0.53 ± 0.2 g with a cell concentration of 109 CFU/g were used immediately. 2.3. Programmable water bath treatment A dynamic heating experiment was designed to compare the inactivation rate after conventional water bath heating and microwave heating. Glass test tubes (9 mm diameter, 150 mm height) were filled with approximately 1 g of Ca-alginate gel, sealed by a sterilized aluminum paper and then subjected to linear heating in a programmable water bath (Hart Scientific 9105, American Fork, UT, USA). The water bath temperature was programmed to increase linearly from 20 °C to 64 °C at 9 °C/min, which was calculated by a linear regression of the microwave heating ramp for the lethal range (i.e. 50–64 °C). The temperature of the gel was measured in the geometrical center of the tube by using a sterile thermocouple linked to a data logger (AOIP datalog, 91133 Ris Orangis, 317 M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 France). At specific temperatures (50, 55, 57, 59, 62, 64 °C), the heating was ended by immersing the tube in iced water. Viable cells were then enumerated. Results are the average of at least three independents trails. 2.4. Microwave instrument and treatment The experimental apparatus was a microwave system (Fig. 1), supplying a monochromatic wave in the fundamental mode, TE10, operating at a frequency of 2.45 GHz. Microwave energy was transmitted along the z-direction of a rectangular waveguide (cross-section 86 mm 43 mm). To ensure that only a minimal amount of microwave was reflected back to the sample, a water load was fixed at the end of the guide (at 450 mm under the sample, water flow rate of 0.23 L/min, DT 10 °C). Its efficiency in absorbing microwaves was tested by measuring reflected power in the waveguide using a directional coupler. Continuous microwave treatment was performed by putting one cylindrical gel per sterile EppendorfÒ tube (11 mm diameter, 40 mm height), sealing it tightly and then arranging two tubes on a polystyrene plate (84 mm 41 mm 10 mm) placed perpendicular to the direction of the irradiation. The incident microwave power was adjusted to 130 W and the samples were heated from ambient temperature to 64 °C. The effect of the polystyrene layer on the electric field was neglected. A preliminary test has been carried out to ensure that the plastic EppendorfÒ tubes do not absorb microwave energy. Due to the symmetrical condition for the electromagnetic field distribution (TE10 mode), temperatures were measured in one tube as illustrated in (Fig. 1) by using optical fiber sensors (T1 Neoptix, Quebec, Canada) inserted at two geometrical central points and attached to a data logger (ReFlix-4, Neoptix, Quebec, Canada). Like for the water bath treatment, one tube was removed at different temperatures (50, 55, 57, 59, 62, 64 °C), cooled immediately in iced water and then the viable cells were enumerated. Results are the average of at least three independents trails. 2.5. Measurement of cell inactivation An appropriate quantity of McIkaine buffer (0.2 M Na2HPO4, 0.1 M citric acid) was prepared to dissolve the gel in order to release the cells from the beads after the heat treatment. For the programmable water bath assays, 3 mL of McIkaine buffer was added to the tube and the mixture was then drained into a sterile stomacher bag. The test tube was rinsed with 3 mL of PBS and again drained into the bag. For the microwave tests, the gel was transferred, in aseptic conditions, into a sterile stomacher bag and the tubes were rinsed with 1.5 mL of PBS which was then drained into the bag. 1.5 mL of McIkaine buffer was finally added to the bag. The mixture was homogenized by a Stomacher Lab Blender (Interscience BagmixerÒ 400 B054300, Grosseron, 44819 St. Herblain, France) for 25 min. The number of cells released was measured by plating appropriate decimal serial dilutions of the homogenized mixture on Tryptic Soy Agar in duplicate then incubating them at 30 °C for 48 h. The results are the average of at least three independent repetitions for each of these treatments. 2.6. Modeling microbial inactivation under non-isothermal conditions 2.6.1. Modeling of microbial inactivation Without incorporating the tailing effect, as it was not observed in the experimental data, the reduced equations of the model were adopted to describe the non-isothermal inactivation kinetics (Geeraerd et al., 2000). It consists of two coupled ordinary differential equations as follows: dN 1 N ¼ kmax dt 1 þ Cc ð1Þ dC c ¼ kmax C c dt ð2Þ where N represents the microbial population (CFU/g), Cc (critical component) relates to the physiological state of the cells (–), and kmax is the specific inactivation rate (1/min). Thermal inactivation parameters, i.e. the asymptotic decimal reduction time (AsymDref) (Juneja et al., 2001) and the thermal resistance constant (z value), which is the temperature change required to achieve a tenfold change in AsymD, were integrated into the Bigelow model (Eq. (3)) to yield predictions for the specific inactivation rate at a given temperature. kmax ðTÞ ¼ ln 10 ðlnz10ðTT ref ÞÞ e AsymDref ð3Þ Within the lethal range of 50–64 °C, the heating ramp of 9 °C/ min was implemented in the numerical model with a linear regression of the experimental data. The reference temperature, Tref, was chosen to be equal to the middle of the lethal experimental temperature range (i.e. 50– 64 °C) in order to minimize the uncertainty of AsymDref (Poschet et al., 2005). 2.6.2. Estimation of bacterial inactivation kinetics The parameters implemented in the inactivation model (AsymDref, z, and Cc(0)) were estimated by using the Levenberg– Marquardt optimization method (available in MatlabÒ software) This technique has already proved its reliability for estimating the kinetic parameters of the inactivation model (Valdramidis et al., 2008). The criterion to minimize is defined following the root mean square error between the water bath experimental data and the numerical data: J¼ Fig. 1. Microwave system. t final X i¼t init Nsimul ðiÞ Nexp ðiÞ log log N0 N0 !2 ð4Þ 318 M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 where N0 is the initial microbial population (CFU/g), Nsimul is the simulated microbial population, and Nexp is the experimental microbial population at the same time. To our knowledge, there is no inactivation data available in the literature for E. coli K12 in a gel media; therefore, the model parameters were numerically calculated based on previous observations in the literature concerning E. coli (Juneja and Marmer, 1999; Juneja et al., 1997; Valdramidis et al., 2005). The initial estimates for the unknown parameters were: AsymD57 = 5 min, z = 6 °C/min, Cc(0) = 0.82 (–). The optimization algorithm was also tested with different initial parameters to reduce the risk of stopping on a local minimum. The 95% confidence interval of the optimized parameters was also calculated (nlparci function in MatlabÒ software). The maximum amplitude of the incident electric field was located at the center of the sample. Due to the non-uniformity of the electric field along x and the symmetry considerations at the center, 1=4 of the rectangular waveguide was modeled. As a result, only one half of the cylindrical sample was considered (Fig. 2). Maxwell’s equations were solved in both air and the cylindrical sample, and the microwave heat generation in the sample was deduced from the electromagnetic field distribution. For the TE10 mode (Ex = Ez = 0), the general governing equation for electric field propagation after mathematical simplification leads to (Curet et al., 2009): @ 2 Ey @ 2 Ey þ 2 @x2 @z ! þ x2 le0 1 j r E ¼0 xe0 y ð5Þ With the associated initial and boundary conditions: 2.7. Modeling of heat transfer during microwave heating E¼0 In order to analyze the heat transfer during microwave heating of a cylindrical sample, the following assumptions were made: Assumption 1: The product is surrounded by a medium with zero dielectric losses (air). Thus, the heat transfer is not spatially solved within the surrounding medium (air) due to the dielectric characteristics being very close to a vacuum. However, natural convection to the air is considered as a boundary condition. Assumption 2: The product is homogeneous and isotropic. Assumption 3: The thermophysical properties are constant and the dielectric properties are temperature-dependent. Assumption 4: The mass transfer is negligible. Assumption 5: The walls of the waveguide are perfect electric conductors. Assumption 6: The initial temperature of the sample is homogeneous. Assumption 7: The shrinkage of the sample is neglected during the thermal treatment. 2.7.1. Modeling of microwave propagation In our case, the TE10 mode was considered and the electric field was contained within the (xOy) plane with only one component Ey. at t ¼ 0; 8x y z Ein ¼ E0 cos p x a at z ¼ þ1; 8x y; 8t i 0 n ðHair Hsample Þ ¼ 0 nH¼0 Ey ¼ 0 at r ¼ R; 8z and z ¼ L=2; 8r; 8t i 0 at x ¼ 0; 8z y; 8t i 0 at x ¼ a=2; 8z; y; 8t i 0 The heat generation due to microwaves was computed from the local electric field strength at any point of the cylindrical domain. Q abs ¼ 1 x e0 e00r jElocal j2 2 ð6Þ 2.7.2. Modeling of heat transfer Heat transfer is based on the generalized heat equation, which depends on the thermo-physical properties of the product, as follows: qC p @T ¼ div ðkrTÞ þ Q abs @t Fig. 2. Model design. ð7Þ M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 The local electromagnetic heat generation term Qabs quantifies the amount of power dissipated into the gel by dielectric losses. The associated initial and boundary conditions can be expressed as follows: T ¼ T0 k at t ¼ 0; 8r 8z; T 0 ¼ 20 C @T ¼ 0 8z; 8t i 0 @r r¼0 @T k ¼ hðT T 1 Þ 8z; 8t i 0; @r r¼R k @T ¼ hðT T 1 Þ @z z¼L=2 319 COMSOLÒ Multiphysics 4.2a. The mesh consists of 26750 tetrahedral elements and is a good compromise between precision and computation time. In order to simulate 270 s of the complete microwave heating process, the total CPU time required was approximately 30 min on a SUNÒ Microsystems U40 Workstation, equipped with 2 AMDÒ Opteron processors, at 3 GHz, with 20 GB of RAM, running on RedHatÒEnterprise LINUX 5, 64 bits. 2.8. Model validation T 1 ¼ 18:5 C 8r; 8t i 0 The convective heat transfer coefficient is due to natural convection between the surrounding air medium and the surface of the sample. As a first approximation, the convective coefficient was calculated from empirical correlations for vertical isothermal plates with a correction factor to make them applicable to vertical isothermal cylinders (Cebeci, 1974). The local heat transfer coefficient from a vertical isothermal plate can be obtained from an empirical correlation (Churchill and Chu, 1975). 2.7.3. Thermophysical and dielectric properties The thermophysical properties of Ca-alginate gel were taken directly from the literature for a sodium alginate gel (Lin et al., 1995). They were thus determined to be: Density, q = 1010 kg m3 Specific heat, Cp = 4120 J kg1 K1 Thermal conductivity, k = 0.8374 W m1 K1 The key factor for the numerical modeling during microwave heating is the knowledge of the dielectric properties of Ca-alginate gel. Due to experimental complexity, the dielectric properties were numerically estimated, over the heating range (20–64 °C), based on temperature dependant equations available in the literature for sodium alginate gel (Lin et al., 1995). During the optimization procedure, five numerical parameters related to linear or polynomial functions were adjusted (Eqs. (8) and (9)). The Levenberg–Marquardt optimization method was used to minimize the error between the temperature–time microwave experimental measurements at the geometrical center of the sample and the simulated ones. 2.7.4. Computational details Based on a Finite Element method, the three-dimensional numerical model was solved with the computational code After establishing the microwave coupled model and selecting the appropriate parameters, the simulated temperature profile at the geometrical center was compared with the experimental data. The volumetric mean inactivation predicted from the model was also compared to the experimental inactivation data. 3. Results and discussion 3.1. Inactivation of E. coli K12 during microwave and water bath heating The experimental temperature at the geometrical center of Caalginate gel exposed to 130 W microwave power and to a programmed water bath treatment is displayed in Fig. 3.a. The time– temperature profile shows an almost linear come-up profile, previously reported for microwave heating (Pitchai et al., 2012; Ramaswamy and Pilletwill, 1992). Several studies have reported that thermal inactivation of a micro-organism not only depends on treatment temperature and holding times, but also how fast the samples were brought to the treatment temperature (Chung et al., 2007; Huang, 2009; Valdramidis et al., 2007). Based on microwave experiments, a heat ramp of 9 °C/min was reproduced by a programmable water bath to eliminate the effect of heating history on microbial death. The temperature of the water bath was automatically controlled to increase linearly from 20 °C to a final temperature of around 64 °C. The lag time at the beginning of the curve is due to the thermal conduction from the outside layers to the center of the tube. Nevertheless, the global temperature profiles for the water bath and microwave treatments show the same heating rates from 20 to 64 °C (Fig. 3a). The experimental survival curves during conventional heating of E. coli K12 within Ca-alginate gel was compared to the inactivation curves obtained with a microwave heating process (Fig. 3b). No significant differences in microbial inactivation were observed for temperatures up to 59 °C. For higher temperatures, the inactivation due to microwave heating was largely lower (more than 5log) than that obtained for water bath heating. Fig. 3. (a) Heating ramps under microwave (continuous line) and programmed water bath (dashed line) treatments, linear regression (dotted lines), and (b) experimental inactivation of E. coli K12 in Ca-alginate gel during microwave (s) and water bath heating (d), standard deviations (|). 320 M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 Table 1 Identification of parameters based on water bath inactivation data. AsymD57 (min) z (°C) Cc(0) (–) 3.9 ± 0.7 6.28 ± 0.36 0.23 ± 0.23a a The sensitivity analysis reveals that the Cc(0) value does not significantly influence the optimization results. The experimental and predicted data of E. coli inactivation within water bath are presented in Fig. 4. The bacterial concentration did not change significantly at the early stage of the heating process. However, the rate of bacterial inactivation accelerated above 59 °C. Reliable microbial inactivation parameters were extracted. The model was able to describe the inactivation of the bacteria under water bath treatment. It thus appears that the Geeraerd et al. (2000) model provides a very good fit for our experimental results under dynamic conditions. The relevance of this methodology during a microwave inactivation process within Ca-alginate gel is now evaluated. 3.3. Simulation of heat transfer during microwave treatment Fig. 4. Fit of the reduced Geeraerd et al. (2000) inactivation model (continuous line) for water bath experimental data (d) (from 50 °C to 64 °C) with the use of a linear temperature profile (dashed line), standard deviations (|). To explain this lower microbial microwave inactivation, it was assumed that the geometrical center of the sample may not be the actual cold point despite the small volume of the gel. Due to the difficulty in predicting experimentally the cold point location, the numerical simulation remains a reliable tool. Thus, numerical simulations were used to study the temperature distribution within the gel, and to explain the inactivation efficiency differences between the two treatments. In order to predict the temperature profiles in the sample during microwave heating, a three-dimensional Finite Element model of coupled heat transfer and electromagnetism was designed. The convective heat transfer coefficient is obtained from an empirical correlation dedicated to vertical isothermal cylinder. The natural convection coefficient ranges from 7 to 13 W m2 K1 and is a function of temperature of the sample. The temperature-dependent dielectric properties of Ca-alginate gel needed to be accurately characterized. Based on literatures equations, the numerically optimized dielectric properties of the gel in this research were found to be similar to those of sodium alginate gel (Fig. 5b), particularly for the dielectric loss factor for which very close values were obtained. The influence of the dielectric constant on the heating was more remarkable. The difference between the optimized Ca-alginate and the literature Na-alginate values is due to the different salt content in the two studies (Stogryn, 1971). At the optimum, five parameters were adjusted and the dielectric properties were expressed as functions of temperature, as shown in Eqs. (8) and (9): Dielectric constant; 3.2. Modeling microbial inactivation under water bath heating Water bath inactivation data were used to predict the inactivation curves of E. coli K12 in Ca-alginate gel under dynamic heating conditions from the Geeraerd et al. (2000) model. The model used in this study was validated with a predefined temperature profile with a heating rate of 9 °C/min. The resulting parameters based on the Levenberg–Marquardt optimization technique and their confidence intervals are shown in Table 1. e0r ¼ 86 0:27 T ð CÞ Dielectric loss factor; e00r ¼ 19:92 0:296 T þ 0:0025 T 2 ð8Þ ð9Þ The modeling of microwave absorbed power and temperature distribution in microwave heating was highly reliable and the numerical data fitted the experimental data very well. The evolution of the experimental temperature compared to the numerical data is depicted at the sample center (Fig 5a) Three-dimensional temperature contours obtained from the numerical simulation (Fig. 6). The simulation highlights uneven temperature distributions and a large temperature gap (more than Fig. 5. (a) Measured temperature profiles (s) with standard deviations (|) at the sample center, simulated temperature profile with the optimized Ca-alginate dielectric properties (continuous line) and simulated temperature profile with the Na-alginate dielectric properties (dashed line), and (b) comparison of the dielectric properties of Caalginate (continuous line) and Na-alginate (dashed line). M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 Fig. 6. (a) 3D temperature distribution within the cylindrical Ca-alginate gel at the end of microwave processing (Pin = 130 W, t = 270 s), (b) cross-section at the gel top surface, (c) cross-section at the gel center, and (d) cross-section at the gel bottom surface. 5 °C) is observed between the hottest and coldest points within the heated sample. Confirming the focusing effect observed by previous studies for cylindrical objects (Vilayannur et al., 1998; Zhou et al., 1995), the numerical simulation demonstrates that hot spots occurred along the central axis whereas cold spots were located near the surface. As a consequence, the bacteria located at the surface were not significantly affected by the heating temperature. The natural convection at the surface and the heat generated by microwaves tends to a local thermal equilibrium. This may explain the difference between the water bath and microwave inactivation results observed (Fig. 3). Thus, despite the small volume of the sample, the large inactivation variability between the water bath and microwave treatment is probably due to a significant non-uniform temperature distribution during the microwave treatment. 3.4. Simulation of microbial inactivation during microwave treatment As the temperature inside the food product is not uniform, the microbial evaluation is a function of space coordinates. Thus, the overall destruction of bacteria during microwave heating was evaluated by implementing the coupled ordinary differential equations of the Geeraerd et al. (2000) model into the 3D Finite Element model over the entire course of the heating process. The previous parameter estimation results during water bath treatment were taken as inputs for the microwave kinetic parameters. To accept this 321 Fig. 7. (a) 3D E. coli inactivation distribution within the cylindrical Ca-alginate gel at the end of microwave processing (Pin = 130 W, t = 270 s), (b) cross-section at the gel top surface, (c) cross-section at the gel center, and (d) cross-section at the gel bottom surface. application, the non-thermal effect of microwaves on microorganisms was neglected. In this study, microbial inactivation is defined at any point as a function of time. The 3D distribution of E. coli inactivation in the gel was calculated using the simulation procedure during a microwave treatment of 270 s (Fig. 7). These results demonstrate a problem of non-uniform inactivation and agree with the uneven temperature distribution. The inactivation efficiency varies a great deal (more than 2log) between the different locations within the sample. The microbial survival data from the coupled model were integrated numerically over the whole geometrical volume. The mean inactivation values predicted by the numerical model as a function of temperature located at the center of the sample are presented in Fig. 8. The results show very similar inactivation behavior for both numerical and experimental points. This result also demonstrates the accuracy of the kinetic parameter estimation and the successful data extrapolation from water bath experiments to microwave processing. As a result, the microwave treatment is a thermal process and no difference with the conventional treatment was numerically confirmed. It is clear that uncontrolled process conditions lead to the development of unacceptable uneven temperature distributions caused 322 M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 Fig. 8. Fit of the reduced Geeraerd et al. (2000) inactivation model for microwave experimental data (s) (continuous line) and water bath data (d) (dashed line). by a number of interacting factors. The most important factors that influence the uniformity of temperature distribution are the dielectric and thermophysical properties of the food, the shape and size of the product and the frequency and power of the incident electromagnetic wave (Datta, 1990). Uniform and effective heating depend on the proper integration of all these parameters at the same time. One of the possible reasons for obtaining this heterogeneity in our study is the use of continuous microwaves. Some studies found that pulsed microwave heating provides more uniform heating within agar gel cylindrical samples comparing to continuous microwave heating (Gunasekaran and Yang, 2007). Furthermore, another study reported a more marked influence of pulsed waves than continuous ones on the inactivation rate of E. coli K12 IF0 3301 (Sato et al., 1996). Thus, we can hypothesize that pulsed microwaves are more reliable for microwave pasteurization. In order to design a reliable microwave heating operation, knowledge of the local temperature distribution during the treatment is required. Currently, there are a number of different methods for measuring temperatures in microwave fields; their advantages and shortcomings are discussed in a recent study (Knoerzer et al., 2009). A three-dimensional temperature map dedicated to microwaveheated products is an essential requirement to ensure food safety in microwave pasteurization processes. The spatial resolution achievable by using fiber-optic sensors is often unsatisfactory and the reliability of using fiber-optic sensors to ensure food safety in microwave pasteurization processes can therefore be questioned. By the use of numerical modeling, our study clearly demonstrates the possibility of locating the coldest point inside the food matrix and predicting the microwave inactivation of bacteria. 4. Conclusion The objective of this research was to compare a microwave inactivation of E. coli K12, entrapped within Ca-alginate gel, with a conventional inactivation in dynamic heating conditions. Due to non-uniform microwave heating, lower inactivation efficiency was obtained by the microwave treatment. By using a Finite Element method, a predictive modeling approach for microwave pasteurization is proposed. Governing equations for electromagnetic propagation, heat transfer and microbial inactivation were successfully coupled to predict the temperature distributions and microbial inactivation within the gel. The suitability of Geeraerd et al. (2000) models for describing the survival of E. coli was confirmed for a solid medium during water bath and microwave inactivation treatment. The results also highlight the possibility of modeling the microwave process, provided that a good estimation of the dielectric properties is available. Microwave heating differs from conventional heating in that measuring the temperature at a few locations does not guarantee the real temperature distribution in the product, as the heating pattern can be uneven and difficult to predict. Thus, volumetric measurement of temperature or accurate determination of the cold point within the product is mandatory. This study clearly demonstrates that the differences between conventional and microwave inactivation processes are due to temperature heterogeneities. As a perspective, the coupled model should now be tested with new operating conditions in order to evaluate its robustness in predicting microbial inactivation for microwave pasteurization. A further development of this approach describes a feedback-control loop in the simulation based on a combination of electromagnetism, heat transfer and microbial inactivation calculations, which helps to optimize microwave processes to ensure their safety as a reliable pasteurization method. Acknowledgment The authors acknowledge the financial support provided by the Syrian Ministry of Higher Education and Scientific Research. References Albert, I., Mafart, P., 2005. A modified Weibull model for bacterial inactivation. International Journal of Food Microbiology 100 (1–3), 197–211. Apostolou, I., Papadopoulou, C., Levidiotou, S., Ioannides, K., 2005. The effect of short-time microwave exposures on Escherichia coli O157: H7 inoculated onto chicken meat portions and whole chickens. International Journal of Food Microbiology 101 (1), 105–110. Barnabas, J., Siores, E., Lamb, A., 2010. Non-thermal microwave reduction of pathogenic cellular population. International Journal of Food Engineering 6 (5), 20. Bohr, H., Bohr, J., 2000. Microwave-enhanced folding and denaturation of globular proteins. Physical Review E 61 (4), 4310–4314. Cañumir, J.A., Celis, J.E., de Bruijn, J., Vidal, L.V., 2002. Pasteurisation of apple juice by using microwaves. LWT – Food Science and Technology 35 (5), 389–392. Cebeci, T., 1974. Laminar free convective heat transfer from the outer surface of a vertical slender circular cylinder. In: 5th International Heat Transfer Conference, Tokyo. pp. 15–19. Chen, H., Tang, J., Liu, F., 2008. Simulation model for moving food packages in microwave heating processes using conformal FDTD method. Journal of Food Engineering 88 (3), 294–305. Chung, H.J., Wang, S.J., Tang, J.M., 2007. Influence of heat transfer with tube methods on measured thermal inactivation parameters for Escherichia coli. Journal of Food Protection 70 (4), 851–859. Churchill, S.W., Chu, H.H.S., 1975. Correlation equations for laminar and turbulent free convection from a vertical plate. International Journal of Heat and Mass Transfer 18 (11), 1323–1329. Cinquanta, L., Albanese, D., Cuccurullo, G., Di Matteo, M., 2010. Effect on orange juice of batch pasteurization in an improved pilot-scale microwave oven. Journal of Food Science 75 (1), E46–E50. Curet, S., Rouaud, O., Boillereaux, L., 2008. Microwave tempering and heating in a single-mode cavity: numerical and experimental investigations. Chemical Engineering and Processing: Process Intensification 47 (9–10), 1656–1665. Curet, S., Rouaud, O., Boillereaux, L., 2009. Effect of sample size on microwave power absorption within dielectric materials: 2D numerical results vs. closed-form expressions. AIChE Journal 55 (6), 1569–1583. Datta, A.K., 1990. Heat and mass transfer in the microwave processing of food. Chemical Engineering Progress 86 (6), 47–53. Daugthry, B.J., Davey, K.R., Thomas, C.J., Verbyla, A.P., 1997. Food processing – a new model for the thermal destruction of contaminating bacteria. In: Jowitt, R.E. (Ed.), Engineering and Food at ICEF 7. Sheffield Academic Press, pp. A113–A116. Fujikawa, H., Ushioda, H., Kudo, Y., 1992. Kinetics of Escherichia coli destruction by microwave irradiation. Applied and Environmental Microbiology 58 (3), 920– 924. Geeraerd, A.H., Herremans, C.H., Van Impe, J.F., 2000. Structural model requirements to describe microbial inactivation during a mild heat treatment. International Journal of Food Microbiology 59 (3), 185–209. Geeraerd, A.H., Valdramidis, V., Van Impe, J.F., 2005. GInaFiT, a freeware tool to assess non-log-linear microbial survivor curves. International Journal of Food Microbiology 102 (1), 95–105. Giuliani, R., Bevilacqua, A., Corbo, M.R., Severini, C., 2010. Use of microwave processing to reduce the initial contamination by Alicyclobacillus acidoterrestris in a cream of asparagus and effect of the treatment on the lipid fraction. Innovative Food Science & Emerging Technologies 11 (2), 328–334. M.M. Hamoud-Agha et al. / Journal of Food Engineering 116 (2013) 315–323 Guan, D., Gray, P., Kang, D.H., Tang, J., Shafer, B., Ito, K., Younce, F., Yang, T.C.S., 2003. Microbiological validation of microwave-circulated water combination heating technology by inoculated pack studies. Journal of Food Science 68 (4), 1428– 1432. Guan, D.S., Plotka, V.C.F., Clark, S., Tang, J.M., 2002. Sensory evaluation of microwave treated macaroni and cheese. Journal of Food Processing and Preservation 26 (5), 307–322. Gunasekaran, S., Yang, H.-W., 2007. Effect of experimental parameters on temperature distribution during continuous and pulsed microwave heating. Journal of Food Engineering 78 (4), 1452–1456. Heddleson, R.A., Doores, S., 1994. Factors affecting microwave-heating of foods and microwave-induced destruction of foodborne pathogens – a review. Journal of Food Protection 57 (11), 1025–1037. Hong, S.M., Park, J.K., Lee, Y.O., 2004. Mechanisms of microwave irradiation involved in the destruction of fecal coliforms from biosolids. Water Research 38 (6), 1615–1625. Huang, L.H., 2009. Thermal inactivation of Listeria monocytogenes in ground beef under isothermal and dynamic temperature conditions. Journal of Food Engineering 90 (3), 380–387. Huang, L.H., Sites, J., 2007. Automatic control of a microwave heating process for inpackage pasteurization of beef frankfurters. Journal of Food Engineering 80 (1), 226–233. Juneja, V.K., Eblen, B.S., Marks, H.M., 2001. Modeling non-linear survival curves to calculate thermal inactivation of Salmonella in poultry of different fat levels. International Journal of Food Microbiology 70 (1–2), 37–51. Juneja, V.K., Marmer, B.S., 1999. Lethality of heat to Escherichia coli O157: H7: Dand z-value determinations in turkey, lamb and pork. Food Research International 32 (1), 23–28. Juneja, V.K., Snyder, O.P., Marmer, B.S., 1997. Thermal destruction of Escherichia coli O157:H7 in beef and chicken: Determination of D- and z-values. International Journal of Food Microbiology 35 (3), 231–237. Kindle, G., Busse, A., Kampa, D., MeyerKonig, U., Daschner, F.D., 1996. Killing activity of microwaves in milk. Journal of Hospital Infection 33 (4), 273–278. Knoerzer, K., Regier, M., Hardy, E.H., Schuchmann, H.P., Schubert, H., 2009. Simultaneous microwave heating and three-dimensional MRI temperature mapping. Innovative Food Science & Emerging Technologies 10 (4), 537–544. Kozempel, M.F., Annous, B.A., Cook, R.D., Scullen, O.J., Whiting, R.C., 1998. Inactivation of microorganisms with microwaves at reduced temperatures. Journal of Food Protection 61 (5), 582–585. Lau, M.H., Tang, J., 2002. Pasteurization of pickled asparagus using 915 MHz microwaves. Journal of Food Engineering 51 (4), 283–290. Lin, Y.E., Anantheswaran, R.C., Puri, V.M., 1995. Finite-element analysis of microwave-heating of solid foods. Journal of Food Engineering 25 (1), 85–112. Linton, R.H., Carter, W.H., Pierson, M.D., Hackney, C.R., 1995. Use of modified Gompertz equation to model nonlinear survival curves for Listeria monocytogenes scott-A. Journal of Food Protection 58 (9), 946–954. Mafart, P., Couvert, O., Gaillard, S., Leguerinel, I., 2002. On calculating sterility in thermal preservation methods: application of the Weibull frequency distribution model. International Journal of Food Microbiology 72 (1–2), 107– 113. Marquenie, D., Geeraerd, A.H., Lammertyn, J., Soontjens, C., Van Impe, J.F., Michiels, C.W., Nicolai, B.M., 2003. Combinations of pulsed white light and UV-C or mild heat treatment to inactivate conidia of Botrytis cinerea and Monilia fructigena. International Journal of Food Microbiology 85 (1–2), 185–196. Peleg, M., 1999. On calculating sterility in thermal and non-thermal preservation methods. Food Research International 32 (4), 271–278. Pitchai, K., Birla, S.L., Subbiah, J., Jones, D., Thippareddi, H., 2012. Coupled electromagnetic and heat transfer model for microwave heating in domestic ovens. Journal of Food Engineering 112 (1–2), 100–111. Poschet, F., Geeraerd, A.H., Van Loey, A.M., Hendrickx, M.E., Van Impe, J.F., 2005. Assessing the optimal experiment setup for first order kinetic studies by Monte Carlo analysis. Food Control 16 (10), 873–882. 323 Ramaswamy, H.S., Pilletwill, T., 1992. Temperature distribution in microwaveheated food models. Journal of Food Quality 15 (6), 435–448. Sapru, V., Teixeira, A.A., Smerage, G.H., Lindsay, J.A., 1992. Predicting thermophilic spore population dynamics for UHT sterilization processes. Journal of Food Science 57 (5), 1248–1252. Sato, S., Shibata, C., Yazu, M., 1996. Nonthermal killing effect of microwave irradiation. Biotechnology Techniques 10 (3), 145–150. Shaman, A., Mizrahi, S., Cogan, U., Shimoni, E., 2007. Examining for possible nonthermal effects during heating in a microwave oven. Food Chemistry 103 (2), 444–453. Stogryn, A., 1971. Equations for calculating dielectric constant of saline water. IEEE Transactions on Microwave Theory and Techniques MT19 (8), 733–736. Sun, T., Tang, J.M., Powers, J.R., 2007. Antioxidant activity and quality of asparagus affected by microwave-circulated water combination and conventional sterilization. Food Chemistry 100 (2), 813–819. Tang, Z.W., Mikhaylenko, G., Liu, F., Mah, J.H., Pandit, R., Younce, F., Tang, J.M., 2008. Microwave sterilization of sliced beef in gravy in 7-oz trays. Journal of Food Engineering 89 (4), 375–383. Vadivambal, R., Jayas, D.S., 2010. Non-uniform temperature distribution during microwave heating of food materials – a review. Food and Bioprocess Technology 3 (2), 161–171. Valdramidis, V.P., Belaubre, N., Zuniga, R., Foster, A.M., Havet, M., Geeraerd, A.H., Swain, M.J., Bernaerts, K., Van Impe, J.F., Kondjoyan, A., 2005. Development of predictive modelling approaches for surface temperature and associated microbiological inactivation during hot dry air decontamination. International Journal of Food Microbiology 100 (1–3), 261–274. Valdramidis, V.P., Geeraerd, A.H., Bernaerts, K., Van Impe, J.F.M., 2008. Identification of non-linear microbial inactivation kinetics under dynamic conditions. International Journal of Food Microbiology 128 (1), 146–152. Valdramidis, V.P., Geeraerd, A.H., Van Impe, J.F., 2007. Stress-adaptive responses by heat under the microscope of predictive microbiology. Journal of Applied Microbiology 103 (5), 1922–1930. Velliou, E.G., Van Derlinden, E., Cappuyns, A.M., Nikolaidou, E., Geeraerd, A.H., Devlieghere, F., Van Impe, J.F., 2011. Towards the quantification of the effect of acid treatment on the heat tolerance of Escherichia coli K12 at lethal temperatures. Food Microbiology 28 (4), 702–711. Venkatesh, M.S., Raghavan, G.S.V., 2004. An overview of microwave processing and dielectric properties of agri-food materials. Biosystems Engineering 88 (1), 1– 18. Vilayannur, R.S., Puri, V.M., Anantheswaran, R.C., 1998. Size and shape effect on nonuniformity of temperature and moisture distributions in microwave heated food materials: part I simulation. Journal of Food Process Engineering 21 (3), 209–233. Whiting, R.C., 1993. Modeling bacterial survival in unfavorable environments. Journal of Industrial Microbiology 12 (3–5), 240–246. Xiong, R., Xie, G., Edmondson, A.E., Sheard, M.A., 1999. A mathematical model for bacterial inactivation. International Journal of Food Microbiology 46 (1), 45–55. Yang, H.W., Gunasekaran, S., 2004. Comparison of temperature distribution in model food cylinders based on Maxwell’s equations and Lambert’s law during pulsed microwave heating. Journal of Food Engineering 64 (4), 445–453. Yilmaz, I., Arici, M., Gumus, T., 2005. Changes of microbiological quality in meatballs after heat treatment. European Food Research and Technology 221 (3–4), 281– 283. Yoo, I.K., Seong, G.H., Chang, H.N., Park, J.K., 1996. Encapsulation of Lactobacillus casei cells in liquid–core alginate capsules for lactic acid production. Enzyme and Microbial Technology 19 (6), 428–433. Zhou, B., Shin, S., Hwang, K., Ahn, J.-H., Hwang, S., 2010. Effect of microwave irradiation on cellular disintegration of Gram positive and negative cells. Applied Microbiology and Biotechnology 87 (2), 765–770. Zhou, L., Puri, V.M., Anantheswaran, R.C., Yeh, G., 1995. Finite-element modeling of heat and mass transfer in food materials during microwave heating – model development and validation. Journal of Food Engineering 25 (4), 509–529.

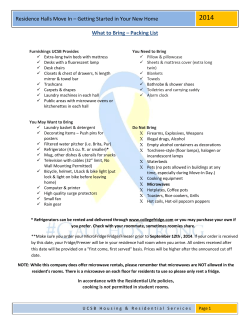

© Copyright 2026