BREATHING AIR COMPRESSORS

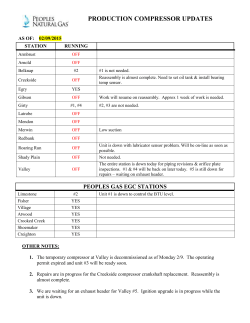

IRWIN AIR LTD BREATHING AIR COMPRESSORS We offer 3 styles of compressor units with different configurations and features to help meet your varying breathing air needs. “H” Horizontal These are ideal starter systems that allow you to build to suit. “C” Compact This unit offers a list of convenient features built on a compact open frame. “V” Vertical Our Vertical systems come with a large list of standard components, built in an enclosed cabinet. AVAILABLE FEATURES: STD Powder Coated Frame H, C, V Vibration Isolation Of Compressor And Motor H, C, V Pressure Switch Activated Shutdown H, C, V Inter-stage And Final Stage Safety Relief Valves H, C, V Inter-stage And Final Oil/Water Separators H, C, V CRN Registered Purification And Final Separator Towers H, C, V Pressure Maintaining And Check Valves H, C, V Optional 5 Hour Continuous Run Shut Down C, V H Automatic And Manual Operation Modes C, V H Individual Stage And Discharge Pressure Gauge Panel C, V H PLC Control Of Compressor System C, V H Visual And Audible Fault Indicators C, H H Ergonomic Gauge And Control Panel C, V H Automatic Condensate Drain With Silent Collection Reservoir C, V H High Air Temperature Alarm And Shutdown V H, C Low Oil Level/Pressure Alarm And Shutdown V H, C Not Available Sound Insulating Panels V H, C Ultra Silent Package V H, C Carbon Dioxide or Moisture Monitors H, C, V Low Pressure (Shop Air) Connection H,C, V With deliveries from 4.2 thru 25 scfm and pressures up to 6000psi, we offer units for rural fire departments, industrial sites and large urban centers. Model PSI Stage SCFM HP Phase Frame Style Purification C35 4500 4 4.2 3.5 1, 3 “H” 5,000CUFT C55 5000 3 6.6 5 1, 3 “H”, “C”, “V” 15,000CUFT C90 5000 3 10.8 7.5 1, 3 “H”, “C”, “V” 28,000CUFT C90H 6000 3 9.0 7.5 1, 3 “C”, “V” 28,000CUFT M13 6000 4 14 10 1, 3 “C”, “V” 40,000cuft M16 6000 4 19 15 3 “C”, “V” 60,000cuft M25 6000 4 26 20 3 “C”, “V” 80,000cuft COMPACT VERTICAL HORIZONTAL IRWIN AIR COMPRESSOR UNITS Irwin Air Ltd. has sold compressor systems and provided field service throughout British Columbia for 40 years and we are expanding across Canada. We specialize in a single product line, High Pressure Breathing Air Compressor Systems including Compressors, Fill Stations, Control Panels and Cylinders. Our reputation has been built by our ongoing commitment to service. Irwin Air compressors are built to withstand the stresses of modern, continuous duty applications in the most demanding environments. Our systems are the ideal choice for flexibility and trouble-free performance in situations calling for pressures up to 6,000 psi with delivery capacities from 3.5 to 25 scfm. All Irwin Air compressor units are built to the highest quality standards and are supported by a 2 year warranty. In each one of our models you can expect... Dependable Performance: suited for continuous operation, due to the rugged design and corrosion resistant filters and cooler assemblies. State-of-the-Art Design: balanced moving parts in the drive gear allow for low vibration and balanced rod loads. Inter-stage coolers, finned cylinders and heads, and high output fan produce cooler operating and discharge temperatures. A ringed final piston and 1st stage reed valve allow for quieter more efficient operation. Top Grade Materials: cast iron cylinders for long life; ductile iron counterbalanced crankshaft with large diameter throw for low bearing loads and increased life; aluminum cylinder heads for superior heat dissipation; 7075-T6 aluminum connecting rods for high strength. Quality Assurance: All compressor pumps are individually tested and certified for performance and all electrical components and systems are inspected and approved by CSA. Our in-house manufactured purification filters and CRN vessels provide the highest quality of air to meet CSA Z180. As a licensed contractor (MA-2272) and manufacturer through BC Safety Authority we build CRN components and ASME Pressure Piping to CSA B31.1, B31.3 & B51-97. High Quality Components: anti-friction bearings for smooth operation with lower horsepower; front and rear bearings for precise crankshaft alignment and long shaft life; fly wheel precision-balanced and fan-bladed for excellent cooling capacity; generous lubrication to critical wear areas for longer pump life; stainless steel inter and after coolers, disc-in-plate valves for long wear and excellent heat resistance and dissipation. Easy To Operate and Maintain: quick change air-intake filters and purifier cartridges for easy maintenance Irwin Air Ltd. Unit #306- 5327 192nd Street Surrey, BC, Canada, V3S 8E5 Toll Free 855-575-9697: Office 604-575-9697: Fax 604-575-9685 E-Mail [email protected]: Website www.irwinair.com Your Air, Is Our Business IRWIN AIR LTD FILLING PROTECTION CC (Cylinder Containment) Fragmentation Cabinet The CC-2 is designed for use with existing fill controls and fill lines to provide protection should a failure occur. All our fill stations have been 3rd party tested and meet or exceed NFPA 1901/CSA Z180. Standard Features: - All Steel Construction Grade 8 Steel Structural Hardware 3rd Party Tested To Meet NFPA 1901/CSA Z180 Standard Ergonomic Design for Easy Operation Vertical Blast Tubes Direct Air Blast And Debris Away From The Operator Should A Failure Occur Use with Existing Fill Controls 1 or 2 SCBA Recharging Designed To Fit All Sizes Liners To Reduce Wear To SCBA Cylinders Upgradeable to SS-2MS SS/CS (Space Saver) Fragmentation Stations Our Space Saver series offers great functionality in an ergonomically designed package. All our fill stations have been 3rd party tested and meet or exceed NFPA 1901/CSA Z180. Standard Features: - All Steel Construction Grade 8 Steel Structural Hardware Design 3rd Party Tested To Meet NFPA 1901/CSA Z180 Ergonomic Design For Comfortable Operation Heads-Up Control Panel Allows Monitoring And Adjustments From a Standing Position Vertical Blast Tubes Direct Air Blast And Debris Away From The Operator Should a Failure Occur 1 or 2 SCBA Recharging Designed To Fit All SCBA Cylinders Single or Multiple Fill Pressures Isolation Valve for each Fill Pressure Safety Relief Valve for each Fill Pressure Supply Shut-Off Valve Color Coded Labels for Each Fill Position and Fill Pressure Color Coded Fill Lines for each Fill position and Fill pressure Adjustable, Self-Venting Regulator With Inlet & Outlet Gauges Liners To Reduce Wear To SCBA Cylinders SS-4PD SS-2MS Space Saver Fill Stations Model Cylinders Pneumatic/Manual Dual/Single Pressure CS-2 2 Manual Single SS-2MD 2 Manual Dual SS-2PS 2 Pneumatic Single SS-2PD 2 Pneumatic Dual SS-3PS 3 Pneumatic Single SS-3PD 3 Pneumatic Dual SS-4PS 4 Pneumatic Single SS-4PD 4 Pneumatic Dual SS-5PS 5 Pneumatic Single SS-5PD 5 Pneumatic Dual SS-6PS 6 Pneumatic Single SS-6PD 6 Pneumatic Dual Fill Station Options - Auxiliary Bulkhead Fill Connection - Open Door Safety Shut Off - Integrated Cascade Cylinder Controls - SCUBA Blast Tube(s) - Low Pressure (Shop Air) Outlet CC-2 IRWIN AIR FILL STATIONS Irwin Air Ltd. has sold compressor systems and provided field service throughout British Columbia for 40 years and we are expanding across Canada. We specialize in SCBA Compressor Systems including Compressors, Fill Stations, Control Panels and Cylinders. Our reputation has been built on our ongoing commitment to service. Irwin Air Fill Stations withstand the stresses of modern, continuous duty applications in the most demanding environments. They are the ideal choice for flexibility and trouble-free performance with supply pressures to 6,000psi and cylinder capacities from 2 to 6. All Irwin Air products are built to the highest quality standards and are supported by a 2 year warranty. In each one of our models you can expect... State Of The Art Design Irwin Air Fill Stations have been 3rd party tested to NFPA 1901/CSA Z180. Our units protect in the worst case failure of an SCBA. When a bottom rupture occurs the cylinder becomes a projectile. The reinforced top, bottom venting and vertical blast tubes offer the highest protection available. Atypical Rupture (air blast and projectile) in this failure the SCBA separates into 2 pieces the top half including the valve leaves the blast tube like a mortar. Air blast and projectile protection needed. Typical rupture (air blast only) The most common failure the SCBA stays intact in the blast tube. Air blast protection needed. Quality Assurance: All Fill stations are individually tested and certified for performance. As a licensed contractor (MA-2272) and manufacturer by the BC Safety Authority we build CRN components and ASME Pressure Piping to CSA B31.1, B31.3 & B51-97. High Quality Components: We use only the highest quality components in our fill stations. Wika Gauges, Aqua Environment, Parker Hannifin and Sherwood are examples of our premium components. Irwin Air Ltd. Unit 306 – 5327 192nd St. Surrey, BC, Canada, V3S 8E5 Toll Free 855-575-9697: Office 604-575-9697: Fax 604-575-9685 E-Mail [email protected]: Website www.irwinair.com Your Air, Is Our Business

© Copyright 2026