I

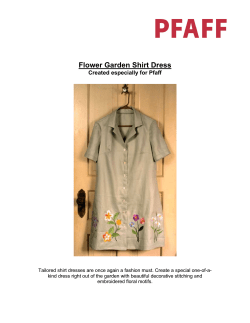

Sewing & Fashion - Section I Table of Contents Sewing & Fashion Princess Seams .......................................................I-3 Tailored Shirt Placket ................................................I-4 Finding Inspiration in Italian Marble Floors ................I-5 Recipes for Success When Using Stabilizers ...........I-6 Tips & Techniques for Hemstitching with the Wing Needle.................................................................I-8 A Year’s Worth of Jackets From One Great Pattern .I-9 Creating Perfect Squares Made Simple ....................II-10 From Inspiration to Reality ........................................II-10 How to Sew a Custom Fit Half Slip ............................II-11 Delectably Simple Mountains ....................................II-12 Outdoor Quilts ..........................................................II-13 Guests .....................................................................II-14 Due to the size of this section, it has been separated into two sections in order for it to be downloaded more quickly. For instance, “Princess Seams” is in Section I on page 3, whereas “Creating Perfect Squares Made Simple” is in Section II on page 10. 2 Princess Seams Excerp from The Art of Fashion Draping by Connie Amaden-Crawford Fit Princess Seams, Bust Cup and Hip Area Contour and shape the front and back waistline and princess seam areas of the model. The front and back princess seams (usually shoulder or armhole seams) are areas that can be used to fit and contour to the body’s shape. Refit the bust cup area Open the princess seam over the bust cup at least 2 inches above and below the cupped area. Reshape the princess seam area to match the bust cup amount of the model. Add fullness to make a larger cup size, decrease fullness to make a smaller cup size. If needed, clip from the bust area to the side seam and add fabric. Then repin the princess seams. Refit the waistline area and/or the hip area Contour and shape the front and back waistline areas of the model. Add or decrease the princess seam amount over the waist area. Mark a new stitchline. Princess Seams Pattern Reference Listed are several princess seamed patterns that have been especially draped for mature figures. The patterns are available in size XS to 6X at www.fashionpatterns.com. B5620 B5538 B5574 B5575 3 Tailored Shirt Placket Reference Patternmaking Made Easy and A Guide to Fashion Sewing for the pattern and sewing details of the Tailored Shirt Placket, the Hidden Placket, Shirt Neckline Placket and the Budget Shirt Placket The tailored shirt placket method is the method most commonly used in the garment industry. It saves time and produces a clean, professional look. SEW THE RIGHT SHIRT PLACKET: (Illustrated for a woman’s shirt—left side for a man’s shirt). A. Fold and press the front shirt placket on the first foldline to the inside of the shirt (the width of the finished placket). The right and left front shirt placket pattern pieces are figured in the same manner as for the shirt neckline placket, however, the notches for the plackets are placed differently. The illustration shows the placket amounts and the notches transferred from the pattern. B. Fold and press again on the second fold line to the inside of the shirt. ATTACH INTERFACING TO THE GARMENT PLACKET SECTIONS OF THE SHIRT. C. Stitch the placket 1/4-inch away from the last foldline on the correct side of the garment. • LEFT SHIRT: Place the interfacing on the left front shirt placket, 1/2-inch from the outer edge of the garment piece, as illustrated. D. Press the placket out and away from the shirt. • RIGHT SHIRT: Place the interfacing on the right front shirt placket, along the outer edge of the garment piece, as illustrated. NOTE: Women’s button opening is shown and described here. Reverse the interfacing for the men’s button opening. NOTE: This gives the right placket a clean-finished area on the inside of this placket. 4 Finding Inspiration in Italian Marble Floors THE LEFT SHIRT PLACKET (FACING). (Illustrated for a woman’s shirt - left side for a man’s shirt). A. Press the first edge of the left side of the shirt under 1/2-inch (along the first edge of the interfacing). “Wow! That’s beautiful! I could never make it.” That remark from another quilter encouraged me to write my book, “Bella Bella Quilts.” The “Wow” factor of these quilts comes from the number of pieces and their interplay, not from the difficulty of the piecing. Most quilters have made the blocks in these quilts before. Anybody with basic patchwork skills can make the project quilts because the real work is repetitive, not difficult. Though I like quilt projects as much as the next quilter, these designs are so thrilling that I’m willing to take some extra time to make them. I enjoy the “thrown together” aspect of rainbows of color and texture. I like the variety of patterns. I like the curves that set these quilts apart. And I love the “wow! factor.” B. Fold and press the foldine on the left side of the shirt (along the opposite edge of the interfac-ing). COURTESY: Norah McMeeking Quilter & Author www.bellabellaquilts.com C. Stitch the facing in place at the first foldline pressed edge. Top stitch the opposite edge for a placket finishing effect. COURTESY: Connie Crawford Fashion Patterns by Coni www.fashionpatterns.com 5 Recipes for Success When Using Stabilizers Make Patterns Stitch onto the wrong side of the fabric. • You will be able to topstitch and/or decorative stitch easily because Fuse ’n Stitch stabilizes the fabric, and remains on the fabric to keep it stiff. • When you make Tote Bags and Purses and you want the sides and handles to be sturdy, simply fuse Sulky Fuse ’n Stitch to the wrong side of your fabric. • Fuse ’n Stitch is perfect for Costumes when you need “stiffness” as in special hats, cuffs, wings, tails, etc., and for Belts where you want to retain shape. Stabilizer: • Sulky Soft ‘n Sheer™ - permanent • Sulky KK 2000™ Temporary Spray Adhesive Procedure: Use Sulky Soft ‘n Sheer to create very lightweight, sturdy, permanent, reuseable patterns and save the flimsy tissue patterns as masters. • Use yardage from a bolt of Sulky Soft ‘n Sheer. • Cut pieces of Soft ‘n Sheer a little larger than the pattern pieces you wish to trace. • Lightly spray the Soft ‘n Sheer with KK 2000 and smooth the pattern piece over it. The KK 2000 keeps the pattern in place while you trace it. • Write all notations on the Soft ‘n Sheer pattern pieces. • Store in zip-lock baggies along with the original pattern package. Underlining Stabilizer: • Sulky Tender Touch™ - iron-on, permanent Procedure: I keep a bolt of Tender Touch on hand so I have the wider widths available for underlining some fabrics. Since underlining will change the “hand” of the fabric, when a fabric tends to be too lightweight for the type of garment I am making, I fuse Tender Touch to the wrong side of the entire piece of fabric before cutting out the garment pieces. (I have a lightweight tweed wool and silk jacket that would have “sagged and bagged” as I wore it if I had not added the Tender Touch underlining.) Make Alterations Stabilizer: • Sulky Totally Stable™ - iron-on, temporary Procedure: Use Sulky Totally Stable to make alterations to patterns. • Cut the pattern as needed, then insert a piece of Totally Stable and fuse it in place to add length or to make a designer detail adjustment. • Because you can iron Totally Stable and then pull it off, reposition it, and press it again many times, you can experiment with the pattern details before cutting into the fabric. Facings Stabilizer: • Sulky Tender Touch™ - iron-on, permanent Procedure: I have used Tender Touch as my “facing fabric” to eliminate bulk and still have the ability to fuse the facing to the wrong side of the garment so it stays in place. • This is great for “fast facing” on costumes and other quick garments and when a garment fabric is too heavy to use as a facing. • Cut the facing pieces from Sulky Tender Touch. • Sew them to the garment piece in the same way you would stitch a facing, with the fusible side out. • Trim your seam allowances with pinking shears to eliminate bulk. Turn the facing to the wrong side and fuse in place. • One of the first places I used this technique was on a metal sequin evening fabric that had “points” in Heavy Interfacing Stabilizers: • Sulky Fuse ’n Stitch™ - iron-on, permanent • Sulky Tender Touch™ - iron-on, permanent Procedure: Tote, “Sunday Dinner Apron”, a Vanilla House Design. “Frenchy Bags” designed by Amy Butler featuring Moda fabrics. • Fuse ’n Stitch was used to stiffen the Apron’s waistband, and Tender Touch was used to add body to the neck strap and apron ties. • To add the stiffness you need, iron Sulky Fuse ’n- 6 the pattern of the sequins. I made the hem edge of the top beautiful by placing a strip of Sulky Tender Touch, right sides together with the sequin fabric along the bottom edge of the sequin top; then I stitched along the shape of the “points”, trimmed the excess seam allowance along the points, turned the Tender Touch to the wrong side and fused it in place. Tender Touch “facings” finish the neck edge and sleeve hems. fabric, right sides together, as you sew. • Then, tear away the stabilizer when the stitching is complete. Interface Knits Stabilizer: • Sulky Tender Touch™ - iron-on, permanent Procedure: For years, I’ve been a real fan of fusible tricot interfacing and I was “sew” happy when Sulky introduced Tender Touch since the packages and rolls are very easy to work with and to store. Tender Touch fusible tricot is the interfacing in most of the garments I sew today. • Sulky Tender Touch has more stretch in one direction than in the other, so keep the stretchier direction on the crosswise of your pattern pieces. • When pinning the facing pattern piece to cut the interfacing, pin inside the seamlines, then slip your pinking shear under the pattern piece and cut along the seamline to eliminate the bulk in the seams. • Using the pinking shears means the edge of the interfacing won’t “press through” as a ridge on your garment. • To fuse your Tender Touch interface piece to the garment piece, place the garment piece, wrong side up, on your ironing surface, and place the Tender Touch interfacing piece, fusible side down, with the pinked edges at the seamlines. • Before fusing together, give the pieces a “blast of steam” to remove any wrinkles or shrinkage. Place a Sulky Tear-Easy “press cloth” on top and press the Tender Touch onto the fabric with lots of steam. Do not move the iron back and forth! Hold the iron in one place for 10 seconds and then move to the next place. • Turn the fabric over and use another “press cloth” to press from the right side. Mark one of your Sulky Tear-Easy “press cloths” to be used for fusible only. • Replace “press cloths” often. Make a Hem Gauge Stabilizer: • Sulky Cut-Away Plus™ - permanent Procedure: Use Sulky Cut-Away Plus to create a Hem Gauge. • Cut a rectangle 4” wide by 12” long for skirts and 4” x 6” for pants; use a permanent marking pen to draw lines across the 12” and 6” length at 1/2”, 1”, 1 1/2”, 1 3/4”, 2”, 2 1/2” and 3” from the edge. • By inserting my “Hem Gauge” into the hem I can fold the hem allowance up over the Cut-Away Plus to the correct line and press it there. • You can make a Sulky Cut-Away Plus “Hem Gauge” for any size hem you need. This can be really helpful for home dec sewing when you need a double 4” hem in your drapes. For a curved hem on skirts, etc., use the original curve of the skirt as your pattern to cut the Sulky Cut-Away Plus piece, then measure from the curve for your hem allowance and mark. Stay-Stitching Stabilizer: • Sulky Tender Touch™ - iron-on, permanent Procedure: I love to cut strips of Tender Touch with the length of the strip on the least stretchy direction to “interface” the seam allowances where stretch can occur while sewing. • This is especially important when putting a zipper into the seam of a bias cut skirt. Simply “interface” the seam allowances in the zipper area with strips of Sulky Tender Touch. Tip: I usually interface the garment not the facing because I want the structure on the garment side. There are exceptions such as sheers, lightweight silks, very light t-shirt knits, etc., because the “fusible dots” can show through on the right side on very light, sheer fabrics. In this case, press the Tender Touch onto the facing piece or use Sulky Cut-Away Soft ’n Sheer as a “sew-in” interfacing. Tame Seams & Edges Stabilizer: • Sulky Tear-Easy™ - temporary tear-away Procedure: I tame construction seams on the most challenging fabrics with Sulky Tear-Easy. • Some lightweight, or sheer, or slippery fabrics can be difficult to stitch (even the seams) without puckering or slipping. • Simply place strips of Sulky Tear-Easy under the COURTESY: Sue Hausmann Sulky of America www.sulky.com 7 Tips and Techniques for Hemstitching with the Wing Needle and Sulky® Sticky Fabri- Solvy™ and Sulky PolyLite™ Thread Originally a hand-sewn technique, then stitched on hemstitcher machines manufactured around 1900, today hemstitching creates fabulous designer details quickly and easily on home sewing machines. The key is stitching with very fine thread so the thread does not fill the “holes” and stabilizing to prevent puckering as the stitch goes back and forth and side to side. The new Sulky PolyLite Thread is a fine weight, 60/2 and comes in a myriad of colors perfect for hemstitching colored linens, silks and cottons for a tailored lace look. There are several important elements to creating machine hemstitching in your fabric. Insert a wing needle. This needle is very thick and wide and actu-ally looks as though it has “wings” on each side, hence the name. The needle is meant to make holes in your fabric as you stitch. Wing needles come in size 100 and size 120. Sometimes the wing needle pokes a larger hole than you desire or “catches” on the fabric as you stitch. If so, experiment with a large universal needle size 100 or 120 to see if you like the effect. Always experiment on scraps before hemstitching on your project. Sulky Sticky Fabri-Solvy is the perfect stabilizer be-cause you “stick” your fabric to the Sticky Fabri-Solvy so it cannot pucker or move as the intricate stitches move back and forth and sideto- side stitching the hole made by the wing needle in an open position. After stitching, rinse your fabric in water to completely remove the water soluble stabilizer, Sulky Sticky FabriSolvy! Hang to dry and press. Hemstitching Hemstitching is one of my favorite creative techniques. Originally thought to be only used in Heirloom Sewing, today we see hemstitching on home dec, placemats, curtains, tailored blouses and “sew” much more. It is magic to watch the wing needle create a lace effect in the fabric by punching holes and sewing them open. Most sewing machines have some stitches for hemstitching and many have complete menus of hemstitches. Select a stitch that sews back into the same hole several times. Even the most basic machines have a stretch stitch Hemstitching will be most effective on natural fiber fabrics such as linen and cotton, and the fabric cannot be too tightly woven or too high a thread count. The needle must be able to “spread” the fibers as it enters the fabric, and the stitch will sew it in the open posi-tion. One of the reasons the synthetic fibers and per-manent press fabrics do not hemstitch well is that they have been “trained” to return to their original state and do not want to let the hole stay open! Practice on scraps. Some synthetics hemstitch beautifully. called a ric-rac stitch. 8 You want to see the “holes” more than the stitch, so thread with a fine (2 ply) thread on top and in the bobbin because a heavier thread will fill the holes. Sulky PolyLite 60/2 thread is perfect and comes in a myriad of colors for a rich tone-ontone embellishment. You can stitch beautiful hemstitches with Sulky 40 weight Rayon machine embroidery threads when you want to see the actual stitch as well as the holes. Be sure to use the same thread in the top and bobbin. Usually hemstitching is sewn with the thread matching the fabric. Use a standard presser foot or a transparent foot with flat underside for better visibility. Place fabric on Sulky Sticky Fabri-Solvy water soluble stabilizer. • Rain coat with added hood or hat Summer • Sheers with rolled serged edges; use the selvages for trim • Light weight cottons, linens or blends, eyelets and embroideries • Shorten and widen the sleeves • Use old cotton linens with lovely embroidery or table cloths • Single layer cotton home decorator prints; choose a few that coordinate • Put the seams on the outside and cover with a ribbon or trim Remember to use the Start/Stop to sew without the foot control for long rows of hemstitching. This makes it even easier as you have two hands free. Do not “help” the fabric feed through the machine!! This will distort the beautiful hemstitches! Your job is to simply guide the fabric. Fall • Necklines that lend themselves to scarves • Vests in heavier fabrics like boiled wool, denim or corduroy • Try some collage or appliqué on a vest; work modularly • Light weight outerwear fabric in dark colors or prints • Strip piecing along the seam line; perfect for very small but precious scraps • Sparkly fabrics and cut velvets for little party tops • Narrow the sleeves and cuffs to accommodate a coat Many computer embroidery machines and em-broidery software are designed for you to bring in the hem-stitches from your machine and create beautiful hem-stitch designs, yokes, and “sew” much more so you simply hoop your fabric, touch a button and hemstitch! COURTESY: Sue Hausmann Sulky of America www.sulky.com Winter • Quilt light weight wools or vintage fabrics to Thinsulate™ or wool batting • Line with flannel backed “Zeus” • Wash wools and old sweaters for piecing • Overlap the seams and stitch together with a decorative stitch • Use felted wools or old blankets for jacket bodies • Knit the sleeves for a cozy look • Pair large challis prints with solids in the sides and trim • Add flower pins or attached corsages for a hint of spring to come A Year’s Worth of Jackets From One Great Pattern Choose a basic Square Armhole Jacket pattern, like the Tabula Rasa Jacket from Fit for Art Patterns Spring • Light weight outerwear fabrics with a partial or full lining • Choose lighter and brighter colors • Make it reversible - perfect for travel • Large silk prints used in the body and sleeves, solids for the sides and trim • Mixed prints and polka dots COURTESY: Rae Cumbie Assn. of Sewing & Design Professionals www.raecumbie.com 9

© Copyright 2026