âTransport baskets and flexible sterilisation packaging: the best of

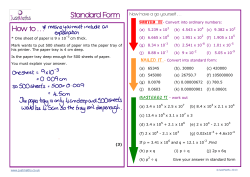

“Transport baskets and flexible sterilisation packaging: the best of both worlds.” Karina Engels HALYARD HEALTH BETTER CARE DESERVES A NEW NAME Kimberly-Clark has been a leader in better care for nearly 100 years. Because we believe when you put care first, healthier living is contagious. Now it’s time to move forward. We’re bringing that belief with us and focusing on preventing infection, eliminating pain and speeding recovery 2 EN ISO 11607 - Definitions • Sterile Barrier System: minimum package that prevents ingress of micro-organisms and allows aseptic presentation of the product at the point of use demonstrated under test conditions which consider sterilization process, handling, distribution, transport and storage (amendment EN ISO 11607, 2014) • Protective Packaging: configuration of materials designed to prevent damage to the sterile barrier system and its contents from the time of assembly until the point of use • Packaging system: combination of the sterile barrier system and protective packaging Choice sterile barrier systems Depending upon device, local habits, preference, logistics Characteristics container • Perceived as strong (secure feeling) • Easy to store • Quality bacterial barrier highly dependent on maintenance • Heavy • High investment cost • Noisy Bacterial barrier containers Measurement of the microbial barrier effectiveness of sterilization containers in terms of the log reduction value for prevention of nosocomial infections Sterile container: CFU per 600 cm² Paper filter: 2 out of 11 1000 900 800 700 600 500 400 300 200 100 0 Permanent filter: 14 out of 15 Paper filter Permanent filter (teflon) Textile filter: 9 out of 79 Textile filter 1 6 11 16 21 26 31 36 41 46 51 56 61 66 71 76 Num ber Source: Dunkelberg et al; American Journal of Infection Control 2006; 34:285 - 9 Source: Dunkelberg et al; American Journal of Infection Control 2006; 34:285 - 9 6 Recent publication AFNOR FD S98 053 (2014) National survey France Characteristics flexible packaging material Example: HALYARD ONE-STEP* or QUICK CHECK* • Every sheet new bacterial barrier • Light • Easy to store • No maintenance • Possible pinholing or tearing Pinholing sterilisation wrap COMPARAISON DES CONTENEURS ET DES FEUILLES D’EMBALLAGE À USAGE UNIQUE POUR LE CONDITIONNEMENT COMPOSITIONS D’INSTRUMENTS À STÉRILISER* *Source: DIALLO S, BREBANT T, et al., Service Stérilisation Centrale, Bloc Opératoire Central, Hôpital FOCH, presented CEFH Lyon 2012 The cause “We have no space” “We have no time” “Our storage is poor” “Changing shelves is too expensive” “It is the OR who is stacking” “It is the CSSD, they deliver us damaged material” “Transportation is the issue” “The packaging material is not strong enough” The frustration “We had to cancel a patient” “The surgeon was yelling” “We are going to buy containers” “We need to rent the loaner set again” Typical approach A sterilized tray is handled 4 to 5 times prior to opening Step 1: Load sterilizer Step 2: Unload sterilizer on transport trolley Step 3: Transportation Step 4: Store sterilized tray in OR Step 5: Remove tray from shelf Step 6: Present tray aseptically in OR 4 to 5 times risk to damage sterilized package! Familiar? The solution Use of transportation baskets Step 1: put the packaged instrument tray in a transport basket Step 2: put transport baskets in the sterilizer loader: toploading and floor loading are possible Use of transport baskets The sterilized instrument basket is only handled at the point of aseptic presentation Step 3: put transport basket in open or closed Stericart Step 4: transfer the transport basket to the U-flex storage system Transport baskets Different types Stakeable/nestable baskets Grids Grids with rim Transport baskets Different vendors • Belintra • Hüpfer • Landanger • ......... Characteristics transport baskets • Initial investment cost • Light • Easy to handle • Minimal maintenance • Pinholing and tears reduced to...... • Increased patient safety • Optimizes storage capacity • Improved overview of inventory Improved overview of inventory Financial feasibility ? ? ? ? £ ? ? ? ? Financial example £ Hypothesis 1 Sterilized STU/day 200 £ Cost transportation baskets 29.600 € 21.438£ 22.785 € 16.502£ 2.192 € 1.587£ 54.577€ 39.527£ (74€/basket 400 baskets)** Annual amount 60.000 Cost Stericarts (9 carts, different types)** Sterilization cost/STU* Total sterilization cost/year 48.49 € 2.909.400 € 35.12 £ Cost U-Flex storage system** 2.107.200 £ Hypothesis 2 Torn trays: 2% of case Cost re-sterilization 58.188 € *Source: BESCO study, presented Zeist, October 2014 **Prices are purely indicative 42.144 £ Total installation cost Conclusion • The use of flexible packaging e. g. Halyard One-Step* or Quick Check* provides an excellent bacterial barrier • Torn tray wrap can be prevented by using transport baskets, the so called basket-inbasket system • The combination of both systems is userfriendly, provides optimal patient safety and is financially feasible

© Copyright 2026