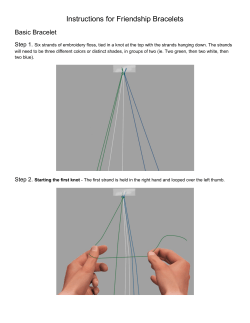

2012 Corporate Responsibility Report