Silk-like Polyester Fabrics: Recent Advances

Indian Journal of Fibre & Textile Resea rch

Vol. 21, March 1996, pp. 79~89

Recent advances in the development of silk-like polyester fabrics

Pushpa Bajaj

Department of Textile Technology, Indian In stitute of Technology, New Delhi 110016, India

Silk-like po lyes ter fibres ha ve been one of the most important targets for the textile industry in the present

era. Key technologies starting from fibre engineering to finishing process have been illustrated for producing

silky polyester fabric s with bulk y hand touch and superior drape. Effects of polymer additives, delustrant s,

surfact a nt s, e tc. on a lkaline hydro lysis of polyester fabrics for improving silk-like characteristics have a lso

been highl ighted.

Keywords:

Alkaline hydrol ysis, Bicomponent fibres , Micro-crator pol yes ter, Microfibrcs. Shingosen,

Silk-like pol yes ter. Spinning tec hn o fogies

by simulating the characteristic features of silk fibre ,

I Introduction

Polyester fibre has conquered the leading position VIZ.

• The design of cross-sectional shape,

among the three major synthetics because of its

• Enhancement of drape characteristics through

excellent properties such as high strength, abrasion

resistance, wash and wear, and wrinkle-free

weight reduction of conventional pol yes ter

fibres or by the development offine denier fibres.

characteristics. However, polyester does have some

and

deficiencies, i.e. it is hydrophobic and oleophilic. Due

to this, 1t is easily soiled and accumulates the static

• Creation of moderate bulk and soft handle.

History of the progress made in silk-like pol yester

charge. Oily stains are also difficult to remove .

Polyester fabrics are, therefore, not as comfortable as fibres is given in Table I and the technologies

natural fibre fabrics.

developed for the production of Shin-Go sen (Shin =

On the basis of consumers' comments, Latta I has new & Gosen = synthetic fibre) in Japan are

. also mentioned the following limitations of illustrated in Fig.l .

synthetics:

In this review, the va rious processes developed for

• Unnatural hand and unfamiliar skin cqntact

sensations,

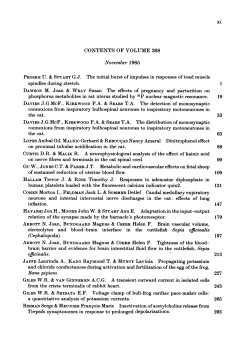

Table I- Histpry of the progress of silk-like polyester fibres9

• Unpleasant thermal sensations,

Generation

Properties

Idea of technology

• Lack of moisture absorbancy,

Brightness

• Clamminess of fabric in contact with skin, and Copy of natural Lustre

Drape

Shape of cross-section

silk

• Static related problems.

To overcome some of these problems, blending

with natural fibres, particularly cotton, gained a big

market. An extensive work related primarily to

polyester fabrics comfort has been published in

excellent reviews 2 - 6 in the recent past. From the

wearer trials using knit fabrics it was reported that the

comfort of polyester was substantially improved by

cross-section variations, pressure jet treatments and

certain engineering modifications of the ·polyester.

The Japanese industry has also made great strides

in improving the comfort and aesthetic properties of

I

"Sh'mgosen " h as b een

po Iyester. S I'lk - I'k

I e po yester

developed by different technologies? Various

approaches have been tried to develop silky polyester

(trilobal, triangle)

( 1964-)

Rustle of clothes

Copy of silk

touch

(1975-)

Fullness and softness Shrinkage-mix fibres

Drape

Structure of crimps

Delicacy

Persuit for the

aesthetic

properties

(1979-)

Persuit for

micro shape of

cross-section

(1983-)

Silky-spun like

Naturality

Dry touch

Air texturing

False twisting

Thick and thin ya rns

Lustre

Fullness and softness

Drape

Rustle of clothes

Naturality

Tri-petal like crosssection

Microfibres

Cross-sectional shape

Very nice ta ilored

Aim for high

sense and quality fini sh characteristics

(1988-)

Liveliness

Development of

new polymer

80

INDIAN J. FIBRE TEXT. RES., MARCH 1996

Shrinkag~-mix filam~nt - - - - i High shrinkage yarn

t - - - { Difference in

fibre length

High spQed spinning yarn

Spontaneous extension

Polymer modification

------I

Polymer with partic~s

from catalyst residue

Polym~r with added

particles

Brightness

'"r---Fullness and

softn~ss .

)----.Lu~e

r:s-ur--:f:-a-ce-ro-u-g-:-hn-e-s....

s\.--L- Dee p co 10 ur

Vi vid colour

Dry hand

Special spinning - - - - - - - 1

Denier mix

Non-circul~r crosssection

Conjugated yarn

I ' - - - { Shape of (ross - ' f f - - - Soft hand

He<lvy denier

Fine dQnier

I-----{

section

Rustle of (Iothes

Difference of

denier

'c---\--

Spread anti-drap!

Texturing - - - - - - - - - - 1 False twisting

Air tuturing

1----;rr;(o~m;;;m;;ii~ng~l;in;;;g-:-·-~~r\--~ Naturality

Afttr treatment - - - - - - - 1 Twisting

(austic reduction

After finish

Fabric density

l---'~S;;tr~u::-ct:tu:r:e--:of;-""""":----+-~S t iff ness

dagree

fabrics

Springy properties

Drape

Fig. I- Fabric properties of Shingosen and key technologies

51 L~

SI LOOK ROYAL

I

I

1

fI

1\

..... 1...-

\I

/

"

o

SILK

I" / '"

--

I

\../

\V

1/

10

20

30

0

10

20

30

0

10

20

30

Tim~Jms

fr----o

A-Sompl, 'tobric I

B- '" ie rophont

c- W, ight , SOOt 14 em I

0-"'0_ '1Oem Imin I

Fig. 2- Wave of ru stli ng sound of three typical fabrics

the production of silk-like polyester have been

highlighted . Special emphasis has been made on the

saponification or caustic reduction treatments for

prod ucing si lk-like polyester fabrics .

2 Cross-sectional Shape 7 The shape of a silk fibre after removing se ricine

during scouring is triangular. For imitating the

triangular shape of silk fibres, polyester fibres ha ve

<)

been developed with triangular or trilobal

cross-sections. This resulted in lustrous polyester

fibres. The appearance also changed from that of

plastic to a silk eq ui valent.

PET fibres with a tripetal cross-section have also

been developed to provide silky look . There is a

groove at the tip of each lobe oftrilobal cross-section.

This unique cross-section is believed to bring the

rustling so und to polyester fabrics when friction

occurs among them. The wave of rustling sound of

three typical fabrics has been compared (Fig.2) .

'Sillook Royal' has, therefore, not only the lustre of

natural silk, but also a rustling sound similar to that of

the natural sil k.

Polyester fibres wit h petal-like cross-sectio ns ha ve

been produced by conjugate spin ning technologylo.

In this process, small a mounts of easily hydro lysable

components are located at the tips of each lobe.

During saponification or ca ustic trea tment, this

component gets dissolved and grooves a re formed.

The width and depth of each groove can be controlled

at the sub micron level.

3 Differential Shrinkage Polyester Yarn

One o f the techno logies to bring out silk-like bulk

and handle in PET is to use differenti a l shrinkage

polyester component yarn. T wo method s have been

tried to produce different shrinkage levels in mixed

BAJAJ: SILK-LIKE POLYESTER FABRICS

yarns. One is a parallel sort of mixture, just like

Quiana (nylon ya rn produced by Du Pont) and the

other is a se rial kind (Fig. 3).

The parallel structure is made by mixing fibres of

different shrinkage levels either by using different

polymer fibres or by mixing fibres of polyester drawn

at different temperatures. The serial type is produced

by random heat setting along individual fibres during

fibre processing 1 I . The fibres shrink randomly with

TYPE

PARALLEL

Mi Xlld Yarn of

I'ETHOO D~rmt Shrinkage

Lt'it I

SERIAL

Rnndom Hrat- set

AmollJ Individual Fibre

.. _........................................ ... ......

YARN

I--------:--+------:::---~

.~.

'"'-./ .... ..../V.....

--v-..... J"'v... _.

~ ....... "'-." .....

~

""'"

81

the heat treatment. In the parallel structure, higher

shrinkage components form a core, and lower

shrinkage components form waves or loops around

the core. On the other hand , in the serial type

structure, higher and lower shrinkage parts are

di stributed randomy in the yarn and there is no core

(Fig.3). The resulting fabric from serial type

arrangement of different shrinkage level fibres

showed a more natural silk look than the parallel

type.

Uchida 12 has also demonstrated the role of

shrinkage in producing Shingosen. Fukuhara 7 from

Toray Industries has shown that for the production pf

Shingosen, initially dry heat shrink process was tried

and later the wet-heat shrink process. But, a double

shr'unk fabric appears to be closest to silky textiles

(Fig. 4). It has comparatively hi'gher bulkiness and is

more airy and soft. Sillook Sildew, produced recently,

is a double shrunk fabric with large waves or loops on

the surface of the fabric.

For making double shrinkage fibres, the

researchers have to first design the polymers by

selecting a suitable comonomer and its content for

accomplishing the desired shrinkage level. Degree of

polymerization (DP) should also be controlled as a

polymer with higher DP is likely to provide higher

shrinkage.

Parallel yarn str ucture

After screening the polymer with a desired

composition and DP, the fibres can be made from two

, or more polymer components by the same spinneret

from different nozzles. This kind of conjugate

spinning provides fibres with in situ differential

shrinkage. So, additional step for mixing fibres as

discussed earlier is not required and the resulting

Strial yarn structure

mixture directly produced from spinning line is

Fig. 3- Two kinds of shrinkage. Parallel a nd seri al ya rn

uniform.

structures

~I

Double shrin k type

----,..........

I ____~D_r_y_-_he_a_t_s_h_ri~nk~tY_p_e

~ ~~

Grey

fabric

Fig, 4

'-----

__

~_~

1st

2nd

Final

hQat-set

ntat-set

heat-~t

scouring

caustic

dyeing

reduction

Shrinkage d'iagram of polyest .r fab ri c after caustic

treatment

4 Topical Finishes

Finishes also modify the tactile, static and moisture

related properties of polyester fabrics. The

enhancement of polyester properties by treatment

with aqueous sodium hydroxide was recognized soon

after the invention of polyester 13 . Treatment of

untextured yarn fabric with alkali produces softer

tactility with a less synthetic hand . A calendar,

heat-set' and caustic soda saponified fabric was

patented a few.years later as the treatment was said to

produce high fabric lusture without paper-like ,

handle l4 .

Polyester undergoes nucleophilic substitution and

is hydrolyzed by aqueous sodium hydroxide . The

hydroxyl ions attack the electron-deficient carbonyl

carbons of the polyester to form an intermediate

anion,

82

rNDiAN 1. FIBRE TEXT. RES., MARCH 1996

Table 2- Summary of alkalization processes

SI.No . Materials

2

3

Formulations

Conditions

Remarks

Po lyeste r fa bric

0.3% NaOH in ethano l

50% pick up and

stored

Weight loss 2 1%

Po lyes ter fabric

Kodel IV drawn

P ET fibre &

hea t-set

6% NaOH in 5% ethano l

-do-

-do-

5- 15% sodium hydroxide

lOOT, I h

90 e

Weight loss 12-43 %

OH < t-but ox id e

< sec. pro pox id e

< methoxide

< ethoxide

Wei ght loss

12. 15-29.7 %

4

Terene fibres

1. 5 in . sta ple le ngth

5- 15%

5

Trevi ra fabric

Batch: 1.5-2 % NaOH

0.2% di spersing agent

H .T. beam: 0.05 % accelerator

Pad-ba tch: 19% NaOH

0.2% wetting agent

C ontinuo us: 19% NaOH

0 .2% accelerator

90 g/m2

aOH

0

I h

I lOT, 20 min

Weight loss 18%

R.T. fo r 24 hr

batching

120 e I min

Silk-like handle

Silk-like fini sh

More unce rtain

16-20% weight loss

Weight loss, %

17.5

20.1

21 .9

24.4

Wei ght loss 15 °;.)

Silk:like effec t

0

6

Textured P ET fi la ment

l. 87 oz!ya rn

Celenese

Fortrel 73 1

15% NaOH

0.56 o r 0.87 % quate rnary

Lauryl dimethyl ben zyl

a moniull1 chloride

Bath ratio 10: 1

30-60 min

60 min

30 min

60 min

7

Po lyes ter

3% NaOH

95°C

8

100 % Dacron P ET

fa bri c

10%

w e

9

Li ght weight PET

'68.5 g/m 2

Po lyeste r

4 % aO H

4% NaOH + I % accele ra to r

WY., Na O H

90T. 60 m in

M:L: : 1:60

lOOT. 15 min

II

Po lyester c re pe

100 g/m 2

10% NaOH

n. 1% s url~l c tant

IJOT

M : L::1: 30

12

13

Pol yes ter

Po lyes te r

14

Polyester textured yarn

Polyester textured fabric

Polyester

Polyester yarn

PET fibre , fabric

10

15

16

17

18

PET & POY

fibre s

Heat-set delustred

PET fabric

aO H

120min

30T

70T

Weig ht loss

21-23 % aft e r 60 min

20% afte r 15 min

Strength loss

10-70% warp

WI. loss of tex t > flat > spun yarn

Weight loss

STEG > SD EG > SEG

Fle x. rigidit y

STEG < SDEG < SEG

Weight loss 41 %

Weight loss 27 %

Weight loss 26 .8%

Weight loss 18-25 %

Weight loss 23 %

15 %

90T. I h

Weight loss 20-80%

60T

0-70 h

Weight loss

0-90%

Pad-ba tch

Sodium tri eth ylene gl ycolate (STEG»

Sodium d ie th ylene gl yco late (SDEG ) >

Sodium e th ylene gl yco late (SEG)

3-5 % NaOH

5% NaOH

7. 5% Meth o no lic NaOH

10 % NaOH

15 % Hydrazin hydrade

or ethylene diamine

M:L: : I :20

10% NaOH

M :L:: I: 150

2-8 mol NaOH

I % cet yl trimethy l

ammonium bromide

( 1% w / w)

Weig ht loss 10. 1%

Stre ngth loss 29'10

Weight loss 10.5-1 7.0 %

Stre ngth loss 25%

Weight loss

13.74-14 . 11 %

93-1 2 1°e Ih

104T,. 1 h

2 1°C, I h

59T, 1-6 h

BAJAJ: SILK-LIKE POLYESTER FABRICS

Chain scission follows and results in the production of hydroxyl a nd carboxylate end-gro ups.

83

Table 3- Properties of polyester sa mples sapon ified

pad -steam techniques

[Ca ust ic cone .. 150 gi L; Steaming temp ., 102°C]

Sample

No .

Time of

.steaming

(min)

Weight

loss

(%)

Flexural

ri gidity

(mg. em)

5

10

15

20

12.3

15.7

18.6

2 1.1

24.77

11.99

9.28

8.39

6.55

I

2

3

4

5

by

Strength

loss

(%)

7.3

15.8

17. 1

26.2

The effect of ca ustic solution on a PET fabric

depends on the following parameters 15 - 19:

• Concentration of a lk a li ,

• Time and temperature of alka li treatment,

• Use of surfactants,

40r------------------------------,

• Fibre type (composition and cross-section),

and

o~

• Heat se tting.

- 30

The fibre loses weight as the reaction occurs. Over a

\II

\II

wide range of temperature, the relatio n between

o

weight loss and time or sq uare root of residual weight ~ 20

and time has been found to be linear provided that a

large exee ,; of alka li is used so that the reagent is not

large ly comumed during the treatment time. If an

excess oT alkali is not used and its concentration

decreases as the reaction continues, then the weight

loss/time relation becomes exponential. Various

conditions used for saponification and the weight

Treatment Time (h)

reduction for polyester fabrics with aq ueous sodium

Fig.

5Rdationship

between weight loss and treatment time for

hydroxide are listed in Table 2. It has been concluded

polyester fabric treated with aqueous ca ustic soda [( +) regular

that the influence of temperature on the rate of the polyester, (0) regular pol yester havi ng CTAM, ( x ) AMPET

reaction is greater than that of concentration of alka li,

substituted for regular polyester)

which, in turn , is greater than that of time. Use of

quaternary ammonium salts as accelerators for

saponification has also been recommended 6.20.2 1.

In presence ofCEMDA and CTAM, weight loss of

Samples hydrolyzed using 10% aqueous sodi um 24% co uld be achieved on ly in 40 min at 130°C.

hyd roxide a t 60°C showed linear relationship

Correlation between weight loss, strength loss a nd

between the weight loss and the alkali treatment time flexural rigidity (Table 3) points out that the silk-like

(Fig. 5). Further, the addition of a cationic surfactant, soft handle of polyester can be realised 22 when the

namely certrimmonium bromide (cetyl ammonium fabric loses a weight of about 16% and the flexura l

bromide) CTAM, or the replacement of PET with an rigidity reduces to about 9 mg. cm by trea ting with

anionically modified polyester (AMPET) increases 15% NaOH at 130°C.

the rate of saponi fication considerably. G awish and

End group analysis of saponified polyester

coworkers 21 have shown that the rate of hydrolysis of indicates that with increasing weight loss of

polyester crqe fabric in \0 % NaOH (owl) at 130°C saponified polyester, the number of end groups of

was vcry slow and it required six hours to the [COOH] increased and a valu e of 47.10

theoretical weight loss of 24%. However, with the equivalents/10 6g was achieved at 2 1% weight loss

addition of different quaternary ammonium (Fig.6). The number for control being 32.8

surfactants as accelerators, the rate of hydrolysis equivalents/ I 06 g. The increased number of [COO H)

co ul d be enhanced significantly. The activity of the end groups after the saponification suggests that the

quaternary a mmonium surfactants was in the reaction of a lk a li wi th polyester is of hydrolysis with

scission of polyester chain molecules, resulting in

following order:

Cetyl ethyl methacrylate dimethyl ammoni um more number of [COO H) end groups, and confirms

bromide (CEMDA) > cetyl trimethyl ammonium the mechanism of hydrolysis as shown earlier.

bromide (CT AM) < oleyl bis-(2-hydroxylethyl)The data on sa ponified polyester indicates that

both the acc umula ted charge (acceptance potential )

cetyl ammonium bromide.

84

IN DI A N 1. F IBR E TEXT. R ES., MA RC H 1996

Tah k 4

48

250

Sa mple

No.

46

CII

200

.,

c:

o

">"

90

3

5. 24

160

240

..

4

13.5 1

11 5

;J

5

25 .1 4

90

10

e

40 '"

.

'0

c:

38~

c:

0

0

E

W

.

L....J

Cl.

36 ~

u

-<

ci

z

50

34

°0~------~----~12~----~18~----~~

24

0.31

200

30

2U

u

0. 29

(5)

190

Cl.

.. 100

I

(V)

1.6 1

Cl.

I

(% )

II 2

I

42 "'.

-

o

Accepta nce

po ten tia l

2

CII

~150

Weight

loss

44CDO

;J

>

Eifec i ofs url;lce sapo ni fica ti o n o n elect ri c cond uct ivit:

of po lyes ter sam pl es

Weig~t Loss

0.33

Mo isture

(~o I

I

0. 35

0. 37

32

I

Regain, 'I,

Tab le 5- Fi ni s hin g stages of po lyes te r fibre fa brics 15

Sa m ple A

Sa m ple B

Loo m sta te

Loom

Relaxa ti o n in washer

( I lOT. 20 min)

Relaxa tion in jet d ye ing

( I l OT. 20 min)

Hea t-se tti ng in hea tsett ing un it

( 190' C 20 s)

Weigh t reduction

( 16'Yo in 40 gi L NaO H )

Hea t-sett ing

Weigh t red uctio n

(25 % in 40 gi L NaO H )

Dye in g in jet dye ing

mac hine (no'c. 30 min)

D yei ng in jet dyein g

mac hine (130'C. 30 min )

Raising

Ra isi ng

SI a te

( 190' C 205)

Fig. 6--Co rrelations betwee n .weigh t loss. [COO H] end gro u ps

and acceptance pote nti a l in saponified po lyes ter

and 11 /2 (the time fo r ha lf the accumul ated charge to

decay) reduce with increasing we ight l oss~ The va lue

of acceptance potentia l red uced from 200 V fo r

control sa mple to 90 V for the saponified sa mple (25%

weight loss) and the di ssipati on time 11 /2 reduced fro m

240 s to lOs. The data also show that up to about 13%

we ight loss the acce pta nce potenti a l dec reased

rapidl y to 11 5 V and with furth er increase in we ight

loss to 25%, it dropped slowly to 90 V (Ta ble 4). The

reducti on in stati c charge acc umul ati on of the

alk ali-t rea ted polyes ter may be attributed to th e

surface saponi fica ti on of polyester as indica ted by the

inc reased nu mbe r of hyd rophili c [COO H] and O H

end gro ups, wick ing a nd , to a limited ex tent , th e

moisture rega in .

T he effect of th e ca usti c solutio n on a po lyester

fa bric depe nds a lso o n th e fi bre type, fa bric

co nstructi on, and hea t-settin g conditi o ns. Bright

fi bres with rou nd cross-section lose we ight slowly

th an de lustred fib res with mult ilobal cross-sectio n.

Reaso ns fo r thi s di ffe rence in the rate of weight loss

co uld be d ue to the fo llowi ng:

• For a give n linea r densit y, a multil obal fib re

wo uld have a large surface area th an a ro un d

fi bre.

• The prese nce of de lustrant may acce lerate th e

we ight loss of the fib re 23 . 24 .

• For peach like effect. hi gh solubility polymers or

ino rga ni c pa rticles are inco rpora ted in PET

melt, which esse nti all y solubilize or leac h out to

give pit effect on surface, thereby affec tin g th e

feel and hand le of th e fa bric. Thi s radi ca l

alterati on in the surface has bee n ensued by

Japanese to prepare dry touch ya rn . Microcraters res ult in low convex-co ncave co nfig urati on.

• Samples ap pea r to lose we ight fas ter after

tex turin g. Fo r exa mple, th e losses in weight of

non-tex tured ya rn and tex tured ya rn when

treated with 5% ca ustic soda at 104°C for I h were

36% anri 41 % respectively.

Ma tsud aira a nd Matsui 25 have al so studied the

effect of various fi nishing stages after the loom state on

th e fa bric handl e. The di ffe rence betwee n sa mples A

and B is in the stage of relaxi ng and we ight reducti on

(Table 5). The effect of relaxing in a washer is expected

to be greater than that in ajet dyeing machine. Overall,

th e polyes ter fi bre fa bric is remark a bl y softe ned and

fa bric hand le by re laxa ti on, whi ch includes desizi ng,

~h rin k i n g of fibres, and relax ing of in te rn al residual

stress. Subseq uent we ight reducti on d ue to alka li

produces "efrecti ve ga p" betwee n the fi bres/o r ya rn s

and th e splitting of fi bres. T be minimum amount of

weight red ucti on necessary to split fi bres is ex pected

to be a pp rox. 10%. By using di scrimi na nt a nalysis

85

BAJAJ: SILK-LIKE POLYESTER FABRICS

with the primary hand values as variables, a

distinctive zone for silk-like and peach-skin type

polyester fabric can be found.

Sodium hydroxide treatment reduces electrostatic

charge generation from 280 V to 100 V and the halflife

from 5 to 2.5 s. Sol brig and Obendorf2 6 have reported

the considerable weight loss after sapon ifying

polyester fibre containi ng 2% Ti0 2 (Fig.7) and the

pitting on the surface, obsefved through SEM, mainly

axiall y oriented a long the fibre surface. Treating

polyester fibre with 10% aq. NaOH at 100°C (by

steaming) for 45 min produced hygroscopic polyester

fibre.

In another study, a wide range of particles have been

used for creating microvoids on the fibre surface. A

common method is to remove microparticles blended

in the polyester polymer by a lka li treatment. By

applying this method to vario us polyester fibres

containing differt'nt types of particles, fibres with

vario us patterns of voids on surface are obtained.

Originally, this modification was carried out to give

depth of colour.

30

Dull

25

Bright

Serri().jll

~

0

- 20

Clear

'"'"

.3

15

.....

~

.~

'"

~

10

5

OE-__L -_ _L -_ _L -_ _

~

_ _ ~ _ _ ~_ _ _ _ ~

Treatment Time

Fig. 7-Change in weight of clear. bright. semi-dull ai1d dull PET

yarns over 6 h of treatment with \0 % NaOH solution

A method of forming a controlled microcrater on

the fibre surface is proposed. The fibre pretreated by a

;pecific resist is exposed to a laser beam and then

treated again with chemicals. This process can control

the dimensions of voids such as depth , length and

height, and their density.

A blend containing PET and 4% BaS04 (~ 2%, av o

jiam. :::; 9 /-1m) was melt sp un at 1800 m/min to give

290% elongation at Kuraray Co. The fibre wa~ used as

sheath and later on textured by Taslan process and

causticized to give 30% weight loss.

For improved lustre, polyester fibres containing :::;

0.04% inorganic oxide particles and having

birefringence 0.03-0.08 were draw twisted for ~ 0.15 s

at 130-170° and then untwi sted to give textured yarn

with very good lustre 2 7 .

The effect of BaS04 on the extent of saponification

has a lso been studied in o ur laboratories 28 . As the

treatment time and concentration of NaOH

progressively increased from I to 2 h and from 5 to

10% respectively , the loss in weight of the polyester

fibre increased from 3.03% (Po, 5% NaOH , I h) to

15.2% (Po, 10 % NaOH , 2 h) at 90°C bath

temperature.

It can be seen from Table 6 that PoSi loses more

weight over Po or P oSiF 5. This is perhaps due to th e

formation of sodium si licate in the presence of a lk ali.

due to si li cone oil coati ng on PET, which see ms to

acce lerate the sapon ificat ion process. The reduction

in diam.is a lso maximum in PllSi fibres.

After hydrolysis, elongated pits, o ri ented in the

direction of the fibre ax is, on the surface of PllSi F "

sample were noticed . However. unfilled fibres did not

show a ny pits. It was found that the size of the pits

depended on the length of expowre to alk ali, while the

number of pits depended on the concentration of

BaS04 in the fibre (Fig.8). As the treatment time and

a lk a li concentration increased from I to 2 h and 5 to

10% respectively, the pits en larged mainly in the fibre

axis direction. Longer treatment increased th e size of

the pits without changi ng their numbers. H ydro lyt ic

Table 6-Change in weight and diameter of BaSO.-filled polyester fibres after saponification

5% NaOH

Sample

\0% NaOH

2h

I h

Wt loss

%

Ih

Diameter

Wt loss

Diameter

~m

%

~m

39.4

3.03

Po

6.4

. 38.6

PoSi ·

4.{)5

39.1

PoSiF s

Diameter of Po (unsaponified). 40 ~m; PoSi -

38.9

5.0

38 .3

8.3

5.52

38.8

silane coated; PoSiF s -

Wt loss

%

2h

Diameter

Wt loss

~m

'1.

~m

15.2

22.2

18.8

36.8

35 .2

36.04

8.4

38.2

13.4

37.22

10.5

37.94

5% BaS04-filled PET

Diameter

00

0'1

z

o

);

z

;-

::!l

0:1

"

tTl

rri

><

:-i

fii

y')

!:

»

":t

(j

'"'"

0\

Fig. 8- SEM of saponified BaSO"-fi lled PET [( a) No rm al PET, (b) PET fill eu wilh 5% B"SO", (e) PET tilled wilh to'Yt, B"SO", (d)

Saponified norma l PET. (e) Saponified PET ti lled wi th SU!c, 8:ISO", alld (n Saponified PET fi lled with IO'y', 13aSO"1

87

BAJAJ : SILK-LIKE POLYESTER FA BRICS

Table 7- Te nsile properti es of sa ponified po lyeste r fibres

[NaOH conc .. 5% ]

Treatment time

Sample

code

I h

Tenacity

cN /tex

2h

Strength

r<: tenti on

%

Brea king

elongati o n

%

M odulu s

N ' tex

P"

P"Si

38

96.5

21

10

34

87. 1

IH

8.3

P"SiF,

36

97.0

18

11. 2

degrada ti on of the polyester begins a t the surface o f

the fibre an d continues until a BaS04 particle is

exposed (Fig.8). Pits appear to develop from

preferential hydrol ysis of polymer aro und the fill er

particle, locations where alkali can diffuse more easil y

due to hyd rophilic nature of the fill er. Thi s action

leaves an axially-oriented elli ptica l voi d around the

filler particle, forming an entry point for the alkaline

solution to attack polymer beneath the original

surface. Possibl y, the drawin g process used in th e

production of fibres ca uses the pi ts to be ellip tical.

Strength

ret ent ion

Te nacity

eN / tex

36.3

29 .5

35. 1

19

9.5

75. 6

14

7.8

94 ..8

17

10.6

.5:.'../:,

POlyester..q;~t.".

. :rf~(/"

J. •

..,

.h

• ..,ft:· .•

{

. .l "'f'

.....

,f

/-

ct>

'i"

:J!.t!Jzo

Sil ica ~.i"'~

f R','N'

New

$;Jji.~

~("~

The effect of silica particles on the lustre and handle

of po lyester fibres after saponification has a lso been

st udied by Yamaguchi 29. The fine concave and

convex structure is formed by a difference in solubility

in alk al i between the pol yeste r and the particles

uniformly dispe rsed in polyester. For making a fine

concave and convex st ructure of a specific size, firstly

ultrafine particles, which have a-similar refraction

rate to fibrcs and an average di ameter below 100 nm .

are uniforml y di spersed in polyester fibre wi th out

co hesion. Silica has a tendency to cohesion by

hydrogen bond of silica surface. So , silica in water is

stabilized by Na + cation as silica solution. To prevent

silica particles cohesion or agglomeration , silica sol is

mixed with et hylene glycol and particles are stabili zed

and PET is mad e by direct estc rifica ti on method.

92.1

'~':

~.

5 Te nsile Properties

The tenacity, breaking elonga ti on a nd initial

modulus decrease wi th the increase in weight loss due

to sa ponification (Table 7). Tensi le strength retention

in Po fibres is 92% and 73.6% at 5% and 15.2% weight

loss res pectivel y. However, under the same condition s of treatment the percentage strength retenti on

for P"SiF 5 samples is slig htl y better, i.e. 94.8% and

75.4% at 5.5 % and 18.8% weight loss due to

sa ponification .

Modulus

N/tex

%

Brea king

elongation

ala

surface

Alkaline

treatment

Fig. 9- Pieture of the fine concave a nd convex mechanism after

alkaline treatment

Sol-dispe rsed silica as selected particles

P ro[)enics

Silica

So lubilit y rati o a gainst alkali

80

Index of refract ion

1.55

Oi <l me te r( pill)

0.05

Pol yester

1.62

10

~

10

The fibre s containing silica are treated with an

etc hi ng meth od using alkali . Their surfaces are peeled

ofr. Silica's solubili ty ratio against alkali is so ra pid

that a fin e concave and convex structure is formed

(Fig.9).

Kurara y Company ha s dcveloped this fibre as the

super microcrator polyester fibre '-' SN 2000" . Fig.1 0

shows the relation between fibre surface area (BET

method) and alk aline weight reduction . The effect of

microcrator due to alkali treatment o n the depth of

black colour has also been shown. So, at high alkaline

weight reduction , polyester fibre of fine surface

provides not only a deeper colour shade but an

improvement in lustre and ha ndl e of the fabrics .

Toray Industr ies 30 prepared polyester fibres with

mild silk-like luster by polycondensing glyco l slu rries

co ntainin g particles with (RI 1.3-2.0) and average

88

-

INDIAN J.FIBRE TEXT. RES., MARCH 1996 .

1.2 r-- - -- - - -- - -- - - - - - , 1 5

.

...'"

Table 8- Moisture regain , st rength retention and the durability

to washing of the chitosan-treated fabrics 33

~~-.--------r_

Micro-crater polyu.ter

Fabric

E

-0

0

.c;

Add-on

(%)

1. 0

16

E'"

>....

co

'"'"

OJ

d

~

.q:

17

0·8

d

QI

u

..&-._ ._ ._ . - - 0

d

~

::>

Vl

c:

-'"

u

-..vt-

.-:: ...a.-r

..&. .............. __

----------r

J.

co

Untreated

Chitosan-treated

without curing

Chitosan-trea ted

with c uring"

6.6

15.3

6.4

16.7

Moisture Strengt~ Durability to

regain retenti on washing

(%)

(°lc,)

(weight

remained, % )

0.4

I.7

2.4

1.6

2.4

100

75.6

87.6

138.0

150.0

2.5

2.3

95.0

84.4

Alkali trea tment: 10% Sodium hyd roxide, 90 min, 60' C

C uring condition: 130' C, 90 min

Regular polyesf~r

Alkaline

Weight Reduction

(%)

Fig. I O-Relationships between the surface area, blackness and

a lkaline weight reduction (Black dyed Georgette fabric)

primary particle diam.45 J.1m and average secondary

particle ciiam.350 J.1m with polyacids to form PET,

melt-spun and drawn to give trilobal fibres with silica

content of 0.01-0.4% .

For rapidly hydrolyzable PET fibres , melt blending

of PET with 2-10% sulfo containing aromatic diol(l)

was carried out by Teijin Ltd 3J .

H-t 0 C2H4)mO ----@{-OC C2H4 0

(I)

~H

S03 M

.

application and the nature of amine. Amide

formation results in chain scission. Amines were

found to reac t and attack amorphous as well as

crystalline regions. It appears, according to Zironian,

that the weight loss/time curves are affected by the fine

structure of the polymer and the location of attack.

7 Aftereffects

o Deterioration in tensile properties

o Broadens dye class for PET

o Improved wettability

o Oily soi l release improved

o Good antistatic property

o Increased moisture regain

o Cracks developed on fibre surface

o Brittleness increased

o Flex life decreased

o Shift in endothermic melting peak to lower

temperature

o Improved pilling resistance.

References

A woven fabric of the fibre showed weight

reduction rate of 41 % / h in boiling aqueous NaOH.

Ester Co. Ltd has developed polyester fibre with

superior softness and gloss by dispersing 0.5-20%

EPR in PET fibre. M~lt kneading was carried out and

then spun into fibre 32 •

Matsukawa et al. 33 have shown the recovery in

tensile strength of alkali-treated polyester fabrics by

subsequent treatment with chitosan (Table 8). The

chitosan was fixed to the surface of saponified PET hy

the reaction of the carboxyl groups .arid the amino

groups of the chitosan molecu·les.

6 Weight Reduction by Amines 1s

The reaction is similar to that by NaOH . The

location of attack varies and depends on the mode of

I Latta B M, Clothing com/ ort : . Interaction of thermal.

ventilation . construction and assessment faClors (Ann Arbor

Science, Ann Arbor, Michigan, USA), 1977, .33-35 .

2 Slator K , Text Prog . 9(4) (1977).

3 Yoon H N & Buckley A , Text Res l. 54 (1984) 289.

4 Yoon H, Sawyer LC& BuckleyA, Text Res l . 54(1984)357.

5 Zeronian S H & Collins M J, Text Chern C%r . 20(4) (1988)

25 .

6 Matsumoto M, Indian Text l . (Jan. 1991) 'J4 .

7 Fukuhara M, Text Res l . 63(7) (1993) 387.

R Wada 0 , 1 Text Inst . R3 (1992) 322.

9 Sato M, Takakashi H, Sato Y, Sasaki H & Na beshiwa K, Proc.

ISF'94 . (The Society of Fibre Science & Technology,

Yokohama, Japan), 1994, 323.

10 lap Pat 62-53606; II November 1987.

II lap Pat 51-30620; 2 September 1976.

12 Uchida A , Kakogijulsj. 25(4) (1990) 226.

13 Hall J D H, Ridge B P & DeMartino R N, US Pat 2,590,402

( 1952).

14 Gajjar N J , U S Pat 2,828,528; I April 1958.

BAJAJ: SILK-UKE POLYESTER FABRICS

15

16

17

18

19

20

21

22

23

24

25

Zeronian S H & Collins M J, Text Prog, 20(2) (1989) 70.

Houser K D, Text Chem Color. 15 (1983) 70.

Gawish S M & Ambrioise G , Am Dyest Rep , (Feb. 1986) 30.

Rane S S, Man-Made Text India, (July 1992) 251.

Ichida E, Uyama Y & Ikada Y, Text Res}, 61(8) (1991)4iD.

Yasutome K & Watanabe K, Jap Sen'e Kako , 33(2) (1981)

336.

Gawish S M, Bourgeois M & Ambrioise G , Am Dyest Rep ,

(Dec. 1984) 37.

Rao A L N, Silk likefinish onpo/yestei and itsb/ends, M. Tech.

thesis, Indian Ins~itute of Technology, Delhi. 1986.

Solbrig C M, The alkaline hydrolysis of titimium dioxide

delustred PET, Masters thesis, Cornell University, 1986,

44-45.

Solbrig C M & Obendorf S K, Text Res J , 61 (1991) 177.

Matsudaira M & Matsui M, J Te'x t Inst , 83 (1992) 144.

89

26 Kurara y.£:"o .. Jap Po/ 07,90,736; C/refll Airs/I', 123 (1995)

I I 5250g.

27 Toray Ind, Jap Pat 06,322.625; Chem Abstr, 122 (1995)

108592w.

28 Koul R, X-ray and (m/isra/ic polyester fibres, Ph . D thesis,

Indian Institute of Technology, Delhi , 1994.

29 Yamaguchi S. Proc. ISF'94 , (The Society of Fibre S cience &

Tec/rnology , Yokohama , Japan) , 1994, 326.

30. Toray lrid .. Jap Pat 05.171,516; Chem Abstr, 1201(994)

56600j.

31 Teijin Ltd, Jap Pal 06.263.971; C/rern Abstr, 122 (1995)

190257x.

32 Nippon Ester Co. Ltd. Jap Pat 06,313,214; Chern Abs/r, 122

(1995) 1902601.

33 Matsukama S. Kasai M & Mizuta Y. Sen-i-Gakkaishi, 51 (I)

(1995) 17.

© Copyright 2026