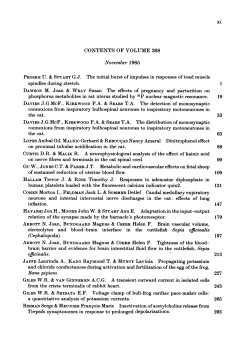

Thompson Tractor Opens New Huntsville, Alabama, Facility USE yOUR CAT

PAGE 2 MCDONALD BROS. CONSTRUCTION KNOWS HOW TO CREATE A SOLID FOUNDATION PAGE 2 Use your cat accessaccount card and get 0% financing ® PAGE 3 accugrade ... New software new models ® SPRING 2009 INSIDE Thompson Tractor Opens New Huntsville, Alabama, Facility THE THOMPSON CAT RENTAL STORE CELEBRATING 10 YEARS OF GROWTH page 4 Two hours after Rickey Borden of Borden Contracting Co., Lacy Springs, Ala., brought in the first machine to be serviced at the new facility, work on a ‘96 CAT D6H complete undercarriage was well under way. GREAT FINANCE SPECIALS page 5 BUMPER TO BUMPER – THOMPSON TRUCK SOURCE HAS YOU COVERED page 6 NEED A FORKLIFT? DO YOUR RESEARCH page 7 The new 42,000-sq.-ft. Huntsville, Ala., branch of Thompson Tractor is located just off I-565 at 3600 Governors Drive. On March 2, 2009, Thompson Tractor opened its new Huntsville, Ala., branch facility. Customers, friends and supporters were invited to be a part of Thompson Tractor history at its new store’s first day. Customers could stop in, take a tour, grab a coffee, stay for lunch, or just take a leisurely look around and talk with those that helped to make the new branch a reality. The branch is situated on 10 acres at 3600 Governors Drive, Huntsville, Ala., right next to I-565. The store combines Thompson Tractor Company with The Thompson CAT Rental Store in a 42,000-sq.-ft. facility purposely built for expansion. Two floors of office space provide ample space for the entire staff and for future additions to the work force. The service area of the facility encompasses almost 18,000 sq. ft. and includes four dedicated rental bays and four truck bays, both of which are equipped with 5-ton overhead cranes. There are a total of four bays (with the capacity for 8 machines) for the heavy equipment side of the business with a 10-ton overhead crane to accommodate work on the heavy machines. An impeccably organized parts-stocking warehouse occupies more than 8,000 sq. ft. Future “vertical” growth plans within the building are already in the making. Kenny Bishop, vice president of sales stated, “We manage our business very well through good times and bad. This new branch is a long-term investment we are making for our customers and is our way of providing them the assurance that we are able to provide them with the level of service they are accustomed to no matter what the economic conditions may be.” To provide historical background as to why the company built the facility during “not so perfect economic times,” Sammy Dean, northern region manager, said, “Thompson has been in Decatur since 1959. At the time, Decatur was the most populated area in north Alabama. In the 70s and 80s Huntsville and Madison saw rapid growth in the aerospace, technology and defense industries and are now the most populated areas in the northern portion of the state. We’re simply positioning ourselves to be in the heart of the growth area where we can work closely with our customers to ensure retention. With the team approach at any of our locations, each and every staff member shares and owns our customers’ good experiences as well as any problems they may have.” In looking to the future, both Dean and Bishop concurred that they have confidence in the Huntsville area for growth of their business and that the economic downturn will be a thing of the past in the very near future in this part of Alabama. GREAT DEALS ON USED EQUIPMENT AND PARTS pageS 5, 7, 8 2401 Pinson Highway Tarrant, AL 35217-2051 PAID Permit No. 68 Wichita, KS PRSRT STD U.S. Postage Produced by: With more than 8,000 sq. ft. of space, the parts area is well-stocked, well-organized and supplies the parts needed. The first machine to roll into the shop was a 1996 CAT® D6H dozer which was brought in by Rickey Borden (C) of Borden Contracting Co., Lacy Springs, Ala. Thompson Tractor service representatives on hand to welcome Borden were (L-R) David Brand, Brian Peters, Borden, Mark Slocumb and Reggie Sharp. Soon after the service staff arrived on the first day of operations, trucks from Hertz Equipment Rental and McPRO were in for CAT® engine service. The boys from Vulcan Materials stopped by to take a tour of the new Huntsville branch. (L-R) are Eli Christopher, Vulcan Materials; Kenny Bishop, Thompson Tractor; Joey West, Vulcan Materials and Sammy Dean, Thompson Tractor. At 7:15 a.m. on the branch’s first day, McDonald Brothers Construction of Huntsville, Ala., purchased a CAT® 289C Skid Steer Loader. It was the new branch’s first sale. (L-R) are Eric Stogner/ Huntsville Rental, Jeff Pope/ Birmingham Rental sales manager, Kenny Bolton/ The CAT Rental Store branch manager, Jimmy Tew/ Birmingham Rental, Neal Porter/ Huntsville Rental, Dell McDonald/ McDonald Brothers Construction, Huntsville, Ala., Sammy Dean/ Northern Region manager and Joe Cuzzort, Huntsville Sales. Two recently retired equipment operators were recognized during opening day. (L-R) are Bruce Black and Henry Hopkins, who were presented with large framed prints of themselves with the machines they used to operate. The prints were signed by APAC and Thompson Tractor representatives and many others in “the construction community.” These two gentlemen have 95 years of combined service throughout their careers with Ashburn Gray Construction and APAC of Huntsville, Ala. Throughout their careers, they have only run Caterpillar® machines. Discussing the service capabilities of the new branch facility are (L-R) Thompson Tractor’s Sammy Dean and Kenny Bishop; Scott Langford of C.A. Langford Company Inc., Guntersville, Ala.; and Langford’s Thompson Tractor sales representative, J.D. Miles. www.thompsontractor.com 2 SPRING 2009 Thompson Tractor Co. McDonald Bros. Construction Proving that routine maintenance and competent operators create a solid “foundation” Combine solid machines, a company’s commitment to maintenance, experienced and conscientious operators, and dealer product support, and you have a formula for long, productive life and maximum value from earthmoving machines – something that helps strengthen a company’s bottom line, especially in today’s economy. Such has been the case for two Caterpillar® machines used by McDonald Bros. Construction in Huntsville, Ala. S.O. and Charlie McDonald founded McDonald Bros. Construction in 1961. During the company’s first two decades, it focused primarily on residential site prep and house pad construction. In 1984, S.O. purchased his brother’s share of the company and shifted the focus more toward commercial work. The company handles all aspects of site prep – demolition, earthmoving, underground utilities, curb and gutter and base – except for paving. In addition, McPro Hauling was created in 2001 to separate the company’s trucking operations from the construction side of the business. “He foresaw where Huntsville was going as far as commercial work,” says S.O.’s son, Dell, who joined the company in 1987, “and Huntsville’s been very, very good to us.” S.O. McDonald continues to serve as President, joined by Dell as Vice President and General Superintendent; and Mike Propst, S.O.’s nephew, who joined the company in 1989, as a 0 Project Manager and Head Estimator. “Since the move to a commercial site prep focus, the company has grown from 15 to 17 employees to 135 during busy summers,” Dell continues. It’s been those employees, some of whom have worked for the company since Dell was a child, and his father’s commitment to maintaining equipment that have helped the company maximize their investment in their Caterpillar machines. The company currently operates a fleet of nearly 60 pieces of equipment, a quarter of which are Caterpillar. “Dad’s of the school if you take care of your equipment, it’s going to take care of you,” Dell says. The company handles its own routine maintenance, and sends oil samples regularly to Thompson Tractor Company’s Fluid Analysis Lab. With the opening of Thompson’s newest location in Huntsville, McDonald Bros. also has more convenient access to Thompson’s parts department and service department for more involved repairs. Sales Represent, Joe Cuzzort and Product Support Representative, David Brand serve McDonald Bros. from the new Huntsville store. Operator Clyde Morrison’s been with McDonald Bros. for more than 35 years, and for the last 13 years he’s been the only operator of one of the company’s CAT® 953B Track Loaders. The machine has more than 18,000 hours on it, and once got 10,000 hours out of an undercarriage. It’s not like Left to right: Dell McDonald (McDonald Bros. - Owner), David Brand (Thompson PSSR), Philip Sloan (McDonald Bros. - Operator), Clyde Morrison (McDonald Bros. - Operator), and Joe Cuzzort (Thompson Salesman). the machine has been babied, but it has been used smartly. “If it’s in rock or on a tough house pad, that’s the loader that goes,” Dell says. Clyde attributes the long life of the machine to a “good operator.” % * FINANCING He’s even fashioned his own stops on the throttle and shifter to keeps the machine within what he feels are its most productive settings. “It’s a good smooth operating machine,” Clyde says. “And for what I do and the grading, you don’t need to be running it wide open.” Another longtime operator is Phillip Sloan. He’s been with the company 21 years, the last 10 as the sole operator of a CAT 325B L Hydraulic Excavator that’s surpassed 15,000 hours. While he might trade his machine for a new Caterpillar excavator, he prefers his current mount to any of the other brand machines he’s operated. “There ain’t no comparison (with Cat) to me,” Phillip says. McDonald Bros. focuses most of its attention on the commercial market in Madison County, with some projects in Marshall or Jackson County, and it still tackles a few residential jobs. Among the company’s recent projects are Huntsville Hospital Medical Towers and bridge relocation, Covenant Presbyterian Church with Turner Universal, Mayfair Surgery Center with Joe Steel Building Co., and Williams Middle School and Trinity Baptist Church with Consolidated Construction. Dell says he’s hopeful the economy will pick in the latter part of 2009. Bidding for what jobs are available is very competitive, but the company resides in a good market to be in when the upturn begins. “Huntsville’s always going to be one of the busiest and fastest growing areas in the state,” he concludes. THOMPSON TRACTOR IS NOW OFFERING ZERO PERCENT FINANCING PROGRAMS THROUGH CATERPILLAR® FINANCIAL SERVICES’ CAT® ACCESSACCOUNT CARD PROGRAM. SEE IF ONE OF THESE OFFERS IS THE SOLUTION TO YOUR CURRENT CHALLENGES. Thompson Tractor is now offering ZERO PERCENT FINANCING programs through Caterpillar® Financial Services’ Cat® AccessAccount card program. Call your Thompson Tractor Service Representative or the Service Manager at your local Thompson Tractor shop about the particulars on the following 0% offers. • Certified Powertrain Rebuilds • Powertrain & Hydraulic Component Rebuilds • Emissions Retrofit Products www.thompsontractor.com • GET, Protective Systems, Wheel and Bucket Rebuilds • Cat Work Tools & Attachments • Cat Undercarriage (metal or rubber tracks) • Truck Engine OPT/Reman Engines • Cat Compact Generator Sets Make sure you ask about our SPECIAL SECOND QUARTER REBUILD PROGRAM Each of these offers has a particular set of qualifications and expiration dates, so get in contact with Thompson Tractor today and see if you qualify and can take advantage of these 0% finance rates. *0% Financing will be provided through Cat AccessAccount on all eligible purchases. Must be pre-qualified by Thompson Tractor and approved for financing by Caterpillar® Financial Services Corporation. Each of these offers have their own individual terms and limitations. Please check with your Thompson Tractor or Caterpillar Financial Representative for specific terms and limitations. These offers are made based on current financial conditions and may be withdrawn, changed or altered at any time without any written notice or further communication. ©2009, Thompson Tractor Earthmoving Thompson Tractor Co. SPRING 2009 3 New AccuGrade Grade Control System Software Expands Capabilities and Adds Three New Machine Types ® Caterpillar has released new software that expands the capabilities of the AccuGrade grade control system, the Cat factory-integrated, sensor-independent solution for machine control and guidance. The new on-board software, CD700 v. 11, and new office software, AccuGrade Office v. 7.2, provide software support for three new machine families — wheel loaders, wheel dozers and towed scrapers. New, more capable configurations also are offered for track-type tractors, motor graders and hydraulic excavators. AccuGrade systems continue to support soil compactors and wheel tractor-scrapers. The new software includes Sky Plot, which allows the machine operator to view GPS and GLONASS satellites available when using MS980 or MS990 receivers. The operator also can enable or disable use of the GLONASS satellite constellation from the cab when using the MS990 receivers. The capability can help ensure optimum satellite coverage for fast start-up and accurate operation. The new software also enhances diagnostic support information. AccuGrade Office wireless users now can remotely retrieve radio settings, machine measurements, valve calibration tables and machine settings. The capability speeds diagnostic and calibration tasks. Enhanced capabilities for specific machines The new software provides specific benefits for each machine type. For example, on hydraulic excavators the CD700 display now supports site and laser reference, which can be used when GPS or the Universal Tracking System (UTS) are not available. The system supports single GPS, which provides a lower cost entry level 3-D system. Similarly, single UTS support allows use of a 3D-design when GPS positioning is not available. Also on hydraulic excavators using the CD700 display, profile and cross-section views are available simultaneously to the machine operator so that all critical dimensions are in view. Additionally, the new system enables excavator bucket center guidance, which improves accuracy when working on side slopes. On motor graders, dynamic pitch allows the operator to maintain accuracy when rolling the blade during grading. A blade pitch sensor and a Product Support mainfall sensor are required, but the system eliminates the need for the operator to keep the mast vertical when using GPS or UTS. For the CAT® D8T, D9T and D10T Track-Type Tractors, an entry-level, indicate-only system is available for earthmoving and early site-preparation tasks. The system uses a single, cabmounted GPS antenna. AccuGrade Version 11.0 • v11 allows Caterpillar CD700 displays to be swapped with Trimble® CB430 displays – display portability so now AccuGrade can be used on most CAT machines. • CD700 now has all the extra options that CB430 had: – Machine types – Valve types – Other options New Features Single 3-D (GPS and ATS) Hex Support AccuGrade for Excavators now supports Single GPS and Single ATS. Note: Caterpillar does not recommend Single 3-D for machines that are working on a moving platform or for machines with tracks that must be moved in order to still receive guidance. 2-D Excavator Support The “Depth and Slope” configuration gives features that are similar to those features that are offered on the CB410 display. Yet, the features are displayed on the larger screen of the CD700 display. This configuration provides clear guidance and functionality when GPS is not available. Split Profile and Cross Section View for Excavators Support has been provided for a view of split cross section and profile on excavators. This feature allows the user to view both the cross section and the profile at the same time. Excavator Bucket Center Guidance This feature adds support for bucket center guidance for excavators. It offers better guidance when working on side slopes. Bucket center guidance is available for both 2-D mode and 3-D modes. Sky Plot This feature allows the operator to view the currently available satellites. Rolling the Blade on Motor Graders This feature allows the operator to roll the blade while operating the machine with accurate grading results. Note: A blade-pitch sensor must be installed. Use the 336-4806 Sensor and Mounting kit. A mainfall sensor is also required – see picture. Modified Limits to the Range for Auto Control for Dozers and Motor Graders Depending on the size of the machine, this feature has automatic ranges that change. Large machines allow a wider automatic range versus small machines. Also, the range can be modified. This modification is dependent on the needs of the application. 2-D Remote Switch Functionality The remote increment switch or the remote decrement switch can now be used to adjust elevation and the slope on the following list of applications: laser, sonic and slope. Previously, this adjustment was performed only on the display. AccuGrade Indicate-Only Option This feature allows the installer to configure the system as an indicateonly system for dozer and motor grader machine types. This feature allows the system to continue to give indicate cut/fill and horizontal guidance. If GPS technology plays an important role at today's construction sites. AccuGrade® Grade Control System at work. AccuGrade® technology increases accuracy and efficiency at the worksite. there are active diagnostics that are registered by the A4M1 ECM, the system will provide the information with this new feature. Extra Diagnostic Support Information This feature allows for extra diagnostic information to be obtained from AccuGrade Office with wireless. The file includes the following information: - Settings for the radio - Measurements for the machine - Table for valve calibration - Machine settings For more information about AccuGrade for your jobsite, contact your Thompson Tractor Sales Representative. www.thompsontractor.com 4 SPRING 2009 Thompson Tractor Co. The Thompson Cat Rental Store: Celebrating 10 Years of Growth Thompson Tractor Co. Inc. has always rented machines, but it was more in the rent-to-sale businesses. Customers would typically rent these machines and purchase them rather than return them to us. In April 1999, Thompson Tractor decided to be in the full-line rental business (rent-to-rent) and started the Thompson CAT Rental Store. In the beginning, there were two locations employing 13 people, one in Birmingham at 6th Avenue South and the other was in Montgomery off the northern by-pass. The Thompson Cat Rental Store now also has Alabama locations in Anniston, Calvert, Dothan, Huntsville, Mobile, Shelby County, Tuscaloosa and Thomasville. We also have locations in Panama City and Pensacola, Florida, as well as a new facility built in the Birmingham location. We currently have about 150 employees at these 12 locations servicing our customers. Some people ask, “What’s a full-line rental store?” Well, at Thompson it’s a rental store that has a very wide range of products in the rental fleet — including a range of aerial lifts, excavators, backhoes, water pumps and more. Of course, the Thompson Cat Rental Store carries the CAT® machines such as the 320 excavator, D5 dozer, 930 rubber tire loader, skid steer loaders, mini-excavators and so on. But what some do not know is that Thompson CAT Rental stores also carry a large amount of non-CAT machines, such as manlifts, carry decks, cranes, dump trucks, water trucks, water pumps, air compressors, welding machines and small electric drills. Thompson CAT Rental Stores are also dealers for many product manufacturers, including Shuttle Lift Cranes, Manitex truck-mounted cranes, Miller Welding, Multi-Quip and Genie Industries. The Thompson CAT Rental Store has almost any item a contractor would need to rent on almost any job. Thompson strives to be a “One-Stop Shop” for our customers’ rental needs. Not only that, Thompson is more than happy to rent these products for a day, a week, or really, as long as the customer needs them. That’s the point, providing the services that our customers want. The Thompson CAT Rental Store also has the privilege to market and distribute the Caterpillar® CCE (Compact Construction Equipment) products in the state of Alabama and in the Panhandle of Florida. These products consist of skid steer loaders, multiterrain loaders and compact wheel loaders. The sales of these products have consistently grown over the years, and now represent a large part of our business. With the additional products now available from Caterpillar, the Thompson Cat Rental Store can compete with any product offering from our competition. What’s the Right Machine for You? Deciding between Skid Steer Loaders, Multi-Terrain Loaders and new Compact Track Loaders Matching the right machine to the primary services offered by a contractor can save time and, ultimately, make a job more profitable. But deciding when to use a skid steer loader versus a multi-terrain loader can be a difficult decision — and the answer can change from one job to another. The introduction of new Cat® Compact Track Loaders, meanwhile, has added another machine to the equation. The good news: If you properly analyze the benefits, you’re all but guaranteed to improve your crew’s productivity and your bottom line. So which machine — skid steer loader, multi terrain loader or compact track loader — is the best fit for your jobsite? Skid Steer Loaders (SSL) SSLs have been around longer than their rubber track counterparts, and are still the best fit for many applications — mostly because of their speed. “For everyday work the skid steer, we’re finding, can grade very well,” says Dan Hollowell, owner of APEX Excavation and Services Inc., Meridian, Idaho. “Any time we have a crew of concrete guys behind us, we can outrun a grader.” Consider the wheeled machine when: • Working on surfaces that aren’t particularly sloped, rugged or wet. If a SSL can get the job done, it’s often the right choice because of the speed and productivity the wheels provide. • Looking for compaction. The tires compact materials, which is desirable in some applications. Multi-Terrain Loaders (MTL) MTLs feature rubber track undercarriages, which don’t damage tender surfaces. “You can get through a finished yard without destroying it,” says Steve Hutchison, an operator for Mike Dusselier Concrete Flatwork Co. Inc., Olathe, Kan. That saves the firm substantial seeding and sodding time. Also consider MTLs when: • Working in wet conditions. The undercarriage provides low ground pressure and excellent flotation so contractors can work in almost any weather. • Traveling over curbs and sidewalks, which also could be damaged by other machines. • Working in sharp aggregate or construction sites where nails and other objects can puncture tires. • Working on grades. Operators report the MTLs have better gripping than SSLs. Compact Track Loaders (CTL) CTLs feature a steel track undercarriage, compared with the rubber undercarriage on MTLs. The steel provides extra strength and durability. “It’s more of a gritty machine,” says Steven Stratton, president of Steven Stratton Inc., Hastings, Fla. “It’s designed to be a workhorse.” Consider CTLs when: • Working in the toughest applications. The undercarriage can handle sand, coarse mud and even demolition work. Those in the field also report that the tracks hold up well when working in jagged stone. • Working in fines. Silt and sand sometimes damage rubber track undercarriages, but those involved in the testing of the Cat CTLs reported no problems from the fine materials. • Power is required. The Cat® CTLs have an increase of about 10 horsepower over the comparable MTLs, but those in the field report it feels more like 20 horsepower. • Speed AND tracks are required. The fully suspended steel track undercarriage helps deliver a smooth ride, which in turn aids in load retention. The standard two speed on the Cat CTLs mean the machines can move at 8.5 mph while retaining their load. The speed of the Cat CTLs has not gone unnoticed by Cork Peterson, vice president of Peterson Contractors Inc. “If you can get one (hole) more per day, it doesn’t cost you anything — just a little bit of rock,” Peterson says. “The labor is the same, the machine is the same. The secret is getting the rock to the hole fast enough.” Connecting Machines with Attachments for Maximum Productivity The Cat® Rental Store Business Tip Making the right connection of machine and attachment can help maximize productivity on the jobsite. First, select a machine that allows easy exit and entry of the machine and offers good visibility from the operator’s seat to the attachment. Its coupler configuration should allow an operator unobstructed access to the seat and a clear view to the attachment. Second, determine the type of coupler the machine will need. The universal coupler interface and low profile side plates of mechanical quick couplers allow the most attachments to match properly while keeping dirt and debris out. Two high-leverage handles serve to engage or disengage the attachments. Hydraulic quick couplers have a rocker switch in the cab that controls two hydraulic cylinders (that replace the manual handles of a mechanical coupler), allowing the operator to change attachments while in the cab. Hydraulic cylinders control the vertical wedge pins that lock the attachments in place. www.thompsontractor.com High-Flow and Standard-Flow Hydraulics Hydraulic power not only provides power to the wheels, but it also operates the loader to enable lifting and tilting, and runs the auxiliary circuit, which drives attachments. The criteria for “high-flow” or “standard-flow” may differ from one manufacturer to another. Typically, high-flow circuits exceed 26 gallons per minute and 3,300 psi. Highflow machines designated “XPS” (33 gallons/ minute at 4,050 psi) are capable of maintaining maximum pressure regardless of attachment speed or working conditions, at low or high idle. The typical flow for a standard-flow machine is 22 gallons per minute. Types of Attachments Attachments fall into two groups: fabricated and hydromechanical. Buckets and forks, which do not have moving parts controlled by the operator, are “fabricated” attachments. Hydromechanical attachments include multi-purpose buckets, mulchers, hammers, augers, grapples, rakes and other attachments that are powered by the machine’s auxiliary hydraulics. “Choosing attachments that can be operated by multiple machines may enhance flexibility and productivity on the jobsite. Fabricated attachments are the most universal, and the machine from one manufacturer can attach the buckets or forks made by another manufacturer with very little trouble, as they do not require additional hydraulics to operate. Hydromechanical attachments have more specific requirements. Therefore, most equipment manufacturers recommend that machines use the hydromechanical attachments from the same manufacturer. Why? Hydraulic hose hook-ups and fittings are of the same strength and brand, ensuring a proper match and tight fit to reduce leaks and loss of pressure. Machines and attachments are designed to work as a system, and these pairings are intended to maximize the horsepower and hydraulic capabilities. Attachments to Match Equipment manufacturers may offer an attachment in a variety of configurations. Augers are a good example: Direct drive or planetary drive augers are available for standard hydraulic flow machines. These configurations are designed to maximize the capabilities of the hydraulic circuit and are intended for medium-duty applications. A high-flow planetary-driven auger on a high-flow hydraulic machine would be appropriate for extreme-duty applications. The high-flow configuration is designed for maximum torque, and the hydraulic hoses and seals are built to withstand the additional pressure and maintain a leak-free connection. Additionally, some are designed to accommodate (or compensate for) machines of a certain size. For instance, a landscape tiller model for machines up to 66 inches wide is offset to cover one set of the machine’s tire tracks. Thompson Cat Rental Thompson Tractor Co. SPRING 2009 5 we want to finance your next machine. Better rates could apply! Call today for more information. DID YOU KNOW ... That for the same amount as a lunch for two, a half tank of gas, a fraction of a grocery bill … you can own a WHOLE machine for your business! That’s right, for as little as $23.64 a day you can own a Skid Steer Loader*, Mini Hydraulic Excavator, Multi-Terrain Loader or a Compact Track Loader from Thompson Tractor. $23.64 / day* 246C Skid Steer Loader $28.41 / day* 257C Multi-Terrain Loader $41.57 / day* 299C Compact Track Loader $27.14 / day* 303C CR Mini Hydraulic Excavator Caterpillar® machines deliver industry-leading performance with exceptional comfort. Match your equipment with a wide range of work tools and you will be ready for any job. Saving you time and money, count on Thompson Tractor. *Based upon 5.9% Financing, 60 month term plus applicable taxes. This offer is made based on current financial conditions and may be withdrawn, changed or altered at any time without notice. Used Rental Equipment For Sale 1 2007 CAT 301.8 2 2007 CAT 302.5C 3 2007 CAT 303C CR 4 2007 CAT 304CCR 5 2008 CAT 303C CR 6 2007 CAT MTL745 7 2007 CAT MTL775 8 2004 CAT TH350B 9 2005 CAT TH350B 10 2005 CAT TH460B 11 2005 CAT TH210 12 2006 CAT TH350B 13 2007 CAT TL943 14 2006 CAT 246BVTS 15 2007 CAT 252B 16 2007 CAT 216BVTS Rough Terrain Reach Forklifts/Telehandlers 17 2007 CAT 256C 18 2008 CAT 232B2 www.thompsontractor.com Mini Excavators Skid Steer and MTL Model 247B 247B2 257B Photo 7 257B 257B2 267B 267B 277C 277C 287B 287B 287C 287C 287C 297C 297C Photo 6 297C 297C 216B 216B 216BVTS Photo 16 216BVTS 226B 232B2 Photo 18 236B 236BVTS 242B 242B 246BVTS Photo 14 252B Photo 15 252BVTS 252BVTS 256C Photo 17 262B 262BVTS ID# MTL794 MTL847 MTL775 MTL801 MTL805 MTL566 MTL638 MTL788 MTL808 MTL650 MTL671 MTL725 MTL741 MTL742 MTL744 MTL745 MTL756 MTL765 SL1087 SL1106 SL1118 SL1121 SL1086 SL1271 SL937 SL1039 SL1281 SL1282 SL926 SL1116 SL1136 SL1138 SL1180 SL1054 SL1055 Thompson Cat Rental YEAR 2007 2008 2007 2007 2008 2006 2006 2008 2008 2006 2006 2008 2008 2008 2007 2007 2007 2008 2007 2007 2007 2007 2007 2008 2006 2006 2007 2007 2006 2007 2007 2007 2007 2006 2006 HOURS 430 952 950 377 302 948 1444 268 239 469 1376 278 477 431 278 340 900 500 495 387 871 549 566 135 607 525 628 281 1286 571 380 390 257 814 744 PRICE $32,000 $33,000 $31,000 $33,000 $38,000 $31,000 $29,000 $48,000 $48,000 $39,000 $37,000 $52,000 $50,500 $51,000 $53,000 $53,000 $46,000 $60,000 $18,500 $20,000 $29,000 $29,500 $24,000 $25,000 $24,000 $41,000 $24,000 $25,000 $34,500 $26,500 $36,000 $36,000 $32,000 $27,000 $37,500 MODEL 301.8 Photo 1 301.8 302.5C 302.5C 302.5C 302.5C 302.5C Photo 2 302.5C 303C CR Photo 3 303C CR 303C CR 303C CR 303C CR 303C CR Photo 5 303.5CCR 303.5CCR 303.5CCR 303.5CCR 303.5CCR 303.5CCR 303.5CCR 304CCR 304CCR 304CCR 304CCR Photo 4 304CCR 304CCR 305CR 305CCR 305CCR 305CCR 305CCR 305CCR 308CCR 308CCR 308CCR 308CCR 308CCR 308CCR ID# ME329 ME456 ME296 ME326 ME327 ME331 ME333 ME462 ME357 ME373 ME378 ME382 ME389 ME439 ME307 ME346 ME361 ME380 ME415 ME479 ME484 ME321 ME370 ME406 ME408 ME416 ME451 ME286 ME355 ME365 ME395 ME453 ME457 TH361 TH363 TH335 TH337 TH358 TH376 YEAR 2007 2008 2006 2007 2007 2007 2007 2008 2007 2007 2007 2007 2007 2008 2006 2007 2007 2006 2007 2008 2008 2006 2006 2007 2007 2007 2008 2006 2007 2007 2007 2008 2008 2006 2006 2007 2007 2007 2008 HOURS 350 109 593 582 306 702 498 65 623 758 788 550 476 262 564 769 809 825 713 175 96 920 1078 204 943 662 110 1027 1371 916 590 294 213 1165 1376 892 1023 881 643 PRICE $25,000 $28,000 $23,000 $27,000 $29,000 $28,000 $29,000 $33,000 $31,000 $31,000 $31,000 $31,500 $32,000 $35,000 $30,500 $33,000 $32,000 $32,000 $33,000 $38,500 $41,000 $34,000 $33,500 $38,500 $37,000 $37,500 $44,000 $37,500 $42,000 $43,000 $44,000 $52,000 $48,000 $57,000 $57,000 $72,000 $72,000 $73,000 $88,000 Model TH210 TH210 TH210 Photo 11 TH215 TH215 TH350B TH350B Photo 8 TH350B TH350B TH350B TH350B Photo 9 TH350B TH350B TH350B TH350B TH350B TH350B TH350B TH350B TH350B TH350B Photo 12 TH350B TL642 TL642 TL642 TL642 TH460B TH460B TH460B Photo 10 TH460B TH460B TH460B TH460B TH460B TH460B TH460B TH460B TL943 TL943 Photo 13 TH560B TH560B TH560B TH560B TH560B TH580B TH580B TH580B TH580B TH580B TH580B TH580B TH580B TH580B TL1055 ID # RL313 RL318 RL320 RL317 RL367 RL203 RL207 RL212 RL234 RL239 RL241 RL243 RL244 RL245 RL247 RL268 RL393 RL421 RL423 RL288 RL391 RL374 RL449 RL450 RL451 RL452 RL564 RL251 RL254 RL256 RL257 RL258 RL259 RL272 RL299 RL300 RL399 RL462 RL463 RL307 RL409 RL412 RL306 RL338 RL224 RL225 RL228 RL230 RL231 RL269 RL311 RL342 RL435 RL455 Year 2005 2005 2005 2005 2006 2004 2004 2004 2005 2005 2005 2005 2005 2005 2005 2005 2006 2006 2006 2005 2006 2006 2006 2006 2006 2006 2004 2005 2005 2005 2005 2005 2005 2005 2005 2005 2006 2007 2007 2005 2006 2006 2005 2006 2005 2005 2005 2005 2005 2005 2005 2006 2006 2006 Hrs. 1428 1343 1177 1346 821 2103 2262 2182 1823 3295 1481 1565 2794 1500 1875 1859 1466 2001 1495 1595 3276 2097 1140 1159 1499 668 3100 2677 1944 2331 2690 2009 1864 1974 2369 1903 1759 1108 1140 2833 1825 2987 4133 3925 3175 3200 2680 2227 2296 3136 2990 1648 1242 1131 www.thompsontractor.com Price $28,000.00 $28,000.00 $28,000.00 $31,000.00 $35,000.00 $30,500.00 $30,500.00 $30,500.00 $38,000.00 $36,000.00 $38,000.00 $38,000.00 $36,000.00 $38,000.00 $38,000.00 $38,000.00 $49,000.00 $48,000.00 $49,000.00 $47,000.00 $44,000.00 $47,000.00 $48,000.00 $48,000.00 $48,000.00 $49,000.00 $58,000.00 $48,000.00 $49,000.00 $49,000.00 $48,000.00 $49,000.00 $49,000.00 $49,000.00 $49,000.00 $49,000.00 $65,000.00 $72,000.00 $72,000.00 $65,000.00 $69,000.00 $68,000.00 $68,000.00 $72,000.00 $68,000.00 $68,000.00 $68,000.00 $69,000.00 $69,000.00 $68,000.00 $68,000.00 $73,000.00 $75,000.00 $72,000.00 6 SPRING 2009 Thompson Tractor Co. Thompson Truck Source ... We’ve got you Covered We are pleased to announce that Thompson Tractor recently joined the HD America Parts Network. HD America is a heavy-duty truck parts marketing group headquartered in St. Louis, MO. This alignment enables Thompson to offer a complete line of total chassis parts for all makes of on-highway trucks and trailers. Thompson now has direct access to truck and trailer parts such as suspensions, brakes, lighting, wheel bearings, shocks and driveline components, to name a few. Thompson Tractor has traditionally only focused on the selling and servicing of Caterpillar® engines. Now with the HD America partnership, Thompson is expanding our offerings to include parts and service for our customers’ entire truck and trailer needs. Thompson Truck Source is proud to offer and support these fine brands: ArvinMeritor (drivetrain systems), Bendix (air brake components), Spicer (chassis), Delco Remy (alternators and starters), Gates Rubber Company (belts, hoses, and hose fittings), Grote Industries (lights, mirrors, and flashers), Timken (bearings), Phillips Industries (electrical and air components), Donaldson (exhaust and filtration products), Kit Masters (fan clutch repair kits), Roadmaster (stainless steel and chrome accessories), Pacific Cargo (cargo control equipment), Webb Wheel (wheels, hubs, brake drums, and rotors), and many more. HDA Parts Network is a heavyduty truck parts marketing group. Their members are the best heavyduty aftermarket distributors with over 500+ warehouses throughout the United States and Canada. Thompson Truck Source has 12 full-service locations with over 70 dedicated truck service bays. 1-877-642-6002 www.thompsontrucksource.com Lauderdale Madison Limestone Jackson Colbert Lauderdale Madison Lawrence Limestone Franklin De Kalb Jackson Morgan Marshall Colbert LawrenceCullman Marion FranklinWinston DeCherokee Kalb Morgan Marshall Etowah Blount Marion Winston Cullman Cherokee Fayette Walker Calhoun St Clair Etowah Lamar Blount Cleburne Jeffereson Fayette Walker Calhoun St Talladega Clair Lamar Randolph Shelby Pickens Tuscaloosa Jeffereson Clay Cleburne Talladega Randolph Chambers Shelby Coosa Pickens Bibb Greene Tuscaloosa Clay Tallapoosa Hale Chilton Perry Chambers Coosa Bibb Greene Sumter Tallapoosa Lee Hale Chilton Elmore Autagua Perry Macon Dallas Russell Marengo Lee Sumter Montgomery Elmore Choctaw Autagua Bullock Lowndes Macon WilcoxDallas Russell Marengo Barbour Montgomery Clarke Choctaw Pike Bullock Butler Monroe Lowndes Crenshaw Wilcox Barbour Clarke Pike Dale Henry Butler Washington Monroe Conecuh Coffee Crenshaw Covington Henry Washington Dale Escambia Geneva Conecuh Coffee Houston Mobile Covington Holmes Escambia Escambia Geneva Houston Jackson Mobile Santa Rosa Holmes Walton Washington BaldwinEscambia Okaloosa Jackson Calhoun Bay Santa Rosa Walton Washington Baldwin Okaloosa Calhoun Bay Gulf ALABAMA ALABAMA Gregg Shelton Jack Musso GreggVeal Shelton Derek Jack Musso Russell Lefever Derek Veal Chris Rayburn Russell Lefever Chris Rayburn FLORIDA FLORIDA Gulf Caterpillar Teams with Richard Childress Racing ® Prior to the 2009 NASCAR® season, Caterpillar® Inc. and Richard Childress Racing® (RCR®) agreed to a multi-year partnership for the No. 31 Chevrolet® Impala® SS to be driven by veteran driver Jeff Burton. Burton, a 21-time winner in NASCAR Sprint® Cup™ Series competition, is currently 13th in the 2009 point standings, only seven points out of the 12th and final spot in the “Chase for the NASCAR Sprint Cup”. With one top-five and two top-10 finishes in the season’s first six races. The No. 31 team has made the “Chase for the Championship” the past three seasons, finishing seventh in 2006, eighth in 2007 and sixth in 2008. “To represent a well-known global brand like Caterpillar is an honor,” said Richard Childress, president and CEO and RCR. “Cat products have played a big part over the decades in construction projects at RCR, Childress Vineyards and Yadkin River Angus. Jeff and I look forward to meeting the Cat dealers and customers who loyally follow NASCAR racing.” The 2009 season marks Caterpillar’s 17th year of sponsorship in NASCAR. It will also be Richard Childress’ 40th anniversary in the sport. Jeff will also be the second “Burton” to drive the Caterpillar car. His brother, Ward, drove the #22 Caterpillar car for Bill Davis Racing from 1999 – 2003. “Success in the highly competitive environment of the NASCAR Sprint Cup Series requires substantially greater levels of technology and investment than even a few years ago,” said Jim Parker, vice president of Caterpillar’s North American Commercial Division. “Joining Richard Childress and his team matches two organizations that share common values, as well as high levels of success. I’m confident this new partnership will excite Caterpillar’s customers, dealers and employees.” RCR has earned 12 NASCAR championships, including six in the Cup Series with the legendary Dale Earnhardt, five in the Nationwide® Series™ and one in the Truck Series. Remaining 2009 NASCAR ® Sprint ® Cup™ Schedule (all times ET) May 16 All-Star Race 8:30 p.m. May 24 Charlotte 5:00 p.m. May 31 Dover 1:30 p.m June 7 Pocono 12:30 p.m. June 14 Michigan 12:30 p.m. June 21 Sonoma 3:30 p.m. June 28 Loudon 12:30 p.m. July 4 Daytona 6:30 p.m. July 11 Chicago 6:30 p.m. July 26 Indianapolis 1:00 p.m. August 2 Pocono 1:00 p.m. August 9 Watkins Glen 1:00 p.m. August 16 Michigan 1:00 p.m. August 22 Bristol 6:30 p.m. September 6 Atlanta 7:00 p.m. September 12 Richmond 7:00 p.m. September 20 Loudon 1:00 p.m. September 27 Dover 1:00 p.m. October 4 Kansas 1:00 p.m. October 11 Fontana 2:30 p.m. October 17 Charlotte 7:00 p.m. October 25 Martinsville 1:00 p.m. November 1 Talladega 12 p.m. November 8 Texas 2:30 p.m. November 15 Phoenix 2:30 p.m. November 22 Homestead 2:30 p.m. (Sunday night race on Labor Day weekend) The stylized No. 31 and the RCR checkered flag logo are registered trademarks of RCR Enterprises, LLC. CAT, CATERPILLAR, CAT RACING, their respective logos, “Caterpillar Yellow,” the “Power Edge” trade dress, other marks and corporate identity used herein are trademarks of Caterpillar and may not be used without permission. JEFF BURTON and Jeff Burton’s autograph are trademarks of Jeff Burton Autosports, Inc. All trademarks, personal likenesses and the likeness of the No. 31 race car are used under license from their owners. © 2009 Caterpillar Inc. Thompson Tractor is your source for power generation and temperature control Generators Air-Cooled Chillers Transformers and Substations Water-Cooled Chillers Utility Grade Transfer Switches Air Conditioning Units Tap Boxes Air Handlers Uninterruptible Power Supply Modules Cooling Towers Load Banks Coolant Pumps Distribution Switchboards, Panels and Breakers Heaters Fuel Tanks Desiccant Dehumidifiers Stop in or contact your sales representative when you are in need of any of the above. www.thompsontractor.com Power Systems Thompson Tractor Co. SPRING 2009 7 When Choosing The Right Forklift To Rent, It Pays To Do Your Research When it comes to choosing the right lift truck, you need to look at your entire operation and material-handling needs. There are 10 basic issues to consider when choosing the right lift truck. 1. The maximum weight to be lifted. Add 600 to 800 pounds to the weight of the load. This will offset unusual lifting conditions, such as odd-shaped or unevenly balanced loads. 2. Attachments used and their weight. A good weight “cushion” to add is 2,000 lbs. of capacity for most attachments such as roll clamps or load stabilizers. 3. The maximum lift height. Add 1 ft. to the height of your load to help clear materials from racks. 4. Physical constraints. Determine aisle widths in which the lift truck must maneuver, type of rack and typical distances traveled. 5. Operating conditions. You need to know floor or ground conditions, and if there are inclines or ramps. You’ll need more power as grade increases. 6. Air quality issues. Do lift trucks work around food items, for instance? If so, your industry probably requires batterypowered (electric) equipment instead of internal-combustion engines. 7. Operator preferences. From the operator’s standpoint, the best lift truck is well made, physically (ergonomically) comfortable and an effective, reliable performer. 8. Longevity. Which lift trucks in your current fleet have given you the most uptime and cost the least per hour to run? 9. Ease of maintenance. Does a certain brand of lift truck break down more often? Are components easily accessible for maintenance? 10. Dealer reputation. Will your lift truck supplier be there for you after the sale? Will the dealer understand your business well enough to help you match the lift truck to the application, let operators test the unit at your facility, resolve problems quickly and provide service, training, parts and advice? (Hint, we do this – and more.) If all this research seems a bit time consuming, call Thompson Lift Truck. We’ll be glad to perform a thorough material-handling application survey and give you a report of what we found. Then you can more accurately decide which is the best lift truck for today and tomorrow’s needs. Lower Maintenance Costs Take control of lift truck costs and they’ll go down. There’s a lot more to lifetime lift truck costs than the initial price of the truck. Two more factors greatly impact what you pay per hour of lift truck use. 1. Operator costs – One of the largest costs related to a lift truck fleet comes from paying the operators’ wages and benefits. Of course you have to add in payroll taxes, paid time off, expenses related to hiring and training operators, and time spent keeping records. All this makes a big impact on your material-handling budget. 2.Operating costs – A big factor in operating costs relates to Planned Maintenance (PM) and repairs. Typically, maintenance costs exceed the purchase price by more than 50 percent over a lift truck’s life. So if your company’s maintenance practices are inefficient, you can expect to spend more than double the initial price in parts and labor. One often-overlooked way to reduce operating expenditures is through fleet standardization. If your fleet consists of many different makes and models, you could cut your costs by 50 percent or more by going with all one brand. To provide maximum lift truck productivity at a minimum cost, follow the tips in the panel for good fleet management. If you don’t have enough hours in the day to improve your fleet management and focus on lowering costs, we’re here to help. Don’t hesitate to ask Thompson Lift Truck about maintenance programs, operator training or a free facility audit. 43,299 parts for HYSER 34,745 parts for CLARK YOUR SINGLE SOURCE FOR 21,295 parts for RAYMOND 17,510 parts for KOMATSU 26,050 parts for TCM FORKLIFT PARTS & SERVICE Did you know that Thompson Tractor, your authorized Promatch® parts dealer, can service your entire forklift fleet? We offer a comprehensive product line of replacement parts through the Promatch parts program. Thompson Tractor is committed to being your single source for parts and service regardless of your forklift make or model. 60,170 parts for TOYOTA Keep Records For Each Lift Truck With them, you’ll be able to track repair trends and/or operator damage or abuse. Records also help you determine each unit’s ownership and maintenance costs, which you’ll need to determine when it’s time to replace the lift truck (and which brand gives the lowest cost per hour, if you run a mixed-truck fleet) Match Lift Trucks To The Job 36,882 parts for YALE 13,700 parts for NISSAN Your operation may have changed in the past year or two. Ask Thompson Lift Truck to perform a thorough audit to see the tasks lift trucks do, loads lifted, travel speeds and more. We’ll let you know if your fleet matches the work at hand, or if you might have more lift trucks than you need. 39,573 parts for CROWN Do PM’s Regularly By following the manufacturer’s recommended maintenance schedule, you’ll reduce downtime, major repairs and overall operating costs. Train Your Operators Damage to the truck and/or products caused by poor operator practices are costly. Thompson Lift Truck offers the Cat Lift Trucks Operator Safety Training program. This is an excellent way to help operators be the best they can be. Practice Good Housekeeping Dirt and debris can damage lift truck systems, as can operating surfaces in poor condition. Used Lift Trucks 1 2004 CATERPILLAR DP90 Catalog #: CU912703, Stock #: UL06848, S/N: T32B60058, SMU/Hrs: 9,174, Rating: EXCELLENT, Description: MAST 179 SIM/150.5 OAL/2.7 FFH, TILT CYLINDERS 15F/10B, CARR S/S SHFT 87” WD-SIM MST, SGL FNCT INT HOSE-SIM MFH 179, FORKS 3.0X7.1X96” SHAFT PALLET, Price: $73,000 Lift Truck 2 2002 MITSUBISHI FORKLIFTS FGC20K Catalog #: CU812922, Stock #: UL068333, S/N: AF82D01051, SMU/Hrs: 7,859, Rating: As-Is, Description: MST 188” TRI, SS 36”, SFIH FKS 42” PALLET, NO MARK DR TIRES SMOOTH, NO MARK ST TIRES SMOOTH, BUA, STROBE, REARVIEW MIRROR, LP TANK 43LB, Price: $9,500 Contact: Nathan Dayhuff at 1-404-362-1404 3 2004 CATERPILLAR C5000LP Catalog #: CU823705, Stock #: LW064018, S/N: AT9000030, SMU/Hrs: 2,704, Rating: EXCELLENT, Description: MST188TRI, SS, SFIH, LUG NO MRK DR TIRES, SM NO MRK ST TIRES, STROBE, DRAW BAR PIN, Price: $17,500 4 2003 CROWN 20MT Catalog #: CU971384, Stock #: UL068511, S/N: 1A267998, Rating: EXCELLENT, Description: ENGINE TYPE – ELECTRIC, 42X25, CASTER WHEELS, DISCHARGE METER, WET BATTERY Price: $8,000 6 2005 CATERPILLAR P5000LP 5 2005 KALMAR DCE16012 Catalog #: CU938343, Stock #: LW075039 S/N: T431050013, SMU/Hrs: 4,476 Rating: EXCELLENT, Description: 36,000 LIFTING CAPACITY @ 48” LC, 197”LIFT HGHT, 96” FRK LNGTH, AC, 24/12V CONVERTER, HORN, ADD. SWITCH 4 FWD/ BCK, Price: $165,000 Catalog #: CU941210, Stock #: LW075083 S/N: AT3504536, SMU/Hrs: 4204, Rating: EXCELLENT, Description: ENGINE TYPE - LIQUID PROPANE, FRKLFT TRUCK LP PNEU 5000LB, MST 188 TRI/84.5 OAL/36 FFH, 4 SECTION CONTROL VALVE , DUAL FNCT INT HOSE - TRI, Price: $18,500 www.thompsontractor.com 8 SPRING 2009 Thompson Tractor Co. USED EQUIPMENT Hydraulic ExcavatorS Track-Type TractorS Wheel LoaderS Asphalt Equipment OFF-HIGHWAY TruckS USED EQUIPMENT listings MODEL OFF-HIGHWAY TRUCKS 2005 CATERPILLAR 725 2006 CATERPILLAR 735 2006 CATERPILLAR 735 2005 CATERPILLAR 735 2005 CATERPILLAR 735 2005 CATERPILLAR 735 2004 CATERPILLAR 735 2004 CATERPILLAR 735 2007 CATERPILLAR 740 2006 CATERPILLAR 771D 1999 CATERPILLAR 771D LOADER BACKHOES 2005 CATERPILLAR 420D 2005 CATERPILLAR 420D 2004 CATERPILLAR 420D COMPACTION EQUIPMENT 2006 CATERPILLAR 815F 2006 CATERPILLAR CP-433E 2006 CATERPILLAR CP-433E 2006 CATERPILLAR CP-563E 2005 CATERPILLAR CS-563E HOURS PRICE 5651 hours 4607 hours 2980 hours 3532 hours 4363 hours 5066 hours 6786 hours 7125 hours 2417 hours 3800 hours 14615 hours $152,500 $199,500 $199,500 $172,500 $172,500 $172,500 $142,500 $142,500 $350,000 $375,000 $205,000 1608 hours 2053 hours 2102 hours $42,500 $42,500 $39,500 1260 hours 575 hours 492 hours 1727 hours 1228 hours $250,000 $92,500 $92,500 99,500 $94,500 MODEL EXCAVATORS 2005 CATERPILLAR 318CL 2005 CATERPILLAR 320CL 2006 CATERPILLAR 325CL 2006 CATERPILLAR 325CL 2006 CATERPILLAR 325CL 2006 CATERPILLAR 325CL 2003 CATERPILLAR 325CL 2006 CATERPILLAR 325DL 2005 CATERPILLAR 330CL 2004 CATERPILLAR 330CL 2004 CATERPILLAR 385BL MOTOR GRADERS 2005 CATERPILLAR 12H 2004 CATERPILLAR 12H 1978 CATERPILLAR 140G 2004 CATERPILLAR 140H 2002 CATERPILLAR 140H SCRAPERS 1998 CATERPILLAR 621F 1997 CATERPILLAR 621F HOURS PRICE 2431 hours 2808 hours 2695 hours 2176 hours 2695 hours 2766 hours 7694 hours 2023 hours 4444 hours 4397 hours 10383 hours $75,000 $79,500 $130,000 $130,000 $120,000 $120,000 $107,500 $149,500 $125,000 $120,000 $275,000 3204 hours 5161 hours 7970 hours 2359 hours 4136 hours $129,500 $125,000 $59,500 $169,500 $129,500 4846 hours 5986 hours Call Call MODEL DOZERS 2001 CATERPILLAR D3C LGP III 2006 CATERPILLAR D3G LGP 2006 CATERPILLAR D3G LGP 2005 CATERPILLAR D3G LGP 2005 CATERPILLAR D3G XL 2004 CATERPILLAR D3G XL 2007 CATERPILLAR D5G LGP 2006 CATERPILLAR D5G LGP 2002 CATERPILLAR D5G LGP 1999 CATERPILLAR D5M XL 2006 CATERPILLAR D5N XL 2006 CATERPILLAR D5N XL 2007 CATERPILLAR D6N LGP 2006 CATERPILLAR D6N XL 2006 CATERPILLAR D6N XL 2005 CATERPILLAR D6N XL 2006 CATERPILLAR D6R LGP III 2005 CATERPILLAR D6R XL II 2006 CATERPILLAR D6R XL III 2006 CATERPILLAR D6R XL III 1994 CATERPILLAR D8N 2006 DEERE 450J Looking for parts? HOURS PRICE 2656 hours 713 hours 1287 hours 2213 hours 717 hours 413 hours 1175 hours 1797 hours 3322 hours 2818 hours 2384 hours 881 hours 3237 hours 1449 hours 1735 hours 1658 hours 2779 hours 1620 hours 1985 hours 4043 hours 7176 hours 1472 hours $29,500 $59,500 $55,000 $49,500 $53,000 $47,500 $105,000 $65,000 $45,000 $45,000 $105,000 $105,000 $165,000 $149,500 $142,500 $135,000 $149,500 $169,500 $169,500 $159,500 Call $49,500 MODEL FORESTRY EQUIPMENT 2005 CATERPILLAR 525B 2005 CATERPILLAR 525B 2005 CATERPILLAR 525B 2005 CATERPILLAR 525B 2004 CATERPILLAR 525B 2004 CATERPILLAR 525B 2004 CATERPILLAR 525B 2007 CATERPILLAR 553 2004 DEERE 435 2005 TIMBER KING TK560 2004 TIMBER KING TK560 2004 TIMBER KING TK560 2004 TIMBER KING TK570 WHEEL LOADERS 2006 CATERPILLAR 928GZ 2006 CATERPILLAR 930G 2004 CATERPILLAR 962G II 2003 CATERPILLAR 988G ASPHALT EQUIPMENT 2006 CATERPILLAR AP-800D HOURS PRICE 5203 hours 5611 hours 5625 hours 6822 hours 6661 hours 6802 hours 7692 hours 2438 hours 7112 hours 5502 hours 6749 hours 7277 hours 4289 hours $75,000 $75,000 $72,500 $67,500 $62,500 $57,500 $45,000 $107,500 $45,000 $79,500 $65,000 $47,500 $69,500 1011 hours 1679 hours 7080 hours 9278 hours $105,000 $107,500 $125,000 $395,000 1632 hours $199,500 Over 30,000 line items in stock. Want to save $$$? Recent arrivals for parts D3C, D4H, IT24F, IT28F, 315, 320L, 330L, 416B, 525B, 416C, 773B, 773D, 777B, 836F, 928F, 928G, 930G, 950H, 966E, 980G Thompson Used Parts offers a wide range of used, rebuilt and new surplus Caterpillar® parts to suit most any make or model. Over 30,000 line items on hand, and if we don’t stock it, we can find it for you through our extensive Dealer Networks! Contact us at 1-800547-0760, or ask your Product Support Sales Representative today! We currently have over 60 machines in inventory for dismantling! We own what we advertise! GET THE USED PARTS ADVANTAGE Robby Jasper 205-849-4207 Tommy Riggs 205-849-4524 Jason McLendon 205-849-4536 Todd Singletary 205-849-3656 Danny McCroskey Non-Cat Specialist 205-247-2827 Thompson Used Parts 2274 Pinson Highway • Birmingham AL 35217 1-800-547-0760 • www.thompsontractor.com/usedparts Thompson Tractor Our Locations Heavy Equipment, Lift Trucks and Power Systems Albany 5730 Newton Road Albany, GA 31701-7459 (229) 435-2247 Atlanta 5559 Old Dixie Road Forest Park, GA 30297 (404) 361-8370 (800)799-5438 Macon 4380 Mead Road Macon, GA 31206 (478) 785-1119 (800) 596-5438 Augusta 4031 Mike Padgett Highway Augusta, GA 30906 (706) 792-9500 (800) 449-5438 Savannah 6006 Commerce Blvd. Garden City, GA 31408 (912) 964-7156 Attalla/Gadsden 121 Gilberts Ferry Rd. S.E. Attalla, AL 35954 (866) 811-7609 Decatur 6969 US Highway 31 Tanner, AL 35671 (800) 435-0922 Birmingham 2401 Pinson Highway Birmingham, AL 35217 (800) 547-0760 Dothan 118 Vulcan Way Dothan, AL 36303 (334) 671-1040 Crestview 2106 3rd Ave. Crestview, FL 32539 (850) 682-6510 Huntsville 3600 Governors Drive Huntsville, AL 35805 (256) 532-1776 FL Store Locations Rental Locations Mobile 30950 State Hwy. 181 Spanish Fort, AL 36527 (800) 243-0665 Montgomery 10120 Hwy. 80 E. Montgomery, AL 36117 (800) 521-9511 Tuscaloosa 3550 Joe Mallisham Pkwy. Tuscaloosa, AL 35401 (205) 247-2800 New le l Huntstviion loca en. now op ALABAMA Marianna 3742 U.S. Hwy. 90 W. Marianna, FL 32446 (850) 526-2241 (850) 526-4607 Fax Opelika/Auburn 302 Fox Run Ave. Opelika, AL 36801 (334) 749-3359 Pensacola 2650 West Nine Mile Rd. Pensacola, FL 32534 (850) 471-6700 Oxford/Anniston 2300 Hwy. 21 S. Oxford, AL 36203 (800) 547-8897 Shelby County 2070 Corporate Woods Dr. Alabaster, AL 35007 (205) 664-4833 Panama City 4109 Cato Rd. Panama City, FL 32404 (850) 785-4007 Thomasville 2501 Joe Davis Industrial Blvd. Thomasville, AL 36784 (334) 636-0420 Tuscumbia 1410 S. Hook St. Tuscumbia, AL 35674 (256) 381-2771 Cat Rental Stores 1-800-RENT-CAT connects customers to their nearest Cat Rental Store. GEORGIA Birmingham 3317 Messer Airport Hwy. Birmingham, AL 35222 (205) 326-0334 Dothan 118 Vulcan Way Dothan, AL 36303 (334) 673-3300 Madison 107 Jetplex Lane Madison, AL 35758 (256) 772-0034 Montgomery 2217 S. Forbes Rd. Montgomery, AL 36110 (334) 262-1101 Panama City 4109 Cato Rd. Panama City, FL 32404 (850) 873-6540 Calvert 216 Hwy 43 N Calvert, AL 36513 (251) 829-5777 Huntsville 3600 Governors Drive Huntsville, AL 35805 (256) 532-3001 Mobile 1950 East I-65 Service Rd. N. Mobile, AL 36617 (251) 452-1180 Oxford/Anniston 2300 Hwy. 21 S. Oxford, AL 36203 (256) 835-5737 Pensacola 2650 West Nine Mile Rd. Pensacola, FL 32534 (850) 471-6710 Thomasville 2501 Joe Davis Industrial Blvd. Thomasville, AL 36784 (334) 636-2903 Tuscaloosa 3550 Joe Mallisham Pky. Tuscaloosa, AL 35401 (205) 247-3402 Shelby County 2070 Corporate Woods Dr. Alabaster, AL 35007 (205) 664-9489 Lift Truck Only Locations used equipment www.thompsontractor.com

© Copyright 2026