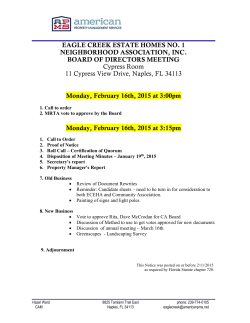

- Cypress Employment Services