sampling tools product design process on pre heater process in

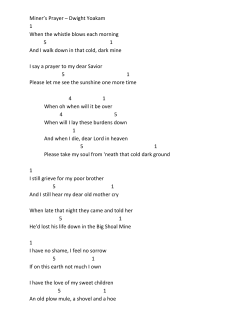

International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 SAMPLING TOOLS PRODUCT DESIGN PROCESS ON PRE HEATER PROCESS IN CEMENT PRODUCTION Edi Sutoyo, Yohanes Dewanto, Agri Suwandi Mechanical Engineering, Pancasila University Jl. Srengseng Sawah, Jagakarsa, Jakarta Selatan 12640, Indonesia. e-mail: [email protected], [email protected], [email protected] Abstract Product sampling tool in Indonesian cement plant pre heater sometimes get jammed when sampling is done, so sometimes it is not picked up, it affects the quality control process. One solution to this, is a tool to design an appropriate sampling pre heater products. In this paper, discussed the design of product sampling tool pre heater for a maximum capacity of 40 kg, using the Pahl and Beitz design method. By using this method generated design tool with length 1900 mm, width 170 mm, height 600 mm, weight 37 kg, 500 g and sampling capacity for semi-automatic operation is done using the PLC. . Keywords: sampling, pre heater, design, concept, pneumatic INTRODUCTION The Quality product and processing efficiency are considered important in the process of making the product, therefore through the optimization of the performance improvement and quality control tool of choice to realize the product quality and efficiency of better products. Obtained quality products with quality control at every point of production by taking samples with a particular method, the next sample will be analyzed for their quality and expected results represent the quality of a number of products that have been produced. Performed quality control from raw material preparation to ready the product delivered to the consumer. The availability of a representative sample can’t be separated from the role of the sampling methods used, one of the methods used is the use of sampling or sampler. With the sampler sampling process becomes easier and the results more convincing. The One of the Indonesian cement producer PT. XXX is the cement manufacturers implement strict quality control, an implementation of quality control is with the sampler at each production process. But one of the sampler PT.XXX preheater products which many officers had complaints of mechanical sampling. Movement of the tool is less than perfect, often stalled when sampling position was done manually and complicate the process of sampling that sometimes samples are not taken. This course will disrupt the process control of the quality of the product itself preheater. PT.XXX circumstances of the sampler used preheater background to design a better tool, specifically this tool retrieve some data from one of the production units PT.XXX but the use of these tools is expected to be applied in all other producers. MATERIALS AND METHOD METHOD The Product design methods used in this study is common method Beitz. In order to flow Pahl and Beitz design process consists of four stages or phases [6]: Clarification of the task, concept design, product shape design, detail design. Each phase of the design process ends at the results phase, as the first phase produces a list of requirements and design specifications. The results of each phase will ME-07 | 1 International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 then be input to the next phase and a feedback to the preceding phase. It should be noted also that the results of the phase itself can be changed at any time by the feedback received from the subsequent phases. (see Figure III-1. Flowchart Pahl and Beitz design products). MATERIALS In this section elaborated specifications, to obtain specifications then made a table of user needs and other expectations for the tool which is a requirement that must be met by the tool, then after that the result realized a specification tool. Table 1. User Needs to Sampling Tools Product Preheater needs 1. Capable of taking a sample of at least 500 g with ± 850°C temperature in a preheater Duct. 2. Sample collection floured material falling After gate 40 kg 3. There should be shelters sampling results 4. Automated tools and manual control 5. Easily obtainable materials 6. Fast sampling movement 7. Easy in operation tools 8. Not be danger when the tool being operation 9. Samples are not contaminated with previous samples 10. Long life tools Table 2. Hope to User Product Sampling Tools Preheater Expectation 1. Appliance is not heavy 2. Dimension is not too large 3. Does not require special care 4. If there is an damage, the spare parts are ready available 5. Easy to dismantle and install 6. Rapid installation and dismantling 7. The working principle tools is simple 8. Not much outside air coming into the system preheater through this tools From the two tables above is the conclusion of discussions with employees PT.XXX, then from the tables above, then the equipment specifications formulated as follows: Table 3. Preliminary List of Equipment Specifications Product Sampling Based Needs and Expectations Preheater List of specifications Geometry length of 2000 mm width of 500 mm height 500 mm Weight weight less than 50 kg Kinematics sampling speed of 15 seconds Take a sample of the powder and the vertical duct poured on catch Force Take a samples of material flow 165 kg / sec, after gate 40 kg Material Use the finished product in the market Standard material Temperature resistant material ± 850°C at the time of sampling Interpretation expectations no.2 expectations no.2 expectations no.2 expectations no.1 needs no.6 needs no.1 needs no.2 expectations no.4 needs no.5 needs no.1 ME-07 | 2 International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 List of specifications Operations Automatic and manual Sampling capacity and catch 500 g 1 time sampling 600 g to catch Interpretation Needs no. 4 and 7 Needs no.1 and 3 RESULTS AND DISCUSSION In this section outlined the principles for the solution of each sub-function to generate variants that could be the final solution. Principles of energy conversion solutions by driving, selected three principles solutions electric motor, pneumatic and hydraulic equipment. The principle of sampling solutions, selected 3 solution is, long tipped shovel cylinder, tip boxes next to the shovel, the last cylinder and threaded cylinder. Principle solution to the sample transport container, the cylinder and screw then the screw is driven by an electric motor with a particular system allows the material that has been accommodated in the cylinder and transported to the shelter. By using a pneumatic cylinder connected to the sampler that brings the material that has been in the sampling. Principles of cleaning solution sample attached at the time of pouring the sample. The solution is given electric vibrator that produces vibrations from the electric motor movement ends asentris given load, and produces vibrations that can deteriorate the material attached to the sampler. Principles of solution casting samples, samples that have been taken and have been transported to the shelter then poured the solution principles and threaded cylinder, with screw transport can sample directly on point to the shelter. Semirotari pneumatic, with this tool allows the casting can be done because a circular motion. Figure 1. Model of Pahl and Beitz design process [6] ME-07 | 3 International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 Reservoir solution principle, there are two solutions, namely cylinders and boxes. The second form is a simple form that can be used to hold the sample. Principle solution used PLC controller (Programmable Logic Controller) simple as wiring, relays and timers to the next solution because not everyone understand PLC programming languages. Of searches done with variants that produced the following forms: First there are 8 variants proposed, after the calculation of the variants, then there is a good 2 variants, variant number 2 (V2), consists of the following parts: Energy conversion using pneumatic equipment, samplers using long-tipped shovel cylinders, transport the sample to the container using a pneumatic cylinder, which is attached to the sample cleaning using pneumatic vibrator, pouring samples using a pneumatic semirotary, cylindrical sample container, using PLC control. Figure 2. Concept variant number 2 and number 5 variants The second variant is number 5 (V5), consists of the following parts: Energy conversion using pneumatic equipment, samplers using long-tipped shovel box, transport the sample to the container using a pneumatic cylinder, which is attached to the sample cleaning using pneumatic vibrator, pouring samples using a pneumatic semirotari, a sample container box, use Relay control and trimmer. Calculation and Component Selection a. End of the shovel End of the shovel should be able to take a sample weighing 500 g sample, so that the size of a shovel that is designed to accommodate 500 g sample. If the density of the sample is 670 kg/m3, the volume of space expected to be obtained: v = 746,268.65 mm3 By utilizing stainless steel pipe to form a standard size shovel the end of a long pipe is as follows: If the specified thickness of the shovel that is designed around 5 mm then used in the design is a 3 inch pipe, Schedule 40 to make the end of the shovel. Description: size in mm, angles in degrees (°) and section cut areas are colored gray. total area of a circle = A = = 22/7 . 392 = 4780,29 mm2 broad segment 90° = = 392 = 1.195,07 mm2 Description: size in mm, angles in degrees (°) and section cut areas are colored gray. total area of a circle = A = = 22/7 . 392 = 4780,29 mm2 broad segment 90° = = 392 = 1.195,07 mm2 ME-07 | 4 International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 2. torque minimum 1 what material.and minimum dimension? Temperature 8500C 3.minimum force ? Figure 3 piece circular area area of the triangle ABC = Figure 4 The concept of calculation and selection of components based on the load = = 760.52 mm2 broad segment = broad segment 90°- area of the triangle ABC = 434,55 mm2 The area of the blue = area of a circle – broad segment = 4345,45 mm2 Length of the inner pipe = sample volume / area wide blue = 171, 73 mm ≈ 172 mm Total pipe length after both sides covered with material thickness of 5 mm is the total length of pipe: 182 mm b. Catch samples Created catch weight is 600g with a choice of tip material with a shovel so long pipe sections, /0,00067 = 895.522,39 mm3 If r = 39 mm, then the length of the inner pipe = volume / area of a circle = 187.34 mm ≈ 188 mm. If the bottom of the pipe cap thickness 5 mm designed the total pipe length is: total pipe length = 193 mm. c. Stem diameter pneumatic spades and component selection Material selection, size and base the selection of pneumatic components depicted in Figure 4: Calculate the minimum diameter of the trunk shovel, calculate the minimum torque to rotate the shovel, after all the expenses that will be driven pneumatic cylinder is known, then the calculated minimum force to be able to move all of the load, then the style and strokes are known then searched the product catalog to suit your style and pace. Here are the calculations and the selection of pneumatic components: 1. Trunk diameter shovel To take a sample from the duct to reach half of the duct diameter (1 m), the length of the rod bearing to near the middle of the duct is: l = ½ diameter duct to duct out (design) = 700 mm With a length of 700 mm and the pedestal is 40 kg load. From the concept of the above then begins loading calculations to determine the diameter of the trunk shovel: m= 40 kg, g = 9,8 m/s2, l = 700 mm = 0,7 m, if the material used in stainless steel with = 580 N/mm2 and safety factors used v = 3 then, stem diameter 24.37 mm minimum shovel ≈ 25 mm. ME-07 | 5 International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 Figure 5. The concept of loading shovel shaft Figure 6. Product sampling tool preheater results plan With a diameter of 25 mm is used then the voltage that occurs is: 178.809 Nmm2 When compared with the elastic strength of the material at 240 Nmm2 or compressive strength of 580 240 Nmm2 the shovel shaft is safe to support the weight of 40 kg. Minimum torque to rotate the screw and rotary pneumatic spring election. Volume = 1,002,007 mm3 shovel, shovel binder = 4050.97 mm3, from previous data, the weight can be calculated by multiplying the density of material, time and type of fastener material spade a spade is stainless steel with a density of 7.9 kg / dm3 (7.9 million kg / mm3). 2 pieces of heavy shovel and shovel power shovel binder are : 8.64 kg Next is to determine the coefficient of friction between steel and brass bearing form, and used the proximity of the steel with brass μ = 0.35. Thus the calculation of moments of friction between the bearing shaft shovel obtained: 0.37 Nm. If the load safety factor of 3 was given to the dynamic load M = 1.11 Nm, semirotary requirements that must be met is the minimum torque 1, 11 Nm and 180° swivel angle, by looking at the XX catalog specifications that can be used is the diameter of the shaft 10 mm with 270° swivel angle can be set angle. 2. Minimum force calculation pneumatic cylinders, pneumatic cylinders and selection. Load transported by a pneumatic cylinder is, shovels, samples, 2 pieces of binder shovel, clutch, bearing shovels, pneumatic connecting plate and semirotary. For heavy shovel, shovel fastener, bearing shovels and analysis relationship in the Pro ENGGINEER. Special material for bearings made of brass with ρ = 8.7 kg / dm3 = 8,700,000 kg/mm3 Same as previous step volume obtained as follows: v = 10639.3 mm3 bearings, bearing m = 0:09 kg, v = 153 028 mm3 connecting plate, connecting plate m = 1.21 kg, the total time = 10, 43 kg. Minimum force to move the shovel from rest is a force to counter the force of the friction load bearing = 35, 78 N, If you use the factor of safety 2 so = 71, 56 N. Terms for selecting pneumatic cylinders is the minimum force is 71.56 N with a step is 700 mm, the cylinder can be used is the ISO 15552 standard cylinder, cylinder diameter 32 mm and length of 700 mm steps. 3. Pneumatic vibrator Selection of pneumatic vibrators based tool that has been used in PT.XXX the frequency generated at a pressure of 6 bar is 39.7 min-1.After all complete component selection and the concept of providing the form is completed the next step to do the design into details on the components that have been conceptualized. In the detail design of the components are made in advance given the size and adjusted conjunction with other components. Giving size done with the help of Pro ENGINEER software and compiled into engineering drawings. Here is a sampling tool design drawing material preheater ME-07 | 6 International Conference on Engineering of Tarumanagara (ICET 2013) Faculty of Engineering, Tarumanagara University, Jakarta-Indonesia, 2-3 October 2013 ISBN: 978-979-99723-9-2 products that have been assembled see Figure 6. CONCLUSIONS 1. Specifications: Length: 1900 mm, width: 170 mm, height: 600 mm, weight of equipment: 37 kg, maximum load sampling: 40 kg, sampling capacity: 500 g, bin capacity: 600 g. 2. Stem diameter shovel: 25 mm, material spade a spade and stem rust-resistant material selected due to acid and high temperature resistant material right is rust resistant stainless steel DIN 1.4439 3. Pneumatic cylinder: ISO 15552, cylinder diameter 32 mm and length of steps is 700 mm.Semirotary: shaft diameter of 10 mm with 270 ° swivel angle can be set to 180° REFERENCES [1] Dahmar Dahlan, Elemen Mesin, Citra Harta Prima, Jakarta, 2012. [2] Darmawan Harsokoesoemo, Pengantar perancangan Teknik, ITB, Bandung, 2004. [3] Daryanto, Teknik Mekatronika, Bandung, PT. Sarana Tutorial Nurani Sejahtera, 2010. [4] Duda,H. Walter, Cement Data-Book 1, Bauverlag, Berlin, 1985. [5] Hewlet, Peter C, LEA’s Chemistry Of Cement and Concrete 4th Edition, Buterworth Heinemen, 1988. [6] Hurst Ken, Prinsip-Prinsip Perancangan Teknik, Erlangga, Jakarta, 2006 [7] L.Mott Robert, Elemen-Elemen Mesin Dalam Perancangan Mekanis, ANDI, Yogyakarta, 2009. [8] Rosnani Ginting, Perancangan Produk, Graha Ilmu, Yogyakarta, 2010 [9] Shigley, Josep Edward dan D. Mitchel, Larry, Perencanaan Teknik Mesin, Erlangga, Jakarta, 1986. [10] Ulrich Fisher, Max Heinzler, Friedrich Naher, Heinz Paetzold, Roland Gomenringer, Roland Kilgus, Stefan Oesterle, Andreas Stepan, Mechanical and Metal Trade Handbook, VERLAG EUROPA LEHRMITTEL, Nourney, Vollmer GmbH & Co. KG, Haan-Gruiten, Jerman, 2006. [11] westsidedelivers.com/item.asp?pid=15929, at 13 Desember 2012 , time 19:21 WIB. [12] www.americancementcompany.com/aboutus.asp, at 27 September 2012, time 21:36 WIB. [13] www.ebay.com.au/itm/SMC-VS4120-Solenoid-valve-NEW-/13027023374, at 27th September 2012, time 22.15 WIB. [14] www.engineeringtoolbox.com/ansi-stainless-steel-pipes-d_247.html, at 13th Oktober 2012, time 17:40 WIB. [15] www.engineershandbook.com/Tables/frictioncoefficients.htm, at 13th Oktober 2012, time 19:39 WIB. [16] www.festo.com/cat/en-gb_ww/xDKI.asp, at 5th January 2013, time 18: 56 ME-07 | 7

© Copyright 2026