2015-DLB1 Catalogue

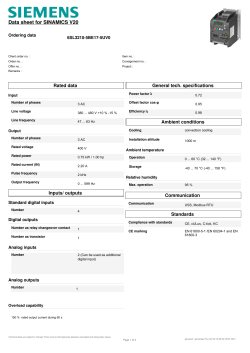

DLB1 Catalogue 1 Name plate Graph 1-1 Nameplate Graph 1-2 product models - 02 - DLB1 Catalogue 2 Product series Rated output power (kW) Rated input current (A) Rated output current (A) DLB1-0D40S2G 0.4 5.9 2.5 DLB1-0D75S2G 0.75 8.3 4 DLB1-01D5S2G 1.5 14.1 7 DLB1-02D2S2G 2.2 24.2 10 DLB1-0D40T2G 0.4 4.1 2.5 DLB1-0D75T2G 0.75 5.3 4 DLB1-01D5T2G 1.5 8.0 7 DLB1-02D2T2G 2.2 11.8 10 DLB1-0004T2G 4.0 18.1 16 DLB1-05D5T2G 5.5 21.0 20 DLB1-07D5T2G 7.5 33.1 30 DLB1-0011T2G 11 43.8 42 DLB1-0015T2G 15 57.4 55 DLB1-0018T2G 18 71.6 70 DLB1-0022T2G 22 81.7 80 DLB1-0030T2G 30 112.1 110 DLB1-0037T2G 37 137.4 130 DLB1-0045T2G 45 165.3 160 DLB1-0055T2G 55 205.8 210 DLB1-0D75T4G 0.75 4.3 2.5 DLB1-01D5T4G 1.5 5.2 3.7 DLB1-02D2T4G 2.2 6.0 5 DLB1-0004T4G 4.0 10.5 8.5 DLB1-05D5T4G 5.5 15.5 13 Inverter model Single Phase input: AC 220V, 50/60Hz Three phase input: AC 220V, 50/60Hz Three phase input: AC 380V, 50/60Hz - 03 - DLB1 Catalogue Inverter model Rated output power (kW) Rated input current (A) Rated output current (A) DLB1-07D5T4G 7.5 20.5 16 DLB1-0011T4G 11 27.6 25 DLB1-0015T4G 15 37.1 32 DLB1-0018T4G 18 41.9 38 DLB1-0022T4G 22 49.3 45 DLB1-0030T4G 30 65.7 60 DLB1-0037T4G 37 80.6 75 DLB1-0045T4G 45 96.4 90 DLB1-0055T4G 55 117.6 110 DLB1-0075T4G 75 166.4 150 DLB1-0093T4G 90 184.3 170 DLB1-0D75T7G 0.75 4.1 2.5 DLB1-01D5T7G 1.5 4.9 3.7 DLB1-02D2T7G 2.2 5.7 5 DLB1-0004T7G 4.0 9.4 8 DLB1-05D5T7G 5.5 12.5 11 DLB1-07D5T7G 7.5 18.3 15 DLB1-0011T7G 11 23.1 22 DLB1-0015T7G 15 29.8 27 DLB1-0018T7G 18 35.7 34 DLB1-0022T7G 22 41.7 40 DLB1-0030T7G 30 57.4 55 DLB1-0037T7G 37 66.5 65 DLB1-0045T7G 45 81.7 80 DLB1-0055T7G 55 101.9 100 DLB1-0075T7G 75 137.4 130 DLB1-0093T7G 93 151.8 147 Three phase input: AC 460V, 50/60Hz - 04 - DLB1 Catalogue 3 Technical standards Specifications Control system Drive performance Maximum frequency Wave-carrier frequency Input frequency resolution control mode Starting torque Performance and function highly integrated Current Vector General Purpose Inverter. Induction motor and Synchronous motor. Vector control: 0~300Hz; V/F control: 0~3200Hz. 0.5kHz~16kHz; Depending on load, can automatically adjust wave-carrier frequency. digital setting: 0.01Hz; analog setting: maximum frequency×0.025%. Open vector control(SVC); Closed loop vector control(FVC); V/F control. G type: 0.5Hz/150%(SVC); 0Hz/180%(FVC). P type: 0.5Hz/100%. Speed range 1: 100(SVC) 1: 1000(FVC) Speed stability accuracy ±0.5%(SVC) ±0.02%(FVC) Torque control accuracy ±5%(FVC) Overload capacity Torque boost G type: 150%rated current60s; 180%rated current3s; P type: 120%rated current60s; 150%rated current3s. Automatic or manual 0.1%~30.0%, Basic functions V/F curve · Straight-line V/F curve · Multi-point V/F curve · N-power V/F curve (1.2-power, 1.4-power, 1.6-power, · 1.8-power, 2-power square) V/F separation Two types: complete separation; half separation. AVR output. Ramp mode · Straight-line ramp · S-curve ramp Four groups of acceleration/deceleration time with the range of 0.0–6500.0s DC braking DC braking frequency: 0.00 Hz to maximum frequency Braking time: 0.0–36.0s Braking action current value: 0.0%–100.0% JOG control JOG frequency range: 0.00–50.00 Hz JOG acceleration/deceleration time: 0.0–6500.0s Easy PLC, multiple speeds Onboard PID Auto voltage regulation (AVR) Up to 16 speeds via the simple PLC function or combination of DI terminal states Process-controlled closed loop control system Keep constant output voltage automatically when grid voltage fluctuates. Overvoltage/ Overcurrent stall control The current and voltage are limited automatically during the running process so as to avoid frequent tripping due to overvoltage/overcurrent. Fast current limit function Torque limit and control Protect inverter from overcurrent malfunctions. It can limit the torque automatically and prevent frequent over current tripping during the running process. Torque control can be implemented in the FVC mode. - 05 - DLB1 Catalogue Power dip ride through Special Functons Timing control Two-motor switchover Fieldbus Background software The load feedback energy compensates the voltage reduction so that the Invertercan continue to run for a short time. Time range: 0.0–6500.0 minutes Two motors can be switched over via two groups of motor parameters. Supports RS485, Profibus-DP, CANlink, CANopen (need extention cards) Change inverter parameter & vitual oscillograph to monitor inverter status. Operations Command source · Operation panel · Control terminals · Serial communication port You can perform switchover between these sources in various ways. Frequency source 11 frequency sources, such as digital setting, analog voltage setting, analog current setting, pulse setting and serial communication port setting. You can perform switchover between these sources in various ways. Auxiliary frequency source 11 auxiliary frequency sources. It can implement fine tuning of auxiliary frequency and frequency synthesis. Input terminal 6 digital input (DI) terminals, DI5 supports up to 100 kHz high-speed pulse input; 3 analog input (AI) terminals, support 0–10 V voltage input or 4–20 mA current input Output terminal 2 digital output (DO) terminal (FM supports 0–10 kHz square wave signal output) 1 relay output terminal 2 analog output (AO) terminal that support 0–20 mA current output or 0–10 V voltage. LED display Display and panel Key lock Protection function Optional parts Displays parameters. It can lock the keys partially or completely and define the function range of some keys so as to prevent mis-function. Motor short-circuit detection at power-on, input/output phase loss protection, overcurrent protection, overvoltage protection, undervoltage protection, overheat protection and overload protection PG card, brake unit, RS485 card, CAN card, Profibus-DP card Environment Location Indoor, free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapour, drip or salt. Altitude Lower than 1000m. Ambient temperature -10° C to +40° C (de-rated if the ambient temperature is between 40° C and 50° C) Humidity Less than 95%RH, without condensing Vibration Less than 5.9m/s2 (0.6g). Storage temperature - 20℃ ~ + 60℃ . - 06 - DLB1 Catalogue 4 Product outline Graph 2-3 400W ~ 3.7KW product outline & dimensions Graph 2-4 5.5 ~ 7.5KW product outline & dimensions - 07 - DLB1 Catalogue Graph 2-5 11 ~ 55KW product outline & dimensions - 08 - DLB1 Catalogue 5 Installation dimensions Input voltage 380V (mm) Outline dimensions (mm) Inverter model (mm) A B H H1 W D 114 177 190 190 127 168 φ5.5 142 232 245 245 155 172 φ5.5 130 384 350 400 202 184 φ6 150 409 375 425 226 184 φ6 160 484 450 500 260 222 φ7 180 570 540 590 270 267 φ10 DLB1-0055-T4G DLB1-0075-T4P 180 590 560 610 280 282 φ10 DLB1-0075-T4G DLB1-0093-T4P DLB1-0093-T4G 240 720 680 740 340 333 φ10 DLB1-0D40-T4G DLB1-0D75-T4P DLB1-0D75-T4G DLB1-01D1-T4P DLB1-01D1-T4G DLB1-01D5-T4P DLB1-01D5-T4G DLB1-02D2-T4P DLB1-02D2-T4G DLB1-03D7-T4P DLB1-03D7-T4G DLB1-05D5-T4P DLB1-05D5-T4G DLB1-07D5-T4P DLB1-07D5-T4G DLB1-0011-T4P DLB1-0011-T4G DLB1-0015-T4P DLB1-0015-T4G DLB1-0018-T4P DLB1-0018-T4G DLB1-0022-T4P DLB1-0022-T4G DLB1-0030-T4P DLB1-0030-T4G DLB1-0037-T4P DLB1-0037-T4G DLB1-0045-T4P DLB1-0045-T4G DLB1-0055-T4P -9- Weight (kg) DLB1 Catalogue Input voltage 660V (mm) Outline dimensions (mm) Inverter model (mm) Weight (kg) A B H H1 W D 180 540 520 560 320 240 φ7 37 320 740 710 760 470 315 φ10 69 DLB1-0018-T7G DLB1-0022-T7P DLB1-0022-T7G DLB1-0030-T7P DLB1-0030-T7G DLB1-0037-T7P DLB1-0037-T7G DLB1-0045-T7P DLB1-0045-T7G DLB1-0055-T7P DLB1-0055-T7G DLB1-0075-T7P DLB1-0075-T7G DLB1-0093-T7P DLB1-0093-T7G - 10 - DLB1 Catalogue 6 Detachable keyboard(operation panel) dimensions Graph 2-6 detachable keyboard outline dimensions Graph 2-7 detachable keyboard aperture dimensions - 11 - DLB1 Catalogue 7 Standard wiring diagrams Graph 2-8 0.4~18.5KW inverter wiring diagram - 12 - DLB1 Catalogue Graph 2-9 22 ~ 93KW inverter wiring diagram - 13 -

© Copyright 2026