Cooling - UCSB College of Engineering

* Some of the images used in these slides are taken

from the internet for instructional purposes only

Building Energy Systems

- HVAC: Cooling -

Bryan Eisenhower

Associate Director

Center for Energy Efficient Design

Researcher and Lecturer

Department of Mechanical Engineering

UCSB

Winter 2015

Systems - of - Systems

Outdoors

Thermal Zone

Fresh Air

Systems - of - Systems

Outdoors

Thermal Zone

Fresh Air

Hot Water

Systems - of - Systems

Outdoors

Thermal Zone

Fresh Air

Hot Water

Chilled water

Systems - of - Systems

Outdoors

Thermal Zone

Fresh Air

Hot Water

Chilled water

Refrigerant

Systems - of - Systems

Outdoors

Thermal Zone

Fresh Air

Hot Water

Chilled water

Refrigerant

Cooling Tower

Systems - of - Systems

Outdoors

Thermal Zone

Fresh Air

Hot Water

Chilled water

Refrigerant

Cooling Tower

Controllers

HVAC

Occupied

area

Past

Air

Distribution

Earth

Next lecture

Secondary

Systems

Now

Primary

Systems

EnergyPlus documentation

HVAC

Cooling:

(Natural Ventilation)

Refrigeration cycles

Absorption cycles

Evaporation

Heating:

(Natural through envelope – solar, internal gains)

Boilers (water / steam)

Furnaces

Electric

Refrigeration

Natural – solar collector

** These subjects cover how to create cooling/heating, distribution comes later

Refrigeration Cycles

Compression and expansion transfers heat:

Heat removed from cycle

1. A compressor draws in gas and

compresses it

Condenser

This places energy into the fluid

(usually electrical energy > thermal

Expansion

Compressor

energy)

2. A condenser takes this very hot fluid and

allows it to cool which then turns it

Evaporator

(condenses) into liquid

Energy

added

Energy leaves the fluid, often to the

Heat added to cycle

outdoor environment

3. An expansion valve expands the liquid so

that it is a low pressure and very cold liquid

Very little energy transfer here

4. An evaporator is used to evaporate the

liquid into a gas so that it can be

compressed again

The evaporator draws in heat (usually

from the indoors)

wikipedia

Refrigeration Cycles

Types of refrigeration / vapor

compression cycles:

Chillers (typically create chilled water

or ice)

Air conditioners (typically create cold

air)

Heat Pumps (typically create cold or

hot air or water)

Chillers stand out as being large

in size and with large connections

Aside from automotive, AC’s and Heat

Pumps look very similar

www.unitedindustries.com.au

parkercoloradoairconditioning.com

retekool.en.made-in-china.com

www.diytrade.com

Compressors

Compressors:

Reciprocating

Most common, much like an auto engine (piston

and cylinder)

Screw

Two meshed screws

Rotary

Rotating gears (small)

Centrifugal

Like a fan

Scroll

Spiral scroll gears

Capacity vs. vibration / noise are

some of the main tradeoffs in

compressor design

Trane

Mostly driven by electric motors, but

can be engine driven, etc.

<1

1

10

100

1000 (Tons)

Screw

Rotary

Scroll

Reciprocating

*Adapted from Mitchell

Centrifugal

chinaxuemei.en.made-in-china.com

1 Ton = 3.52 kW

www.directindustry.com

Expansion Devices

Depending on the conditions (e.g. full load,

partial load, start/stop), the pressure

differential between the high pressure and

low pressure sides needs to be changed

Expansion device

Historically a thermostatic device is used

maintained the desired pressure differential,

now electronic options are available

Thermostatic

Electronic

www.smartclima.com

honda-tech.com

Heat transfer

The heat added and removed from the cycle can

be done in many ways:

Evaporator (cold side)

Chilled water loop (liquid)

Direct expansion (air)

Condenser (hot side)

Cooling tower loop (liquid)

Air cooled

Heat transfer

Refrigerant / Air heat exchangers (also known as coils)

Heat exchanger coils

Refrigerant can be cooled or heated based by passing

it through a heat exchanger that has forced air on the

other side of it

A typical residential AC is

called a split system

because the condenser

and evaporator are

separated in space

Split system

www.e-refrigeration.com

www.rae-corp.com

Air cooled condenser on a chiller

When the evaporator is in

the airstream it is called a

direct expansion (DX) unit

This house has

refrigerant coming/going

to a AC unit (split)

This house has an air

duct coming/going to a

AC unit (packaged)

www.amanahac.com

www.diytrade.com

Heat transfer

Refrigerant / Liquid heat exchangers

Heat can be transported to/away from the

refrigeration cycle with liquid as well.

Liquid to refrigerant heat exchangers used

close-fitting pipes or plates to transmit the

heat

More on what happens after this in the next

lecture

renewableenergyengineering.com

www.unitedindustries.com.au

Refrigerants

Ammonia was one of the first refrigerants, not safe for residential

Halocarbons (carbon + chlorine & fluorine) = C’s below

Many halocarbons have adverse environmental effects because of long break down periods

Balance between toxicity, flammability, and long life

Ammonia, Water, CO2

Refrigerant

CFCs/HCFC

s

HFCs

HCs

Natural

R12

R22

R134

a

R410

A

R404

A

R29

0

R600

a

R71

7

R71

8

R74

4

ODP

1

0.05

0

0

0

0

0

0

0

0

GWP (100yr)

7100

1500

1300

1730

3260

20

20

2

<1

1

Flammable

No

No

No

No

No

Hig

h

High

Low

No

No

Toxic

No

No

No

No

No

No

No

Yes

No

No

Relative Price to

R22

-

1

4.0

5.0

~5.0

0.3

~0.3

0.2

<

0.1

0.1

Vol. Capacity

[Btu/ft3]

89

148

104

236

174

133

55

160

0.63

715

Critical Temp. [F]

234

205

214

163

162

206

275

270

705

88

Pressure at 70F

[psia]

85

136

86

215

163

125

45

129

0.36

853

HVAC

Cooling:

(Natural Ventilation)

Refrigeration cycles

Absorption cycles

Evaporation

Heating:

(Natural – solar, internal gains)

Boilers (water / steam)

Furnaces

Electric

Refrigeration cycles used as heating

Refrigeration

This is a little bit out of order, but since

Natural – solar collector

we are on the topic…..

Heat Pumps

A heat pump ‘pumps’ heat from one

location to another.

The temperature of the heat does

not have to be too significant (e.g. a

HP can extract heat from 40F air in

the winter

The source and sink for the heat

can be of many choices:

Outside air, earth, lakes, ocean,

inside water, inside air

Reversing heat pump

http://www.heatpump-reviews.com

http://hepisontheway.com

Heat Pumps

Heat pumps can be used to pump heat out of or

into

Air

Ground

Water

….

Ground / earth based heat rejection is typically

more stable than atmospheric air and may be at

more beneficial temperatures

Heat removed from cycle

Ground,

water, ….

Condenser

Expansion

Compressor

Evaporator

Energy

added

Heat added to cycle

gaci.biz

http://greenwise.weebly.com/

Heat Pumps

As with economizers, geothermal heat pump

applications vary in their effectiveness based

on where you are

Installation costs are usually pretty high, but

have been falling in recent years

** Geothermal power generation not covered

in this class

http://www.buildingscience.com/

nwcommunityenergy.org

Heat Pumps @ UCSB

16,500 sf LEED-Gold complex

at UC Santa Barbara is the

result of a partnership

between the university and

NOAA.

Heating – baseboard hydronic

heaters with hot water from

ocean source heat pump

Cooling – windows, ceiling

fans, chilled water from ocean

source heat pump for

equipment / computer rooms

Heat Pumps @ UCSB

Heating

Ocean

UCSB ocean source

heat pump diagram

Cooling

Research Direction

There is ongoing research into

designing better components

of refrigeration cycles

- lighter, quieter, more

efficient, cheaper

At the systems level, there is

significant work in identifying

when the refrigeration

equipment needs to be

serviced

- Is there dirt on the heat

exchange surfaces?

- Compressor worn out?

- Loss of refrigerant?

- Can you do this remotely?

Braun @ Purdue

Research Direction

New cycles (or old cycles with new interest) are being developed

Transcritical cycles leave the two-phase boundary by exceeding the critical

point in pressure

Because of this, the condenser becomes a gas cooler (no condensation), and

must operate at very high pressures

Phase change occurs across the expansion valve

New degrees of freedom for control because of the lack of temperature glide

on the condenser

www.achrnews.com

Research Direction

CO2 Heat Pump

3 units heat

(ambient air)

1 unit

electricity

Multiple equilibria

4 units

hot water

Because of the design of the CO2 heat pump, a new control variable is available

Depending on how the machine is started, very efficient or inefficient operation

can occur

Mathematical controls are needed that ensure efficient operation

Control Measurement

Efficiency

CO2 Heat Pump – Startup

CO2 Startup Movie

Physic-based modeling

𝜕𝐴𝜌 𝜕𝑚

+

=0

𝜕𝑡

𝜕𝑧

𝜕 𝐴𝜌ℎ − 𝐴𝜌

𝜕 𝑚ℎ

+

= 𝜋𝐷𝛼(𝑇𝑤 − 𝑇)

𝜕𝑡

𝜕𝑧

Evap. Enthalpy Change

CO2 Heat Pump – Efficient Controller

No control

Control Variable (water flow)

Nonlinear

Control

Insight into a nonlinear controller

that provides robust efficient

operation obtained from model

and tested on prototype

[US 6,813,895, US 7,171,820, US 7,127,905, US 7,010,925, US 7,225,629, US 6,993,921

Eisenhower 2005, 2007, 2009]

Research Direction

Chiller plant optimization

Often more than one chiller is needed to

satisfy the cooling needs of a group of

buildings

For a campus, the available chillers may

range in size, age, efficiency etc.

Research question: As the amount of

cooling changes through the day, which

combination of chillers should be used?

bigladdersoftware.com

Efficiency curves

are different for

each machine

google

HVAC

Cooling:

(Natural Ventilation)

Refrigeration cycles

Absorption cycles

Evaporation

Heating:

(Natural through envelope – solar, internal gains)

Boilers (water / steam)

Furnaces

Electric

Refrigeration

Natural – solar collector

** These subjects cover how to create cooling/heating, distribution comes later

Absorption Cycles

Absorption cycles obtain similar results as the vapor compression cycle by using

heat and chemical reactions

An example:

Heat is added to a ammonia water solution which vaporizes the ammonia

The vapor ammonia is then condensed in a condenser and the liquid ammonia

is taken for cooling

An evaporator is used to partially vaporize the ammonia

Apsorption Cycle

Absorption cycles are desired

because they require very little

electricity and can run off heat

Because of this, they are great

options for combined heat and

power applications

www.eurocooling.com

UTC PureComfort™ CHP System

…Two different control systems, one common function

Capstone MicroTurbines

Carrier Chiller

Gas -> Electricity and hot exhaust

Gas fired burner -> Cold / hot water

Capstone control system

Carrier control system

+

Carrier

Controller

Capstone

Controller

UTRC PureComfort CHP

Goal: Modify Carrier controller for supervisory needs

Necessary Controller Changes

Adjust to operation of chiller to different heat

source:

1. Micro-turbines at full power all 4 microturbines on

2. Micro-turbines load following

a)

All 4 micro-turbines running with power

fluctuations below 60kW

b) 1-2 micro-turbines turned on/off with

power fluctuations greater than 60kW

c) All 4 micro-turbines shut down

3. Include Damper Valve Model

4. Start/Stop Procedures

a)

Chiller does not start if all 4 micro-turbines

are turned off

b) Chiller shuts down safely if all 4

c) micro-turbines are shut down

5. Refine Protective Limits and Alarms

…necessary changes take many

months to implement, many more to

test/certify

Modelica Modeling for H-I-L

LiBr Modelica component libraries built in collaboration with

SJTU

Subcomponent Level Models

Conservation Equations

geo

init

charv

Sensor to model validation

charf

282

charfg

geofg

e.y[11]

chiller.Tchw out

initfg

281

Volume

pdropv

//Dynamic Mass Balance

M_x = transposex*M;

for i in 1:nspecies loop

derM_x[nspecies] = summdot_x[:, nspecies]

end if;

//Dynamic Energy Balance

U = M*h - p*Vt;

derU = sumqdot + sumheat.Q_s + sumheat.W_loss;

// Volume conservation

M[1] = d[1]*V[1];

280

279

pdropf

278

3E4

3.5E4

4E4

4.5E4

5E4

5.5E4

5E4

5.5E4

h...

Q

burner

e.y[12]

chiller.Tcw out

308

a...

306

fluegaspipes

304

302

3E4

3.5E4

Component Level Models

System Level Model

HPG

Ta...

r...

LPG

CON

hig...

of...

co...

c...

h...

Fl...

co...

Ejc

Di...

HX

p...

flu...

Di...

EVA

ABS

LX

p...

Mi...

Gain1 Flow ... Flow _...Flow ...

Bool...

-

pump

>...

Gre...

k={tr...

k={1.8...

PI

T={10} uMa...

Ma...

h...

Va...

sin...

co...

chiller

c...

Di...

si...

InitV

c...

so...

c...

p...

ch...

s...

4E4

4.5E4

Modeling and Reduction for RT sim.

𝑥 = 𝑓(𝑥, 𝑝, 𝑢, 𝜀)

http://www.mm.bme.hu/IDEAS14/logo.jpg

=

x

+

x

Efficiency:

Analytical

(modeling

paradigms)

Numerical

(localization)

Computational

(solvers)

Fast

=

x

Slow

+

x

Necessary Controller Changes

Adjust to operation of chiller to different heat

source:

1. Micro-turbines at full power all 4 microturbines on

2. Micro-turbines load following

~

a)

All 4 micro-turbines running with power

fluctuations below 60kW

b) 1-2 micro-turbines turned on/off with

power fluctuations greater than 60kW

c) All 4 micro-turbines shut down

=

3. Include Damper Valve Model

4. Start/Stop Procedures

a)

Chiller does not start if all 4 micro-turbines

are turned off

b) Chiller shuts down safely if all 4

c) micro-turbines are shut down

PureComfort

5. Refine Protective Limits and Alarms

…necessary changes take many

months to implement, many more to

test/certify

Sensors

System Model

Realtime

computation Actuators

Carrier

Controller

HIL Experimentation Environment

Necessary Controller Changes

Adjust to operation of chiller to different heat

source:

1. Micro-turbines at full power all 4 microturbines on

2. Micro-turbines load following

a)

All 4 micro-turbines running with power

fluctuations below 60kW

b) 1-2 micro-turbines turned on/off with

power fluctuations greater than 60kW

c) All 4 micro-turbines shut down

3. Include Damper Valve Model

4. Start/Stop Procedures

a)

Chiller does not start if all 4 micro-turbines

are turned off

b) Chiller shuts down safely if all 4

c) micro-turbines are shut down

5. Refine Protective Limits and Alarms

…necessary changes take many

months to implement, many more to

test/certify

HVAC

Cooling:

(Natural Ventilation)

Refrigeration cycles

Absorption cycles

Evaporation

Heating:

(Natural through envelope – solar, internal gains)

Boilers (water / steam)

Furnaces

Electric

Refrigeration

Natural – solar collector

** These subjects cover how to create cooling/heating, distribution comes later

Latent Cooling

Latent heat: heat released during a process that occurs without

change in temperature (e.g. just removing water)

Latent & Sensible Cooling

(B to A)

Changes the temperature

while also changing the

amount of water in the air

This is what typically

happens in a HVAC

system if the outdoor air

temperature and humidity

is high

Note condensation that

comes out of air

conditioners

Evaporative Cooling

Works on the principle of heat absorption (latent) from the evaporation process

(e.g. boiling at low temperature)

Evaporative coolers can be

- Direct: air touches evaporating water

- Indirect: air and water is separated

Indirect evaporative cooling

www.eere-pmc.energy.gov

Direct evaporative cooling

www.arcticfoxairconditioning.com

Cooling Towers

Warm water is sprayed in the

atmosphere over a flow of air

driven by a fan

The heat lost from evaporation

cools the water

Waste heat is delivered to the

atmosphere

Heat removed from cycle

Cooling

Tower

Condenser

Expansion

Compressor

Evaporator

Energy

added

Heat added to cycle

http://www.nucleartourist.com

cset.mnsu.edu

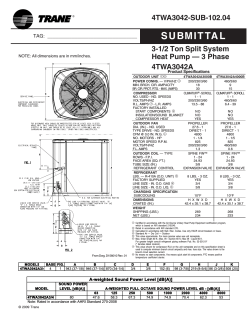

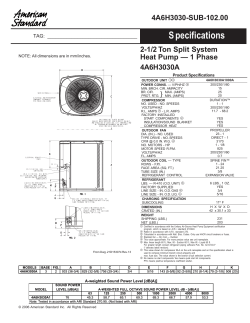

Specifications

Cooling equipment is selected based on numerous specifications

Type of refrigerant (R-22, R134a, R744, etc.)

Cooling Capacity

In the US, cooling capacity is often quantified in terms of Tons (e.g.10-500)

1 refrigeration ton = 1 TONScond = 12,000 BTU/h = 3,025.9 kCal/h = 12,661 kJ/h

Type of heat exchangers and flow capacity

Liquid vs air, and flow rates / pressure drops

Rated efficiency (COP = Useful energy/ costly energy… or EER = 3.413*COP)

Efficiency is rated at the factory under certain conditions on the heat

exchangers (input and output flow conditions)

Part load ratio performance

How the efficiency changes between idle and full blast

© Copyright 2026