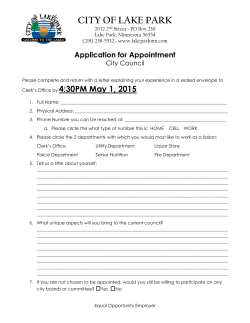

The Pulping Properties

Cost Reduction Through Advanced Control of Chlorine Dioxide Generators Bruce Allison, Leonardo Kammer and Thanh Trung Pulp and Paper Research Institute of Canada Vancouver, BC, Canada Abstract The cost of producing chlorine dioxide (ClO2) is a major contributor to the overall bleaching cost in a kraft mill. Therefore, methods to reduce this cost by increasing ClO2 generator efficiency are needed. A major factor that adversely affects generator efficiency is poor process stability, and high variability due to a lack of adequate process control. In this report, we present an advanced control strategy for ClO2 generators that consists of an inferential feedback scheme for liquor composition control, averaging level control of the ClO2 storage tanks for production rate smoothing, and a method to tune the generator liquor level controller. The strategy was applied at two mills, and on two different types of generator (SVP-LITE and R8). In both cases, substantial reductions in the variability of liquor composition, production rate, and generator level were achieved. Efficiency gains due to reduced consumption of sodium chlorate resulted in savings estimated to be between $300,000 and $500,000 per year. 1. Introduction According to 1999 data [1], the single-vessel, methanol-based (R8®/SVP-LITE®) process now accounts for roughly 60% of chlorine dioxide (ClO2) generation capacity in Canada. Other single-stage processes represent another 21% of capacity. Despite improvements in process technology, the cost of producing ClO2 is still a major contributor to the overall bleaching cost in a kraft mill. Therefore, methods to reduce this cost by increasing generator efficiency are needed. Trace contaminants that enter with the chemical feeds are a major source of efficiency loss due to decompositions for some mills, but this problem can usually be solved by using chemical filters. Another major factor that adversely affects efficiency is poor process stability and high Rob Laurendeau Canfor Corporation, Intercontinental Mill Prince George, BC, Canada Gerry Pageau Howe Sound Pulp and Paper Limited Port Mellon, BC, Canada variability due to a lack of adequate process control. This is the topic of the present report. Chlorine dioxide generator stability and efficiency are highly dependent on tight control of the chlorate and acid concentrations in the generator liquor. However, these variables are seldom, if ever, under closed-loop control. Early generator control systems focused on regulating the ClO2 solution strength [2]. While this helps to stabilize downstream operations in the bleach plant, it has no impact on the operation of the ClO2 generator itself. In [3], a control strategy for a R8 generator was proposed, but no consideration was given to the control of liquor composition, and the strategy was tested in simulation only. A multivariable predictive controller (MPC) was applied to a dual-vessel ClO2 plant in [4]. Although the authors reported controlling chlorate and acid concentrations in the generator liquor, it is not clear from their paper how the measurements were made. The need to coordinate two reactors was cited as the justification for using MPC, however, it is questionable if MPC would be required for the control of a single-vessel plant. Recently, an advanced control strategy called ERCO Smarts™ was applied to a R8 generator [5]. This strategy uses thermodynamic relationships between process variables, such as temperature, pressure and concentration, as well as balance equations to control liquor composition. As the control system is being sold commercially, very little detail is given in their paper. In recent work at Paprican [6], we proposed a novel generator liquor composition control strategy for single-vessel chlorine dioxide processes. In the scheme, Paprican’s infrared sensor technology is used to measure the composition of the generator liquor. A Kalman filter is then used to filter the FT-NIR and laboratory concentration measurements, and to provide estimates of the liquor composition between measurements. Finally, the Kalman filter estimates are employed in a decentralized, inferential feedback 2. Process Description In this report, we are mainly concerned with the single-vessel, methanol-based (R8®/SVP-LITE®) chlorine dioxide process. Several references that describe the process technology are available (see [1], [10]), so only a brief description is given here. Figure 1 shows a simplified schematic diagram of the singlevessel process. Here, methanol (CH3OH) is used to reduce sodium chlorate (NaClO3) in an acidic solution (H2SO4). The main chemical reaction is: 12NaClO3 + 8H2SO4 + 3CH3OH → 12ClO2 + byproducts (1) The heart of the process is a titanium reactor, which combines ClO2 generation, sodium sesquisulphate crystallization, and evaporation in a single-vessel. The main body of the generator is essentially a forced-circulation evaporator. During normal operation, the generator is about half full of a liquid slurry composed of sodium sesquisulphate crystals (a by-product), and unreacted chlorate and acid in solution. Recirculating liquor passes from the body through an in-line circulating pump, up through a steam-heated reboiler, and back into the generator body to complete the loop. The reboiler is a shell and tube heat exchanger to which steam is added to heat the liquor and sustain evaporation. Sodium chlorate is fed into the recirculation loop just ahead of the pump. Sulphuric acid is added just after the heat exchanger. The point for methanol addition depends on the process. Methanol is mixed with sodium chlorate prior to addition in the SVP-LITE process, and after the heat exchanger in the R8 process (see Figure 1). Chlorine dioxide is formed in the recirculating liquor so that the mixture returning to the generator body contains a significant volume of ClO2 gas and water vapour. This gas mixture enters a vapour space above the liquor and is separated from unreacted material that falls back into the liquor reservoir. Removal of gas is facilitated by the fact that the generator operates under a vacuum. Steam ClO2 Storage Acid Condenser ClO2 Generator Methanol† Saltcake Absorber Chilled Water To Ejector Filter Reboiler control scheme. In related work, Paprican’s averaging level control algorithm (Paprican ALeC) was applied to ClO2 storage tank level control in [8]. Averaging level control aims to control a storage tank level within upper and lower limits while minimizing changes to the manipulated variable, in this case generator production rate. In addition, closed-loop process identification was used in [9] to improve the tuning of a generator liquor level controller. The purpose of this report is to review results of the work mentioned above at two mills. In particular, we are interested in assessing the impact of advanced control on generator efficiency. The remainder of this report is organized as follows. The single-vessel chlorine dioxide process is described in Section 2. Section 3 outlines the overall control strategy for the generator. Results in terms of variability reduction and efficiency gains at two mills, one equipped with a SVP-LITE generator and the other with a R8, are covered in Section 4. Section 5 discusses reasons for the difference in results between the mills, and the potential opportunity for additional efficiency gains by optimization of composition target values. Finally, the conclusions of the study are stated in Section 6. A Chlorate/ Methanol* To Bleach Plant Figure 1. Simplified schematic diagram of the single-vessel chlorine dioxide process. Entry point for methanol; SVP-LITE (*) and R8 (†). Location of ClO2 flow and concentration measurements (“A”). Gases from the top of the generator pass into an indirect contact cooler where the water vapour is condensed. The ClO2 gas then passes into an absorption tower, where it is dissolved in chilled water forming a solution that is approximately 10 g/L ClO2, and sent to storage. Sodium sesquisulphate crystallized in the generator body is removed when a portion of the slurry is pumped to a rotary drum filter. Filtrate returns to the generator and the dewatered saltcake drops into a dissolving tank. The saltcake is dissolved in black liquor as a means of conveying it into the chemical recovery system. 3. Control Strategy 3.1 Mass Flow Control of Chemical Feeds As a starting point, it is assumed that mass flow controllers exist for all three chemical feeds, i.e. methanol, acid and chlorate. Typically, the flows are measured volumetrically. For methanol and acid (93% by weight), conversion to mass flow is usually done using an assumed density. Sodium chlorate is usually supplied as a solution that contains a nominal sodium chlorate concentration and an unknown but usually very low sodium chloride concentration. Conversion to sodium chlorate mass flow may be done either by assuming a nominal sodium chlorate concentration, or by measuring the density and temperature and calculating the mass flow using standard correlations for chlorate solutions. 3.2 Chlorine Dioxide Mass Flow Chlorine dioxide flow is typically measured volumetrically in the line between the absorption tower and the storage tank (point marked “A” in Figure 1). An optical analyser in the same line provides a ClO2 concentration measurement so that the mass flow can be calculated. 3.3 Ratio Control of Chemical Feeds As shown in Figure 2, the methanol mass flow setpoint is proportioned (ratioed) to the target ClO2 production rate in a ratio controller. Chlorate and acid mass flow setpoints are determined in one of two ways. Figure 2a shows chlorate and acid being ratioed to the methanol setpoint, while Figure 2b shows them being ratioed to the target ClO2 production rate. Note that as a result of this ratio control structure, all three feeds are automatically manipulated in a feedforward manner when the target production rate is changed. 3.4 Liquor Composition Control Figure 3 is a simplified schematic diagram of the liquor composition control strategy for chlorate, first described in [6]. The heart of the strategy is the Kalman filter block. The Kalman filter is a DCS algorithm that executes once per minute. The inputs to this block are real-time measurements of chlorate and ClO2 mass flow, the generator liquor chlorate concentration test, and FT-NIR measurement when available. The output is the liquor chlorate concentration estimate. This estimate is input as the process variable to a standard PID controller. The PID controller setpoint is the chlorate concentration target. The PID controller manipulates a ratio (here kg chlorate / kg methanol is assumed) which is multiplied by the methanol mass flow setpoint in a ratio controller to get the chlorate mass flow setpoint (see Figure 2a). The generator liquor acid concentration is controlled in the same way. Note that the Kalman filter sampling interval (one minute) is generally much faster than the sampling interval for laboratory tests (2-4 h) and the FT-NIR analyzer (~15 min). Thus, the PID controller uses Kalman filter estimates (model predictions) for feedback between tests. ClO2 Production Target (kg/min) Ratio Chlorate / Methanol (kg/kg) Ratio Methanol / ClO2 (kg/kg) ClO2 Production Target (kg/min) RATIO Controller RATIO Controller Methanol Feed Flow (kg/min) RATIO Controller Ratio Methanol / ClO2 (kg/kg) Methanol Feed (kg/min) Chlorate Feed Flow (kg/min) ClO2 Generator ClO2 Production (kg/min) ClO2 Production Target (kg/min) RATIO Controller Methanol Feed Flow (kg/min) RATIO Controller Ratio Acid / ClO2 (kg/kg) + − PID Controller Ratio RATIO Controller Chlorate Feed (kg/min) ClO2 Generator ClO2 Production Measurement (kg/min) Chlorate Test (g/L) Kalman Filter Chlorate Concentration Estimate (M) a) Ratio Chlorate / ClO2 (kg/kg) RATIO Controller Chlorate Concentration Target (g/L) Acid Feed Flow (kg/min) Ratio Acid / Methanol (kg/kg) Ratio Methanol / ClO2 (kg/kg) RATIO Controller Figure 3. Block diagram of liquor composition estimation and control strategy for chlorate. The acid concentration in the liquor is controlled in a similar way. 3.5 Chlorate Feed Flow (kg/min) ClO2 Generator ClO2 Production (kg/min) Acid Feed Flow (kg/min) b) Figure 2. Ratio control of chemical feeds. Methanol mass flow is ratioed to the target ClO2 production rate. (a) Chlorate and acid mass flows are ratioed to methanol. (b) Chlorate and acid mass flows are ratioed to production rate. ClO2 Storage Tank Level Control Figure 4 is a simplified schematic diagram of the ClO2 storage tank level control loop, first described in [8]. The heart of this loop is the optimal averaging level controller (Paprican ALeC). The ALeC block is a DCS algorithm that executes once every ten seconds. The inputs to ALeC are the tank level measurement, the setpoint, and upper and lower level constraints. The output is the ClO2 production rate target. The methanol feed flow setpoint is ratioed to the target ClO2 production rate, as shown in Figure 2. Ratio Methanol / ClO2 (kg/kg) Tank Level Constraints (%) Tank Level Setpoint (%) ALeC ClO2 Production Target (kg/min) RATIO Controller Methanol Feed (kg/min) ClO2 Generator ClO2 Solution (L/s) Storage Tank Tank Level (%) 1. 2. 3. Figure 4. Block diagram of optimal averaging level control strategy (Paprican ALeC) applied to chlorine dioxide storage tank level control. 3.6 Generator Liquor Level Control The generator liquor level control loop is a simple PID feedback controller from the liquor level (calculated from differential pressure and density measurements) to the reboiler steam flow. This controller also contains feedforward compensation for the total inlet water flow. A closed-loop process model identification method and PID tuning rules for this loop were reported in [9]. 4. Results 4.1 Mill A Mill “A” is equipped with a SVP-LITE generator (see Figure 1) designed to produce 45 t/d of ClO2. This generator is very well instrumented. Pure sodium chlorate mass flow is calculated on-line from measurements of volumetric flow, density and temperature of the chlorate feed solution using a Micro Motion device. Sulphuric acid is supplied at 93% by weight and, under some circumstances, may be diluted prior to addition. The ClO2 solution strength is monitored and controlled via a continuous photometric analyser. Laboratory tests of liquor composition (chlorate and acid concentration) are made once every 2 hours. This mill was also the first to install a FT-NIR analyser to measure the concentrations of chlorate and acid in the liquor. The FT-NIR measurements are made once every 15 min. Details on the development and commissioning of the analyzer were obtained from [7]. Mill A is also equipped with a Foxboro IA distributed control system (DCS) to handle many of the low level loops, such as flow rate of chemical feeds, generator pressure and level. All chemical feeds are metered by mass using mass flow controllers as discussed in the previous section. The setpoints of the mass flow controllers are determined by ratio controllers (see below). The Kalman filters and ALeC were each implemented as sequence block algorithms in the Foxboro system. The new control strategy was commissioned between May and September, 2002. During this period, the following steps were taken: 4. ALeC implemented – May, 2002. Chlorate and acid ratioed to methanol instead of methanol and acid ratioed to chlorate – July, 2002. Liquor composition control commissioned – September, 2002. Generator liquor level controller retuned – November, 2002. Regarding step 2, the original configuration was to ratio acid and methanol to chlorate. This appears to be standard practice for this make of generator. However, this clearly represents a conflict since, under such a strategy, the chlorate mass flow must be manipulated to control both production rate and chlorate concentration. By ratioing chlorate and acid to methanol, this conflict is resolved since methanol can be used to control production rate and the ratio of chlorate to methanol used to control chlorate concentration. Results from Mill “A” are contained in Figures 5 to 9 and Tables I and II. Here, “manual operation” refers to operation with ratio control only, i.e. as shown in Figure 2a. The term “automatic control” refers to a fully automated system where ALeC determines the target production rate (Figure 4) and chlorate and acid ratios are determined by composition feedback (Figure 3). Figure 5. Comparison of conventional (PID) control and ALeC showing reduction in production rate (methanol) variability with ALeC. Level setpoint – blue line, level measurement – green line, level constraints – red dotted line. Light red shaded areas correspond to periods of manual operation. Figure 5 shows a comparison between tight storage tank level control (PID) and ALeC. Under ALeC, the storage level is allowed to deviate farther from the setpoint, provided it does not exceed upper or lower level constraints, which are shown by the dotted red lines. The main benefit of allowing the level to vary over a wider range is that the production rate manipulations (methanol flow) are generally much smoother. Thus, ALeC uses the available storage tank capacity to partially buffer the chlorine dioxide plant from the changing demands of the bleach plant. switch to auto a) be more reliable than the laboratory tests and so the Kalman filter for acid was designed to put more weight on the FT-NIR measurements. This difference between the Kalman filters for chlorate and acid can also be seen in Figure 8. Returning to Figure 6, the chlorate concentration continues to drift slightly, even after the controller is switched on at the one day mark, but then it lines out nicely once the acid controller is switched on at the two day mark, as shown in Figure 6b. Also, the controller output is less variable after the controller is switched on. Note that the variability of the Kalman filter estimates is much smaller than the variability in either the laboratory tests or the FT-NIR readings, particularly under automatic control. This is because most of the “true” liquor composition variability is removed by the feedback controller, and the variability that remains is essentially random noise that is filtered out. 1. 2. 3. 4. switch to auto b) Figure 6. Two ten day periods of operation. “Manual” refers to a period during August 2002 before the liquor composition controllers were commissioned, and “Automatic” a period from September 2002 when the controllers were first commissioned. (a) Chlorate controller. (b) Acid controller. Figure 6 shows two ten day periods of operation, one (titled “Manual”) from August 2002 before the liquor composition controllers were commissioned, and the other (titled “Automatic”) from September 2002 during the period when the controllers were first commissioned. Figure 6a shows the chlorate concentration data – setpoint, laboratory tests, and Kalman filter estimates – in the upper plot, and controller output – essentially a scaled and normalized ratio where 100% corresponds to stoichiometric chlorate addition – in the lower plot. Figure 6b shows the acid data, including the FT-NIR readings. The FT-NIR readings are not shown for chlorate because the data was very noisy. To reflect this, the chlorate Kalman filter was designed to use laboratory tests primarily. The opposite situation was true for acid, that is, the FT-NIR data was thought to Figure 7. Comparison of liquor chlorate and acid composition variability (laboratory test data) under manual operation and automatic control for Mill “A”. 1. Implementation of ALeC. 2. Feed chemicals ratioed to methanol. 3. Implementation of liquor composition controls. 4. Retuning of generator liquor level controller. TABLE I: Liquor composition variability reduction – Mill “A”. Control Mode Manual Operation Automatic Control SVP-Lite Generator Chlorate Acid Standard Standard Target Target Deviation Deviation 39 g/L 27 g/L 280 350 (0.37 M) (0.55 N) g/L g/L (2.6 (7.1 18 g/L 14 g/L M) N) (0.17 M) (0.29 N) Figure 7 and Table I compare liquor composition variability under manual operation and automatic control. Figure 7 shows chlorate and acid laboratory test data for the year 2002 when all of the control improvements were implemented. The numbers in the figure refer to the steps listed above. In Table I, the variability is compared under manual and automatic, where the first four months were taken to represent manual operation, and the last four months to represent automatic control. As seen from the table, the standard deviation of chlorate was reduced by about 55%, and acid by about 45%. Note that this comparison, and others made later on in this report, is based on laboratory test data. Given that there is a certain amount of random variability (due to sampling, testing, etc.) in laboratory data (see Figure 6 for example), it is highly likely that the variability reduction in the true underlying concentrations is even greater. Thus, the values reported here may be considered conservative estimates of variability reduction. In Figure 8, a two and one-half day period of operation is shown where the mill experienced a power outage due to a severe electrical storm. As indicated in the figure, the power outage occurred at about the 24-hour mark. The reason for showing this figure is that, during the period immediately after the outage and for about the next 18 hours, laboratory tests of the generator liquor were unavailable as the operators and mill workers were busy getting the mill back up and running. During this period, the generator controls operated with FT-NIR analyser feedback only. As can be seen in the figure, tight control of the liquor composition was maintained during this time, and when a laboratory test was finally made at about the 42 hour mark, it agreed very well with the FT-NIR measurements and the Kalman filter estimates. Clearly, the consumption of all three chemical feeds decreased after implementation of the new control system. The decrease in methanol use observed in the first six months of 2002 (prior to commissioning the new controls) is believed to be associated with a change in liquor composition target values made in the fall of 2001. This also appears to have had a small effect on chlorate use, but no apparent effect on acid. Acid use clearly decreased after implementation of the new controls, and chlorate use continued to exhibit a downward trend. Taking the period January 1, 2001 to June 30, 2002 to represent “manual operation”, and the period July 1, 2002 to June 30, 2003 to represent “automatic control”, then the savings associated with this improvement may be calculated, as shown in Table II. Here we can see, for example, that chlorate use dropped by 0.062 kg per kg ClO2. This represents an efficiency gain of 3.6%. The efficiency gain for acid was 4.3%. No attempt was made to identify the source of efficiency gain, but one plausible explanation is a decrease in the number of decompositions caused by chemical imbalance. The values in the column labelled “Savings” in Table II were calculated by multiplying the difference in chemical consumption (manual minus automatic) by the chemical cost and total yearly ClO2 production. After summing the values in this column (not including methanol), the total savings associated with making the transition from manual to automatic were estimated to be over $500,000 per year for this mill. Control System Implemented Outage Figure 8. Generator start-up after a power outage showing controls operating with FT-NIR analyser feedback only. Figure 9 shows chemical consumption (kg feed per kg ClO2 produced) going back to the period starting January 1, 2001. Chemical consumption was computed from accumulated values (flow times concentration) from the DCS data base over successive six-month periods (i.e. semi-annually). Figure 9. Reduction in chemical consumption over time. The new controls were commissioned between May and September 2002. Chlorate and acid efficiency gains were estimated to be 3.6% and 4.3%, respectively. 4.2 Mill B Mill “B” has a R8 generator with a design capacity of 35 t/d. The layout of the R8 process is TABLE II: Savings – Mill “A”. Feed Chemical Chlorate Acid Methanol Chemical Consumption ( kg per kg ClO2 produced) Manual Automatic Difference 1.682 1.620 -0.062 1.064 1.016 -0.048 0.227 0.214 -0.013 essentially that of the SVP-LITE, except for the location of methanol addition as indicated in Figure 1. Mill B was not equipped with either the Micro Motion or FT-NIR devices. Thus, it was necessary to assume a value for the sodium chlorate concentration in the chlorate feed solution, and to base the liquor composition control strategy on laboratory tests only, which were done on average once every four hours. Mill B was equipped with an ABB Master DCS, and the Kalman filters and ALeC were implemented as program modules using algorithms written in AMPL, which is a process-oriented high level language that uses graphic symbols. It is worth mentioning that, in this case, the mill engineer was able to complete the implementation and commissioning on his own. Examples of the Foxboro code from Mill A were provided along with a default set of tuning parameters. Consultations with Paprican staff were done via telephone and Email. No capital expenditures were required, and the only cost was the time required to implement the new algorithms in the DCS. 1. 2. Figure 10. Comparison of liquor chlorate and acid composition variability (laboratory test data) under manual operation and automatic control for Mill “B”. 1. Implementation of ALeC. 2. Implementation of liquor composition controls. In the case of Mill B, ALeC was commissioned in November 2002 and the liquor composition control strategy in January 2003. The results are shown in Figure 10 and Table III, and are once again based on laboratory test data. Despite the lack of Savings (k$/y) 493 49 96 Efficiency (%) Manual 93.8 91.1 - Automatic 97.4 95.4 - Difference 3.6 4.3 - instrumentation, substantial reductions in liquor composition variability were still achieved. As shown in Table III, chlorate standard deviation was reduced by about 40% and acid by about 30%. Table IV compares chemical efficiencies in September 2003 to the yearly average for 2002. In this case, chlorate efficiency increased by 2.2% under automatic control. This represents a yearly savings of almost $300,000 for this mill. TABLE III: Liquor composition variability reduction – Mill “B”. R8 Generator Control Mode Manual Operation Automatic Control Chlorate Standard Target Deviation (34 g/L) (170 0.32 M g/L) 1.60 (20 g/L) M 0.19 M Target (440 g/L) 9.0 N Acid Standard Deviation (25 g/L) 0.50 N (17 g/L) 0.34 N 5. Discussion There are potentially many reasons why Mills A and B have different absolute efficiencies. Despite sharing common chemistry, the SVP-LITE and R8 processes run at very different operating points. For example, the R8 process typically operates at a much higher acidity (compare target values in Tables I and III). Furthermore, the chemical feeds, particularly the sodium chlorate, are purchased from different sources and, despite having similar production rates, the generators differ in their design capacity. Finally, and probably most important, in many cases the data used to evaluate efficiency comes from field devices that are prone to error. Thus, as a rule, one should not put too much emphasis on an absolute efficiency calculation. Differences in operation from one period to another, on the other hand, are much more meaningful. This is because any bias errors cancel out. Thus, if we limit the discussion to changes in performance brought about by the implementation of automatic control, we can say that the variability TABLE IV: Savings – Mill “B”. (Sept 2003 vs 2002 average). Feed Chemical Chlorate Acid Methanol Chemical Consumption ( kg per kg ClO2 produced) Manual 1.753 1.200 0.182 Automatic 1.711 1.200 0.183 Difference -0.042 0. 0. reduction and efficiency improvement for Mill A were seen to be, roughly speaking, twice that of Mill B. The question is why? The most likely explanation is the difference in instrumentation. Mill A is instrumentation rich. Since pure chlorate mass flow is measured on-line, changes in the composition of the chlorate feed – one of the main disturbances – may be detected and corrected by the chlorate mass flow controller in a relatively short period of time. In the case of Mill B, corrections cannot be made until these disturbances pass through the process and are detected in the laboratory liquor composition measurement, which is made only once every four hours. In another scenario, if some unmeasured disturbance, for example a change in efficiency, occurs in the process, then Mill A again has the advantage. Since the FT-NIR analyser measures the liquor composition once every 15 minutes, any change will be detected and corrected relatively quickly. Once again, Mill B may have to wait up to four hours to detect the same disturbance. M+ M+ NH igh NL ow Lim White-Out Zone it Automatic Control plus Target Shift Manual Operation Lim it Sluggish Reaction Zone Automatic Control Figure 11. Illustration of how variability reduction, followed by a target shift, might allow operation at a higher overall efficiency, while still operating in the target zone. The results presented in this report support the idea that efficiency gains may be achieved simply by stabilizing the process and reducing variability. However, variability reduction alone may not be enough to realize the full potential of automatic Savings (k$/y) 294 0 0 Efficiency (%) Manual 90.0 - Automatic 92.2 - Difference 2.2 - control. Figure 11 illustrates how variability reduction, followed by a target shift might allow operation at a higher overall efficiency, while still maintaining operation within the target liquor composition zone. As there is very little, if any, information in the open literature on what concentration targets might yield the best efficiency, it is likely that each mill would have to conduct a set of trials to find the best operating point for their particular operation. The generator manufacturer should be involved to ensure that safe operating conditions are maintained at all times. However, it is important to note that it is only by first reducing the variability about a set of target values through the implementation of automatic control, and then shifting those targets, that such a process investigation even becomes possible. 6. Conclusions In this report, we have proposed a control strategy for the methanol-based single-vessel chlorine dioxide process. The strategy was applied at two mills and on two different types of generator (SVP-LITE and R8). In both cases, substantial reductions in the variability of liquor composition, production rate and generator level were achieved. Efficiency gains due to the reduced consumption of sodium chlorate resulted in savings estimated to be between $300,000 and $500,000 per year, depending on the available instrumentation. In addition, the control strategy has been well received by the plant operators and process engineers alike. The main conclusion that one can draw from this work is that substantial savings may be achieved by reducing variability and increasing process stability, particularly with respect to variability in the composition of the generator liquor. 7. References 1. 2. 3. 4. 5. D. Owen, “Chlorine Dioxide Generation”, Course notes from: TECH 99: Pulp Bleaching Course, PAPTAC, Thunder Bay, ON, Oct. 3-8 1999. J.W.C. Evans, “Automated ClO2 Generation Improves Bleaching, Cuts Effluent”, Pulp & Paper, Vol. 57, No. 2, 1983, p. 69-71. P. Tessier, M. Pudlas, and Y. Ying, “Dynamic Modelling, Simulation and Control of a R8 Generator”, In PacWest Conference, Jasper, AB, Session 2A, Paper 1, May 17-20 2000. D.B. Smith, J. Robinson, P. Aggarwal, and H. Lindstrom, “Advanced Control of a Chlorine Dioxide Plant”, In TAPPI/ISA-PUPID Process Control, Electrical, and Information Conference, San Antonio, TX, Session 12, Mar. 25-29 2001. C. Pu, J. Birks, and J. Hopmans, “ERCO Smarts™ Advanced Control of a Chlorine Dioxide Plant: The First Year”, In PacWest Conference, Harrison Hot Springs, BC, Session 4B, Paper 3, May 7-10 2003. 6. B.J. Allison, “A Liquor Composition Control Strategy for Chlorine Dioxide Generators”, In PacWest Conference, Jasper, AB, Session 3, Paper 3, May 1922 2004. 7. T. Trung, Personal Communications, July 5 (2001). 8. L.C. Kammer, B.J. Allison, R. Laurendeau, “Optimal Averaging Level Control of Chlorine Dioxide Storage Tanks”, In PacWest Conference, Harrison Hot Springs, BC, Session 2A, Paper 2, May 9-12 2007. 9. L.C. Kammer, B.J. Allison, R. Laurendeau, M. Kopat, “Closed-Loop Identification of an Integrating Process: Application to Chlorine Dioxide Generator Liquor Level Control”, Pulp Paper Can. 107(3):T59-62 (2006). 10. Alkaline Pulping, T.M. Grace, B. Leopold, and E.W. Malcolm, eds., 3rd ed. (Pulp Pap. Manuf., vol. 5), Jt. Textbook Cttee. Pap. Ind., Montreal, 1989.

© Copyright 2026