Flex Essentials Flyer - Digital

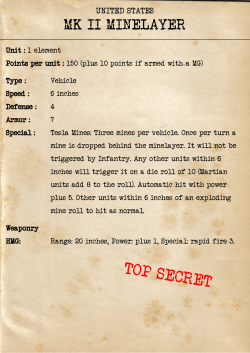

PACKAGE LEAK DETECTOR/SEAL TESTER Model FP201413 Leak Detector FPSA - Semi-Automatic Control Package www.flexpakinc.com Model FP392220 Leak Detector FPFA - Fully-Automatic Control Package OPTIONAL Control Packages are Retrofittable to All Brands of Similar Leak Detectors! Package Leak Detector and Seal Integrity Testing Device Package Leak Detector and Seal Tester for: Package Manufacturers Meats Fish and Seafood Cheese Pet Food Grains Cereal Bakery Products Snack Food Coffee Confectionery Much, much, more PACKAGE LEAK DETECTOR/SEAL TESTER www.flexpakinc.com is a device used to test seal and substrate integrity in many different kinds of packaging including: stand-up pouches and bags of many varieties, rigid trays, packages that are gas flushed (MAP), and all types of food or medical packaging. The leak detector consists of a transparent vacuum tank, a vacuum system, a control valve and indicator gauge that indicates vacuum level. The unit is mounted on a stainless steel stand. The device is simple, reliable and repeatable allowing consistent quality control and process monitoring. The package to be tested is simply submersed in the tank, the lid is closed, and the vacuum valve is engaged, atT M which time, if there is a leak, the Quality Control www.flexpakinc.com Inspector can easily see air or gas in the form of bubbles escape from the package. Adjust Vacuum Level to Evaluate Seal Integrity A complete test can be done in less than 30 seconds! FLEXPAK is a device used to test seal and substrate integrity in many different kinds of packaging including: stand-up Package Leak Detector/Seal Tester and bags of vacuum many varieties, rigid trays, packages that are air. gas flushed (MAP), and all types of food or There arepouches no electrics; the is created using pressurized medical packaging. can be used for measuring pass test assystem, a product fail point test. In additon, The FLEXPAK leak detector consists ofaa minimum transparent vacuum tank,as a well vacuum a control and indicator gauge simulation that indicates testing. vacuum level. The unit is mounted on a the device can valve be used for altitude stainless steel stand. Machine seal bar settings such as dwell, temperature and pressure can then be adjusted to correct any The device is simple, reliable and repeatable allowing consistent quality control and process inconsistencies with the seal integrity that are discovered with this tester. monitoring. The package to be tested is simply submersed in the tank, the lid is closed, and the vacuum valve is engaged, at which time, if there is a leak, the Quality Control Inspector can easily Adjust Vacuum Level To see air in the form of bubbles escape from the package. A complete test can be done inEvaluate Seal Integrity. less than 30 seconds! There are no electrics; the vacuum is created using pressurized air. FLEXPAK can be used for measuring a minimum pass test as well as a product fail point test. In additon, the device can be used for altitude simulation testing. Machine seal bar settings such as dwell, temperature and pressure can then be adjusted to correct any inconsistencies with the seal integrity that are discovered with this tester. Faulty Seal - See The Air Bubbles! Good Seal Integrity - No Bubbles! Sizes - Pick the model to The suit package size! Faulty Seal – See Airyour Bubbles! Good Seal Integrity FlexPak Sizes – Pick the model to suit your package size! Inside Tank Dimensions Model Number FP110808 FP181210 FlexPak Unit Model Unit Number Inches mm Inches FP110808 Inches mm mm Inches Inches mm mm Inches FP201413 Inches mm mm Inches FP242015 Inches mm mm Inches FP302016 Inches mm mm Inches FP322619 Inches mm mm FP181210 FP201413 FP242015 FP302016 FP322619 FP392220 FP392220 Distributed by: Distributed By: Inches mm Maximum Inside Tank Dimensions Length Width Length 11 11 280 280 18 18 460 460 20 20 510 24 510 610 24 30 610 760 30 32 760 810 32 39 810 990 39 Width 8 8 200 200 12 12 305 305 14 14 355 355 20 20 510 510 20 20 510 510 26 660 26 22 660 560 22 Height Height Package Size 8 (L8x W x H) 10 x 7 x 5 200 200 25010 x 180 x 130 10 255 17 x 11 x 7 255 43013 x 280 x 180 13 19 x 13 x 10 330 330 48015 x 330 x 250 15 380 23 x 19 x 12 380 16 58016 x 480 x 300 410 29 x 19 x 13 410 74019 x 480 x 330 19 31 x 25 x 15 480 20 480 20 790 x 630 x 380 510 38 x 21 x 16 Maximum Package Size (L x W x H) 10 x 7 x 5 250 x 180 x 130 17 x 11 x 7 430 x 280 x 180 19 x 13 x 10 430 x 330 x 250 23 x 19 x 12 580 x 480 x 300 29 x 19 x 13 740 x 480 x 330 31 x 25 x 15 790 x 630 x 380 38 x 21 x 16 970 x 530 x 400 990 560 510 970 x 530 x 400 Flex Essentials Inc. 17769 Centreville Creek Rd. Caledon East, ON L7K 2L9 Canada Flex Essentials Inc.E-mail: 17769 Centreville Creek Rd. Caledon East,www.flexpakinc.com ON L7K 2L9 Canada Tel: 416.399.5583 [email protected] Tel: 416.399.5583 E-mail: [email protected] www.flexpakinc.com

© Copyright 2026