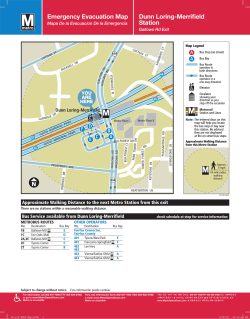

Effective: December 27, 2010