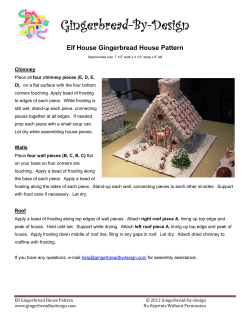

The Homeowner’s Guide To CHIMNEYS, FIREPLACES AND