Design of Self-Heating Containers Using Sodium Acetate Trihydrate

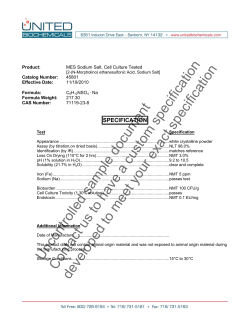

International Conference on Chemical, Metallurgical and Civil Engineering (ICCMCE'2015) March 16-17, 2015 Abu Dhabi (UAE) Design of Self-Heating Containers Using Sodium Acetate Trihydrate for Chemical Energy – Food Products Rameshaiah GowdaraNarayanappa, Prithvi Chandh Manikonda, Manoj Kumar, Suraj Bhavan, and Vikram Singh Crystallisation is an exothermic process that evolves heat when a nucleation site is activated inside a supersaturated solution. When we boil the solid, we melt it back to liquid state. We can repeat this cycle forever, theoretically, just as we can freeze and melt water as many times as we like. For design and Fabrication purpose different conducting and insulating materials need to be tested. Abstract— Long ago heating of food was only related to fire or electricity. Heating and storage of consumer foods were satisfied by the use of vacuum thermo flaks, electric heating cans and DC powered heating cans. But many of which did not sustain the heat for a long period of time and were impractical for remote areas. The use of chemical energy for heating foods directed us to think about the applications of exothermic reactions as a source of heat. Initial studies of calcium oxide showed desirability but not feasible because the reaction was uncontrollable and irreversible. In this research work we viewed at crystallization of super saturated sodium acetate trihydrate solution. Supersaturated sodium acetate trihydrate has a freezing point of 540C (1300F), but it observed to be stable as a liquid at much lower temperatures. Mechanical work is performed to create an active chemical energy zone within the working fluid, when crystallization process is initiated. Due to this, the temperature rises to its freezing point which in turn heats the contents in the storage container. Present work- endeavor to design a self-heating storage container that is suitable for consumer dedications. II. PROCEDURE This experiment deals with the use of Supersaturated Sodium acetate trihydrate for heating purpose. Supersaturated sodium acetate trihydrate has a freezing point of 58 degree Celsius (130 degree F), but it is observed to be stable as a liquid at much lower temperatures. When a mechanical work is performed to create an active zone within the working fluid, crystallisation process is initiated. Due to this the temperature rises to its freezing point (58 degree C) which in turn heats the contents in the storage cell. Sodium acetate trihydrate crystals melt at 58 °C, dissolving in their water of crystallization. When they are heated to around 100 °C, and subsequently allowed to cool, the aqueous solution becomes supersaturated. This solution is capable of cooling to room temperature without forming crystals. By providing a suitable mechanical work, a nucleation centre is formed which causes the solution to crystallize into solid sodium acetate trihydrate again. The bond-forming process of crystallization is exothermic, hence heat is emitted. The latent heat of fusion is about 264–289 kJ/kg. The sodium acetate crystal can be recycled to liquid form by boiling. When you boil the solid, you melt it back to the liquid state. We can repeat this cycle forever, theoretically, just as you can freeze and melt water as many times as you like (since sodium acetate is a food additive and it is non-toxic). Table I Keywords—Super saturation, crystallization, vacuum thermo flask, self-heating container, exothermic reactions. I. INTRODUCTION N recent year’s food heating before consumption has become a major criteria especially in remote areas, cold climatic regions, high altitude regions, military encampments, etc. Many people may have the concept that whenever keeping food warm, it should be related to fire or electricity. But in our investigation, we will try to reach the same purpose with chemical approach i.e. the use of portable heating storage units that can provide an instant plan of action to troubleshoot consumption issues. So to achieve above we are using crystallisation property of supersaturated solutions. I Rameshaiah GowdaraNarayanappa is Associate professor, Department of Chemical Engineering, B M S College of Engineering , P.B. No. 1908, Bull Temple Road, Basavangudi, Bangalore- 560019, Karnataka, INDIA, ([email protected] , [email protected] , Mobile No. +91 82771 26901) Prithvi Chandh Manikonda, Manoj Kumar, Suraj Bhavani, Vikram Singh, are Research Scholars, Department of Chemical Engineering, B M S College of Engineering, P.B. No. 1908, Bull Temple Road, Basavangudi, Bangalore560019, Karnataka, INDIA (email: [email protected], [email protected], [email protected], vikram1singh90@ gmail.com) http://dx.doi.org/10.15242/IIE.E0315529 CONDUCTING MATERIALS FOR DESIGN Conducting materials Alluminum Brass Copper Silver “W= Watt, m= meter, K=kelvin” 42 Conductivity 204 W·m−1·K−1 124 W·m−1·K−1 385 W·m−1·K−1 420 W·m−1·K−1 International Conference on Chemical, Metallurgical and Civil Engineering (ICCMCE'2015) March 16-17, 2015 Abu Dhabi (UAE) TABLE II INSULATING MATERIALS FOR DESIGN Insulating materials Conductivity 0.026 W·m−1·K−1 0.42 W·m−1·K−1 0.15 W·m−1·K−1 0.12 W·m−1·K−1 Air Polystyrene Plastic Wood “W= Watt, m= meter, K=kelvin” III. PROCESS Fig. 1 Details of the process flow IV. CONCLUSION The thermodynamic and heat transfer properties of sodium acetate trihydrate was studied and is implemented in an effectively designed storage vessel for ready heating of the stored food for consumer satisfaction. ACKNOWLEDGMENT We wish to express our sincere gratitude to Dr. Mallikarjuna Babu, Principal and BMS COLLEGE OF ENGINEERING for providing the academic ambience for our project. We would also like to take this opportunity to thank Dr. Samita Maitra, Head of the department, Chemical Engineering, BMSCE for her continuous support. REFERENCES [1] Burger, R. Double walled vessel with a space for a vacuum between the walls. U.S. Patent 872795 A, December 3, 1907. [2] Lacy, H. E. Electrically heated cup. U.S. Patent 2046125 A, June 30, 1936. [3] Fisher, B.; Spector, G. Rechargeable battery heating unit U.S. Patent 3931494 A, January 6, 1976 [4] U.S. Food and Drug Administration http://web.archive.org/web/20070812132324/www.fda.gov/ora/inspect_ ref/itg/itg17.html [5] Chem fax, Supersaturated Sodium Acetate Solution. flinn sci. 2009, 1-2, 91215. [6] Hollingsw, C. A.; Dietz, P. L.; Jr. Brukner, J. S. Linear Crystallization velocities of sodium acetate in supersaturated solutions. J. Phys. Chem., 61,944-948. [7] Taylor, P.G.; Beevers, C.A. The crystal structure of sodium thiosulphate pentahydrate Acta Cryst. (1952). 5, 341-344 http://dx.doi.org/10.1107/S0365110X52001027 http://dx.doi.org/10.15242/IIE.E0315529 43

© Copyright 2026