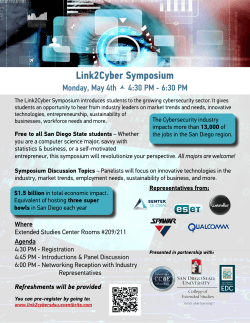

Winter 2015 Newsletter