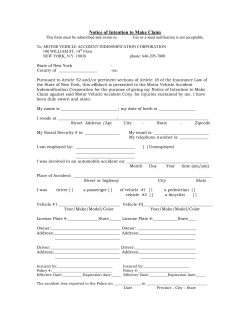

SAFETY AND LOSS CONTROL MANUAL 2009