Thermal Modification of Wood Presented by Jieying Wang Supervised by Dr. P. Cooper

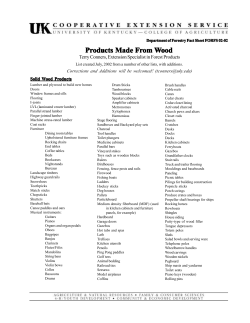

A presentation for course-- Thermal Modification of Wood Presented by Jieying Wang Supervised by Dr. P. Cooper Faculty of Forestry University of Toronto Objectives of Wood Thermal Treatment p Reduce the hygroscopicity of wood; Improve the dimensional stability of wood; Enhance the resistance against biological attacks; Color improvement? p Main advantage: Environmentally friendly. p p p Thermal treatment of wood is not a new technology! p Slight charring treatment: Poles, posts and structures; p Wood drying: Wood exposed to high temperature for some time will have lower hygroscopicity and lower shrinkage (Tiemann 1920, 1951); p Staybwood: Wood heat treated beneath the surface of a molten metal, oil or fused salt, by the U.S. Forest Products Laboratory (Tiemann 1951; Stamm and Harris 1953; Stamm 1964). p Post heat treatment of wood-based composites; p Decreasing growth stresses in wood (e.g. Eucalyptus); p Plasticizing wood (usually in the presence of water); p Fixation of compression or bending of wood; p Accelerating reactions in wood or composites; p Killing pests inside wood. Long-time conditioning of wood at low temperature p Old wood structures ASE (anti-shrinking efficiency) of old wood can be as high as 40%. p Species related, e.g. Teak Rosewood low temperature drying-- 1. Main Processes of Thermal Treatment of Wood in the Industry --Thermo Wood (or Premium wood) in Finland --Retification Process (New Option Wood) and Le -Bois Perdure in France --Plato Process in Netherlands --Oil-heat treatment in Germany (OHT-Process) 1.1 Thermo Wood (or Premium wood) in Finland Fresh wood Wood drying T: 100 C, then 130 C Time: 0-48 hrs Heat treatment T: 150 -- 240 C Time: 4 hrs Media: Steam Cooling and conditioning T: 70 C Time: 24 hrs Developed by VTT Building Technology, Finland (Syrj Syrjäänen and Kangas 2000; Syrj Syrjäänen 2001; Jä ms msää 2001; Militz 2002a, 2002b; Welzbacher and Rapp 2002; P. Kamdem 2002) 1.2 Retification Process (New Option Wood) and Le Bois Perdure in France p Retification Process (Developed by the Ecol des Mines de Saint It treats air-dry wood (12 % m.c.) in a specific vessel at about 240 C and in a nitrogen atmosphere with less than 2 % of oxygen; Etienne and commercialized by S. A.): p Le Bois Perdure Process starts with fresh wood, applies to the wood with a fast drying and high-temperature treatment under steam atmosphere. (Dirol and Guyonnet 1993;Vernois 2001; Militz 2002a, 2002b; Welzbacher and Rapp 2002; Jermannaud et al. 2002 ; P. Kamdem 2002) 1.3 Plato Process in Netherlands Green or air-dry wood Hydrothermolysis T: 160-190 C Time: 3-5 days Pressure Dry curing T: 170-190 C Time: 14-16 hrs Conditioning Time: 2-3 days (MC: 10 %) (Tjeerdsma et al. 1998a, 1998b, 2000; Militz and Tjeerdsma 2001; Boonstra et al. 1998; Militz 2002a, 2002b; Welzbacher and Rapp 2002 ; P. Kamdem 2002) 1.4 Oil-heat treatment in Germany (OHT-Process) p It is carried out in a closed vessel, with hot crude vegetable oil circulating around the wood during the treatment, usually at the temperature of 200-220 C. (Sailor et al. 2000a, 2000b; Rapp and Sailer 2001; Militz 2002a, 2002b; Welzbacher and Rapp 2002 ; P. Kamdem 2002) (from Rapp and Sailer 2001) Table 1. Comparison among the five wood heat treatment processes Media Wood initial M.C. Treatment Temperature( C) Steps Approximate Cost (Euro/m 3) Oil-heat treatment (Germany) Hot oil Air-dry, e.g., 6% 180~220 One step Thermo Wood (Finland) Steam Fresh wood 150~240 Temperature rising and drying, heat treatment, and cooling and condtioning Retification process N2 Air-dry, e.g., 12% 200~240 One step 150~160 Bois Pserdure Steam Fresh wood 200~240 One step 100 Plato process (Netherlands) Steam or air Green or air-dry wood 170~190 Hydrothermolysis, drying, and curing 100 65~95 1.5 Applications of thermally Treated Wood Above ground non-structural use: Siding, cladding; Decking and flooring; Garden furniture; Children playground; Window and doors frame; Indoor furniture; Musical instrument. (From P. Kamdem. 2002) (From P. Kamdem. 2002) (From P. Kamdem. 2002) (From P. Kamdem. 2002) 2. Properties of Thermally Treated Wood ----Durability: Biological durability, weathering, reological properties ----Hygroscopicity, dimensional stability and water absorption ----Mechanical properties 2.1 Biological Durability --Against microorganisms: bacteria, fungi (blue stain, white rot, brown rot, soft rot) --Against insects: e.g. beetles, termites --Against marine borers: e.g. shipworms Biological durability of treated wood p Staybwood: Considerable decay resistance (Stamm and Harris 1953; Stamm 1964); p Thermo Wood: Improved biological resistance at higher than 220 C and longer than 3 hrs, no increasing durability in ground contact (Jämsä and Viitaniemi 2001); p Retification process: Temperatures of 230~240 C are ideal for the durability (Vernois 2001); p Plato process: Improved durability against decay fungi and soft rot fungi, especially against brown rot fungi. And the hydrothermolysis has more effects on soft rot and brown rot decay, while the curing step has more effects on white rot decay (Tjeerdsma et al. 2000, 1998b; Militz and Tjeerdsma 2001); p Oil-heat treatment: At the highest temperature of 220 C, the wood gains the highest resistance against fungi, especially to brown rot fungi, but no improved durability against marine borers (Rapp and Sailer 2001; Sailor et al. 2000a, 2000b). Durability classification of treated wood p The Plato wood and the oil-heat treated wood can be classified as “durable”, the Thermo wood and the Retified wood can be classified as “moderately durable” (according to EN 350-1), but there are only slight differences in the mass loss during decay tests among the four processes (Welzbacher et al. 2002); p The heat treatment of the French process could improve the durability of wood from non-resistant to moderate or resistant species depending on the fungi (ASTM 2017), but the treated wood was not sufficiently decay resistant to ground contact use without further protection (Kamdem et al. 1999, 2002). Special reports---- Resistance of oil heat treated wood to Formosan Subterranean Termites (by W. R. Smith et al. 2003) Scots Pine Norway Spruce Heat treatment Media: rape seed oil T: 220 C Time: 4 hrs Conditioning T: 120 C hot air Time: 24 hrs Vacuum pressure Impregnation T: 120 C 15 mins V at 20 mbar, 15 mins P at 10 bar Conditioning T: 120 C hot air Time: 24 hrs Retention: 0.40 gm/cc (Sample preparation was done by Bundesforschungsanstalt fur Forst- und Holzwirtschaft and provided to the Louisiana Forest Products Laboratory) Hot oil treatment schedule Average density change before and after treatment SPHT: Scots pine heat treatment SPHTI: Scots pine heat treatment and impregnation NSHT: Norway spruce heat treatment Results of sample weight loss and termite mortality after 28 days no choice laboratory test SPC: Scots pine control SPHT: Scots pine heat treatment SPHTI: Scots pine heat treatment and impregnation NSC: Norway spruce control NSHT: Norway spruce heat treatment SYPC: Southern yellow pine control Main results of this study p Only heat treatment in hot oil was not effective to resist Formosan subterranean termite. p Scots pine with a combination of hot oil treatment then vacuum pressure treatment with hot oil was found to show promise in increasing resistance to FST attack (28 days, AWPA E1-97). Formosan subterranean termite 2.2 Weathering resistance --Against UV: color change, wood degradation (especially lignin) and surface roughness; --Against moisture fluctuation: swelling, crack; --Against temperature fluctuation and other outdoor conditions Special reports---- Weathering of ThermoWood (by S. Jämsä et al, 2000) Heat treament T: 225 C Time: 6 hrs Planed or sawn spruce and pine (WL higher than 10%) Coated with commercial coatings for exterior cladding, window joinery or fences CCA treated as reference Weathering vertically on the racks in Espoo, in Finland Weathering assessment (Color, roughness, crack, flake of coating, MC of wood) Weathering of uncoated heat treated wood---- Moisture change---- Moisture change ---- Performance of the coating---- Conclusion of this study p Without coating the heat-treated wood is not weather resistant. The original dark brown color turns grey. p Cracking of the heat-treated wood without coating was at the same level as that of the untreated wood despite the lower moisture content of the heattreated wood. The unpigmented or low build stains and oils did not prevent cracking of the heat-treated wood. p Weather resistance of the heat-treated wood was improved by the water- or solvent-borne paints. Heat treated wood as a substrate for coatings is comparable to untreated wood . 2.3 Hygroscopicity, Dimensional Stability and Absorption --Hygroscopicity : i.e. Adsorption of wood; --Dimensional stability: ASE (important index); --Water absorption: Related to porosity of wood Anti-swelling efficiency (ASE) S: Swelling; Dw: Wet dimension, after immersion in water or conditioned at high humidity; Dd: Dry dimension, after ovendrying. ASE: Anti-swelling efficiency; Snt: Swelling of non-treated sample; St: Swelling of treated sample. Results of Staybwood-Heating at 320ºC for 1 min or at 150ºC for 1 week, ASE: 40% to 50%; The temperature decreases linearly with the increase of the logarithm of the time for a given ASE; The ASE increase seems to be associated with the darkening of wood. T (ºC) (Stamm and Harris 1953; Stamm 1964) Results from Europe-p Thermo Wood: Wood gains the swelling reduction of about 80% to 90%, while its equilibrium moisture content (EMC) is reduced by 40% to 60% (Syrjänen and Kangas 2000); p Retification Process (New Option Wood): Heating in nitrogen at the temperatures of 180 C to 220 C, EMC of wood is 4-5%, instead of 1012% (Vernois 2001), and the corresponding dimensional stability of wood is improved by about 50% (Jermannaud et al. 2002); p Plato Process: Wood can obtain the swelling (or shrinking) reduction about 50%, generally with the higher reduction in the tangential direction than in the radial direction (Tjeerdsma et al. 1998b; Militz 2002a, 2002b); p Oil-heat treatment: At 220 C for 4 hrs, wood has the fibre saturation point of 14%, compared with 29% (Rapp and Sailer 2001). Hygroscopicity results from D. P. Kamdem et al. (2002)-Heat treatment: Retification Process in France, Maritime pine, spruce, beech and poplar, dimensions of 5 cm*10 cm *200 cm, at 200-260ºC for 1-24 hrs. The reduction of hygroscopicity seems more obvious for hardwoods and at higher humidities. Swelling results from D. P. Kamdem et al. (2002)-- The swelling in water is reduced, but the swelling in NaOH? Swelling reduction of Eucalyptus (Santos 2000) Water absorption Water adsorption p The thermally treated wood may have higher water absorption (Vernois 2001), larger pore sizes and broadened pore size distribution, and higher diffusion coefficient of water along the tracheid axis (Hietala et al. 2002). p Oil heat treated wood? Microstructure of Pine: Cell lumena and also pores in cell walls 2.4 Mechanical Properties --Toughness --Abrasion resistance --MOR (modulus of rupture) --Hardness --MOE (modulus of elasticity) --Screw and nail withdrawl load Effect of heat on mechanical properties p Youngs (1957): Most of the mechanical properties or rheological properties of wood in the transverse direction are significantly affected by the heat treatment at 82 C for 30 days; p Shafizadeh and Chin (1977): Wood may lose 10% of its original MOE heated at 120 C for about one month. Mild heat treatments at temperatures ranging from 140 C to 200 C within certain time limit increase the MOR and MOE of wood (Dwianto 1999a; Santos 2000). n The biggest disadvantage—Great reduction of mechanical properties! The reduction of the mechanical properties depends on the temperature, time, heating media of the heat treatments, the species and so on: Drastic reduction of the mechanical properties of wood, especially the toughness, abrasion resistance and MOR. For the hardness, a reduction of 21% at ASE of 40% and a reduction of 33% at ASE of 60% for wood heat-treated in the absence of air were reported (Stamm and Harris 1953; Mitchell 1988); Retification process: Heat treatments may decrease the MOR of wood by 30% to 40% at 230 C (Vernois 2001); Oil heat treatment: At 220 C, the MOR is about 70% of those of the untreated samples, while the MOE does not drop greatly. The impact bending strength is only about 51% of the value of the controls (Rapp and Sailer 2001; Sailor et al. 2000b). Bending results from D. P. Kamdem et al. (2002)-- The bending performance of Beech was more severely attacked! 2.5 Other changes after heat treatment of wood p p p Color darkening; Weight loss and density decrease (YILDIZ et al. 2003); Smell. However, the emission factor of Thermo Wood, expressed as TVOC and as specific compounds, was less than that of the untreated reference (Bengtsson et al. 2003); p p p Spotted discolorations of rosins (Jamsa and Viitaniemi 2001); Disappearance of rosins on the oil-heat treated wood (Rapp and Sailer 2001) and remove of blue stain in Retification Process? Coating characteristics: For Thermo Wood, adhesive performed very well whereas PVAc adhesive showed an unacceptable percentage of delamination (Bengtsson et al. 2003). 3. Chemical Changes of Wood during Thermal Treatment --Changes of extractives in wood? --Changes of hemicellulose --Changes of cellulose --Changes of lignin Cell wall structure of wood ML: Middle lamella P: Primary wall S1: Outer layer of secondary wall S2: Middle layer of secondary wall S3: Inner layer of secondary wall http://www.extension.umn.edu/distributi on/naturalresources/images/6413f1-7.gif General heat stability of wood components p Wood begins to degrade obviously at the temperature of about 165 C (Stamm and Hansen 1937). Heat Stable? Hemicellulose 225 ~ 325 C Decomposition temperature Cellulose Lignin 325 ~ 375 C 250 ~ 500 C (Shafizadeh and Chin 1977) 180 ~ 300 C 240 ~ 400 C 280 ~ 550 C (Kuriyama 1967) Traditional explanations of chemical changes p Ether linkages? But the swelling of the treated wood in sodium hydroxide, pyridine, or morpholine was still high, instead of the reduced swelling as in the case of formaldehyde crosslinked wood (Stamm and Hansen 1937; Seborg et al. 1953; Stamm and Harris 1953; Stamm 1964); p The improved dimensional stability and decay resistance are attributed to the formation of cross linking and esterification reactions during the heat treatment (P. Kemdem 2002); p The formation of furfural, a less hygroscopic substance from hemicellulose (Stamm and Hansen 1937; Seborg et al. 1953; Stamm and Harris 1953; Stamm 1964) and also from cellulose; p But furfural is unstable in the reaction mixtures and its amount is not high enough to be so critical for the wood properties (Bourgois et al. 1988). Explanation from Plato Process Hemicellulose Hydrothermolysis: Hemicellulose Cellulose Formaldehyde Furfural Water Acetic acid Lignin Degrade Autocondense Curing step: Lignin CH2 Lignin Esterification and other reactions (Tjeerdsma et al. 1998a; Militz and Tjeerdsma 2001) Chemical changes of hemicellulose-- and amorphous and short-chain polymer! http://natural-resources.ncsu.edu:8100/wps/k12activities/ppts/forest/img043.gif Chemical changes of hemicellulose p Generally, hemicellulose (more pentoses) of hardwoods is more unstable than that of softwoods (more hexoses ) (Kamdem et al. 1999, 2002; Bourgois et al. 1988); p Much of the acetic acid (and water?) should be attributed to the decomposition of hemicellulose, especially to hemicellulose with acetyl groups, and hardwoods have higher acetyl groups than softwoods (Browne 1958; Bourgois et al. 1988; Sivonen et al. 2002); p Thermo Wood: The destruction and deacetylation of hemicelluloses is one of the most remarkable changes of thermally treated wood revealed by solid state NMR (Sivonen et al. 2002). p Heat decomposition of beech with restricted air supply: Pentosan content decreases by 8% at 171 C and decreases by up to 20% at 206 C. At 245275 C, 45% of the pentosan and 40% of the acetyl groups are decomposed or separated (Sandermann and Augustin 1964). Side proofs for hemicellulose decomposition p After slight pyrolysis: the hydrogen and oxygen decrease, while the carbon ratio increases greatly (Bourgois et al. 1988; Dirol and Guyonnet 1993); p The treated wood shows a rapid drop of the hydrophilicity from the beginning of torrefication (Bourgois et al. 1988); p Heat treatment of paper causes less strength loss (less darkening?) due to less hemicellulose present in paper (Stamm 1964); p The loss of hemicellulose during incipient brown rot decay of southern pine leads to high levels of strength loss, and the significant loss of glucan (representing cellulose) was barely detected until more than 75% of the original MOR was lost, and the MOR loss appeared to occur at a greater rate than the MOE loss (Curling, 2001). Conclusion for hemicellulose decomposition p It seems reasonable that the increase of dimensional stability and biological resistance, and the reduction of mechanical properties during heat treatments are mainly attributed to the breakdown of hemicellulose; p The degradation products from hemicellulose are not confined to furfural only, and there could be some cross-linking and polymerization reactions associated with hemicellulose taking place during heat treatments of wood. Chemical changes of cellulose-- With high polymerization and crystallinity degree. http://natural-resources.ncsu.edu:8100/wps/k12activities/ppts/forest/img039.gif Changes of cellulose p p p p Sandermann and Augustin 1964: During heat pyrolysis of cellulose, only insignificant decomposition takes place before 257 C and its IR and X-ray spectra remain unchanged, though the numbers of carboxyl and carbonyl groups increase a little; Bourgois et al. 1988: Cellulose does not undergo noticeable modifications in its crystallinity during torrefication of wood sawdust at 260 C by studying its X-ray spectra. Sivonen et al. 2002: The most remarkable changes revealed by solid state NMR were the increase in relative crystallinity of cellulose. Brown 1958: Some of the carbon-to-oxygen bonds in the links between glucosan units of cellulose might cleave along the chains early in the pyrolysis, especially in the presence of water and some acids, and levoglucosan was the characteristic product of the primary pyrolysis of cellulose. Chemical changes of lignin-- Structure of lignin Methoxyl Softwood: Guiaicyl Hardwood: Syringyl Ether Methylene From http://helios.bto.ed.ac.uk/bto/microbes/lignin.jpg Changes of lignin p During heat treatments, the lignin content and the carbon content in wood increase (Bourgois et al. 1988; Dirol and Guyonnet 1993), especially for hardwoods with higher contents of hemicellulose (Kamdem et al. 1999, 2002). p After torrefication of sawdust at 260 C for 4 hrs, lignin increases from 28% to 84%, analysed by sulphuric acid method (Bourgois et al. 1988). p The ether linkages in lignin are easier to cleave during pyrolysis (Browne 1958). From 200ºC to 250ºC, carbon dioxide and other compounds are liberated from lignin; from 250ºC to 400ºC, phenolic and neutral oils etc. are produced, some of them tend to polymerize, and the heat decomposition of lignin becomes exothermic at about 270ºC (Stamm and Harris 1953, p. 66). p Changes in the lignin fraction were mostly registered as diminishment in the methoxyl content (Sivonen et al. 2002). Condensation of lignin p Funaoka et al. (1990) found that during heat treatments of wood at the temperatures from 120 C to 220 C, lignin mainly undergoes the diphenylmethane type of condensation, especially in the presence of moisture in wood. p Lignin seems to be the most reactive among wood components in auto-crosslinking reactions (Back 1967; Back 1987); p Thermo Wood: Demethoxylation of lignin and stable free radicals are observed and it is believed that the radicals take part in condensation reactions leading to crosslinks within lignin and possibly with other components present (Sivonen et al. 2002). Conclusion of lignin changes p There are some cleavage reactions in the weak points of lignin, and there are also some condensation reactions associated with lignin and also with some breakdown products from the main components of wood cell walls. Lignin and acid number changes results from D. P. Kamdem et al. 2002 The increase of lignin means the decomposition of hemicellulose even a little cellulose during the treatment, especially for beech with more pentoses than hexoses. The acid numbers indicates the carboxylic groups or those which are highly susceptible to converting into carboxylic groups in wood, which are reduced during the heat treatment. 4. Effects of External Factors on Thermal Treatment of Wood --Oxygen --Moisture --Inorganic chemicals --Various heating media 4.1 Effect of oxygen—Oxidation? p Most of the heat treatments are carried out in the absence of oxygen, for biological resistance and mechanical properties of wood? p Presence of air during heat treatments leads to higher ASE, higher weight loss, and oxygen acts like a catalyst for the changes of wood components during heating (Dwianto et al. 1997; Wang et al. 2000a); p Mitchell (1988) found that the effects of oxygen on thermal degradation of wood depended on the MC of wood, with greater effects on oven-dry specimens, and oxygen had more influence on MOR and MOE than on reflectivity of wood surfaces. Comparison of ASE of heat treated fir in air or in relative vacuum ASE (%) Treatment time (hr) Comparison of WL of heat treated fir in air or in relative vacuum WL (%) Treatment time (hr) 4.2 Effect of moisture—Hydrolysis of wood and degradation of heating media? p The existence of water in wood during heating must speed up the heat transfer, and accelerate the decomposition of the main components of wood cell walls, since hydrolysis is one of the easiest reactions for wood carbohydrates; p Skaar reported that the heat degradation was 10 times faster for wet wood than for dry wood (reviewed in Yildiz 2002); p Burmester (1973) found that certain moisture in wood led to higher ASE and little reduced strength of wood under certain pressure, and the optimum MC of wood for the heat treatments ranged from 20% to 30%; p During kiln drying of wood, high humidity in the environment reduces the hygroscopicity of wood more than the low humidity does, while higher temperature is needed to achieve the similar reduced hygroscopicity in the case of dry wood (Hillis 1984). 4.3 Effect of inorganic chemicals Inorganic chemicals: e.g. phosphoric acid (H3PO4), diammonium phosphate ((NH4)2HPO4), diphenyl phosphate and zinc chloride (ZnCl2); Main function: Producing more charcoal, accelerating heat transfer? (Browne 1958; Shafizadeh and Chin 1977; 1977 Fung 1974, 1976; Stamm and Hansen 1937; Levan Levan)) Flammable gases levoglucosan Wood Cellulose Hemicellulose Lignin Tar levoglucosenone Char Effect of inorganic chemicals on pyrolysis of wood 4.4 Effect of different heating media p p p p p p Air Steam Nitrogen and other inert gases Molten metals Relative vacuum Other mineral or vegetable oils? Vegetable oils p All vegetable oil and animal fats consist primarily of triglyceride molecules as shown schematically below. R1, R2, and R3 represent the hydrocarbon chain of the fatty acid elements of the triglyceride. p The properties of the triglyceride will be determined by each fatty acid. Fatty acids are designated by two numbers: the first number denotes the total number of carbon atoms in the fatty acid and the second is the number of double bonds. For example, 18:1 designates oleic acid which has 18 carbon atoms and one double bond. http://www.me.iastate.edu/biodiesel/Pages/bio2.html --Composition of various oils and fats Myristic Palmitic Stearic Oleic Linoleic Linolenic Arachidic Gadoleic 14:0 16:0 18:0 18:1 18:2 18:3 20:0 20:1 Soybean 6-10 2-5 20-30 50-60 5-11 Canola 3.9 1.9 64.1 18.7 9.2 0.6 1.0 Hi erucic rapeseed 3.0 0.8 13.1 14.1 9.7 7.4 50.7 44.1 4.4 39.0 10.6 0.3 0.2 3-4 0-1 4-15 Oil or fat Palm 1.1 Tung oil 75-90 Lard 1-2 28-30 12-18 40-50 7-13 Tallow 3-6 24-32 20-25 37-43 2-3 0-1 --Oxidative Stability of Oils and Fats Rating Worst Best Fat or oil Inherent oxidative stability Total double bonds Calculated iodine value Safflower 9.546 168.8 146.1 Soybean 8.579 153.7 133.1 Sunflower 8.489 156.3 135.3 Corn 7.708 148.4 128.4 Cottonseed 6.895 130.1 112.6 Canola 5.349 131.3 113.3 Peanut 4.326 112.6 97.1 Lard 2.426 68.5 59.3 Olive 1.74 95.6 82.4 Palm 1.724 60.8 81.8 Tallow 1.267 55.6 48.4 Palm kernel 0.430 20.1 17.2 Coconut 0.360 11.1 9.6 --Approximate prices of oils and fats Oil or fat Price in 1997 (US $/ ton) Average price during 19921997 (US $/ ton) Tallow 457 392 Soybean 513 528 Sunflower 517 580 Corn 547 555 Fish oil 548 427 Rapeseed 565 563 Lard 575 561 Cottonseed 584 564 Palm 601 580 Linseed 799 747 Coconut 899 758 Castor 915 899 Palm kernel 915 899 Peanut 990 951 Safflower 1301 1344 Tung 2238 1560 Future research on wood thermal treatment p p p p p To develop the applications for such a modified wood material; To optimize the industrial processes and the various parameters; To find some new wood heat treatment processes; To try some combined wood modifications; To clarify the chemical changes of wood during the thermal treatment. Main References p p p p p p p Rowell, R. 1984. Solid Wood Chemistry. American Chemical Society, Washington, D. C. Stamm, A. J and E. E. Harris. 1953. Chemical processing of wood. Chemical Publishing Co., Inc, New York, America. 205-207. Stamm, A. J. 1964. Wood and Cellulose Science. Ronald Press, New York, America. 317-320. Tiemann, H. D. 1951. Wood Technology. Pitman Publishing Company, New York, America. 141-168. Frank D. Gunstone. 2002. Vegetable Oils in Food Technology: Composition, Properties and Uses. CRC Press; Richard D. O’Brien, Walter E. Farr and Peter J. Wan. 2000. Introduction to Fats and Oils Technology. Champaign, Illinois. P. Kamdem. 2002. Heat treatment: Can it replace preservatives? CWPA (Canadian Wood Preservation Association) Proceedings: 122-131. Questions and Advice? Thank you!

© Copyright 2026