2015 Issue

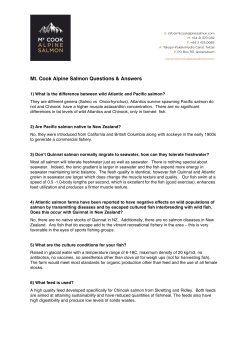

APRIL 2015 INSIGHT FISH PROCESSING NEW INNOVATIONS & NEW PRODUCT FEATURES FleXicut Automatic pinbone removal in whitefish FOCUS ON INNOVA SOFTWARE SOLUTIONS: Innova Labeling, OEE & Quality Control INSIGHTS FROM PROCESSORS OF ALL SIZES I N S I G HT CONTENTS – FI S H PR OCES S ING BRINGING TECHNOLOGY TO THE HEART OF FISH PROCESSING FACILITIES 03 BRINGING TECHNOLOGY TO THE HEART OF FISH PROCESSING with Marel’s FleXicut – automatic pinbone removal for whitefish. 05 STEPPING INTO THE FUTURE with Visir hf. & FleXicut. 06 FASTER, SHARPER, SMARTER PORTIONING with Hofseth International AS & Marel’s I-Cut 130 PortionCutter. 07 SUPERIOR SALMON FILLETING WITH BACK & BELLY TRIMMING with Marel’s MS2730 Filleting Machine. 08 FOCUS ON INNOVA Innova Labeling, OEE & Quality Control. 10 RAISING QUALITY MANAGEMENT TO THE NEXT LEVEL with Nordlaks & Innova Quality Control. 11 THE CERTIFIED BELT WEIGHER SHAPING THE FUTURE OF FISH PROCESSING – TOGETHER that raises the industry standard. We are excited about our innovations for the fish industry, and by the ongoing partnerships that make them possible. 12 PRODUCING WORLD-CLASS SALMON with Mt.Cook Alpine Salmon & a Marel filleting line. 13 HEAD FIRST INTO SALMON SKINNING with Marel’s new MS1710 Salmon Skinner. 14 PORTION CUTTER EXPANDS BUSINESS OPPORTUNITIES at Le Venec SA. 15 PORTION CUTTING ON A LARGE SCALE with Marel’s new I-Cut 610 PortionCutter. 16 FISH PROCESSING EVENTS at Marel’s Progress Point demo center in Copenhagen. We work with processors of all sizes to ensure that our products help raise their efficiency while optimizing yield and throughput and enhancing the overall quality and value of food. The challenges our customers face drive us to design the equipment and software solutions that will help them operate at peak productivity and create value, well into the future. From the water-jet cutter that removes pinbones in whitefish, to the salmon filleting machine that now includes back and belly trim – this edition of Insight Fish Processing highlights some of our most exciting innovations, and looks to the future of seafood processing with Marel. Sigurdur Olason Managing Director, Fish Industry Center, Marel The FleXicut water-jet cutter removes pinbones in whitefish – accurately and automatically. The machine has a neat footprint and a range of benefits, including greater product diversity, and higher yield and throughput. The precision of the machine’s cuts returns on average a greater yield than is possible with manual trimming, as well as ensuring uniformity in the cut and the size of pieces. IMPACT ACROSS THE WHOLE PROCESSING LINE Equipped with high resolution X-ray and water-jet cutters, Marel’s FleXicut incorporates two critical processing steps in one machine: precisely locating the pinbones and then cutting the fillet to remove them. The loin is the most valuable part of the fillet and so it’s crucial for processors to make the most use of it, cutting as close to the bone frame as possible. FleXicut can also divide the loin, cut the belly flap or tail, or portion the fish to customer specifications, skin-on or skin-off. A WIDER RANGE OF END PRODUCTS There are many ways to use the fillet, and FleXicut can make an intelligent decision on how to divide the fillet, taking into account the weight and shape of the fish being processed at the time, as well as customer parameters on yield. FleXicut is easily integrated into most existing factory layouts, and is the key element of the next generation of processing systems that will transform the whole processing floor. The variety in the range of possible cuts is one of the biggest benefits of the machine, as it helps processors maximize the value of the raw material and adjust cutting to meet orders each day, regardless of whether fillets are large or small. “The high level of technology and automation that this development brings us transforms the very nature of fish processing,” says Gudbjorg Heida Gudmundsdottir, Project Manager at Marel. “FleXicut utilizes fillets of all sizes very well,” says Gudmundsdottir, “and when we’re talking about facilities that process dozens of tons per day, this quickly adds up to significant gains in yield, which translates into significant profits for the processor.” An even greater variety of products is made possible as FleXicut can be used for skin-on fillets. This opens up the prospect of producing skin-on products such as skin-on loin and skin-on smart fillets. GETTING CLOSER TO BONELESS FILLETS The FleXicut’s X-ray can detect pinbones that might otherwise slip through manual trimming, significantly decreasing the bone ratio in the fillet. As Gudmundsdottir explains, “Producing boneless fillets is one of our goals as we continue to develop the whitefish systems in coming years.” TAKING FISH PROCESSING INTO THE FUTURE The FleXicut is the heart of the next generation of whitefish processing and the development of the whole system is driven by the technology of the water-jet cutter. Marel first introduced FleXicut early in 2014 and has come a long way towards developing the new generation processing flowlines, 2 3 V I S I R H F. C U S TO M E R I N S I G H T • I N S I G HT F L E XICU T – FI S H PR OCES S ING which are expected to be released by the end of this year. “FleXicut runs with Innova, and even more opportunities are expected to open up as we further develop the software for this new line – such as full traceability through the system, and integrated stock and order management” says Gudmundsdottir. Marel has already developed a product distribution system located after the FleXicut. These developments have been made possible thanks largely to Marel’s close partnerships with fish processors. “We regard this as a journey into the future with our customers,” says Gudmundsdottir. “Marel is bringing hi-tech to the heart of the fish processing factory and this will influence the entire process.” Petur Palsson, CEO of Vísir “It’s very important for us to be able to work so closely with the fish industry in further developing the technology that already enables higher yield, a greater variety in end-products, and better quality.” Strong partnerships with our customers are the bedrock of this new generation of whitefish processing equipment. Marel has a big team working on this project that has been following FleXicut through development and implementation, first in Iceland and Norway, and will continue to do so as the machine is installed in nearby whitefish markets such as Denmark, the UK and Canada, and then more widely. GO TO: marel.com/fleXicut “We regard this as a journey into the future with our customers... further developing the technology that already enables higher yield, a greater variety in end-products, and better quality.” Gudbjorg Heida Gudmundsdottir, Project Manager at Marel STEPPING INTO THE FUTURE WITH VISIR Vísir hf has now been running FleXicut together with automatic pinbone removal and product distribution since February 2015. They are primarily using FleXicut for cod and haddock; with catfish, ling, and redfish also being cut, but not as primary products. Vísir hf. is a fishing, processing, and sales company with four facilities around Iceland. The company produces a diverse product range from various kinds of fish, most of which are caught on long-line by its own fishing fleet. The possibilities for Vísir’s production are almost endless. Salted fish has always been one of the company’s primary products, but its product line also includes a large selection of frozen, fresh, and dried products. Petur Palsson, CEO of Vísir, explains 4 the main benefits of FleXicut for the company: “We’re definitely seeing that the variety in products that we can produce, and having uniform product every time, are great benefits.” “In addition, FleXicut is now doing the same job as 10 employees on the flow line used to do, and the yield is meeting our goals.” “With FleXicut, Marel is bringing hi-tech to the heart of the fish processing factory and this will influence the entire process,” says Palsson. “This is one of the biggest steps towards automation that we’ve seen for a very long time in fish processing technology.” can bring high value to the industry,” Palsson explains. “There are many opportunities out there and we have always worked well with Marel and knew that together we would come up with a solution that would meet all our requirements.” GO TO: marel.com/fleXicut Marel has enjoyed a strong partnership with Vísir for many years. “For the seafood industry, working together with a company like Marel 5 H O F S E TH INTERNATIONAL CU STOM E R INSIGH T • POR TION CU T T E R • FASTER, SHARPER, SMARTER PORTIONING Hofseth International AS saw the need to upgrade their existing portion cutting equipment to meet significantly increasing customer demand. The I-Cut 130 PortionCutter, with its high capacity and high level of accuracy, was the perfect solution to their requirements. Norwegian company Hofseth International AS has a long tradition in fish processing. Each year, they produce approximately 25,000 tons of salmon products which are consumed all over the world. Around 95 per cent of their products are exported, with their largest market being North America. They see their ability to quickly adapt to market and customer requirements as one of their unique strengths. And Marel’s portion cutting equipment plays an important role in helping them to do this. An increase in customer demand meant they needed to be able to cut with very high levels of accuracy whilst running at extremely high speeds. Their existing Marel portion cutters were only four years old, but they saw the potential profit that could be gained from the I-Cut 130 PortionCutter’s increased capacity, higher precision, and innovative software. IN-HOUSE TESTING SEALS THE DEAL Finn Olaf Stokkereit, Technical Manager at Hofseth, first saw the I-Cut 130 PortionCutter at the Boston Seafood Show. “Seeing the machine in action at the trade show, really opened my eyes to its full potential. Its innovative portion cutting technology means it can process higher volumes and reach greater accuracy levels than anything I’ve experienced before,” he explains. An agreement was reached for Hofseth to test an I-Cut 130 PortionCutter at one of their two modern production facilities in Norway. The trial delivered immediate results and the company decided to invest in three portion cutters, which were installed in both their factories in Ålesund and Syvde. GETTING AHEAD WITH FASTER & SHARPER PORTIONING Marel specifically developed the I-Cut 130 PortionCutter to enable salmon processing companies to keep pace with the constantly escalating demands from retail and food service customers. “Just three months after installing the I-Cut 130 PortionCutter in Ålesund, we were able to significantly increase monthly throughput,” says Stokkereit. “We saw an immediate increase in volume to 1,150 tons of raw material per month – something we have never achieved before.” But it’s not just throughput that’s important in salmon processing. A vital part of supplying retailers with fixed-weight packs is being able to supply an exact weight without the risk of it being under-weight, while also ensuring give-away is kept to an absolute minimum. “We are selling our products in fixed-weight packs, with a specific number of portions in each,” says Stokkereit. “With the I-Cut 130 PortionCutter, we can now hit this fixed weight more precisely than ever before, reduce the give-away considerably and increase our yield. This has given us an incredibly fast return on our investment.” NEW GENERATION SOFTWARE OPTIMIZES YIELD One of the main attractions for Hofseth when purchasing the I-Cut 130 PortionCutter was its advanced software. The numerous innovative cutting patterns and features combine to maximize raw material utilization and profits. “The software is very user-friendly and easy for our employees to operate. The flexibility of the cutting FI LLE T I N G MAC HI N E I N S I G HT – FI S H PR OCES S ING programs gives us the options to better utilize raw material, ensuring that more of each fillet is used for our more valuable products,” says Stokkereit. “The I-Cut 130 PortionCutter Quick Weight Adjustment feature has also helped to increase the accuracy of our portion cutting,” Stokkereit adds. “This feature makes it possible to readjust target weights during production without stopping the machine.” RESPONDING TO INDUSTRY TRENDS Not only was customer demand increasing, there was also a requirement for portions cut at a 45 degree angle. The I-Cut 130 PortionCutter is one of the few machines available that can do this. “Our customers in the US have a specific requirement for portions cut at a 45 degree angle, as this gives a larger coverage of the plate. The I-Cut 130 PortionCutter gives us a real competitive advantage in being able to offer this,” says Stokkereit. PLANNING FOR THE FUTURE SUPERIOR SALMON FILLETING WITH BACK & BELLY TRIMMING The MS 2730 Filleting Machine has proven itself as one of the most advanced salmon filleting machines on the market today, and more than 50 have been installed in all sizes of salmon processing facilities in nearly 20 countries around the globe since it was launched in 2012. The MS 2730 takes salmon filleting to a new level in terms of yield, throughput, and automation. Capable of filleting up to 25 fish per minute, it comes with automatic adjustment for a variety of sizes from 2 to 8 kg. “We are always looking for new markets and products and we need to respond quickly to new trends in the industry and to customer demand,” Stokkereit explains. Marel has recently introduced two groundbreaking new features to the filleting machine: back and belly trimming. Including trimming functions in a filleting machine is unique and saves on labor costs by further reducing the need for manual trimming. “Marel continues to deliver the equipment that helps us do this. We also truly value Marel’s local presence, support, and service.” The MS 2730 makes filleting fast and easy by having fish placed belly-down at the in-feed. A set of circular knives cuts the fish from gut to tail, producing additional yield by including the meat close to the center bone in the fillets. The end result is high-quality fillets with improved yield and increased throughput. GO TO: marel.com/portioncutting The unit’s user-friendly multilingual touch screen makes operation extremely easy, providing maximum safety for the operator and reducing downtime arising from mechanical issues. Programs can be stored and used for specific fish sizes, or the machine can perform at a high level by using the automatic size adjustment feature. • High-quality output & high throughput for both pre-rigor & post-rigor fish • Increased yield with an extra cut made from the vent to the tail • Automatically adjusts to fit fish from 2-8 kg • Easy & safe operation via user-friendly touch screen • Easy, fast cleaning process GO TO: marel.com/filleting 6 7 F O C U S O N I N N O VA • I N N O VA L A B E L I N G FOCUS ON INNOVA Innova Software Solutions combine Marel’s production management software and processing know-how to provide full traceability and deliver detailed information on all key processing data from receiving to dispatch. With key performance indicators (KPIs) relating to every stage of processing, users can control and monitor virtually every aspect of the production process in real time – from throughput, yield, and performance to giveaway, product quality, and stock levels. This enables fish processors to improve decision-making in order to maximize yield and throughput, conform to quality standards, ensure food safety, achieve full traceability, and raise efficiency. • I N N O VA O E E • I N N O VA There are many reasons why processing machinery doesn’t always run at 100 per cent. Stoppages, running at reduced speed, or producing products outside the machine’s specifications are among the possible reasons machinery might not be operating effectively at full capacity. But in order to improve performance it’s important to know precisely what is hindering performance. Marel developed Innova Labeling to meet the food industry’s need for control and automation of the labeling process from receiving to dispatch. The Innova OEE module helps you determine and understand the exact reason for any reduction in efficiency so that you can improve your processes, by providing you with all the necessary data to identify inefficiencies. “We use Innova as a daily tool. It’s a way of life for us.” The software provides OEE figures and collects real-time data about process performance. It compiles performance profiles which include detailed figures for breaks, quality losses etc. It also presents key figures that show, for example: Availability – potential vs actual production time Performance – theoretical output vs actual output Quality – the number of products produced to specification vs rejected products Data can also be compiled for multiple lines, in order to easily spot performance differences. 8 PR OCES S ING The new Innova OEE module calculates Overall Equipment Effectiveness (OEE) and provides fish processors with detailed information about the performance of their processes. This enables them to easily identify opportunities for improvement and quickly implement corrective actions. Marel’s Innova Labeling software, for example, enables fish processors to create labels that fulfill the new EU legislative requirements that came into force in December 2014. – Rob Smith, Head of Operations, Morrisons, Grimsby, UK FI S H EQUIPMENT EFFECTIVENESS HOW CAN THE OEE MODULE HELP YOU? The legislation includes changes to mandatory nutrition information on processed seafood, mandatory labeling of catch area or country of production, and allergens information requirements. – INNOVA OVERALL MEETING THE NEW EU LABELING LAWS All fish processors operating within the EU need to comply with the new EU Regulation 1169/2011, which affects labels accompanying all fishery and aquaculture products for EU consumers. I N S I G HT Q C QUICKLY IDENTIFY PRODUCTION PROBLEMS Most importantly, the Innova OEE module presents data in the form of easy to interpret charts and graphs so that you can see at a glance how everything is running. Any improvements required are highly visible and easy to understand. The full report suite and analysis tool make it possible to quickly identify and address the cause of costly production losses. RESPOND IMMEDIATELY TO PRODUCTION PROBLEMS Innova OEE enables you to respond quickly if production is running inefficiently by capturing real-time data which can then be acted on immediately. The software identifies the reasons for stops or losses, then registers the details, which allow you to conduct an evaluation. Corrective actions can then be implemented immediately in order to improve equipment effectiveness. Once corrective actions have been initiated, the software tracks the effect of the improvements and quickly identifies whether the expected outcome has been achieved. GO TO: marel.com/INNOVA INCREASE PRODUCT QUALITY & VALUE WITH INNOVA QUALITY CONTROL With Innova QC, all inspections are directly linked to production, raw material source or final products, for full traceability. Our ultimate aim is to give you paperless control and automation of your quality control. Innova handles various inspection items, inspection processes, and responses to quality assurance inspection results, all configurable by the user: from raw material and product inspections, to box/pallet inspections. • Enable real-time monitoring & rapid response to quality deviations • Link quality data with traceability information • Customize inspection lists & scheduling • Perform offline inspections 9 F O C U S O N I N N O VA “Until now, with everything written down on paper, I can only look back to see for example, a result from yesterday. But with Innova QC we can get a report to see what’s happening now.” – Camilla Kortsen, Quality Manager at Nordlaks • N O R D L A K S C U S TO M E R • I N N O VA Q C • F LO W S C A L E RAISING QUALITY MANAGEMENT TO THE NEXT LEVEL Innova Quality Control (QC) is a ready to use software solution that has proven itself for use in all industries. Innova QC has been developed and designed for food processors to manage their quality control and monitoring system more effectively and with much less paper. At the end of the day, it all comes down to maximizing value by enabling customers to produce safe and wholesome end products with the highest possible quality. And what Marel offers its customers with Innova QC is a user-friendly toolbox to do exactly that. “Marel is the first to offer this kind of product, this kind of solution with Innova,” says Camilla Kortsen, Quality Manager at Nordlaks in Northern Norway. Nordlaks recently celebrated 25 years of producing, processing, and selling Atlantic salmon and Rainbow trout. The company has been working with Marel since the 90s and is now implementing Innova QC. Innova QC workshops run during the installation and implementation phases ensure that the software is meeting expectations, and provide the training that ensures each customer gets the most out of the solution. Combined with ongoing service, the workshops help ensure customers can raise their quality management to the next level. The workshops also strengthen Marel’s partnerships with the fish processing industry, ensuring we stay at the forefront of serving the market’s ever-changing needs. INNOVA QC WORKSHOPS WITH NORDLAKS During workshops, the Innova team 10 I N S I G H T works with customers to design, customize, and implement a user-friendly and potentially paperless QC system, ensuring they can make the best use of the software. “The workshops are very helpful,” Kortsen explains. “If we have a question – can we do this, is this possible – we get an answer very quickly.” “The Innova technicians visiting Nordlaks can understand better what we are doing – we can say, ‘Let’s go down to the production and I’ll show you,’” Kortsen adds. Innova QC workshops help customers make the best use of the software to improve their processing performance. As Rich Otley, Cold Store Manager at Nordlaks, explains, “At the workshops here [in Iceland], being so close to the people doing the hard coding really speeds up the process.” This helps ensure that Norlaks can make the best use of the solution right from the start. “The workshops are a good way to pool resources and find new solutions; adjust it to fit our requirements,” says Otley. DESIGNED FOR A VARIETY OF QC NEEDS In short, Innova QC helps processors catch potential problems early, react in real time, and therefore minimize the risk of compromising the quality of end products. Innova QC is also a great solution for continuously improving quality, increasing food safety, and minimizing time in rework. on factors including the size of the processing operation and the range of processes, as well as industry or country-specific regulations. With this in mind, Marel has developed the Innova QC module to ensure processors can integrate dependable quality control inspection in their processing plants, while being flexible enough to suit the whole range of processing operations and to support various international food safety standards. Each adjustment and update must be tested thoroughly, as it’s vital that customers can rely on their production management software. “Our suppliers’ level of quality control is very important and my experience with Innova is that they’re very thorough,” says Otley. “We don’t get even the smallest change or update until it’s been quality controlled, until it does actually work as designed.” INNOVATING TOGETHER It’s exciting for Marel to be able to offer the food processing industry a new level of quality control, and the product has been strengthened considerably by Marel’s partnership with Nordlaks and other processors. “I feel we’ve stretched this QC module to something it wasn’t in the beginning,” says Otley. “It’s getting beyond our expectations now, and it’s only going to grow and get even better, because we can see the potential, the possibilities.” I N S I G HT – FI S H PR OCES S ING THE CERTIFIED BELT WEIGHER THAT RAISES THE INDUSTRY STANDARD The Flowscale belt weigher is unique in the way it keeps fish on the same level in order to ensure gentle handling. It was released in 2014 with EU, OIML and US NTEP approvals, and is now fully certified. Designed for high-volume weighing of pelagic species, whitefish, and salmon, Marel’s Flowscale is a self-contained belt weigher that sets an industry benchmark in its category by gently weighing up to 100 tons of fish per hour in a continuous flow. “We’re very happy with the performance of the Flowscale. We’ve noticed a significant improvement in handling and efficiency, which is great for maintaining the quality of the fish.” – Robert Parsons, Vessel Manager M/V Northern Victor, Icicle Seafoods, Seattle The compact, high-capacity Flowscale was designed specifically to maintain quality by handling fish gently. The Flowscale is more efficient and effective than its predecessors, and it replaces methods of weighing that inherently diminish product quality, such as hopper-scale weighing. The Flowscale continuously records the weight of product moving across it and displays this data on an M2200 terminal, then registers the accumulated weight for each lot. It is ideal for measuring the total catch of fish coming from a fishing vessel into a processing factory, as well as for measuring the total amount of fish product in and out of a specific process. The Marel Flowscale is Weights & Measures approved for use in commercial businesses, and has received EU, OIML and US NTEP certifications. This fulfills legal requirements, which widely mandate fish processors to have an approved, in-weighing process for raw materials. Using Innova Software Solutions, each flow can be set up through the system based on customer, vessel, and other specifications. Throughout the process, Innova collects flow information and generates reports as needed. The system includes Alibi memory storage that can be crossreferenced with Innova reports for validation purposes and legal requirements. GO TO: marel.com/flowscale GO TO: marel.com/INNOVA But quality control procedures and requirements vary greatly among processors and food safety management standards, depending 11 11 12 M T. CO O K A L P I N E S A L M O N C U S TO M E R I N S I G H T • F I L L E T I N G L I N E • I N N O VA • S A L M O N S K I N N E R I N S I G HT – FI S H PR OCES S ING PRODUCING WORLD-CLASS SALMON EFFECTIVELY & ECONOMICALLY Mt. Cook Alpine Salmon factory processes extremely high-grade salmon using a Marel filleting line and INNOVA Software Solutions. Mt. Cook Alpine Salmon has achieved vertical integration with the completion of a purpose built processing facility at Timaru in New Zealand. Opened in late 2013, the new factory was a milestone for the organization, which is setting out to own and control all the steps from farm through to sales. The factory enables Mt. Cook to handle all of its wet fish processing in-house as production increases. “In line with our business strategy we are experiencing very rapid growth,” Mt. Cook Operations Manager Adrian Hill explains. “It will grow with our production, but most importantly it will allow us to continue to produce extremely high grade salmon, even as production increases.” And with production tipped to reach 1200 tons by 2015, and 2000 tons by 2018, it was paramount that Mt. Cook plan the new factory, equipment, and processes with this in mind. Mt. Cook Alpine Salmon approached Marel in search of a solution for the new facility. They wanted a solution that would reduce the double handling of weight and quality grading, as well as grade out the premium fish suitable to be produced as the high value Saikou. The custom solution that Marel delivered was our own in-house design concept that combines a standard Marel Grader with Flowline type production tables. This is a very economical and effective solution for Mt. Cook. A Proline Packing Grader, two packing stations, and INNOVA software were also included in this project. The INNOVA solution provides traceability from farm to pack. INNOVA takes care of yield data, inventory control, and bar code labeling for packs and finished goods, right through to dispatch. This is integral to the operation of the Mt. Cook factory as it means critical information is on hand in real time. “We worked with local experts across a variety of fields to put together a modern, world-class facility,” says Adrian Hill. “With the factory coming on line this completes the vertical integration of the hatchery, farm, and processing.” GO TO: marel.com/filleting marel.com/INNOVA HEAD FIRST INTO SALMON SKINNING The MS 1710 Salmon Skinner will optimize the flow of salmon processing lines as we know them today. The new Salmon Skinner was launched at the Salmon ShowHow in February 2015, and stands out for the way it skins fillets head first, without any loss in quality or capacity. As salmon fillets are processed with the head first in all processing steps prior to skinning, fillets no longer have to be turned around to be skinned. The reduced handling ensures a better flow on the line, while the risks of damaging the fillet and bacterial contamination are significantly reduced. “Most importantly it will allow us to continue to produce extremely high grade salmon, even as production increases.” – Adrian Hill, Operations Manager Manager at Mt. Cook Alpine Salmon The dual-lane skinner is designed for traditional skinning, silver skinning, or deep skinning with optimum yield. The machine’s unique top feeds enable each lane to operate independently and minimize gaping by lifting off the product. This simple and safe inline skinner will provide salmon processors with increased yields and unbeatable performance. GO TO: marel.com/skinning 13 11 14 13 L E V E N E C C U S TO M E R I N S I G H T • P O R T I O N I N S I G HT C U T T I N G PORTION CUTTER EXPANDS BUSINESS OPPORTUNITIES When Alan Le Venec saw a demonstration of a Marel portion cutter, he knew immediately it had massive potential for his business. Since then, Le Venec has worked with Marel to optimize the portion cutter’s use to successfully expand into new customer segments. This was not only to meet changes in customer preference for portioned fish but also because the company was experiencing more and more difficulty at supply level. This was due to EU quotas being significantly downscaled, especially in terms of fishing net specifications. Le Venec SA was established in 1946 and has been in the Le Venec family since 1970. In 2010 Alan Le Venec took over the business from his parents and has taken the company from strength to strength. The company now has 35 employees based in Concarneau and Erquy. Every day, they buy fresh fish from several wholesale markets in Brittany which is then sorted, portioned, and packaged before being sold. It was therefore necessary for Le Venec to change its business strategy and make a decision to process bigger fish and supply new customer segments. Each year, Le Venec SA sells 2,500 tons of fish directly to the public from its recently expanded store and also to businesses primarily in France, as well as other European countries. The company has an annual turnover of €8 million. OPENING DOORS TO NEW MARKETS SUCCESS THROUGH ADAPTABILITY In the past, Le Venec SA traded almost exclusively in small fish. However, in recent years processes have been adapted to handle larger fish. This meant that larger fish had to be cut into smaller and very precise portions. Originally this was done by hand and was a hard and tiring task for employees who had to work long hours to meet demand. Today, thanks to the portion cutter, new markets are opening up to Le Venec SA. Alan Le Venec explains, “Before, we were limited in terms of capacity and the raw material available in the market. We produced about 200kg per day. Sometimes we were cutting 5,000 portions per day and our employees had to work until very late, it was hard and tiring.” “Now,” he adds, “we process about one ton per day, but the machine actually has the capacity to handle up to one ton per hour. So there is great potential to expand our business even further. We also have much more flexibility when it comes to raw material. Being able to portion the larger fish that is in supply, and developing new customer segments as a consequence, has been critical for the development of our business.” INCREASING COMPETITIVENESS “When we purchased the machine, we were looking to improve the competitiveness and productivity of our business - the portion cutter has definitely helped us do this,” says Le Venec. Marel’s portion cutters are extremely accurate and reliable and are designed to give immediate results on the bottom line. They are the ideal solution for high-value portioning of whitefish into fixed weight and shapes. With user friendly software and flexible functions, it’s easy to move from inaccurate cutting by hand to accurate portions, on weight every time. “We were looking to improve the competitiveness and productivity of our business – the portion cutter has definitely helped us do this.” Alan Le Venec, owner – FI S H PR OCES S ING The portion cutter is not only a time saver that results in less waste, better productivity and a smaller margin of error, it also helps to improve working conditions for employees. Le Venec explains, “The efficiency of the portion cutter has created more time for my employees to perform a variety of other tasks. It has also minimized the overtime necessary for us to keep up with demand. So they now have normal working hours with more varied and interesting tasks.” LOCAL SUPPORT & RAPID RESPONSE An important factor for Alan Le Venec when purchasing a Marel machine was the convenience of a sales and service unit in Brittany. “I appreciate my relationship with Marel. It’s really convenient to work with a supplier located in Brittany,” says Le Venec. “If I have a problem I can call the Sales Manager or Marel’s after-sales staff and speak with their technicians who respond very quickly - that’s really helpful.” Marel provides professional service solutions worldwide, either on-site or via remote access. We constantly seek to ensure that equipment performs at an optimal level and meets customer needs, each and every day. Marel’s global service organization includes more than 600 service specialists, located in approximately 30 countries that perform an average of 1,000 customer service and maintenance visits each day. FUTURE POTENTIAL The portion cutter has allowed Le Venec SA to become more competitive, reduce loss and to provide a better working environment for their employees. “The machine is really important for our business now. It’s allowed us to adapt and expand. We’ve got hope for the future because working like this means we don’t have to put all our eggs in one basket,” says Le Venec. “If I was in need of another machine - I wouldn’t hesitate to buy one from Marel today.” GO TO: marel.com/portioncutting PORTION CUTTING ON A LARGE SCALE The dual-lane I-Cut 610 PortionCutter is designed specifically to meet the processing needs of larger companies. It is the ideal solution for cutting whitefish fillets, salmon fillets, or whole salmon into portions of fixedweight and/or fixed-length. The new generation processing software provides superior programming flexibility and an intelligent choice of cutting patterns that ensure the best use of raw materials. It features intelligent spacing between individual portions and automatic belt adjustment, which significantly increase throughput and thereby profitability. The combination of consistently superior accuracy and optimum raw material usage results in high-quality products with a maximum return on investment. GO TO: marel.com/portioncutting 15 15 PROGRESS POINT EVENTS Progress Point is a unique training and demo facility designed to bring experts together to experience the full potential of Marel equipment and integrated systems in a hands-on environment. Just 5 minutes from Copenhagen’s Kastrup Airport, Progress Point features 2700m2 of demonstration halls, meeting rooms, a large auditorium, dining, and entertaining areas. UPCOMING EVENTS FOR FISH PROCESSORS Packing, Labeling & Dispatch Event 18 June 2015 The state-of-the-art demonstration facilities are designed to imitate real food processing plant conditions, with 900m2 of demo space that includes wet areas and cooling areas. Whitefish ShowHow 26 November 2015 Our showhows and other events at Progress Point incorporate live demonstrations, new product launches, lectures from our own specialists, and guest speaker presentations. Salmon ShowHow February 2016 Global Leader Marel is the leading global provider of advanced equipment, systems and services for the fish, meat, poultry and further processing industries. Our brands – Marel, Stork Poultry Processing and Townsend Further Processing – are among the most respected in the industry. United in one company, we offer our customers the convenience of a single source for products to meet their every need. With offices and subsidiaries in over 30 countries and a global network of more than 100 agents and distributors, we work sideby-side with our customers to extend the boundaries of food processing performance.

© Copyright 2026