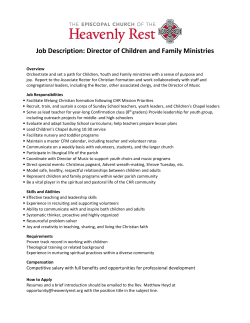

Read More - Natural Leader

TECHNICAL FEATURE This article was published in ASHRAE Journal, June 2015. Copyright 2015 ASHRAE. Reprinted here by permission from ASHRAE at www.carrier.com. This article may not be copied nor distributed in either paper or digital form by other parties without ASHRAE’s permission. For more information about ASHRAE, visit www. ashrae.org. The Sistine Chapel and Saint Peter’s Basilica with the new HVAC system under construction. The Sistine Chapel © 2014 MUSEI VATICANI New HVAC System for Cultural Preservation BY MICHEL GRABON; JACKIE ANDERSON, MEMBER ASHRAE; PETER BUSHNELL, MEMBER ASHRAE; ARITZ CALVO; WILLIAM CHADWICK, MEMBER ASHRAE This article provides a review of the new HVAC and environmental control system designed to preserve the majestic frescoes of the Sistine Chapel. The frescoes that decorate the Chapel’s walls and ceiling faced increasing environmental challenges as a result of a dramatic rise in visitors. When the original HVAC system was installed over 20 years ago, it was designed to accommodate 700 visitors at a time; today there are up to 2,000. Critical factors in the design of HVAC systems for museums and buildings with historic artifacts include air temperature, air humidity, air circulation, airborne pollutants and sound level. In addition, it is important to maintain stable conditions to avoid cyclic effects and gradients that accelerate aging of the artifacts. The Chapel’s new system addresses these factors and new requirements based on studies directed by the Vatican Museums, while providing a level of redundancy that previously did not exist. Air quality management within the Chapel now includes adjusting volume flow to dilute CO2 concentrations while maintaining still air at the frescoes. The system uses special control schemes with video imaging to track visitor levels and respond intelligently to maintain precise conditions. This article reviews the history of the frescoes, describes the new challenges and system requirements, and details the modeling, analysis, and design process used to develop this unique HVAC system that went into service in October 2014. Background The Sistine Chapel was built in the time of Pope Sixtus IV (1471 – 1484) as a religious chapel and site of conclaves for electing new popes. The Chapel interior measures 134 ft (40.9 m) long by 44 ft (13.4 m) wide—the dimensions given in the Bible for the Temple of Solomon. The vaulted ceiling is 68 ft (20.7 m) high, with 12 large windows arranged 10 m above the floor for light and ventilation. The Chapel walls are masonry construction ranging from 7 ft to 10 ft (2 m to 3 m) thick. The Chapel was originally decorated with religious scenes by artists from Michel Grabon is fellow and director, Carrier AdvanTE3C Solutions. Jackie Anderson is senior engineer, Carrier Air Management Systems Technology. Peter Bushnell is fellow, Air Management Systems Technology. Aritz Calvo is controls engineer and William Chadwick is a staff engineer at Carrier AdvanTE3C Solutions. All are with United Technologies Building & Industrial Systems. This article is published in ASHRAE Journal through a license granted by Carrier Corporation. Carrier retains copyright of this article’s content. 20 A S H R A E J O U R N A L ashrae.org J U N E 2015 TECHNICAL FEATURE FIGURE 1 System steady-state model showing the main system components and architecture. Chapel Air-Handling Unit (AHU) Dry Cooler Chiller Skid Airstream AHU 1 VFD Fan 2 Cooling Coil 3 Reheating Coil 4 Electrical Heater 5 Steam Humidifier Refrigerant Stream Water Stream Dry Cooler 6 Adiabatic Ramp 7 Dry Cooler VSD Fans 8 Dry Cooler Coils Skid 9 Heat Recovery Heat Exchanger 10 Heating Coil Pump 11 Cooling Coil/Evaporator Loop Pump 12 Condenser/Dry Cooler Loop Pump the late fifteenth century, including Rosselli, Perugino and Botticelli. Shortly after its completion, the vaulted ceiling developed serious problems due to settling of the building. The original paintings on the ceiling and upper walls were heavily damaged and the structure of the building had to be repaired. In 1508, Pope Julius II commissioned Michelangelo di Lodovico Buonarroti Simoni, commonly known as Michelangelo, to repaint the upper walls and the ceiling. Michelangelo completed the work between 1509 and 1512, using the fresco technique where water-based pigments were applied on freshly laid plaster, resulting in a vibrant and durable painting that is integral with the wall. Michelangelo was later commissioned by Pope Paul III to paint the wall behind the altar, which became the site of the Last Judgment scene, painted during the period 1536 – 1541.1 Michelangelo’s frescoes transformed the Chapel into a masterpiece for the ages. The Sistine Chapel frescoes have endured through the centuries, despite exposure to dust, smoke and pollutants from candles, heaters, outdoor air and people. They Chiller 13 Flooded S&T Evaporator 14 VSD Screw Compressor 15 S&T Condenser 16 Electronic Expansion Valve were also treated with washes and varnishes, which temporarily improved their appearance, but gradually darkened. All of these effects greatly diminished their original beauty. In 1960, the Vatican began an ambitious 34-year restoration project that removed the layers of dirt and varnish and unveiled the frescoes in their original state.1,2 When the restoration was finally completed in 1994, the results were spectacular. In the 1980s the Vatican commissioned a survey of the interior climate of the Chapel. The findings showed highly variable interior temperature and humidity, and significant temperature gradients. It was clear that an environmental control system was needed. This led to the launch of a major project, and in 1993 the Chapel’s first HVAC system was completed. The system, described in ASHRAE Journal in 1996, was designed for the thermal load of approximately 700 visitors at a time, with precise control of air temperature, relative humidity, air velocities and pollutants.3 Designed to be invisible and inaudible to occupants, this system performed very well, meeting its design intent. However, J U N E 2015 ashrae.org A S H R A E J O U R N A L 21 TECHNICAL FEATURE in just over 20 years—from 1990 to 2011—the number of visitors to the Chapel increased dramatically, from 2 million per year to 5 million.4,5 In 2010 new concerns about the Chapel environment were raised when a “whitening” phenomenon was observed on several areas of the frescoes.5 New Requirements for the Chapel Microclimate The Vatican Museums formed another commission in 2011 to study the microclimate in the Chapel. The study found that the original HVAC system was not able to handle the loads produced by the dramatic increase in visitors. Based on these studies, a new set of requirements was formed and a new project was initiated to design, develop, install and commission the next generation HVAC system for the Sistine Chapel. Critical environmental and performance requirements for the design of the new system and the Chapel space were established as follows: 1. Increased airflow while maintaining still air at the fresco surfaces; 2.Controlled air temperature and surface temperatures at the frescoes; 3.Controlled air relative humidity; 4.Controlled pollutant and CO2 concentrations; 5.Controlled dust and particle concentrations; and 6.Minimal noise level. Air circulation is a critical factor to ensure uniform conditions and avoid stagnant regions within the Chapel. The new design requires greater airflow for increased cooling capacity, dilution of CO2, and improved air mixing within the space. In addition, maintaining low velocities near the fresco surfaces is vital, as it reduces the rate of particle deposition on the walls, avoids potential for surface erosion, and limits CO2 exposure over the frescoes. Near-wall air velocity must not exceed 98.4 fpm (0.5 m/s) anywhere in the Chapel. To reduce thermal cycling, space dry-bulb air temperature setpoints remain the same as in the original system: 68°F (20°C) in winter and 77°F (25°C) in summer with a smooth transition between seasons. It is also required to maintain a wall surface temperature that is close to the Advertisement formerly in this space. 22 A S H R A E J O U R N A L ashrae.org J U N E 2015 Advertisement formerly in this space. Advertisement formerly in this space. adjacent space temperature (within ±1.8°F [±1°C]) to minimize dust deposits on the frescoes. A third temperature constraint is to keep the wall surface temperature 18°F (10°C) above the dew-point temperature at all times to avoid any moisture condensation on the walls. Extreme humidity levels pose great risk to the frescoes. Relative humidity above 70% can lead to mold and mildew, while levels below 30% can cause excessive dryness. The original system was able to maintain the wall surface temperature requirement, but its relative humidity control response was not quick enough as visitor levels increased dramatically. The new system relative humidity would continue to be bounded between 50% and 60% with space dew point 18°F (10°C) below the wall surface dry bulb (±1.8°F [±1°C]). However, advanced control schemes would be needed to improve system response. Recent findings showing high CO2 concentrations in the Chapel were particularly alarming to the Vatican Museum conservators. Elevated CO2 levels in the presence of moisture can initiate a chemical process that favors the formation of soluble calcium bicarbonate that can result in a whitish patina.5 The CO2 concentrations measured during the Vatican Museum study with the original HVAC system showed peak concentrations approaching 2,000 ppm, and it was determined that a level below 800 ppm is required. Control of airborne pollutants is also vital. It has been shown that the presence of sulfur dioxide can combine with water to form sulfuric acid, which can attack the fresco materials. Likewise, dust that is carried on visitors’ shoes and clothing is a threat to the Chapel because potentially harmful chemical and biological agents can be introduced with it. The new system is required to maintain supply air dust concentrations (PM 2.5) below 0.003 µg/ft3 (0.1 µg/m3). Exceptionally low sound level is required in the Chapel. The new system would need to be designed for an A-weighted sound pressure level in the 30 – 35 dBA range by controlling all airborne and structure-borne sources and transmission paths. New HVAC System The new system is designed to maintain the critical microclimate conditions for the preservation of the frescoes and the comfort level within the Chapel for an average loading of 1,500 visitors, with peaks of up to 2,000 visitors at a time. The system cooling capacity and supply airflow 24 A S H R A E J O U R N A L ashrae.org J U N E 2015 Advertisement formerly in this space. TECHNICAL FEATURE 26 A S H R A E J O U R N A L ashrae.org J U N E 2015 FIGURE 2 New HVAC system showing air-handling units (top), chiller skids (center) © 2014 MUSEI VATICANI © 2014 MUSEI VATICANI and dry coolers (bottom) during the installation phase of the project. © 2014 MUSEI VATICANI were increased by a factor of three to handle the thermal load and CO2 emissions from the visitors under all weather conditions. Redundant subsystems were designed, each capable of managing conditions in the Chapel under nearaverage loading. All aspects of the HVAC system were integrated with the building, respecting the architecture and the artwork, while remaining inconspicuous to occupants. Extensive simulations were carried out to guide the system design and to develop the control and air-distribution strategies. The range of simulations included both steady-state and dynamic system modeling, along with extensive computational fluid dynamics (CFD) analysis. The steady-state system modeling was used to support subsystem design, component selection and verification of critical operational parameters. The analysis used a proprietary computer program that models component and system level performance and all thermodynamic state points using an iterative solver.6 A schematic of the main subsystem from the steady-state model is shown in Figure 1 (Page 21). Each redundant system consists of a 165 ton (580 kW), R-134a variable speed watercooled screw chiller, an air-handling unit and a dry cooler for heat rejection. Each air-handling unit has six levels of filtration, variable speed supply fan, cooling coil, reheat coil, variable capacity electric heater and a steam humidifier. A reheat coil is connected to the condenser water loop to reduce the load of the dry coolers and improve system efficiency. Condensate from the dehumidification process is collected and sprayed into the dry cooler inlet airstream for evaporative cooling enhancement and system efficiency improvement. In normal full-load operation, each subsystem runs at 66% capacity, and each can manage 75% of full load, twice the capacity of the original system. Each air-handling unit has three filter stages that apply six individual filters to treat return and outdoor air. The filter stages address different airborne pollutants: one stage for mold, pollen and smoke particles; one stage for indoor gaseous pollutants; and one stage for outdoor gaseous pollutants. These filters reduce the presence of airborne pollutants and manage sulfur dioxide concentration below 0.35 ppb, nitrogen dioxide below 2.65 ppb, ozone below 0.94 ppb, total volatile organic compounds (TVOC) below 0.006 µg/ft3 (0.2 µg/m3), and formaldehyde below 1.8 µg/ft3 (65 µg/m3). A preassembled modular system approach was used to enable complete system verification prior to shipment to the site, and to simplify installation and commissioning. Primary modules were chiller skids, air-handling units and dry coolers. Furthermore, a temporary air-conditioning system was installed and operated during a fourmonth period while the original system was removed and the new system was being installed. All equipment was installed on terraces adjacent to the Chapel’s south-facing masonry wall (Figure 2), and silencers Advertisement formerly in this space. TECHNICAL FEATURE were added in the common supply air duct and in each individual return duct for sound attenuation. All ducts are stainless steel and the diffusers include sound-absorbing insulation. Additionally, the outdoor equipment is surrounded with a sound enclosure to minimize external sound radiation, and the dry coolers are designed with low-noise fans to reduce sound levels generated by air movement in the outdoor space. FIGURE 3 (LEFT) CFD simulation of the Chapel. FIGURE 4 (RIGHT) Diffuser installation. Air Distribution in the Chapel At maximum load, the new system was designed to deliver airflow of 31,785 cfm (15 m3/s), three times the original system. The increased airflow was needed for cooling capacity, dilution of CO2, and improved mixing during peak occupancy. This was especially challenging due to the Advertisement formerly in this space. 28 A S H R A E J O U R N A L ashrae.org J U N E 2015 PHOTOS © 2014 MUSEI VATICANI conflicting requirements of still air at the frescoes and limited access points for air supply and return. Since the entire Chapel is essentially covered in artwork, no new openings could be added, and only the existing six penetrations under the windows on the south wall could be used with minor modifications. Extensive studies of options including numerous CFD simulations of the Chapel were carried out using a commercial code.7 The objective was to seek methods to rapidly distribute the airflow in the space with a high level of mixing, while maintaining low velocities near the fresco surfaces. The CFD models were set up to approximate the physics of the problem, including building external thermal loads, conduction through the massive masonry walls, thermal load and CO2 emissions due to people in the space, diffuser discharge jet flow and buoyancy effects. Special attention was given to jet shear layers and trajectories to ensure that good estimates of near-wall velocities were resolved. Most of the simulations were steady-state using the k-ε turbulence model on a halflength symmetric approximation of the Chapel. In the final design, air is delivered to the Chapel through four diffusers below the four center windows in the south wall. Two air returns are located under the outer two windows so the system can use a combination of outdoor and return air, while maintaining slight positive pressure in the Chapel. Figure 3 shows the simulated flow pattern from two of the supply diffusers at maximum load and airflow. The jet can be seen to spread and fall due to Advertisement formerly in this space. buoyancy effects, creating a main recirculaFIGURE 5 Visitor analytics used to enhance system control. tion zone in the lower section of the chapel with a portion of the air diverting toward the ceiling frescoes. All near-wall velocities are maintained below 98.4 fpm (0.5 m/s) with the highest velocities along the bottom half of the north wall. Variable speed fans are used to further reduce air velocities in the space as occupancy decreases. Specially designed diffusers, shown in Figure 4, were developed for the Chapel. Supply air is ducted under the windows at high velocity. The diffusers then rapidly expand the flow, recovering dynamic pressure and producing low-speed discharge jets. The 2.5 area ratio diffusers use horizontal and vertical flow splitters to control diffusion and add structural support. A diamond-shaped perforated outlet baffle is used to further augment diffusion within the very limited space available. Detailed validation tests were carried out on a quarter-scale model CFD modeling was performed for a single diffuser and under isothermal conditions. Reynolds number was Advertisement formerly in this space. 30 A S H R A E J O U R N A L ashrae.org J U N E 2015 © 2014 MUSEI VATICANI TECHNICAL FEATURE Advertisement formerly in this space. TECHNICAL FEATURE matched and jet flow patterns were validated with good results. The scale model was also used for diffuser selfgenerated noise evaluation. System Control Specialized controls were developed for the new system using an extensive set of sensors and video monitoring. Sensors include 17 air dry-bulb, 13 dew-point and 16 surface temperature sensors distributed at key locations on the walls of the Chapel, as well as two CO2 concentration sensors and two dry-bulb temperature and relative humidity sensors installed in the return air ducts of the air-handling units. A video system, shown in Figure 5 (Page 30), was developed to track the visitor level in the Chapel to enable rapid response to the thermal, moisture, and CO2 loads. A first control layer uses a feed-forward approach to set the correct supply airflow, outdoor air ratio, and chilled water temperature as function of visitor level. A second feed-back control layer adjusts system capacity to correct temperature and humidity deviations from setpoint. Every day a graphical report is automatically generated showing the performance of the previous day in terms of system control accuracy and stability. Dynamic system models were built using a commercial simulation code to evaluate transients and to support control algorithm development.8 These simulations included the effects of variable seasonal conditions, latent and sensible loading, CO2 concentration, occupancy schedule and control time delays. The simulations ensured proper control of temperature, relative humidity, pollutants and particles. The new control system calculates a moving 24-hour outdoor air temperature average and maintains indoor air temperature equal to this average value when outdoor temperatures fall between the desired 68°F (20°C) to 77°F (25°C) range. If the outdoor air temperature is outside this range, the system holds the Chapel interior temperature at 68°F (20°C) on cooler days and 77°F (25°C) on warmer days. This control profile reduces the temperature gradient within the Chapel and the potential for thermally induced stress on the frescoes. CFD modeling was used to analyze interior conditions during peak occupancy and to Advertisement formerly in this space. 32 A S H R A E J O U R N A L ashrae.org J U N E 2015 Advertisement formerly in this space. TECHNICAL FEATURE CO2 Concentration (ppm) verify well-mixed thermal conditions FIGURE 6 CFD analysis of temperature distribution within the Chapel. as shown in Figure 6. The system adjusts the total and return airflows based on visitor level from the video system to keep CO2 levels near or below 800 ppm. If concentrations exceed 800 ppm the return air ratio is decreased and the total airflow is increased. As discussed earlier, an increase in airflow three times the original system was needed to dilute the space with outdoor air during peak FIGURE 7 CO2 levels in the Chapel with 1,100 visitors. occupancy. Figure 7 shows the CO2 concentration com1,600 parison between the original and new systems during Legacy System New System similar single days, each with 1,100 visitors. 1,400 The system continuously cycles the supply air through 1,200 the six filters to maintain acceptable dust and pollutant concentrations inside the Chapel, while adjusting 1,000 the ratio of return air to outdoor air to provide proper 800 CO2 dilution. During night operation, return air ratio is increased to remove any remaining contaminants that 600 have accumulated during the day. Summary The new HVAC system began operation in October 2014. The Vatican Museums held a special conference: “The Sistine Chapel Twenty Years Later: New Breath, New Light,” Oct. 30–31, 2014, coinciding with the 450th anniversary of the death of Michelangelo. The conference reflected on the restoration of the frescoes, their current health, the science and analysis regarding their continuing conservation, the new HVAC system, and a new lighting system for the Chapel. The conference attendees had the opportunity to see the Chapel with its new HVAC system in operation, along with the new LED lighting. System performance has been very good, operating as designed based on numerous sensors and data. The system will be monitored continuously in the months and years ahead to ensure a healthy environment for the Sistine Chapel frescoes and their preservation for future generations. Acknowledgments This project was completed by United Technologies Building & Industrial Systems and its Carrier operations. The authors would like to thank the Vatican Museums for their collaboration and confidence throughout the project, 34 A S H R A E J O U R N A L ashrae.org J U N E 2015 400 200 0 12a 4a 8a 12p3p 5p12a Proger S.p.A. for their engineering and installation expertise, and the wide range of teams in United Technologies and Carrier for their support and contributions to this unique project. Finally, we would like to thank Dr. Charles Bullock, a retired Carrier engineer and ASHRAE member, for providing insight from his experience leading the design of the original HVAC system for the Chapel. References 1. Mancinelli, F. 1993. The Sistine Chapel. Edizioni Musei Vaticani. 2.Paolucci, A. 2010. The Sistine Chapel. Edizioni Musei Vaticani. 3.Bullock, C., F. Philip, S. Pennati. 1996. “The Sistine Chapel: HVAC design for special use buildings.” ASHRAE Journal (4)42–56. 4.Cimino V., P. Mandrioli, M. Matteini, U. Santamaria. 2012. Microclimatic Conditions of the Sistine Chapel. Vatican Museums Internal Report. 5.Vatican Museums. 2014. The Sistine Chapel Twenty Years Later: New Breath, New Light. 6.Carrier. IPM System Modeling Software. Syracuse, N.Y.: UTC Carrier Corporation. 7. ANSYS. Fluent. Canonsburg, Pa.: ANSYS Inc. 8.University of Wisconsin. TRNSYS: Transient Systems Simulation Program. Madison, Wis.: University of Wisconsin. Advertisement formerly in this space.

© Copyright 2026