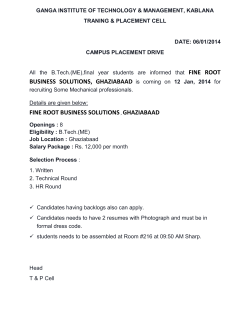

National Power Training Institute.cdr

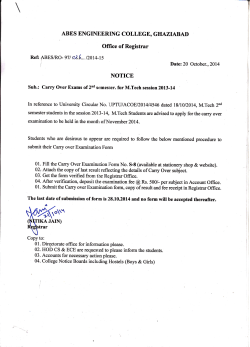

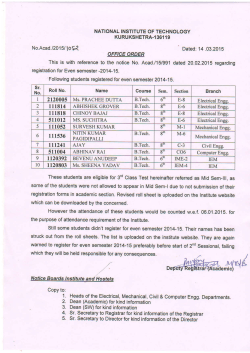

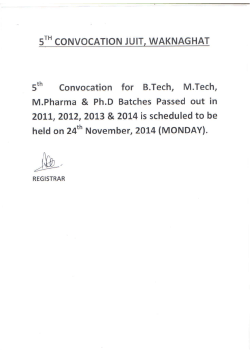

PLACEMENT BROCHURE POST GRADUATE DIPLOMA COURSE IN HYDRO POWER PLANT ENGINEERING PGDC (Hydro), 6th Batch (2014-15) ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p FOREWORD National power training institute (NPTI) an ISO 9001 and 14001 certified organization under Ministry of Power, Government of India is a reputed institute for providing graduates engineers an opportunity to be accomplished with the skills required in the Power Sector Industry in India by providing them specialization courses in various departments of power generation. Due to increase in the awareness in consumer, economic, environment there has been a change undergoing in power sector unlike the past where generation and distribution of electricity was not considered commercial activities. To sustain in this competitive market, organization will have to change their existing core beliefs, process and methodologies and focus on hands on learning to inculcate the necessary knowledge, skills and attitude in the personnel. To keep our trainee abreast with latest technologies, the training infrastructure is also being upgraded. All out efforts are being made to ensure that the courses offered by NPTI stand out and meet the power sector needs. We have been modifying the training calendar to incorporate the program's which are in great demand. I wish the students will be benefitted by the courses offered by NPTI and will lead a successful path in Power sector industry and make it reach heights by providing them professionals highly equipped with knowledge and experience making it a win-win situation for NPTI-HPTC. (Sh. M. R. Chaubey) (Principal Director) HPTC NPTI, Nangal ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p MESSAGE FROM DIRECTOR Hydro Power Training Centre HPTC a specialized Institute of National Power Training Institute (NPTI), an ISO 9001 & ISO 14001 organization, is a National Apex body for Training and Human Resources Development in Power Sector and dedicates services to the professional organizations, engineers and individuals in the country related to Power ( Generation, Transmission, Distribution) & allied Sectors. Commensurate with the huge capacity addition during 12th and 13th plan, there is a necessity of adequate trained man power for design, engineering, manufacturing, erection and commissioning as well as for O&M Of power plants. With an aim to supplement the Indian Power Sector with groomed manpower, HPTC NPTI has taken stride to launch its “40 weeks Post Graduate Diploma Course in Hydro Power Plant Engineering” which is only the training institute in India for Hydro Power Plant Engineering. The fresh engineers of this batch have already acquired sufficient competency level during their nine months rigorous training in key areas of Hydro Power Plants and after completion of the entire course will be competent to take over the charge of Operation & Maintenance of Power station. Placing these engineers in any power utilities /organizations will not only be a win-win strategy for all including the employer, the trained engineers and HPTC NPTI, but it will also be a great contribution to the Indian Power Sector. I would heartily welcome all the stake holders and the industries to our campus for placement of our trained student engineers. (Sh. G.V. Harshe) Director (Tech) HPTC NPTI, Nangal ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p FROM THE PLACEMENT DESK / COURSE COORDINATOR With an objective to create a pool of Trained Engineers in the area of Hydro Power Plant Engineering of Indian Power Sector, HPTC, NPTI has started these 40 weeks PGDC Programme in Hydro power Plant Engineering following the syllabus as per the regulation of Indian Electricity Act. The engineers i.e. (B-Tech in Mechanical & Electrical) over here under go Theoretical inputs along with practical Exposure of Hydro power plant of various ratings. We assure you that the inputs given to these participants are quite practical oriented. HPTC, NPTI Nangal is the only institute conducting this course in our country. After Completion of their training in June 2015, they will be ready to be deployed in various disciplines of Power industry. They will be the most suitable engineers for Hydro Power Stations, Manufacturing units, Design & corporate offices of various power utilities, consulting companies, EPC contractors etc. in hydro Sector. We shall be happy if your esteemed organization visits HPTC, NPTI to judge the capability, aptitude and knowledge level of these groomed engineers and give them a chance to serve your organization and the Indian power sector. (Sh. Motilal Senapati) Asstt. Director (Tech) HPTC NPTI, Nangal ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p ABOUT HPTC, NPTI NANGAL National Power Training Institute, an ISO 9001:2000 AND 14001 Organization has been set up by Ministry OF POWER (GOVT OF INDIA to function as national apex body for human resource Development for Indian Power Sector. The HYDRO POWER TRAINING CENTRE (NPTI), NANGAL is a specialized centre of NPTI, situated on a picture square landscape of about 15 (fifteen) acres. The Campus houses the main Institute building, guest house, boys hostel, Girls hostel, Gymnasium & residential quarters for the employees. The main Institute building houses air conditioned lecture halls , library , administrative office, a 250 MW Hydro Simulator, auditorium hall with the facility of latest Audio/ Video system. NPTI has been conferred the award for“Best Learning and Development Strategy” for the year 2010-11 by the World HRD Congress, under the category Hindustan Times shine.com HR Leadership Award. The award was announced on 9-2-2011 in a ceremony held at Hotel Taj Lands' End, Mumbai. NPTI has also been conferred the award for “Excellence in Training”for the year 2010-11 by the World HRD Congress, under the category Employer Branding Award. National Power Training Institute (NPTI) has been conferred 4th India Power Awards 2011 instituted by Council of Power Utilities for “Excellent work in imparting training to Power Engineers”. The award was received by Sh. Subodh Garg, Director General, NPTI in a glittering ceremony held at India Habitat Center on 24th November, 2011. NPTI was selected for the coveted award by an eminent jury consisting of Sh. P. Abraham, Former Secretary, Ministry of Power, Sh. H. L. Bajaj, Former Member (Technical), Appellate Tribunal for Electricity and others and the jury had unanimously recognized the contribution of NPTI towards excellent work in imparting training to Power Engineers ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p FACILITIES AT NPTI, HPTC, NANGAL HYDRO LAB COMPUTER LAB ELECTRICAL LAB CONTOL & INST. LAB 250 MW HYDRO SIMULATOR LIBRARY TRAINING ON 250 MW HYDRO SIMULATOR HOSTEL ACCOMODATION GYM AT NPTI, HPTC, NANGAL CAMPUS VIEW AT NPTI, HPTC, NANGAL ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p VISION & MISSION NPTI cherishes a vision of value orientation & value addition to national & transnational power & energy sectors through training & Human Resources Development endeavoring to energize people who energize the nations Emerge as global leaders in enhancing human & organization excellence in power &energy Sectors by blending frontier technologies with management to facilitate HRD interventions that are instrumental in provide in reliable, sale economic & clean power. ABOUT PGDC (HYDRO POWER PLANT ENGINEERING) AT HPTC, NPTI: The duration of the course is 40 weeks. The objective of the course is to develop groomed manpower for the power sector having high skills and confidence in running a Power Plant. This course covers the complete syllabus under the provision of Indian Electricity Act Regulations which include the class room sessions as well as on-the-job training. The students are provided on-job practice sessions in various Hydro power plants of BBMB and plant visit to KOLDAM (NTPC Ltd.), THDC Ltd., Naphtha Jhakri (SJVNL) of different unit size. To enhance the personal skills, inputs of Management are also given to the students. After completion of the course the students would be readily available for the Indian Power Sector for taking over the charge of Operation & Maintenance of Power Plant equipments. The course is also open for the sponsored candidates from Power utilities. SPECIALITY OF PGDC (HYDRO) ENGINEERS OF (HPTC): w Taught by eminent experts from utilities, manufacturing organizations and academic field. w Overall personality development of an individual along with technical specialization. w Seminars, Tests, viva voce, projects are conducted from time to time for continuous evaluation. w Workshops on various topics to update the knowledge about the current techniques in power sector w These engineers have practical exposure with on job training (Operation and Maintenance) at Bhakra Hydro power plants of BBMB. w These engineers have learnt various testing procedures in the lab and various workshops. w The engineers have been given exposure of the manufacturing sites of various equipments related to Hydro Power Plants. w The engineers have been given exposure to the practical work which has helped them to build confidence for doing job. w The engineers have been given exposure on the Off job, hands on training on 250 MW Realtime Hydro Simulator at NPTI (HPTC), Nangal.Training Simulator which has helped them to know to reduce plant trip & trouble free start up & optimum usage of resources for less down time and lower costs. ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p IN HOUSE FACULTIES Sl.NO Name & Designation 1. Sh. M.R. Chaubey Principal Director Education/ Professional Membership B.E. (Mech), University of Roorkee,09 weeks Senior Instructor course in CEGBUK.06 weeks training on Emission Up-gradation project at Canada/ USA under CIDA 2. Sh. S.K. Sinha Director 3. Sh. G.V. Harshe , Director 4. Sh. V.J.S. Dehal, Sr. Adviser B.E. Electrical, BIT Sindri, M. Phill Comp. Science JNU New Delhi B.E. (Mech), Member of Institution of Engineers (India), 10 Weeks Sr. Instructor Course under British Electricity International (UK) B.SC, Engg. M.E. 5. Sh.R.Vachaspati, Asstt. Director (T/F) B.E. (Mech.) & Master in Technology (Mech.) 6. Sh. M.L. Senapati, Asstt. Director (T/F) AMIE (Electrical) & Master in Engineering (Industrial Systems & Drives) 7. Sh. C.R. Meena, Asstt. Director (T/F) B.E. (Electrical Engg.) 8. Saurabh Mahajan Asstt. Director (T/F) Mrs. Rasmi Prava Senapati, Faculty B.E. (Electrical Engg.) & PGDC Hydro. One year in Delhi Transco. Ltd. In 400KV Grid Construction. 3.8 years in NHPC ltd in construction & Investigation projects, 06 years in NPTI as a faculty & trainer in250 MW Hydro Simulator 8.5 Years experience of Hydro Power Plants, O&M, construction in NHPC Ltd. (CPS-II, Kambang) and 250 MW Hydro Simulator 04 years in hydro power plant experience in O& M B.E. (Computer science Engg) 2.1/2 year in NPTI Nangal C&I Lab, Hydro simulator 9. Experience &Expertise More than 32 years of service in different positions in Power Engineering comprising Operation, Maintenance, Commissioning, Procurement, Performance Monitoring, Training etc at Renusagar Power Co. Ltd., CTPS, DVC Corporate Centre and NPTI. More than 28 years of service in NPTI. Specialization in Computer & Simulator Total 32 Years Exp. Out of which 8 years O&M of Thermal Power Plant & 24 years in training & development in Steam turbine, Coal Handling Plant, Power plant safety. Teaching (B. Tech, NPTI) 4 Years. O&M of Thermal Power Plant 25 Years, 3. Planning & Procurement 4 Years, 4. Mtc of Distribution system 1 year.,O&M of Thermal Power plant 2 Years design of process equipment, 6 years faculty work for B. Tech students, 6 years of NPTI as a faculty and trainer forB.Tech Classes on Thermal Engineering. ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p GUEST FACULTIES Sl. No. Name & Designation Organization 1 Mr. A.K Singh, DGM (Hydro Engg),Civil 2 3 4 Mr. C.P Singh, AEE (Dam Design), Civil Mr. N.C Goel, Retd. Chief Engineer, BBMB, Bhakra Mr. P.K Yadav, AGM( Civil), KOLDAM Project, Barmana (HP) Mr. Rajeev Vishnoi, AGM(Civil),Tehri Hydro Mr. V.K Gupta, Retd. Sr. Mechanical Maintenance Engineer (valve) Mr. Mayank Jain, Sr. Manager (Hydro Mechanical) Mr. S.K Choudhury, Sr. Executive Engineer (Electrical) Mr. N.K. Yadav, Executive engineer (Electrical) Mr. R.C Choudhury, Addl. S.E (Electrical) Mr. M.K Shrivastav, Retd BHEL Mr. P.K. Dhiman , Asst. Executive engineer (Electrical Protection) Mr. Sanjay Dwivedi, Vice President (Turbine & Valve) Mr. V.K. Pande Sr. Technical Adviser (Turbine Engg.) Mr. A.K. Malhotra, AGM , Tehri Hydro project Mr. Kuuldeep Singh, Retd. AGM , Tehri Hydro project Mr. Udit Goel, Asst. Engineer(Control & Instrumentation) Mr. Man Mohan Gupta, Lecturer First AID & Fire Fighting Mr. Robin Bhatt, PLC trainer Mr. Rajneesh Yadav, PLC & SCADA Mr. Assish nigam , Chief Manager (Automation) Mr. Rajinder Sharma, Chief Engineer, PSPCL, Patiala Dr. Rishipal, HOD ,MBA Dept. IIET, Jind (HR) Mr. R.K. Thaman, AEE, SLDC,BBMB Mr. Ashok Gupta, System Manager,SLDC, BBMB Mr. H.M. Emmanuel, Rtd. Dy.Director, NPTI (WR) Mr. S.M. Dilbagi, SLDC, BBMB Mr. B.B. Bhandarkar, Retd. Executive Engineer (Elect) MAHAGENCO ltd. Mr. Naveen Gupta, Dy. Director , SLDC, BBMB Mr. R. K Thaman, Executive Engineer, BBMB Mr. B.K. Panigrahy, Dean NTPC. Ltd. (Hydro Engg.) Noida BBMB , Bhakra BBMB, Gangual KOLDAM Project, NTPC, Ltd. 5 6. 7. 8. 9. 10. 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 THDC Ltd. NPCL THDC Ltd. BBMB, Bhakra -I BBMB, Bhakra -II BBMB, PONG PH, Talwara BHEL, Bhopal BBMB, Bhakra -II Voith Hydro Ltd. Noida Voith Hydro Ltd. Noida THDC Ltd. THDC Ltd. UPRVUNL St. John Ambulance AB Technology, Chandigarh AB Technology, Chandigarh Voith Hydro Ltd. Noida SLDC, PSPCL, Patiala IIET, Jind (HR) BBMB , SLDC, Chandigarh BBMB , SLDC, Chandigarh Ex-NPTI(WR), Nagpur BBMB , SLDC, Chandigarh MAHAGENCO Ltd. (MH) BBMB , SLDC, Chandigarh BBMB , SLDC, Chandigarh INDUS International University ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p PGDC (HYDRO) SYLLABUS Item No. I II III IV V VI VII VIII IX X XI Particulars General Introduction : World Power Scenario Growth of Power Industry in India Generation Scenario in India Transmission and Distribution Scenario in India Role of Private Power Participants in India Organization / Power sector set up Introduction to Indian standard specifications for Electrical wiring Concept of modern hydro station : Types of stations , their role in power systems, base load, and peaking load, run -off-the river, storage type and pumped storage power plants, concept of unit, typical surface and underground hydro power stations. Choice of location of large hydro station: water availability land availability, selection of installed capacity, selection of type of turbine, choice of size of generating units. Hydraulic system, reservoir, storage capacity, operation of reservoi rs, dams and barrages, intake, surge tank, power tunnel/ channel, fore bay and penstocks, pressure shaft, tail race and tail race tunnel/ channel , protection against water hammer and negative pressure in penstocks and suction head, Dewatering of water co nductor systems Plant lay out in hydro stations above 25MW capacity including machine arrangement, equipment, switchyard and auxiliary arrangements. Constructional details and working principles of valves butterfly, spherical, needle etc.: Requirements and principle of operation Type and selection criteria of valves and their operation and control. Constructional details and working principles of hydro mechanical equipments. Requirements and principle of operation Type and selection criteria of hydro mechanical equipments and their operation and control. Constructional details and working principles of turbines and auxiliaries. Principle of operation, types and characteristics of turbines Choice, rating an d specifications of turbines Components of turbines and their design Type of governors - hydraulic and electronic Guide bearing and shaft seal arrangements Working principles, characteristics and operation of auxiliary systems. Unit Auxiliaries Oil pressure units HP lubrication system Braking and Jacking system Central grease lubrication system Carbon dust collection system for slip rings, exciters and brake pads. Cooling water system. Common Auxiliaries EOT cranes and hoists Ventilation system Air conditioning system Compressed air system Drinking water system Sewerage system Elevator/ lifts Dewatering and drainage system Communication systems Constructional details and working principles of alternators and excitation systems. Alternators, characteristics and rating, types of winding, bearing arrangement s, cooling arrangements Main and pilot exciters, voltage regulators, types and characteristics, amplifier and magnetic amplifier, static excitation system, automatic v oltage Regulation (AVR) Methods of grounding Generator – transformer connections DC and AC power supply for auxiliaries, arrangement of unit auxiliary and station service boards, station lighting and automatic changeover. Station batteries and charging methods. Standby and emergency power and lighting systems. Number of Hours 24 12 12 30 12 18 18 36 30 36 15 ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p PGDC (HYDRO) SYLLABUS XII Transformers: Main transformers, station/ unit transformers, grounding transformers, type of connections, tap changer gear, cooling arrangements, size selection of main transformers, parallel operation and regulations. Outdoor switchyard, bus bar arrangements, single line diagram, circuit breakers, isolators, current transformers, potential transformers, lightning arrestors, wave traps, coupling capacitor, LMU and three element protection devices, grounding arrangements. Indoor and outdoor switch gear: Types: MCB, bulk oil, minimum oil, air blast, vacuum, SF6 breakers, constructional - functional details and characteristics. SF6 gas filled EHV switchgear Working principle and basis of instrumentation and measurements: Detail of measuring instruments for pressure, flow, temperature, level, vibration, alignment and current, voltage, power, reactive power, frequency, energy, winding temperature , auto controllers, recorder, Megger - its use for primary detection of faults , data acquisition system, digital distributed control, UPS, unit co -ordinate master control. Testing of electrical and mechanical testing equipments Control and protection- sequential operation and interlocks Unit protection and interlocks Turbine and auxiliaries and vibration monitoring Turbine governing, speed setting, speed droop setting and control circuits Generator protection, under voltage, over voltage, differential, reverse power, under excitation, negative phase sequence, earth fault, etc. Different types of protection relays Importance of sequential interlocks Transformer protection – differential, overload, over fluxing, restricted earth fault, high temperature, buchholz protection Types of motors and variable speed drive and control Various types of pumps and their starting control Annunciation systems Online monitoring devices Operation control and supervision General machine start and stop procedure and sequence Handling of turbine and generator and auxiliaries under failure condition. Such as, mechanical & electrical auxiliary & governor failure, grid failure & other failure conditions. Alternator- synchronizing, loading, parallel operation active and reactive power sharing and frequency control. Fire safety procedure Fire protection of generator Fire- fighting and emulsifier type protection General safety precautions, treatment of electrical or acid/ alkali burns, permit to work, first aid, protective gear/ clothing, safety in movement and storage of materials, safety aspects of switchyard. Factory ACT, Electricity ACT, 2003, Central electricity Authority (Measures relating to Safety and electric supply) regulations, 2010, and other statutory Regulations concerning power stations (broad outline). Erection, testing and commissioning of turbine, generator control and instrumentation, switchyard and auxiliary systems, maintenance procedures, PERT/CPM method, power station records, mainten ance planning. Plant performance, generation cost, machine availability and other commercial aspects. Personnel management, duties and responsibilities, labour laws and labour welfare. 15 18 XXVI Broad principles of material management, procurement procedure and inventory control. IT Application in power Sector XXVII 250 MW Real time Hydro Simulator Training 60 XIII XIV XV XVI XVII XVIII XIX XX XXI XXII XXIII XXIV XXV 9 36 12 42 45 36 15 12 30 36 18 12 30 ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p PGDC (HYDRO) SYLLABUS XXVIII Hydro Lab. Practical 60 XXIX Electrical lab. Practical 60 XXX Control & Instrumentation Lab Practical 60 Total=(849) 29 Weeks XXXI On job training : Control room desk operation : Pre-start checks Protection interlocks Startup procedure and routine checks Stopping and emergency operation of turbine, generator and their auxiliaries. Operation of generating unit in abnormal circumstances. Fire-fighting and fire safety procedure during emergency 10 weeks 1 week GRAND TOTAL = 40 weeks ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p POWER TRAINING SIMULATORS The Institutes of NPTI are well equipped with Hi-tech infrastructural facilities for conducting different courses on technical as well as management subjects covering the needs of Thermal, Hydro, Transmission & Distribution System, and Energy related fields of the Indian Power and allied Energy Sector. It has 500 MW Thermal Power Training Simulator at Faridabad Institute and 210mw Thermal Power Training simulator at Nagpur Institute for imparting specialized skills to operation personnel across the country.).Full Scope Combined Cycle 430 MW Gas Turbine Replica Simulator at NPTI Corporate office, Faridabad and a High fidelity Load Dispatch Operator Simulator for the National Grid at PSTI, Bangalore has been commissioned. Looking into need of training of operator in hydro power plant a 250 MW Hydro Simulator has been installed at NPTI (HPTC), Nangal, which is the replica of 250 MW unit of Naphtha Jhakri hydro power plant under Sutlej Jal Vidyut Nigam limited. 250MW REAL TIME HYDRO SIMULATOR AT NPTI (HPTC), NANGAL Simulator: The Physical (Plant/Field) and Control System (DCS) are emulated using ProTrax Software which with FORTRAN compiler running in a PC based environment. The Francis Turbine, Dam, valves, Generator, as individual modules are para meterised to acquire the required functionality. The ABB -Advant HMI as in the plant were developed using Wonder ware Intouch Software. The DDE protocol enabled Intouch is integrated with ProTrax by communication of data points in shared memory. Hard panels are wired with Rockwell PLC and integrated with the ProTrax Simulation software to communicate the IO data points. Trainee Station: It is the full replica of the unit control room of the reference plant. In the simulator, the trainee operates the control panel through keyboard and mouse, monitors and controls the process parameters and gets a feeling as if one is involved in the real plant operation. Three operator workstations are provided for this purpose. Instruction Station: It consists of Two Instructor station provided with various controls and remote functions to conduct the training. The facilities available at the instructor station include creation of various plant scenarios, initialization of appropriate terminal conditions, performing field equipment operation, insertion or removal of emergency conditions. ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p SIMULATOR TRAINING FEATURES Initial Conditions (ICS) Initialization Freezing Backtracking Snap shot Malfunction Real-time mode Fast mode Remote functions Normal Start-up, Shutdown, Trend & log monitoring SIMULATOR TRAINING PROFILE Charging of power supply Charging of auxiliary system Automatic unit run-up system Synchronization of Unit to national grid Loading operation up to 100% Emergency handling Planned shutdown ADVANTAGES OF THE SIMULATOR TRAINING Highly efficient learning: No fuel cost on account of training: No wastage of equipment time: Risk free training: High retention level: Improved sharpness: Testbed ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p STUDENT PROFILE KUSHAGRA THAKRE B.TECH%=80.00, 10th%=71.4 , 12th%=63.8 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2014) Training: 1 Month Training In Mechanical Maintenace At Centre For Research And Industrial Staff Performance Bhopal, 15 Days Training At Hindustan Electro Graphite Ltd. Bhopal, 1 Month Training In Autocad From Crisp BHOPAL. Contact Number: 09754870990, 07814310559 E-mail: [email protected] VINAY KUMAR B.TECH%=75.00, 10th%=78.00 , 12th%=74.00 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2014) Training: 6 Month Industrial Training In ACC Barmana (H.P.), 2 Moth Industrial Training In NTPC KOLDAM (4*200) BILASPUR (H.P.), Auto CADD, Solid Works Contact Number: 07831870043 E-mail:[email protected] CHANDRA MOHAN SINGH B.TECH%=74.74, 10th%=87.33 , 12th%=76.70 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2013) Training: 1 Month Tarining In Bsp (Bhilai Steel Plant) , 15 Days Training In Simplex Casting Bhilai, 8 Month Training In Auto CADD , Pro-E , Ansys (basic). Contact Number: 07415350649 E-mail:[email protected] ANCHAL GAUTAM B.TECH%=72.99, 10th%=73.50 , 12th%=69.40 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2014) Training: 6 Months Industrial Training At Ambuja Cement Darlaghat. Auto Cad, CNC Milling, Pro- E Contact Number: 09418086901,09041623811 E-mail:[email protected] P NAGA SAITEJA B.TECH%=72.90, 10th%=89, 12th%=87.80 Qualification(year) : B.Tech – ELECTRICAL & ELECTRONICS ENGINEERING (2014) Training:3 Months Training in Production Dept at SCHNEIDER ELECTRIC PVT. LTD. HYDERABAD Contact Number: 08985667976 E-mail:[email protected] ROHIT PATHANIA B.TECH%=72.88, 10th%=56.28 , 12th%=78.48 Qualification(year) : B.Tech – MECHANICAL ENGINEERING (2013) Training: 1 Month Industrial Training In Advanced Valve, Gagret (H.P), 1 Month Training in Tigaksha Mettalics Pvt. Ltd. Gagret (H.P.) Experience: 6 Months in Johnson & Johnson, BADDI. 4 Months Experience In Automobile Trainer In Govt School (H.P.) Contact Number: 09418393979 E-mail:[email protected] ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p STUDENT PROFILE AJAY THAKUR B.TECH%=72.63, 10th%=68.50, 12th%=77.20 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2014) Training:6 weeks Industrial training at 3X42MW Hydroelectric Plant LARGI. Contact Number:09915523463 E-mail:[email protected] PERMINDER SINGH B.TECH%=71.53, 10th%=77.00 , 12th%=75.00 Qualification(year) : B.Tech – MECHANICAL ENGINEERING (2013) Training: 6 months training at National Fertilizers Limited Naya Nangal, 2 Months Training at International Tractors Ltd., 2 Months course in Unigraphics Auto CADD Experience: 9 Months at New Holland Tractors Service Centre Contact Number: 09501674822, 09463220809 E-mail:[email protected] DEBOBRATA DUTTA B.TECH%=70.00, 10th%=83.00, 12th%=84.00 Qualification (year) : B.Tech –ELECTRICAL ENGINEERING (2013) Training: 1 Month Industrial Training in DVC, 1 Month Training in PLC SCADA , 1 Month Industraial Training in DURGAPUR PROJECTS LTD. (DPL) Contact Number: 09547605648, 07355998037 E-mail:[email protected] TARANPREET SINGH B.TECH%=69.26, 10th%=67.86, 12th%=64.22 Diploma M.E.%=67.56 Qualification(year) : B.Tech - MECHANICAL ENGINEERING(2013) Training: 6 Months Training at Diesel Loco Modernisation Works Patiala, Auto CAD, PRO-E Experience: 10 Months Exp. In quality Inspection Dept. At ESGI Tools Pvt. Ltd. Contact Number: 09780019195 E-mail:[email protected] HARSHIT SHUKLA B.TECH%=69.24, 10th%=84.80, 12th%=75.00 Qualification(year) : B.Tech – ELECTRICAL ENGINEERING(2014) Training:1 Month Training at Field Gun Factory, 1 Month Training at Panki Thermal Power Station Contact Number: 07275310301 E-mail:[email protected] POOJA VERMA B.TECH%=69.00, 10th%=65.00, 12th%=51.00 Qualification(year) : B.Tech – MECHANICAL ENGINEERING (2014) Training:2 Week training in Auto CAD, 2 Week training in CNC/VMC, 1 Month Summer Training in Hydro Power Plant, Knowledge of Ethical Hacking & Ms- Office. Contact Number: 07860568793,09451610600 E-mail:[email protected] ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p STUDENT PROFILE DEEPAK KUMAR B.TECH%=68.88, 10th%=56.00, 12th%=53.40 Qualification(year) : B.Tech – ELECTRICAL & ELECTRONICS ENGINEERING(2014) Training: 1 Month Industrial Training on Power Transformer from Crompton Greave Ltd. Bhopal, Attend 2 Weeks Workshop of Aakash Android Application Programming Contact Number: 09041109755,9525107374 E-mail:[email protected] ABHISHEK SINGH B.TECH%=68.80, 10th%=70.40 , 12th%=70.20 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2014) Training:1 Month Training at BHEL (BHOPAL). 1 Month Training in AutoCAD From Crisp BHOPAL. Contact Number: 09981903369 E-mail:[email protected] ALOK KUMAR SINGH B.TECH%=68.80, 10th%=54.20, 12th%=57.70 Qualification(year) : B.Tech – MECHANICAL ENGINEERING (2014) Training:1 Month training at I.F.F.C.O Power Plant in ALLHABAD, 2 Weeks Training in D.L.W (VARANASI), 4 Weeks training in AutoCAD Contact Number: 08808522406, 09792894719 E-mail:[email protected] MOHIT SINGH B.TECH%=68.55, 10th%=70.8, 12th%=63.4 Qualification(year) : B.Tech – MECHANICAL ENGINEERING (2014) Training: 5 weeks Industrial Training at The GURDASPUR Co-op Sugar Mills Ltd., 6 Months Industrial Training at LUDHIANA BEVERAGES Pvt. Ltd. (Coca Cola) Contact Number: 09988148145 E-mail:[email protected] DEEPAK KUMAR B.TECH%=67.89, 10th%=43.00, Electrical Engg. Diploma%=53.17 Qualification (year) : B.Tech – ELECTRICAL ENGINEERING(2013) Training: One Month Training From 132 KV Substation, 6 Months Training From 220KV Grid, One Month Training from JCT Ltd Chohal, 6 Months Training in PLC & SCADA HR. Contact Number: 09463528667, 09779628667 E-mail:[email protected] LALIT KUMAR VARSHNEY B.TECH%=67.84, 10th%=69.90, 12th%=66.20 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2014) Training: 4 Weeks Experience on Production Aspects At Ambuja Cement (Raipur Bhatapara), 1 Month Industrial Training in Railways (Diesel Loco Shed), Solidworks & AutoCAD (Drafting Software), Software Skills C, C++, MS Office. Contact Number: 08528970990, 09793290910 E-mail:[email protected] ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p STUDENT PROFILE ABID HAWARI B.TECH%=67.73, 10th%=52.60, Automobile Engg. Diploma%=77.89 Qualification (year) : B.tech – Mechanical Engineering (2013) Training: 1 month Summer Training from BHEL (350mw CCPP Plant Surat), 1 Month Training In Auto Cad and 1 Month Summer Training From JAYESHREE Ford Jamshedpur Experience: 8 Months From Bajaj Allianz GIC Ltd. (Motor Claim DEPTT.) and 8 Months From Swastik Fruits Product Ltd. Contact Number: 09636630410, 08289058523 E-mail:[email protected], [email protected] SUBHASH CHANDRA SHARMA B.TECH%=67.66, 10th%=45.66, 12th%=64.00 Qualification (year) : B.Tech - Electrical & Electronics Engineering(2010) Training: 3 Months Industrial Automation Training in PLC, SCADA, HT, LT Panals & Drives from NISUS Micro Tech. Ahemdabad and 1 Month Summer Training on Power Transformer in BHEL JHANSI Experience: 3 Years, Experience in Operation & Maintenance 66kv/11kv Sub Station and Distribution of 11kv/220v From BSES Rajdhani Power Ltd. New Delhi, Contact Number: 09501095835 E-mail:[email protected] MANISH RANA B.TECH%=67.50, 10th%=58.00, 12th%=47.50 Qualification (year) : B.Tech – Electrical& Electronics Engineering (2012) Training: 6 Months Training at BHEL Haridwar, 2 Months Training at National Fertilizer Limited NAYANANGAL Experience: 2 years experience in ALLENGERS MEDICAL SYSTEMS LTD. Contact Number: 09882429997 E-mail:[email protected] AVINASH SHARMA B.TECH%=66.76, 10th%=63.60, 12th%=58.40 Qualification (year) : B.Tech – Mechanical Engineering (2014) Training: 6 Months Industrial Training in NHPC SAINJ, Hydro Power House , 2 Months Industrial Training in Sigma Frudenberg NOK. MOHALI (Pb.) Contact Number: 09041136386 E-mail:[email protected] RAMAN GOLEY B.TECH%=66.75, 10th%=64.00, 12th%=54.00 Qualification(year) : B.Tech – MECHANICAL ENGINEERING(2010) Training: 2 Months Tranning in J.K Tyre Pvt. Ltd GWALIOR., 3 Months Training of AutoCAD. Experience: 8 Months as Service Engineer in Ford Motor Workshop Gwalior. Contact Number: 08962508089, 09302326039 E-mail:[email protected] SIDDHANT SINGH B.TECH%=66.71, 10th%=75.14, Electrical Engg. Diploma%=65.52 Qualification(year) : B.Tech – Electrical Engineering (2013) Training: 1 Month Training From 126MW Largi Hydro Power Project Mandi H.P, 1 Month Training at 12MW Baner Hydel Project Kangra H.P and 1 Month Training In Robotics & PCB Designing from Strobotix Chandigarh. Contact Number:09418644090 E-mail:[email protected] ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p STUDENT PROFILE SACHIN CHAUDHARY B.TECH%=66.40, 10th%=65.80, 12th%=68.25 Qualification (year) : B.Tech – Electrical & Electronics Engineering(2013) Training: 1 Month Training At NTPC (TANDA). Basic Knowledge in Java & C. Contact Number: 09457522038 E-mail:[email protected] ANMOL RANA B.TECH%=66.20, 10th%=62.00, 12th%=60.00 Qualification (year) : B.Tech – MECHANICAL ENGINEERING (2014) Training: 6 Months Industrial Training In JAGER GAMMON Joint Venture in LARJI Power House Kullu (H.P.) , 2 Months Industrial Training from H.R.T.C. Workshop, Palampur (H.P.) Contact Number: 09805890947 E-mail:[email protected] MD IQBAL ANWER B.TECH%=65.60, 10th%=72.00, 12th%=72.80 Qualification(year) : B.Tech – Mechanical Engineering(2013) Training: 1 Month Training in AutoCAD, 1 Month Summer Training from HMT (Hindustan Machine Tools) Experience: 1 Year (AUDI GURGAON) Contact Number: 07087168801, 09529341388 E-mail:[email protected] AJAY SHARMA B.TECH%=61.78, 10th%=61.40, 12th%=72.80 Qualification(year) : B.Tech – MECHANICAL ENGINEERING (2011) Training: 6 Months Training in International Tractors Limited(sonalika), 3 Months Training in AutoCAD and Catia Experience: 11 Months Experience in HIM Cylinder Ltd. as Quality cum Lab Engineer Contact Number: 09805108473 E-mail:[email protected] RAVINDRA SINGH B.TECH%=60.28, 10th%=58.00, 12th%=54.00 Qualification(year) : B.Tech – Electrical & Electronics Engineering (2013) Training: 1 Month Training from D.L.W Varanasi, Java Course from DUCAT Contact Number: 09473662823, 09415390846 E-mail:[email protected] RAJESH THAKUR B.TECH%=59.10, 10th%=58.00, 12th%=66.60 Qualification (year) : B.Tech – ELECTRICAL & ELECTRONICS ENGINEERING (2012) Training: 6 Months Industrial Training at "192 MW A.D Hydro Power Ltd. MANALI (H.P)", 4 Months Automation, PLC and SCADA Course from SOFCON, NOIDA Contact Number: 09816753848 E-mail:[email protected] ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p STUDENT PROFILE PRASHANT JOSHI B.TECH%=58.30, 10th%=62.70, 12th%=58.40 Qualification(year) : B.Tech – ELECTRICAL ENGINEERING(2012) Training: 1 Month Training from 132KV Substation, Six Weeks Training from KOL DAM Hydro Electric Project 200X4 MW (NTPC), Certificate Course in Electrical Design (L.T) and AutoCAD Drafting From Dhanush Engg. Ltd. Delhi, Pursuing PGDPM & LW from H.P.U Contact Number: 09459019417 E-mail:[email protected] RAJAT KUMAR SINGH B.TECH%=52.42, 10th%=70.00, 12th%=59.75 Qualification (year) : B.Tech – MECHANICAL ENGINEERING (1999) ŸExperience: 12yrs 7 months in Transmission, Distribution, Rural Electrification with 33/11 KV Substation, Conversion of LT line to 11 KV on all the Agricultural Consumers fed 3 phase 3 wise feeders under HVDS Scheme. Erection, Testing & Commissioning of new 6.3/10/16/25 KVA Distribution Transformer, New 33/11 line Bay Extension at existing substation, 3.15 MVA 33/11 KV, 3 phase, 50 Hz Power Transformer Installation APDRP Projects, Project Execution Monitoring of Petrochemical Complex. Casting, Manufacturing & Assembly of IC Engines, CNC Machine Tools, Milling M/C, Lathe M/C, Drilling M/C. Training Courses: AutoCAD, Programming & Operation of CNC Machine Tools, C, C++, OOPS, Data Structure, Manufacturing & Assembly of RX 100 YAMAHA Motorcycle at Escorts. Contact Number: 08528175261 E-mail:[email protected] ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p ADVANTAGES TO THE PLACEMENT COMPANIES BY EMPLOYING PGDC (HYDRO) STUDENTS v v v v v v v v v No investment on training and the time for providing training to the newly inducted engineers is saved. The course is a specialized course in Hydro Power Plant Engineering. The engineers trained under this course have an edge over the fresh engineers as they have been specially trained in the Operation & Maintenance, Erection & Commissioning, Manufacturing works, contractor's site etc of Hydro Power Plant. The course curriculum is regularly updated with the latest technologies in the power sector and as per the customized as per the requirements of the industry. The engineers could be placed directly on the site/job after providing a minimal of training concerned with the actual job. HPTC, NPTI helps individual to nurture their talents and skills to transform into a professional. The students avail the opportunity to interact with experienced faculty from prestigious Institutes/ organizations like NTPC, NPCIL. , BBMB, NHPC, PSPCL, THDC,SJVNL, PEC,BHEL, Voith Hydro, CEA The training was given at Power Stations of various ratings ofNTPC (KOLDAM), manufacturingunits like BHEL, Voith Hydro Ltd. and other manufacturer of switchgear, transformers, cables etc. This training program is under the mandatory requirements of the Indian Electricity Regulations act. PLANT VISITS: The trainees have visited the following hydro power plants of different capacities: v Bhakra Power plant PP-I v Bhakra Power plant PP-II v Pong Power Plant, Talwara, BBMB v Ganguwal Canal Power House v Kotla Canal Power House v KOLDAM Project, NTPC Ltd. v Dehar Power Plant, Salapad, BBMB v Tehri Hydro Electric Project, THDC Ltd. ON-JOBTRINING: v v The trainees have undergone On-Job training (operation) 06 WEEKS in BHAKRA Power house, Nangal The trainees have undergone On-Job training (maintenances ) 04 WEEKS in Ganguwal Canal Power house, Nangal TOP RECRUITERS ,u ih Vh vkbZ ikzoh.;a ijkisof`Ùk'p FURTHER CONTACTS MR. MOTILAL SENAPATI Asst. Director (Tech) Programme Director / Placement Incharge HPTC, NPTI, NANGAL (PUNJAB) E-Mail:[email protected] Fax:-01887221129 Mob:- (91)8427202574 Mr. G.V. Harshe, Director(Tech) HPTC, NPTI, NANGAL (PUNJAB) E-mail:[email protected] Fax:-01887221129 For Further information, visit our Website: -www.nptinangal.in

© Copyright 2026