Building a Solar Cell

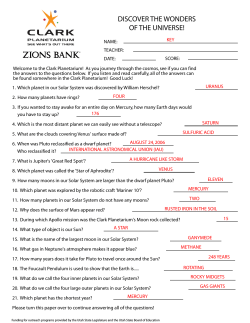

Building a Solar Cell This project was constructed by a group of students from Liceo M.A. Vassalli, Qormi together with their physics teacher. Initial observations During a lesson in the lab, our Physics teachers showed us a solar panel and described how these objects could change the energy given by the sun to electrical energy. We were very interested and asked the teacher a lot of questions about these objects. How could these small black panels change the rays of the sun to electricity in order to drive a motor? Why didn’t we use these things to generate electricity and avoid using fossil fuels that create some much pollution? By using these panels we could do away with using fossil fuels and may be generate electricity in a cheaper way! We could also reduce pollution by reducing our dependency on the power station! Our teacher however told us that these panels were very expressive and we needed bigger solar panels even to light a bulb. Therefore we decided to find out if we could actually construct our own solar cell with material that could be easily found and eventually try to improve our project in order to generate as much electrical energy as possible. Purpose of the Project In this project we want to find out if we can actually construct our own solar cell and improve its design to make it work as efficiently as possible. We would also like to find out how real solar panels work and why electrical energy is generated when these are placed in the sun. The project wants to find an answer to the following questions; 1. 2. 3. 4. Can a solar panel be constructed from the material we find at home? How do actually solar cells work? What is the best design for the solar cell to be more effective? What is the highest voltage and current that can be generated by our solar cell? How can these values be increased? 5. What is the highest power we can generate using the solar cell? 6. How shall our cell compare with a commercial cell? 7. Would it be possible to generate enough energy to light a 100W bulb through our cell? Building a solar cell 1 Our Hypothesis From our initial research on the internet we found out the solar cell can be constructed using simple material such as copper plates and other material found at home and at school. The descriptions found also suggested that the battery could not generate a lot of electrical energy. When considering the questions we want to answer, we think that; 1. The solar cell could be constructed using simple and cheap material. 2. The solar panel changes energy from the sun to electrical energy but there must be some chemical reaction taking place in the solar panel. We needed to find more about this. 3. We believed that the solar cell should actually have a flat shape so that when facing the sun the same amount of energy falls on each part of the solar panel. 4. We also believed that the voltage and current must be low but from our Physics lessons we think that by connecting the batteries in series and/or parallel we can have higher values. 5. The power of the cell shall depend on the amount of sunlight; the more the power of the sun, the higher the power of our battery. Our teacher also suggested that the power can be calculated form the equation Power = Current x Voltage. 6. We believe that our cell will generate less power than a commercial cell. 7. We think that more panels would be needed to light a 100W bulb but a less powerful bulb might light. Identify Variables When constricting our solar cell we needed to have something that remained fixed through the experiment. Therefore we discussed that the better thing to do is to have the same surface area (0.12m x 0.14m = 0.0168m2) for our solar panel and this had to be kept the same way each time a cell had to be constructed. This was our control. The variables in our experiment were; i) the shape of the cell. ii) the amount of sunlight on the cell. iii) the number of cells used to generate electrical energy. Designing the experiments to test our hypothesis Through our research we noticed that we could actually design a solar cell using copper plates and cuprous oxide plates (Cu2O). The research also suggested that we could actually design two types of solar panels we called ‘Bottle type solar cell’ and ‘Flat panel solar cell’. As already suggested, we decided to keep the same area for the solar panel which was 12 cm by 14cm (168cm3) and try to check which solar panel could produce the higher values of Building a solar cell 2 current and voltage. After selecting the best design, we could perform further activities on that particular set up. Before we, decided to find out how the solar cell worked. Theory behind the study In 1839 Edmund Bequeral, a French physicist, documented the effect of sunlight on two electrodes in a weak conducting solution. A small voltage was measured when the setup was exposed to sunlight. Bequeral and other scientists began to build more powerful systems using the sun's energy as a power source for creating electricity, but the knowledge of how to reliably harness the sun's energy was not understood. Further studies where carried out (See Appendix 1) and much later efforts were concentrated on the use of semi-conductors. We tried to follow Bequeral’s steps in constructing our own solar cell. How do typical solar cells work? Different solar cells use different types of semi-conducting materials to work (See Appendix 2). In our solar cell the semi-conductor is the cuprous oxide. In the cuprous oxide there is an energy gap between the electrons that are tightly bound to the atom, unavailable for conduction, and the electrons that are farther from the atom and free to move and conduct. Energy from the sun gives the tightly bound electrons enough energy to bridge the energy gap and move in to the conduction band where they are free to conduct electricity. This takes place because sunlight is composed of photons, which can be thought of as "packets" of energy (the amount of energy in a photon being proportional to the frequency of its light). When photons strike a solar cell, the vast majority are either reflected or absorbed (some really highenergy photons will blow right through, but they're of no concern here). When a photon is absorbed, its energy is transferred to the semiconductor - in particular, to an electron in an atom of the cell. If enough energy is transferred, the electron can escape from its normal position associated with that atom. In the process, the electron causes a hole (i.e., an empty spot where the electron used to be) to form. Each photon with enough energy will normally free exactly one electron, and one hole. Note that both electrons and holes are mobile, and as such can be current carriers. The electron flow provides the current, and a voltage. With both current and voltage, we have power, which is just the product of the two. To find the efficiency of the solar cell we shall calculate the incident power of the sun. To find the incident power from the sun we have to multiply Building a solar cell 3 the solar constant (1000W/m2) by the area of the solar cell in square meters. Typically a photovoltaic cell is composed of a thin wafer consisting of an ultra-thin layer of phosphorus-doped (N-type) silicon on top of a thicker layer of boron-doped (P-type) silicon. An electrical field is created near the top surface of the cell where these two materials are in contact, called the P-N junction. Regardless of size, a typical silicon PV cell produces about 0.5 – 0.6 volt DC under open-circuit, no-load conditions. The current (and power) output of a PV cell depends on its efficiency and size (surface area), and is proportional the intensity of sunlight striking the surface of the cell. For example, under peak sunlight conditions a typical commercial PV cell with a surface area of 160 cm2 will produce about 2 watts peak power. If the sunlight intensity were 40 percent of peak, this cell would produce about 0.8 watts. Therefore we shall also try to compare our results with those of a commercial cell. Constructing our project Solar panel Type 1: Bottle type solar cell Materials A sheet of Copper Crocodile clips Copper wire Large plastic bottles (Picture 5) Some table salt Tap water Sheet metal shears Tools Picture 1: Plastic bottles used An electric stove Ruler A sand paper or a wire brush Scissors Method 1. The first step was to cut the copper in pieces which were about the size of the burner on the stove (Picture 2). Then wash the copper plates with soap to get any oil or grease off of it. Use the sandpaper or wire brush to thoroughly clean the copper plates, so that any sulphide or other light corrosion is removed. Building a solar cell Picture 2: Cutting the copper plates to be burnt 4 2. Place a plate of the cleaned and dried copper on the burner and turn the burner to its highest setting. As the copper gets hotter, it will take a black coating of cupric oxide. 3. When the burner is glowing red-hot, the sheet of copper will be coated with a black cupric oxide coat (Picture 3). Let it cook for another half an hour, so the black coating will be thick. This is important. Since a thick coating will flake off nicely, while a thin coat will stay stuck to the copper. After the half hour cooking, turn off the Picture 3: The black cupric oxide coat burner. 4. Leave the hot copper on the burner to cool slowly. As the copper cools, it shrinks. The black cupric acid also shrinks. But they shrink at different rates, which make the black cupric oxide flack off. When the copper has cooled to room temperature (this takes about 20 minutes), most of the black oxide will be gone. A light scrubbing with your hands under running water will remove most of the small bits. Don’t remove all the black spots by hard scrubbing or by flexing the soft copper. This might damage the delicate red cuprous oxide layer we need to make the solar cell work. 5. Cut in the plastic bottle (Picture 4) and inside put a burnt copper and a new piece of copper of the same size without touching one another. Attach the alligator clips, to the new copper plates and to the cuprous oxide coated plates in a Picture 4: Cut plastic bottle series circuit. Connect the lead from the last clean copper plate to the positive terminal of the meter. Connect the lead from the last cuprous oxide plate to the negative terminal of the meter. 6. Now mix a couple teaspoons of salt into some hot water. Stir the saltwater until all the salt is dissolve. Then carefully pour the saltwater in the bottles being careful not to get the clip leads wet. The saltwater should not completely cover the plates-you should live about 2/3cm of plate above the water, so you can move the solar cell around without getting the clip leads wet. Building a solar cell 5 Solar panel Type 2: Flat panel solar cell Materials (Picture 5) Cd case Silicone rubber glue Copper plates Copper wire Salt Water Large eyedropper Crocodile clips Picture 5: Materials used Tools Ruler Screwdriver Scissors Hot plate Method Picture 6: Cutting the copper plates 1. The first step to make is a cuprous oxide plate. This is done with the hot-plate by bringing one side of the copper plate red-hot as described above in the ‘Bottle Type solar cell’. This time we sanded one corner, clean it all the way down the shiny copper using fresh water. As the copper plates were cut, an end was left as the negative lead to which the crocodile clips and wires could be connected. 2. We made the positive plate by cutting a copper sheeting, a little bit larger than the cuprous oxide plate. Again as the copper plates were cut, ends were left to connect the crocodile clips (Picture 6). Picture 7: Removing some ends of the case 3. The cd cases were opened and some of casing was removed from the middle using a screwdriver (Picture 7). Building a solar cell 6 4. The next thing to do is to glue the copper plate to the cd case. We used plenty of silicone glue so the saltwater won’t leak. 5. We noticed that the silicone glue doesn’t have to completely cover all the copper because some of the copper must eventually have to make contact with the saltwater (Picture 8). 6. The preceding step was to lay a good size bead of glue onto the clean copper plate. This layer will be as an insulator between the copper plate and the cuprous oxide plate. It must be thick to fill it with saltwater. Picture 8: Gluing the copper plates 7. Now the cuprous plate was gently pressed onto the glue. You should press hard to make sure that the glue seals off and there aren’t any gapes. One has to be careful when pressing; make sure that the two plates don’t touch. 8. Note that we left a hole so than we can add the saltwater. To make sure that no saltwater will leak out; make another bead of glue all around the plates. 9. The next step is to add the saltwater with the large eyedropper and fill the cell to the top of the copper plate. Then make another bead of glue to seal the hole and leave the glue to dry. 10. Now the flat panel solar cell was ready to be tried out! Trying out our project: Results and Calculations When trying out our two solar cells, we found out that the ‘Bottle type solar cell” the voltage in the shade was 0.105V while in the sun the voltage was 0.134 and a current of approx. 89 micro amps was reached. Building a solar cell 7 This means that the power generated by the ‘Bottle type solar cell’ in the sun was, P = I . V = 0.000089A x 0.134V = 11.9 micro Watts Where the power Input = 1000W/m2 x 0.0168m2 = 16.8W and power output = 11.9 micro Watts The efficiency of our cell is therefore very low! When trying out the ‘Flat panel solar cell” the voltage in the shade was 0.023V while in the sun the voltage was 0.03V and a current of 34 micro amps was reached. This means that the power generated by the ‘Flat panel type solar cell’ was, P= = = I.V 0.000034A x 0.03V 1.02 micro Watts One notes that the ‘Bottle type solar panel’ generates a higher power output and is more efficient. Therefore we decided to construct a number of ‘Bottle type solar cells’ (9 cells, see picture aside) to increase the power generated. We have also decided to connect the cells in series with each other to try maximize the voltage generated. In the shade the 9 cells generated 0.825V Building a solar cell 8 When connecting the cells in series and placed in the sun, voltage increased to 0.917V (at times it was greater than 1V!) but the current didn’t change much. The current obtained was about 84 micro amps. This generated a power of 77 micro Watts in sunlight. When connecting the cells in parallel the voltage was very low and the current didn’t increase much. Actually the experiment had to be repeated various times to obtain any readings. Conclusions and consideration of results When thinking of our questions we can say that not all our hypotheses were correct. 1. We constructed the solar cell and it worked using simple material found at school and at home. 2. We learnt how solar cells work because they are made of a semi-conductor. 3. The best solar cell was not the one with flat surface but the ‘Bottle type solar cell. It generated a power output of 77micro Watts. It is not a high value but we believe that if the experiment was to be repeated in summer the values can be 2 and even 3 times higher. 4. We noticed that the voltage can be increased when connecting the cells in series and it increased each time we added a cell but the current was still very low. When connecting the cells in parallel the current didn’t increase a lot although when Building a solar cell 9 discussing with the teacher we think it should have increased. Our main problem was to increase the current – We generated only a very low current. 5. The power of the cell depended on the amount of sun because with no sun, the voltage and current were reduced. This really reduced the power generated. For this reason we think that that if the experiment was repeated in summer, when the rays of the sun are stronger, the readings would be better and also our value for efficiency. 6. Our cell generated less power than a commercial cell because while our cell gave 12microWatts of power (in January), we found that a commercial cell would generate 0.8 Watts in peak sunlight. However we are happy with our results because commercial cells need a lot of work and manufacturing to be done and our cell was made up from simple material you find at school and at home. 7. To light a 100W battery we would actually need about 8,000,000 similar! The number will certainly be reduced if the experiment is performed in summer. Another problem with this type of cells is that the copper plates tend to become corroded in the salty water and the performance of the cell reduces with time. We have found out that after a month the cell generates almost no voltage. However we are happy with our results since we learnt a lot about solar cells and how to make one that works. References Breithaupt, J. (2001). Key science. Physics. Cheltenham: Stanley Thornes Lister, T and Rensham, J (1991). Understanding Chemistry. Cheltenham: Stanley Thornes http://www.fsec.ucf.edu/pvt/pvbasics/ http://www.greenenergy.org.uk/pvuk2/technology/types.html http://www.solarenergy.com/info_history.html http://www.solarbotics.net/starting/200202_solar_cells/200202_solar_cells.html http://www.thesolarplan.com/articles/your-own-solar-panel-collector.html http://sci-toys.com/scitoys/scitoys/echem/echem3.html http://sci-toys.com/scitoys/scitoys/echem/echem2.html#solarcell http://www.howstuffworks.com/solar-cell1.htm Building a solar cell 10 Appendix 1: History of Solar cells. After Bequerel, much later in 1877, Charles Fritts constructed the first true solar cells (at least, the first resembling modern cells in that it was made from only solid materials) by using junctions formed by coating the semiconductor selenium with an ultrathin, nearly transparent layer of gold. Fritts's devices were very inefficient, transforming less than 1 percent of the absorbed light into electrical energy, but they were a start. Substantial improvements in solar cell efficiency had to wait for a better understanding of the physical principles involved in their design, provided by Einstein in 1905 and Schottky in 1930. By 1927 another metal semiconductor-junction solar cell, in this case made of copper and the semiconductor copper oxide, had been demonstrated. By the 1930s both the selenium cell and the copper oxide cell were being employed in light-sensitive devices, such as photometers, for use in photography. These early solar cells, however, still had energy conversion efficiencies of less than 1 percent (so they made fine light sensors, but lousy energy converters). PV cell by Bell Laboratories Solar cell efficiency finally saw substantial progress with the development of the first silicon cell by Russell Ohl in 1941. In the early 1950's, Bell Laboratories was able to build the world's first PV cell. The small circuit, similar to that of a transistor battery, harnessed and utilized solar energy for a human advantage-electricity. Scientists were able to capture energy from the sun's photons and transfer the energy into electricity. The early system used layers of pure silicon to serve as semiconductors within the photovoltaic cell. Because of the high expense of these early solar cells, experimentation and use mainly occurred in laboratory settings. Bell tried to advertise the use of photovoltaics for the "everyday" family, but using pure silicon as the semiconductor made this feat monetarily difficult for most people. In 1954, three other American researchers, G.L. Pearson, Daryl Chapin, and Calvin Fuller, demonstrated a further-refined silicon solar cell capable of a 6% energy conversion efficiency (in direct sunlight). By the late 1980s silicon cells, as well as those made of gallium arsenide, with efficiencies of more than 20% had been fabricated. In 1989 a concentrator solar cell, a type of device in which sunlight is concentrated onto the cell surface by means of lenses, achieved an efficiency of 37% thanks to the increased intensity of the collected energy. Building a solar cell 11 Appendix 2: Types of PV cells Monocrystalline Silicon Cells: Made using cells saw-cut from a single cylindrical crystal of silicon, this is the most efficient of the photovoltaic (PV) technologies. The principle advantage of monocrystalline cells are their high efficiencies, typically around 15%, although the manufacturing process required to produce monocrystalline silicon is complicated, resulting in slightly higher costs than other technologies. Multicrystalline Silicon Cells: Made from cells cut from an ingot of melted and recrystallised silicon. In the manufacturing process, molten silicon is cast into ingots of polycrystalline silicon, these ingots are then saw-cut into very thin wafers and assembled into complete cells. Multicrystalline cells are cheaper to produce than monocrystalline ones, due to the simpler manufacturing process. However, they tend to be slightly less efficient, with average efficiencies of around 12%., creating a granular texture. Thick-film Silicon: Another multicrystalline technology where the silicon is deposited in a continuous process onto a base material giving a fine grained, sparkling appearance. Like all crystalline PV, this is encapsulated in a transparent insulating polymer with a tempered glass cover and usually bound into a strong aluminium frame. Amorphous Silicon: Amorphous silicon cells are composed of silicon atoms in a thin homogenous layer rather than a crystal structure. Amorphous silicon absorbs light more effectively than crystalline silicon, so the cells can be thinner. For this reason, amorphous silicon is also known as a "thin film" PV technology. Amorphous silicon can be deposited on a wide range of substrates, both rigid and flexible, Building a solar cell 12 which makes it ideal for curved surfaces and "fold-away" modules. Amorphous cells are, however, less efficient than crystalline based cells, with typical efficiencies of around 6%, but they are easier and therefore cheaper to produce. Their low cost makes them ideally suited for many applications where high efficiency is not required and low cost is important. Other Thin Films: A number of other promising materials such as cadmium telluride (CdTe) and copper indium diselenide (CIS) are now being used for PV modules. The attraction of these technologies is that they can be manufactured by relatively inexpensive industrial processes, certainly in comparison to crystalline silicon technologies, yet they typically offer higher module efficiencies than amorphous silicon. New technologies based on the photosynthesis process are not yet on the market. Building a solar cell 13

© Copyright 2026