We design the future of packaging. .

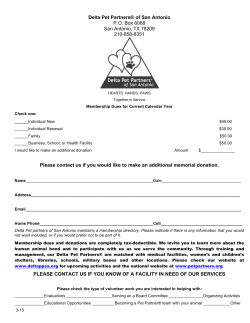

The Company We design the future of packaging. PET ENGINEERING is a world leader in the design and industrialisation of PET containers with a portfolio of exclusive beverage brands such as Rocchetta, Nestlé Waters, PEPSICO, Coca Cola, Rauch, Inbev, Baltika, Efes and many others. A precursor of the market requirements, focusing on the present with a view to the future, PET Engineering is synonymous with design, innovation and Italian-made products. Every idea is transformed into a winning solution capable of not only satisfying the basic requirements of its clients, but also capturing the attention of the consumer, through the adoption of effective and welldefined marketing strategies. A new concept of service and satisfaction. PET Engineering is involved in every phase of the production process: from the designing of the containers and preforms suitable for any type of machine requested, from the industrialisation of the containers right through to the complete start-up of the lines with the supply of blowing moulds and format changes. This makes PET Engineering a unique partner for all requirements relating to beverage packaging. . 2 Our fundamental principles are: • To understand the client – interact with them to understand their requirements and objectives • To be focused – We aim at making our clients’ dreams come true • To be independent – we are not affiliated with any technology • To be innovative – we search for completely feasible design solutions and expressions aimed at industrialisation of the container • To save – small investments for a guaranteed economic return • To provide a complete service – we always keep our promises • To think about the environment – we avoid wasting raw materials and energy and support recycling. 3 The Company Creativity and innovation lead to growth. The Company 4 The company was founded in 1999 with the idea of giving a technical structure to the more and more complex consulting activities of the founder, with the constant drive for growth and improvement of the services. Over time, it has evolved into a cutting-edge technological centre capable of responding effectively to the increasingly more demanding and precise requirements of the clients. The new PET Engineering is an independent and autonomous entity whose working methods are based on absolute confidentiality of the information. Everything is carried out inside the centre with the utmost discretion and professionalism, adopting strict and pre-defined systems and procedures. In these years, the company has found a precise position, being identified with the product offered, and continuing to focus on finding the perfect combination between design and industrialisation. 5 The Company A beautiful environment inspires good work. 6 7 Our modern centre was conceived and built to be an ideal environment where one can work well with passion. It represents and communicates the essence of PET Engineering: rational, unconventional, organised to give the best results, with great technological and aesthetic sense. The architecture of the centre gives preference to wide spaces, light and ergonomics. The Company The areas and atmosphere foster teamwork and personal wellbeing through the equilibrium of the forms and comfort of the operating and relaxation parts, which exist to provide collaborators with moments of recreation. The passage through the functional spaces is fluid because it does not create communication or information barriers, but every area is structured to respond perfectly to its designated use. The Company Constant focus on the future. Key word: innovation. 8 9 The Company Design An innovative laboratory with testing in record time The search for excellence in the performances of the products has always been a key factor of the company’s success. A careful technical analysis of the project according to the client’s specifications, the evaluation of possible improvements aimed at saving materials and energy and making the product “industrialisable”: these are the key elements for creating a new container. Cutting-edge rendering and animation systems are used to develop the designs that lead to defining the technical and stylistic aspects of the packaging, interpreting every requirement coming from the client. Sophisticated simulation software guarantees preventive analysis of the product and mould. A work group closely collaborates to develop the real-size models of the finished products. Maximum precision and guarantee of confidentiality are observed as the projects are covered by industrial secret. In fact, a special Confidential Team, which operates independently from the other company functions, was set up for this purpose. The laboratory of the technological centre is equipped with cuttingedge equipment for testing the containers and for determining the physical-mechanical specifications. PET Engineering offers an in-depth analysis and testing service aimed at supporting the engineering activity and allowing the client to quickly test the bottles and preforms, with careful evaluation of the results. These tests include: • Dimensional tests • Volume and brimful • Top Load and Radial Top Load • Wall Thickness • Analysis and distribution of the material • Thermal stability test • Stress Cracking test • Vacuum analysis • Testing of the carbon dioxide (CO2) and oxygen permeation • Drop Test • Burst Test • Warm and Hot Fill The Company To understand the needs and recognise the goals: this is how we shape your business. 10 11 The Company Production of the moulds Installation and training The company produces moulds for any type of container and blowing machine, ensuring fast delivery and high quality. The simulation software allows conducting preventive analysis on the products and accelerating the production processes. A series of competences together with the most advanced technologies and excellent knowledge of the sector allow the company to offer a highly professional service. An effective and dedicated quality control system guarantees the conformity of the blowing moulds to the requested quality parameters before they are sent to the client. We believe in the transfer and sharing of knowledge, and collaboration according to a principle of complete partnership, before, during and after the realisation of the specific project. The philosophy of PET Engineering is to serve the client in all phases of the project, providing the support necessary for installing and implementing the new formats in the production line, guiding them systematically, and with a personalised approach, in the industrialisation of the product. The assistance also includes setting the parameters of the blowing process and optimising the process for improving the mechanical performances of the container. PET Engineering does not stop here: it also provides clients with actual training on the behaviour of the material, so that they can make independent choices on the type of resins and preforms to use. This translates into an organisational and management advantage for our client, leading to excellent results that can be measured over time. Prototyping The Knowhow 12 Our knowhow is found in every bottle. The Knowhow Research & Development Design Design Prototyping Creativity in the search for elegance and refinement. A new design, ergonomics, captivating and functional containers: these are the rules that govern the design of a container’s structure. Not only objects of design with a cutting-edge style and high technical performances, but also objects designed to comply with and satisfy the needs of people. Thanks to historical experience and more than 8000 bottle designs designed to date, PET Engineering has the expertise to indicate the best design for guaranteeing the efficiency of the line and industrialisation of the container. The prototypes of innovative containers and preforms in record time: you can touch your first bottles after only a few hours from the approval of the design proposal. The use of blowing machines with single or double cavity moulds allows PET Engineering to transform the projects into real objects. Samples and small production batches of up to 100,000 bottles can be produced in very short times, so that the client can view the finished product and test it directly in its production lines. Consultancy Research & Development We provide our knowhow to give a concrete response to all your queries. Our in-depth technical knowledge allows us to support the client in implementing the bottling lines, searching for the best result while limiting useless costs and waste. Our strength comes from being able to provide certified lightweight solutions, working on weight reduction of existing products, converting the thread and on any other type of support fit to promote the industrialisation of a new container. The consulting services are transformed into real turnkey products: we always keep our promises. Consultancy Technological excellence focused on anticipating the market requirements. Constantly looking towards the future in order to find new materials and PET transformation technologies. An activity that is continually evolving according to the market trends in order to identify more evolved and advantageous solutions. In fact, 15% of the PET Engineering personnel work in the R&D department. 13 Beverage design Appealing Brand Design as a form of seduction. Attraction 14 15 More creative freedom Beverage design Marketing Design as an expression of creativity characterised by good taste and research that distinguishes all Italian made products. A design object must be functional, but above all, beautiful and must evoke pleasure. It must have personality and stand out. The harmonious combination of the colours, shape, size and easy-to-handle packaging are what make a container successful; an almost alchemic harmony that only applies to that specific case. The fulcrum of our creative study is that each product has its own reason for being and transmits positive sensations to those who use Creativity it or just want to admire it. Passion, emotion and seduction: these are the sensations conveyed by our designs. A mix to amaze and captivate, enticing the consumer to personally touch what they see on a shelf. A beautiful container translates autonomously into product communication, becoming one with its contents. This clever mix can only lead to market success. The long experience of PET Engineering and direct contact with the marketing department of its clients allows it to produce an excellent product. Ecology Light weighting Eco-munication The value of the environment. 16 Recycling Ecology 17 Ecology The environmental philosophy New behaviours call for new responsibilities. Our attentiveness towards contemporary lifestyles and behaviours, and the needs of society and globally evolving operators, lead us to study daily strategies for assessing the environmental impact of a container. In this context, the study for an eco-friendly packaging represents an important and critical element, pursued with the aim of obtaining a result that allows preserving the characteristics of the product. With the defining of this quality concept comes the necessity to sensitise the final consumer, creating containers that make it possible to recognise, evaluate, appreciate and choose a product, also due to its packaging. Environment Therefore, we are committed to creating packaging and implementing technologies that minimise energy consumption during the blowing phase and that reduce waste production for the final user, both in terms of quantity and type, promoting the use of eco-friendly materials. Special attention is placed on the responsible use of the resources, limiting waste in all the production phases. We promote an environmentally friendly culture by adopting measures that contribute effectively in saving energy. A value that is also of interest to our clients Technical service The best partner for upgrading your lines. Neck finish changeover Upgrading Revamping 18 19 To innovate also means to improve what already exists Start-up Technical service Tuning Making changes is what translates into new excellence and performances for machines that have been set according to parameters that no longer satisfy the requirements of production, design and ease of handling. It is called upgrading. Collaborating closely with clients has always been a cardinal principle of PET Engineering – today more than ever – focused on pursuing an ambitious goal: to be the best partner for the sustainable development of a business, even in financial terms, recommending in a transparent way the necessary intervention levels. At times, it is sufficient to simply to improve and perfect a product without distorting it, always thinking about the quality of the results. Key elements: • Minimal investment with quick economic returns • Blowing process: conversions on the blowing machines (preform thread change) and optimisation of the processes by updating the machines in order to downsize the container Supplying of the complete set for converting and upgrading the entire bottling line Upgrading of the connected or separate lines for developing new preforms and containers. • • Everywhere Where we are in the world. Market Moscow San Vendemiano 20 21 International Everywhere Strategic position Global market San Vendemiano, Italy Moscow, Russia Centre of excellence with an extremely modern prototyping department in the forefront of manufacturing prototypes and industrial moulds. As a result of the specific and particular nature of the services provided, it is the most innovative and important reference in the European sector, making it a very important international player capable of offering a complete, fast and highly professional service. PET ENGINEERING VOSTOK has been serving the strategic market of East Europe since 2007. The factory is located in the heart of Moscow and collaborates closely with the Italian centre to provide a turnkey service that includes logistical coordination, customs documentation, assistance, training and spare parts. Independent client support guarantees technical assistance and consultation for choosing the most suitable containers, machinery and for optimising the production chain. PET ENGINEERING SRL Via Celtica 26 Zona industriale Ungheresca Sud 31020 San Vendemiano (TV) Tel: +39 0438 403069 Fax: +39 0438 408420 e-mail: [email protected] web-site: www.petengineering.com PET ENGINEERING VOSTOK LTD Tel: + 7 495 661 2777 e-mail: [email protected] web-site: www.petengineering.com Graphic design and co-ordination: Portfolio, Udine 22 Photographs: Gabriele De Nardo Stefano Lunardi (P.03) Translation: xxxxx Color Separation: xxxxx Printed by: xxxxx E N G I N E E R I N G P E T P.E.T. Engineering S.r.l. Via Celtica, 26/28, Z.I. Ungheresca SUD 31020 San Vendemiano (TV) Italy Tel. +39 0438 403069 Fax +39 0438 408420 [email protected] www.petengineering.com ENG

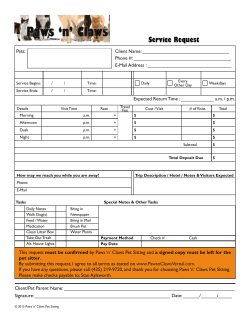

© Copyright 2026