Refractive-index measurement of bulk materials:

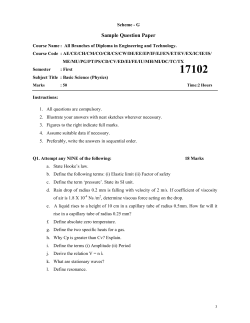

Refractive-index measurement of bulk materials: prism coupling method Hidetoshi Onodera, Ikuo Awal, and Jun-ichi Ikenoue A simple method of measuring refractive indices of bulk materials using a prism coupling procedure is de- scribed. Refractive indices are determined from the measurement of the angle incident to the prism at which total reflection on the prism base breaks. This method is shown to possess the advantages of its simple procedure and sample preparation. The accuracy is comparable with that of minimum deviation method if the prism is well calibrated. Experimental results for several materials are given with an evaluation of possible errors. 1. II. Introduction Refractive-index measurement is one of the most essential techniques in optics. The method of minimum deviations 2 is widely used for this purpose and is regarded as the most reliable standard. However it requires a portion to be cut out of bulk material and a high quality prism to be fabricated for the refractiveindex measurement. It means that we need a sample thick enough (5-10-mm thickness) to cut a prism from. Furthermore, since the refractive index differs from place to place in the sample (due to the slight change in the composition and the amount of impurity), we cannot know the true refractive-index value of the sample on which we are going to work, unless it has the shape of a prism. In this paper we describe a prism coupling method which is applicable to bulk materials of any shape having only one polished face. The experimental arrangement of this method is similar to that of prism excitation in thin film waveguides.3 ,4 Refractive indices can be determined by monitoring the light intensity reflected at the prism-sample interface. The procedure is simple and the accuracy is comparable with that of the minimum deviation method if the apex angle and the refractive index of the prism are well defined. Method The experimental arrangement and the coordinate system are shown schematically in Fig. 1. A tent- shaped prism is tightly mounted on a substrate material whose refractive index should be measured. In the case of an anisotropic substrate, the principal axes should be oriented to the coordinate axes so that the relative permittivity tensor becomes diagonal. The refractive index of the prism np is chosen to be larger than the refractive indices of the substrates nx, ny, nz. As illustrated in Fig. 1, TE(s) or TM(p) polarized light is launched into the prism and is reflected at the prism base with an angle 0. Whether the reflection becomes total or partial is governed by the magnitude of the propagation constant (=npk,, sind) and the refractive index of the substrate. First we assume that the light has TE polarization which senses the refractive index of the y direction ny. If //k 0 is greater than ny, the incident light reflects totally. Therefore the power reflection coefficient Rp becomes unity. When the incident angle 0 decreases and /3/k0 becomes less than ny, some portion of the incident power will be converted into substrate radiation modes, which results in an abrupt decrease in Rp. Numerical expression of Rp is given by ny /kO, Rp = 1, (1) 2 RP - 2 - Se) + (gl + PeSe) tanh2 ged 2 (Pe + Se)2 + (g2 + PeSe) tanh ged = g (pe nig - /3/k0 - ny,, 2 (2) with The authors are with Kyoto University, Electronics Department, Sakyo-ku, Kyoto 606, Japan. Received 25 October 1982. 0003-6935/83/081194-04$01.00/0. © 1983 Optical Society of America. 1194 APPLIED OPTICS/ Vol. 22, No. 8 / 15 April 1983 (3) [ = npko sinO, Pe = (n2kl ge = (2 - n 2)1/2, (4) (5) PRISM Fig. 1. Schematic of experimental arrangement. The coordinate system used in this paper is also illustrated. Se = (nik2 [32)1/2, (6) where ng is the refractive index of the gap between prism and substrate, and d represents the gap thickness. If /3/kois slightly smaller than n, the value of Rp is approximated in a simpler form: 1-4Se tanh2gd 1 (7) 2etanh2ged + Pe In practice, monitoring the power of the output light, the angle of incidence at the prism face a is changed and the critical angle is found where the relation /3/k = ny holds and sudden change of the light power occurs. Then ny can be calculated in terms of a, np, and the prism angle e: ny = sina cose + (n sin 2 a)1/2 sine. - (8) If we turn the prism by 900 on the substrate, n can also be determined. When the incident light has TM polarization, the critical incidence occurs when /3/ko = n The power reflection coefficient Rp for TM polarization has the form: nf - fig S[3/ko /k ,0 Rp = 1, taking the structure of a TiO2 (rutile) prism (no = 2.583, n = 2.865) and a c-cut LiTaO3 substrate (no = 2.176, n = 2.181) as an example. Light of 0.6328-gm wavelength is assumed. The optic axis of the prism is oriented parallel to the prism edge so that TE polarized light senses ne and TM polarized light senses no. The results are shown in Figs. 2 and 3 for TE and TM polarization, respectively. The gap width d is chosen as a parameter. The curves bend sharply at the points where /3/k = 2.176 for TE and 2.181 for TM, which enables us to find the critical angle correctly. Since field penetration of TM polarized light into the air gap is much less than that of TE polarized light, the gap width for TM polarized light should be kept very small to obtain a large decrease in Rp. However, this difficulty can be obviated to a large extent by the use of matching oils for the gap medium. Figure 4 shows the variation of Rp for TM polarization when CH212 (n = 1.74) is used as a matching oil. The rate of decrease in Rp is also related to the refractive index of the prism np. Equations (4), (7), (11), and (14) show that it is preferable to use a prism which has a refractive index close to that of the substrate for a large decrease in Rp. For example, the decrease in Rp is nearly twice that of Fig. 2 when we use a SrTiO 3 prism (n = 2.386) instead of a TiO 2 prism. Ill. incidence is calculated for the same structure employed in Sec. II. The gap is air and the gap thickness is 0.02 gim. For simplicity, we assume that the incident beam is Gaussian in the z direction but homogeneous in the (9)- 2 niRg.2(n.'pm - npsm)2+ (n2n2g, + n4pmsm) tanh 2gmd zm - f242Pm2m22tanh g d 2 g,(n,2p. + flsm + + (nn gm n g m m ix, Rp Error Estimation It is often necessary to measure the refractive index n at some laser wavelengths. When a laser is used as a light source, diffraction problems may be introduced because of the limited radius of the Gaussian beam. This is essentially the same as the diffraction of the beam from a conventional monochromator. To estimate the amount of this error, Rp for Gaussian beam (0) . with Pm = (nk 2 [32)1/2 g. = (2 - n2k2)1/2 S = z (n2k2fix 2)1/2. When /ka is slightly smaller than n, Rp is written approximately IRP as 4nm e1 - !H~Pm 1 - tanh 2 gd fi14) (14) n,2.1 + np4 g. tanh 2gnd fig P. The refractive index n, can be determined in the same manner as for the TE polarized case. To assess quantitatively the variation of Rp around the critical angle a numerical calculation is carried out y direction, and the waist of the Gaussian beam is located at the prism base. In the calculation, a Gaussian beam is decomposed into twenty plane waves having different angular spectra and amplitudes. The results for TE polarization are plotted in Fig. 5. The halfwidth of the Gaussian beam o at the beam waist is chosen as the parameter. The sharp bend of the Rp curve becomes rounded and the point where Rp starts decreasing shifts toward the higher refractiveindex side by the use of a Gaussian beam, which produces some ambiguity in deciding the critical angle. Hence, a large o Gaussian beam should be used in the measurement to obtain high accuracy. For example, if one wants to measure n to the fourth decimal, co should be larger than 0.8 mm. 15 April 1983 / Vol. 22, No. 8 / APPLIED OPTICS 1195 of permitted error in a and eare comparable with those in the minimum deviation method which uses a prism of e = 400 and np = 2. Compared with the Brewster n/k. angle method (Abeles method), these values are relaxed by 1 order of magnitude because a small variation in 0 becomes magnified in a by the refraction at the prism interface. f/. 49.45 49.40 4935 e ( ) Fig. 2. Variation of power reflection coefficient Rp for TE polarization vs the angle of incidence 0 (reflection) at the prism base or the propagation constant [/k0. The parameter at the curves is the gap thickness. /k. nn I- 2181 2130 2.179 d =0.05jmn . 2.182 . 57.60 0.02n e () 0.95 Fig. 4. Rp Variation of power reflection coefficient Rp for TM polar(n = 1.74). ization. The gap is assumed filled with CH2 I2 0.901 I./,~~~~~~ 2.173 0.85 nAr 57.50 -B we 2174 /k. 2175 2.176 2.177 Or/ 57.60 57.55 57.65 e () Fig. 3. Variation of power reflection coefficient Rp for TM polarization. Other errors may originate in the measurement of the incident angle a, the prism apex angle e, and the refractive index of the prism np. By differentiating Eq. (8), we find the amount these errors contribute to the final result. Since these quantities depend on the values of np, e, and a, we consider one example of np = 2.865, e = 50°, and a = -16° (n - 2). When each error is assumed to exist separately, we must know a to better than 30 sec, e to better than 10 sec, and np to better than 0.00013to determine n to within 10-4. 1196 The amounts APPLIED OPTICS/ Vol. 22, No. 8 / 15 April 1983 49.40 () Fig. 5. Variation of power reflection coefficient R, for TE polarization for Gaussian beam incidence. The gap thickness is taken to be 0.02ym. The parameter at the curves is the halfwidth of the incident Gaussian beam. 2173 fl/k. r174 2.175 2.176 2.177 2.178 2179 2.180 P same substrate as in (1), but the measurement was performed another day. The results show the high reproducibility of this method. The substrate used in measurement (3) was cut from the same wafer from which the substrate (1) was cut and annealed at 12000C for 9 h in air. Increases in the refractive index (especially in ne) may be caused by the outdiffusion of Li2 O. , , In measurements (4) and (5), identical refractive indices were measured at different polarizations. Both results agree well within the experimental errors. At these measurements, about two-thirds of the rms errors originated in the use of a Gaussian beam whose halfwidth was 0.42 mm. Hence, the measurement becomes more accurate if a larger Gaussian beam is used. i l -4 00 -350' For example, if we use an 0.8-mm halfwidth Gaussian beam, the amount of the rms errors will be reduced to half. -330' - 340' a' Fig. 6. Measured output light intensity vs incident angle: TiO2 prism; c-cut LiTaO3 sample; TE polarization. Table 1. Measured Refractive Indicesfor Several Materials at 0.6328 lum by the Prism CouplingMethod;These Values are BelievedAccurate to +0.0003 Measurement Substrate 1 2 3 4 5 c-cut LiTaO 3a c-cut LiTaOQa c-cut LiTaO 3 b a -cut LiTaO3c Corning 7059 c-cut LiNbO 3 c-cut A12 03 6 7 TE n = = n = n = 2.1765 2.1765 2.1771 2.1765 n = 1.5283 n = 2.2865 n = 1.7659 fn TM ne= 2.1815 n = 2.1816 ne = 2.1840 no = 2.1765 n = 1.5286 n = 2.2012 ne = 1.7582 a Same substrate was used in measurements (1) and (2). b Substrate was annealed at 1200'C for 9 h in air. cOptical axis was oriented parallel to the propagation direction. IV. Experimental Results V. In the experiment, a He-Ne laser of 0.6328-gm wavelength was used as the light source. Halfwidth of the Gaussian beam was 0.42 mm. The output light intensity was monitored by a Si photocell. All the measurements were performed at 250 i 1C. The prism was TiO 2 and its optical axis was oriented parallel to the prism edge. The refractive indices and the angle of this prism were measured to be ne = 2.8641 0.0001, nr = 2.5830 0.0001, and = 50.773 0.002° in ad- vance by the minimum deviation method. Figure 6 shows the variation of the output light intensity when a c-cut LiTaO 3 was used as the substrate. The polarization was TE so that n was to be measured. The curve agrees well with the theoretical curve illustrated in Fig. 5. Summary We have described a new method of refractive-index measurement utilizing a prism coupling technique widely used in guided wave optics. This method has the advantage of its simple procedure and sample preparation. It is applicable to samples of any shape which have a polished area small enough for prism coupling. Since this method uses an excitation prism as the standard, accurate calibration of the prism is necessary in terms of the refractive index and the apex angle. Another factor limiting the precision is the angular spectrum of the incident beam. Numerical analysis shows that the halfwidth of the Gaussian beam should be more than 0.8 mm to determine the refractive index to within the fourth decimal. The measured refractive indices of LiTaO3 and those References 1. M. Born and E. Wolf, Principles of Optics (Pergamon, Oxford, errors in these results are 0.0003. Since a detectable amount of decrease in Rp was obtained even at TM polarization, we did not use matching oils throughout the measurements. In measurement (2) we used the 1959), pp. 177-180. 2. W. L. Bond, J. Appl. Phys. 36, 1674 (1965). 3. P. K. Tien, R. Ulrich, and R. J. Martin, Appl. Phys. Lett. 14, 291 (1969). 4. R. Ulrich and R. Torge, Appl. Opt. 12, 2901 (1973). of several other materials are listed in Table I. The rms 15 April 1983 / Vol. 22, No. 8 / APPLIED OPTICS 1197

© Copyright 2026