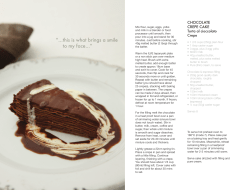

Health Safety Executive