Surface modification of SWRO membranes using

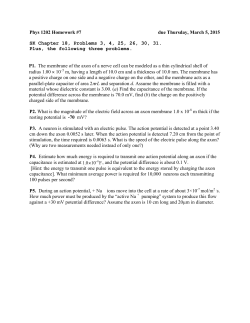

Journal of Membrane Science 486 (2015) 97–105 Contents lists available at ScienceDirect Journal of Membrane Science journal homepage: www.elsevier.com/locate/memsci Surface modification of SWRO membranes using hydroxyl poly (oxyethylene) methacrylate and zwitterionic carboxylated polyethyleneimine Hyoungwoo Choi a, Yongdoo Jung b, Sungsoo Han c, Taemoon Tak a, Young-Nam Kwon d,n a Department of Biosystems and Biomaterials Science and Engineering, Seoul National University, Seoul 151-921, Republic of Korea Toray Chemical Korea, R&D Center, Gumi 730-707, Republic of Korea c Samsung Advanced Institute of Technology, Suwon 443-803, Republic of Korea d School of Urban and Environmental Engineering, Ulsan National Institute of Science and Technology (UNIST), Ulsan 689-798, Republic of Korea b art ic l e i nf o a b s t r a c t Article history: Received 16 December 2014 Received in revised form 12 March 2015 Accepted 16 March 2015 Available online 24 March 2015 Comb-like hydroxyl poly(oxyethylene) methacrylate homopolymer (HPOEM) and zwitterionic carboxylated polyethyeleneimine (carboxylated PEI) were synthesized and applied to the surface of commercially available seawater reverse osmosis (SWRO) membranes to introduce fouling resistance. The successful synthesis of the polymers and modification of the membrane surface were confirmed by X-ray photoelectron spectroscopy, zeta potential and contact angle measurements. Fouling test of the surfacemodified membranes with alginate and bovine serum albumin showed opposite behavior at high salt concentrations: a salting-out effect on the HPOEM-coated membrane and a salting-in effect on the carboxylated PEI-coated membrane. HPOEM-coated SWRO membranes showed better fouling resistance under brackish conditions. However, the zwitterionic carboxylated PEI-coated membrane showed higher affinity to sodium chloride solution than deionized water, and presented an inhibitory effect to foulant adsorption under seawater conditions. This indicates that an effective fouling resistant layer specialized for seawater filtration could be prepared with zwitterionic materials. & 2015 Elsevier B.V. All rights reserved. Keywords: Seawater reverse osmosis Membrane fouling Surface modification Amphiphilic polymer Zwitterionic polymer 1. Introduction Reverse osmosis (RO) membrane technology has been regarded as one of the most economic processes to separate dissolved salts from solvent, and thus has been applied to a wide range of processes including the purification of brackish water, reclamation of wastewater, and desalination of seawater. However, the wide application of RO technology has sometimes been limited due to the problem of membrane fouling. Fouling is the attachment or adsorption of rejected particles or molecules onto the surface or within the pores of the membrane, causing decline of water flux. In order to mitigate membrane fouling, several approaches have been used, such as pretreatment of the feed before membrane filtration, the development of new types of membranes [1–3], and surface modification of membranes [4–7], as well as effective membrane cleaning [8,9]. Surface modification methods to enhance the antifouling characteristics include changes to the surface roughness, hydrophilicity, and charge, without worsening the perm-selective properties. Polyethylene glycol (PEG) has widely been used for the preparation of n Corresponding author. Tel.: þ 82 52 217 2810. E-mail address: [email protected] (Y.-N. Kwon). http://dx.doi.org/10.1016/j.memsci.2015.03.040 0376-7388/& 2015 Elsevier B.V. All rights reserved. fouling-resistant membranes [10–12]. Previous studies showed surface-bound long-chain hydrophilic PEG to be very effective in preventing the adsorption of macromolecules such as protein onto the membrane surface due to the steric repulsion mechanism. They have inherent affinity and a tendency to form a huge complex with the surrounding water molecules, forming hydrated layers on the membrane surface in aqueous solution [13]. Although PEG is known as one of the most effective materials for the preparation of antifouling membrane surfaces to date, it is noteworthy that PEG moieties have also been frequently used for protein crystallization in combination with some salts [14]. This technique, which is called the “saltingout method”, has been used to separate and concentrate proteins in mixed solution of high salt concentration. Zwitterionic polymers (polyampholytes) are polymers possessing both positively and negatively charged functional groups, such as polyphosphobetaine, polysulfonbetaine, and polycarboxybetaine [15]. Ji et al. investigated composite nanofiltration membranes containing zwitterions [16]. The results showed that the extent of fouling was significantly reduced, and most of the fouling was reversible during the MgCl2 and protein filtration test. Zhang et al. prepared ultrafiltration membranes using cardo poly(arylene ether sulfone)s, one bearing pendant zwitterionic carboxybetaine groups (PES-CB) and the other bearing pendant sulfobetaine groups. The carboxybetaine 98 H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 poly(arylene ether sulfone) (PES-CB) membrane showed significant resistance to protein adsorption [17]. Most previous studies on zwitterionic polymers have primarily focused on improvement of their biocompatibility [18,16,19], while little research has investigated the antifouling properties of zwitterionic materials [17,20]. Earlier researchers discovered that polyzwitterions show unique behavior in aqueous solution. The solution behavior of polyampholytes is often opposite to that of polyelectrolytes at high salt concentration, exhibiting the so called antipolyelectrolyte effect (salting-in behavior). Polyzwitterions swell significantly more in saline solutions than in pure water due to chain expansion in the presence of low molecular weight electrolytes [21]. Considering the results of these studies, zwitterionic polymers appeared to be worth of exploration as antifouling coating material for seawater reverse osmosis (SWRO) membranes. Such an expanded polyzwitterionic layer was expected to form an effective steric barrier against membrane fouling in seawater conditions. In the present study, the antifouling properties of the PEG moiety (hydroxyl poly(oxythylene) methacrylate homo polymer, HPOEM) and zwitterionic carboxylated polyethyleneimine (carboxylated PEI) were systematically investigated. Comb-like HPOEM homopolymer was synthesized via free radical polymerization and applied on a commercial SWRO membrane. A zwitterionic carboxylated PEI coating layer was introduced on the SWRO membrane using the dip-coating process followed by cross-linking and N-carboxylation steps. The physicochemical properties of the neat and modified membranes were characterized using various analytical tools, and the antifouling properties of the membranes were evaluated by cross-flow filtration tests under treatment conditions of brackish water and seawater. 2. Experimental 2.1. Materials Seawater reverse osmosis membranes (denoted as SHN) from Toray Chemical Korea were used as the SWRO control membranes. The SHN membrane is a thin film composite (TFC) SWRO membrane with a selective polyamide skin-layer polymerized on the interface of a polysulfone sub-layer supported by non-woven fabric. Hydroxy poly (oxyethylene) methacrylate (HPOEM, number average molecular weight (Mn) 360), Azobisbutyronitrile (AIBN), tetrahydrofuran (THF), petroleum ether, methanol, ethanol, branched polyethyleneimine (PEI, Mw 800), glutaraldehyde solution (GA, grade II, 25%), bromoacetic acid, potassium hydroxide, bovine serum albumin (BSA), and alginic acid from brown algae were purchased from Aldrich Chemical (Korea). HCl and NaOH were purchased from Daejung Chemicals & Metals Co., Ltd. (Korea). All chemicals used in this study were of reagent grade and used without further purification. 2.2. Preparation of HPOEM coated SWRO membrane HPOEM homopolymer was synthesized via free radical polymerization, and the HPOEM homopolymer-coated SWRO was prepared using the previously reported method [22]. Predetermined amounts of HPOEM (80 g) and AIBN (2 g) were dissolved in THF (20 g) in a dropping funnel. A 1000 mL 4-neck round bottom flask containing THF (300 g) was placed in a water bath and preheated to 6671 1C under nitrogen atmosphere and stirred gently for 30 min. The monomer solution in the dropping funnel was added drop-wise to the reaction mixture for 3 h. Polymerization was allowed to proceed for 12 h in refluxing conditions. The resulting homopolymer was precipitated in a mixture solution of methanol/petroleum ether (2:8 v/v), and the precipitate was dissolved again in ethanol at least three times for purification. After purification, the polymer was dried under vacuum at room temperature for 24 h. The molecular weight of the synthesized HPOEM homopolymer was determined using GPC analysis. The polymer had Mn (number average molecular weight) of 15,200, an average molecular weight (Mw) of 38,600, and a polydispersity index (PDI) of 2.54. Neat SWRO membranes were rinsed with fresh deionized (DI) water overnight to remove the moisturizer applied to protect the pores of the support layer by the manufacturer before modification. 0.1 wt% of HPOEM homopolymer dissolved in DI water was prepared, and the fresh SWRO membranes were dipped in the homogeneous HPOEM solution for 1 min. Excess amounts of the solution were gently removed with a rubber roller. The HPOEM homopolymer-coated SWRO membranes were then exposed to aqueous GA solution (0.01 wt%) for Fig. 1. Schematic diagram of the chemical reaction involved in preparation of the PEI-COOH coating layer. H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 99 30 s to fasten the coating layer on the membrane surface [4,23]. After modification, the membranes were fully rinsed with DI water to remove residual chemicals and kept in DI water before experiments. 2.3. Preparation of carboxylted PEI-coated SWRO membrane The synthetic route for preparation of the zwitterionic PEICOOH coating layer is shown in Fig. 1. Surface modification was conducted in three consecutive steps: PEI coating, PEI networking, and PEI carboxylation. The SWRO membranes were first dipped into aqueous PEI solution (0.1 wt%). The immersed membranes were taken out of the solution after 1 min, and excess solution was removed using a rubber roller. The membranes were then exposed to aqueous GA solution (0.01 wt%) at pH 9 for 30 s to form a network structure of the coating material on the membrane surface. The membranes were taken out of the GA solution and excess GA solution was removed. Finally, the GA-treated membranes were dipped in aqueous bromoacetic acid (0.1 wt%) in the presence of potassium hydroxide (0.08 wt%), where they remained for 10 h at 30 1C. The bromoacetic acid solution was used for the N-carboxylation of PEI, and the KOH added to the solution was to remove HBr formed from the reaction of amine and bromoacetic acid [24]. After treatment, the membranes were fully rinsed with DI water to remove residual chemicals and kept in DI water before experiments. 2.4. Membrane surface characterization The chemical compositions of the membrane surfaces were characterized using X-ray photoelectron spectroscopy (XPS) (SIGMA PROBE, Thermo VG, U.K). The atomic percent and the atomic percent ratio of carbon binding energies were calculated by the deconvolution of high resolution C1s core level spectra. The streaming potentials were measured using a BI-EKA streaming potential analyzer (Brookhaven, NY) with 1 mM KCl electrolyte solution. Contact angle measurements were carried out with an FTÅ 200 contact angle analyzer (First Ten Ångstroms, VA) using the sessile drop technique. A dried membrane sample was mounted on a glass support on the specimen stage, and 5 μl droplets of DI and NaCl solution (32,000 ppm) were placed on the membrane surface using a syringe driven by a syringe pump. At least 10 measurements were taken at different locations on the membrane surface within 30 s after delivering the liquid drop onto the membrane surface in order to determine the average contact angle value. Atomic force microscopy (AFM) (XE-150, PSIA, CO) was used to quantify the roughness of the SWRO membranes. AFM was operated in tapping mode in air using a silicon nitride cantilever. AFM images of the dried membranes were recorded over an area of 10 μm 10 μm. 2.5. Fouling experiments V A Ut C permeate R ð%Þ ¼ 1 100 C f eed ð1Þ ð2Þ where Jw is the pure water flux (L/m2 h), V is the permeate volume (L), A is the membrane area (m2), t is the time (h), and Cpermeate and Cfeed are the conductivities of the permeate and feed solutions, respectively. Conductivities were measured using a calibrated conductance meter (Orion model 115). Normalized flux was defined as the flux of membranes divided by the initial flux. BSA and alginate were used as a model protein and a polysaccharide foulant, respectively, to evaluate the anti-fouling properties of the neat and modified SWRO membranes. After measuring the initial water flux and rejection, alginate or BSA stock solution was added to NaCl solution to reach the total concentration of 30 ppm of alginate or 10 ppm of BSA. The flux decline was then measured for 20 h. To evaluate the cleaning efficiency and fouling resistance of the membranes, pure water flux of the fouled membranes was measured again after cleaning. The membrane system was first rinsed with DI water for 30 min, after which the cleaning solution (32,000 ppm NaCl solution at pH 11) was added. Cleaning of the fouled membrane was carried out for 30 min with the flow rate of 6 L/min and no applied pressure (no permeate) [25]. After cleaning, the reservoir and membrane cell were rinsed with DI water to flush out the residual cleaning solution. The flux recovery test was then performed to investigate the cleaning efficiency of the membranes. Water flux was measured at the same conditions as the initial filtration test, and the flux recovery (FR) was calculated according to the following equation: FR ð%Þ ¼ All filtration experiments were conducted using a cross-flow filtration system (Taerang Engineering Co., Ltd., Korea) equipped with membrane cells with the effective area of 30 cm2 (4.0 cm 7.5 cm) (Fig. 2). As a compaction step, the SWRO membranes were filtrated using DI water at 900 psi (6.21 Mpa) until the permeate flux was stabilized. Stock NaCl solution and CaCl2 were added to the feed solution (2571 1C) and the concentrations were controlled to be 32,000 ppm NaCl and 70 ppm CaCl2 at pH 8.0 in 20 L Milli-Q water. The performances of the membranes were characterized in terms of water flux and salt rejection at the operating pressure of 800 psi (5.52 Mpa) and the flow rate of 4 L/min. Water flux and salt rejection were obtained using the following equations: Jw ¼ Fig. 2. Schematic of the reverse osmosis filtration system. Jw 100 Ji ð3Þ where Ji is the initial water flux and Jw is the water flux after membrane cleaning. Fouling experiments were performed for another 20 h after the membrane cleaning step following the same procedure as above. The antifouling properties of the HPOEM and PEI-COOH-coated SWRO membranes were evaluated at the treatment conditions of both brackish water (BW) (2,000 ppm NaCl and 70 ppm CaCl2) and seawater (SW) (32,000 ppm NaCl and 70 ppm CaCl2). Fouling experiments in the brackish water condition were conducted with 100 ppm alginate solution (2,000 ppm NaCl and 70 ppm CaCl2, pH 8, 400 psi (2.76 Mpa)). All other conditions and the overall procedure of the tests were identical to the case of seawater conditions. 100 H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 3. Results and discussion 3.1. XPS analysis High resolution XPS spectra for carbon 1s are shown in Fig. 3 for neat, HPOEM-coated, and PEI-COOH-coated SWRO membranes. Peak deconvolution was carried out to investigate the binding energy shift for carbon 1s and to provide chemical bonding information. The spectra were deconvoluted into four symmetric Gaussian peaks with binding energies (BEs) around 285.0 eV assigned to CH species, at 286.0 eV to CO and CN species, at 288.0 eV to COO species, and at 291.0 eV representing the aromatic carbon species (π–π* shake-up satellite) [26, 27]. Bonding energies of the peaks were observed at the same position for each membrane; however, the peak intensity varied. The ratios of atomic percent of the curve-fitted carbon species to the total carbon atomic percent were calculated and shown in Table 1. When comparing the control and HPOEM-coated SWRO membrane, the ratios of the peaks around 285.0 eV, 288.0 eV and 291.0 eV decreased, while the ratio of the peak at around 286.0 eV increased from 18.3% to 25.3%. It is thought that introduction of the PEG moiety in the HPOEM homopolymer to the membrane surface caused the increase in the atomic percent of CO (at 291.0 eV) and the subsequent decrease of other types of carbon. The carboxylated PEI-coated SWRO showed decreased peak intensity at 285.0 eV and 291.0 eV compared with the control, while showed enhancement of the peak intensities from 18.3% to 24.0% at 286.1 eV and from 12.9% to 14.5%, at 288.3 eV were observed. The decrease in aromatic carbon content and increase in C–N, C–O, CQO contents indicated building up of the PEI-COOH coating layer on the membrane surface after coating. 3.2. AFM Surface morphologies of the SWRO membranes were characterized using AFM. The three-dimensional AFM images (10 μm 10 μm) of the membranes before and after modification are shown in Fig. 4. The peak-to-valley distance (Rpv), root mean square roughness (Rms), and average roughness (Rav) of the membrane surfaces are listed in Table 2. Typical ridges and valley structure were observed in all the membranes, but the surface roughness values decreased slightly after surface coating. The images of the modified membranes were almost identical to that of the unmodified control membrane. The average roughness Table 1 Atomic percent and peak ratio of control, HPOEM, and PEI-COOH coated membranes determined from the curve-fitted C1s core-level spectra. Control HPOEM PEI-COOH Fig. 3. C 1s core level spectra of (a) control SWRO, (b) HPOEM and (c) PEI-COOH coated membranes. Peak BE Atomic percent Peak ratio (%) 285.02 286.16 288.30 291.21 284.99 286.37 288.26 290.93 285.0 286.15 288.31 291.24 49.28 14.15 9.96 4.03 44.74 18.94 8.56 2.7 43.51 18.23 11.05 3.29 63.7 18.3 12.9 5.2 59.7 25.3 11.4 3.6 57.2 24.0 14.5 4.3 H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 101 in surface roughness after surface coating was considered to be attributed to the coating conditions: the size of the coating material, coating solution concentration, dipping time, reaction time, etc. The surface roughness of the modified SWROs is expected to decrease after further increase in the coating solution concentration, dipping time and reaction time, as the result of sufficient coverage of the membrane surface with the coating materials [28,29]. 3.3. Zeta potential Surface charge of the membranes was investigated using streaming potential measurement in the pH range from 4 to 10 to confirm successful formation of the coating layers after modification (Fig. 5). The control SWRO membranes showed charges of 9.0 mV at pH 4.8 and 30 mV at pH 9.9; however, coating of the surface with HPOEM made the membrane less negative due to surface coverage of the negative charge with the neutral PEG moiety of the HPOEM polymer [30]. The negatively charged control SWRO was more effectively neutralized after coating with PEI. It was considered that the positively charged PEI molecules were readily adsorbed on the membrane surface through electrostatic attraction [31]. The zetapotential of the PEI-coated membrane was 13 mV at pH 4.8 and 18 mV at pH 9.9. After treatment with bromoacetic acid, the zeta-potential of the carboxylated PEI-coated membrane became more negative compared with the PEI-coated membrane. The shift to the more negative zeta potential was thought to be attributed to the introduction of COO– groups in acetic acid anchored at the nitrogen molecules of PEI. The carboxylated PEI-coated membrane showed various charge values depending on the pH of the solution. This phenomenon was attributed to the protonation and deprotonation of the amine and carboxylic groups on the membrane surface, and implied that an amphoteric carboxylated PEI layer had been successfully introduced after modification.# 3.4. Contact angle Fig. 4. AFM images of the membrane active layer. (a) Control SWRO, (b) HPOEM and (c) PEI-COOH membranes. Wettability of the membranes was investigated from measurement of the contact angle between the membrane surface and liquid/vapor interface. The contact angle is a measure of the tendency of a liquid to wet the solid surface. The higher the contact angle, the lower the tendency of the liquid to wet the surface and the lower the affinity of the membrane surface to the liquid. Table 2 Root mean square roughness (Rms) and peak to valley distance (Rp-v) of control, HPOEM and PEI-COOH coated SWRO membranes. Sample Rp-v (nm) Rms (nm) Rav Median (nm) Ht (nm) Control HPOEM PEI-COOH 742.3 74.42 58.68 209.0 619.6 68.54 55.19 265.6 669.9 73.31 58.14 211.4 Mean Surface Ht (nm) area (μm2) Prj area (μm2) 201.0 260.7 202.3 100.0 100.0 100.0 186.4 184.9 190.9 values of the control SWRO (a), HPOEM-coated SWRO (b) and carboxylated PEI-coated SWRO (c) membranes were 58.68 nm, 55.19 nm and 58.14 nm, respectively, while the Rms roughness values were 74.42 nm, 68.54 nm and 73.31 nm for each membrane, respectively. The roughness values of the membranes did not show distinctive change after surface coating. The little change Fig. 5. The zeta potentials of SWRO and HPOEM, PEI, and PEI-COOH coated SWRO membranes. 102 H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 Photographic images and contact angles of water drops in the presence or absence of salts are presented in Fig. 6. The control SWRO membrane had almost the same contact angle when drops of DI and NaCl solution were delivered on the surface of the membrane. The change of probe liquid from DI water to NaCl solution increased the average contact angle of the HPOEM-coated SWRO from 30.61 to 40.21. However, the carboxylated PEI-coated SWRO showed the opposite behavior, with the average contact angle of 57.81 in the absence of salt declining to 43.01 in the presence of salt. This opposite wettability behavior of the HPEOM and carboxylated PEI-coated membranes observed in the presence of salty liquid is likely due to the salting-out and salting-in effects of polymeric membranes exposed to a liquid. The PEG moiety in the neutral HPOEM coating layer formed hydrogen bonds with surrounding water molecules, allowing the membrane surface to be hydrophilic and wettable [6,7,11,13]. When the salt concentration became high enough to attract the water molecules interacting with the coating layer, the interactions between the coating material became stronger than the coating surface–water interaction, causing the surface to be less soluble at higher salt concentration (salting-out effect) (Fig. 7). However, carboxylated PEI had both negatively charged carboxyl groups and positively charged amine groups in its structure. These oppositely charged groups had strong interactions between them, exposing hydrophobic hydrocarbon groups on the surface [32]. Fig. 6. Drop contact angle of DI water and 32,000 ppm aq. NaCl solution on membranes: SWRO membrane with DI water (a) and NaCl (b); HPOEM-coated membrane with DI water (c) and NaCl (d); and PEI-COOH-coated membrane with DI water (e) and NaCl (f). With the addition of small ionic molecules (NaCl), the charged property of each group was screened and volumetric transition occurred as swelling of the coating layer (salting-in effect). Baker and coworkers [33] investigated the swelling properties of ampholytic hydrogels. They observed increase in the swelling of amphorytic hydrogels at appreciable NaCl concentrations (4 0.1 M), and assumed the swelling behavior to be attributed to the salting-in effect on ampholytic polymer. The results were agreed well with our contact angle study. 3.5. Fouling experiments The fouling propensity of the control SWRO, HPOEM and carboxylated PEI-coated membranes was investigated using alginate and BSA in both BW and SW conditions. 3.5.1. Membrane fouling by alginate in BW condition The antifouling effects of the HPOEM and carboxylated PEImodified membranes were evaluated compared with the control membrane in BW conditions (Fig. 8). The initial fluxes of the control, HPOEM, and carboxylated PEI-coated membranes were 32.0 L/m2 h, 28.2 L/m2 h, and 30.3 L/m2 h, respectively. The HPOEM-coated SWRO membrane lost about 13% of the initial flux after coating. Meanwhile, the carboxylated PEI-coated membrane showed only a 5% decline of the flux after surface coating, implying that the additional coating layer of carboxylated PEI showed lower resistance to water permeability compared to HPOEM. However, the surface-modified membranes did not outperform the control SWRO membrane during 20 h of fouling test in the BW conditions. The flux of the control SWRO, HPOEM and carboxylated PEI-coated membranes declined after 20 h by about 22.5%, 15.2%, and 20.1%, respectively. The carboxylated PEIcoated membrane showed an almost identical flux decline rate as the control SWRO. An effect of the carboxylated PEI coating layer on alginate fouling was not observed. However, the HPOEM-coated membrane showed a slower rate of flux decline in normalized flux, indicating that the adsorption of alginate on the membrane surface was inhibited by the HPOEM layer. In BW conditions, it was concluded that the HPOEM-coated SWRO membrane showed better fouling resistance. 3.5.2. Membrane fouling by alginate in SW condition Fig. 9 shows the flux and the normalized flux profiles of control and modified membranes operated using alginate solution in SW conditions. The initial fluxes (salt rejection) of the control, HPOEM, and carboxylated PEI-coated membranes were 32.4 L/m2 h (99.2%), 29.8 L/ m2 h (99.3%), and 32.9 L/m2 h (99.1%), respectively. The initial flux of the HPOEM-coated membrane decreased by 8% compared with the control membrane, but the carboxylated PEI-coated membrane showed almost the same initial water flux as the control. In addition, the carboxylated PEI-coated SWRO membrane showed a much slower flux decline rate and outperformed the others during the test. The degree of flux decline after 20 h operation was 15.2%, 14.9%, and 9.1% for the control, HPOEM and carboxylated PEI-coated membrane, respectively. After 20 h of operation, the membranes were cleaned and a second run of the fouling experiment was performed. Both of the surface modified membranes showed higher cleaning efficiency than the unmodified membrane. The flux recovery of the control, HPOEM and PEI-COOH membranes after cleaning was measured as 92.3%, 96.2% and 98.4%, respectively. Another 20 h of operation after cleaning showed that fouling proceeded on each membrane in the same manner. The carboxylated PEI-coated membrane showed the slowest flux decline rate and the highest cleaning efficiency. H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 103 Fig. 7. Schematic diagram of salting-out effect on HPEOM-coated membrane (a) and salting-in effect on carboxylated PEI-coated membrane (b) in the presence of salts. Fig. 8. Time-dependent flux and normalized of control and modified SWRO membranes during alginate filtration in BW conditions. 3.5.3. Membrane fouling by BSA in SW condition The flux and normalized flux declines of the membranes during the BSA fouling test are shown in Fig. 10. The initial fluxes (salt rejection) of the control, HPOEM and carboxylated PEI-coated membranes were 32.3 L/m2 h (99%), 29.9 L/m2 h (99.2%), and 31.5 L/m2 h (99.3%), respectively. Although the initial flux of the carboxylated PEI-coated SWRO Fig. 9. Time-dependent flux and normalized flux of control and modified SWRO membranes during alginate filtration in SW conditions. membrane was slightly lower than the control, it was soon compensated for by the slower flux decline rate. The fouling resistance of the HPOEM-coated membranes was not clearly shown through this experiment. The flux declines of the membranes after 20 h of operation were 20.7%, 18.7%, and 15.4%, while the flux recoveries after cleaning 104 H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 4. Conclusion Amphiphilic HPOEM and zwitterionic carboxylated PEI antifouling layers were introduced on a commercially available SWRO membrane and their performances were investigated in brackish water and seawater conditions. The successful introduction of each coating layer was confirmed by measurements of the zeta potential and contact angle. Due to the ultrathin coating layer prepared under mild modification conditions, the modified membranes showed little morphological changes. The contact angle of the modified membranes shifted differently due to the salting-out and salting-in behaviors of the coating layers in DI and saline solution. The zwitterionic carboxylated PEI-coated SWRO membrane, which presented lower contact angle value with 32,000 ppm of sodium chloride solution than that with DI water, showed improved fouling resistance in SW conditions. The results suggested that effective antifouling SWRO membranes could be prepared with zwitterionic materials. Further studies are needed to investigate the antifouling mechanisms of the zwitterionic layer depending on the salt concentration of feed water and to test the long-term stability of modified membranes. Acknowledgment This study had been carried by support of Center for Eco-Smart Water Works System As part of the Eco-Smart Water System Development Project of the Ministry of Environment (No. 2014001080001). Fig. 10. Time-dependent flux and normalized of control and modified SWRO membranes during BSA filtration in SW conditions. were 92.9%, 94.3% and 95.4% for the control, HPOEM and carboxylated PEI-coated membranes, respectively. 3.5.4. Fouling resistance of membranes in BW and SW conditions The HPOEM and carboxylated PEI-coated membranes showed opposite fouling propensity in BW and SW conditions. In the SW condition, the carboxylated PEI-coating layer clearly showed fouling resistance by demonstrating a lower initial flux decline and slower flux decline rate. Due to these properties along with lower resistance to water permeation, the carboxylated PEI-coated SWRO membrane was able to outperform the other membranes during the period of the fouling experiments. However, the exceptional antifouling properties of the PEG moiety, which have been reported in other studies and shown in experiments herein for the BW condition, were hardly observed in the SW conditions. The lack of distinguishable decline profiles between the control and PEG-containing HPOEM-coated membranes in SW conditions implies that the strategy for the development of fouling resistant SWRO membranes should be differentiated from that of BWRO membranes. It is well-known that the physicochemical properties of the membrane surface such as roughness, hydrophilicity, and electrostatic charge are major factors determining the degree of membrane fouling [34]. Considering that the most noticeable differences in surface properties between the HPOEM and carboxylated PEI-coated membranes were the contact angle and fouling behavior, the fouling of membrane surfaces was dominantly affected by the salting-in and salting-out effect of the membrane surface. This finding suggests that amphoteric carboxylated PEI, which showed salting-in behavior, was more suitable as a fouling-resistant material in SW conditions. References [1] A.V.R. Reddy, J.J. Trivedi, C.V. Devmurari, D.J. Mohan, P. Singh, A.P. Rao, S.V. Joshi, P.K. Ghosh, Fouling resistant membranes in desalination and water recovery, Desalination 183 (2005) 301–306. [2] B.-H. Jeong, E.M.V. Hoek, Y. Yan, A. Subramani, X. Huang, G. Hurwitz, A.K. Ghosh, A. Jawor, Interfacial polymerization of thin film nanocomposites: a new concept for reverse osmosis membranes, J. Membr. Sci. 294 (2007) 1–7. [3] L. Li, S. Zhang, X. Zhang, G. Zheng, Polyamide thin film composite membranes prepared from isomeric biphenyl tetraacyl chloride and m-phenylenediamine, J. Membr. Sci. 315 (2008) 20–27. [4] N. Li, Z.Z. Liu, S.G. Xu, Dynamically formed poly (vinyl alcohol) ultrafiltration membranes with good anti-fouling characteristics, J. Membr. Sci. 169 (2000) 17–28. [5] W. Sun, Y.W. Chen, L. Zhou, X.H. He, Preparing polymer brushes on poly (vinylidene fluoride) films by free radical polymerization, J. Appl. Polym. Sci. 101 (2006) 857–862. [6] S. Kang, A. Asatekin, A.M. Mayes, M. Elimelech, Protein antifouling mechanisms of pan uf membranes incorporating pan-g-peo additive, J. Membr. Sci. 296 (2007) 42–50. [7] J. Hyun, H. Jang, K. Kim, K. Na, T. Tak, Restriction of biofouling in membrane filtration using a brush-like polymer containing oligoethylene glycol side chains, J. Membr. Sci. 282 (2006) 52–59. [8] S.S. Madaeni, T. Mohamamdi, M.K. Moghadam, Chemical cleaning of reverse osmosis membranes, Desalination 134 (2001) 77–82. [9] Y.-y. Lu, Y.-d. Hu, D.-m. Xu, L.-y. Wu, Optimum design of reverse osmosis seawater desalination system considering membrane cleaning and replacing, J. Membr. Sci. 282 (2006) 7–13. [10] A. Sarkar, P.I. Carver, T. Zhang, A. Merrington, K.J. Bruza, J.L. Rousseau, S.E. Keinath, P.R. Dvornic, Dendrimer-based coatings for surface modification of polyamide reverse osmosis membranes, J. Membr. Sci. 349 (2010) 421–428. [11] A.C. Sagle, E.M. Van Wagner, H. Ju, B.D. McCloskey, B.D. Freeman, M.M. Sharma, Peg-coated reverse osmosis membranes: desalination properties and fouling resistance, J. Membr. Sci. 340 (2009) 92–108. [12] S. Azari, L. Zou, Using zwitterionic amino acid L-dopa to modify the surface of thin film composite polyamide reverse osmosis membranes to increase their fouling resistance, J. Membr. Sci. 401 (2012) 68–75. [13] H. Choi, J. Park, T. Tak, Y.-N. Kwon, Surface modification of seawater reverse osmosis (swro) membrane using methyl methacrylate-hydroxy poly(oxyethylene) methacrylate (mma-hpoem) comb-polymer and its performance, Desalination 291 (2012) 1–7. [14] R. Sadeghi, F. Jahani, Salting-in and salting-out of water-soluble polymers in aqueous salt solutions, J. Phys. Chem. B 116 (2012) 5234–5241. H. Choi et al. / Journal of Membrane Science 486 (2015) 97–105 [15] F. Xuan, J. Liu, Preparation, characterization and application of zwitterionic polymers and membranes: current developments and perspective, Polym. Int. 58 (2009) 1350–1361. [16] Y.-L. Ji, Q.-F. An, Q. Zhao, W.-D. Sun, K.-R. Lee, H.-L. Chen, C.-J. Gao, Novel composite nanofiltration membranes containing zwitterions with high permeate flux and improved anti-fouling performance, J. Membr. Sci. 390 (2012) 243–253. [17] Q. Zhang, S. Zhang, L. Dai, X. Chen, Novel zwitterionic poly(arylene ether sulfone)s as antifouling membrane material, J. Membr. Sci. 349 (2010) 217–224. [18] Y. Chang, S. Chen, Q. Yu, Z. Zhang, M. Bernards, S. Jiang, Development of biocompatible interpenetrating polymer networks containing a sulfobetainebased polymer and a segmented polyurethane for protein resistance, Biomacromolecules 8 (2007) 122–127. [19] Y. Chang, W. Yandi, W.-Y. Chen, Y.-J. Shih, C.-C. Yang, Y. Chang, Q.-D. Ling, A. Higuchi, Tunable bioadhesive copolymer hydrogels of thermoresponsive poly(n-isopropyl acrylamide) containing zwitterionic polysulfobetaine, Biomacromolecules 11 (2010) 1101–1110. [20] J. Liu, Y. Zhan, T. Xu, G. Shao, Preparation and characterizations of novel zwitterionic membranes, J. Membr. Sci. 325 (2008) 495–502. [21] A.B. Lowe, C.L. McCormick, Synthesis and solution properties of zwitterionic polymers, Chem. Rev. 102 (2002) 4177–4189. [22] Y. Kwon, S. Hong, H. Choi, J. Jung, J. Moon, T. Tak, Development of foulingresistant ro membranes using pega macromer, Desalin. Water Treat. 15 (2010) 54–61. [23] R.D. Sanderson, E. Immelman, D. Bezuidenhout, E.P. Jacobs, A.J. Vanreenen, Polyvinyl-alcohol and modified polyvinyl-alcohol reverse-osmosis membranes, Desalination 90 (1993) 15–29. [24] A. Masotti, A. Giuliano, G. Ortaggi, Efficient complexation-ultrafiltration process for metal ions removal from aqueous solutions using a novel carboxylated polyethylenimine derivative (pei-cooh), Curr. Anal. Chem. 6 (2010) 37–42. 105 [25] W.S. Ang, N.Y. Yip, A. Tiraferri, M. Elimelech, Chemical cleaning of ro membranes fouled by wastewater effluent: achieving higher efficiency with dual-step cleaning, J. Membr. Sci. 382 (2011) 100–106. [26] C.C. Turci, S.G. Urquhart, A.P. Hitchcock, Inner-shell excitation spectroscopy of aniline, nitrobenzene, and nitroanilines, Can. J. Chem. 74 (1996) 851–869. [27] Z. Liu, K. Pappacena, J. Cerise, J. Kim, C.J. Durning, B. O’Shaughnessy, R. Levicky, Organization of nanoparticles on soft polymer surfaces, Nano Lett. 2 (2002) 219–224. [28] S. Yu, Z. Lue, Z. Chen, X. Liu, M. Liu, C. Gao, Surface modification of thin-film composite polyamide reverse osmosis membranes by coating n-isopropylacrylamide-co-acrylic acid copolymers for improved membrane properties, J. Membr. Sci. 371 (2011) 293–306. [29] V. Freger, J. Gilron, S. Belfer, Tfc polyamide membranes modified by grafting of hydrophilic polymers: an ft-ir/afm/tem study, J. Membr. Sci. 209 (2002) 283–292. [30] X. Ma, Y. Su, Q. Sun, Y. Wang, Z. Jiang, Enhancing the antifouling property of polyethersulfone ultrafiltration membranes through surface adsorptioncrosslinking of poly(vinyl alcohol), J. Membr. Sci. 300 (2007) 71–78. [31] Y. Zhou, S. Yu, C. Gao, X. Feng, Surface modification of thin film composite polyamide membranes by electrostatic self deposition of polycations for improved fouling resistance, Sep. Purif. Technol. 66 (2009) 287–294. [32] S.E. Kudaibergenov, Recent advances in the study of synthetic polyampholytes in solutions, Polym. Latexes Epoxide Resins Polyampholytes 144 (1999) 115–197. [33] J.P. Baker, H.W. Blanch, J.M. Prausnitz, Swelling properties of acrylamide-based ampholytic hydrogels – comparison of experiment with theory, Polymer 36 (1995) 1061–1069. [34] S.Y. Kwak, S.G. Jung, S.H. Kim, Structure-motion-performance relationship of flux-enhanced reverse osmosis (ro) membranes composed of aromatic polyamide thin films, Environ. Sci. Technol. 35 (2001) 4334–4340.

© Copyright 2026