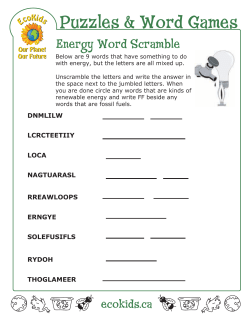

H I U B