/

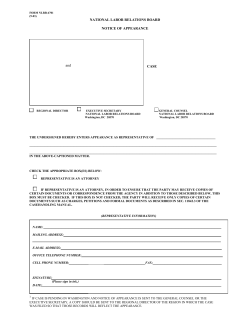

How to use the AS 1851-2012 Logbooks Description of the system or equipment serviced LB2A Chubb Book 1 and the frequency. Some scheduled activities require multiple pages to be completed to finalise the service. This is indicated in the title bar. Your service provider is: LB2A LB2A Automatic FireFire Sprinkler Systems – – Automatic Sprinkler Systems WetWet PipePipe Systems Systems Monthly Service Record – Page 1 of1 1of 1 Monthly Service Record – Page DateDate / / ItemItem No. No.Actions required by Table 2.4.2.1 Actions required by Table 2.4.2.1 Record site details here (site name; site address; site ID number; date of service; time of service and order number). Work Order No. No. Work Order TimeTime SiteSite Address Address SiteSite ID ID PassPassFail FailN/A N/A ItemItem No. No.Actions required by Table 2.4.2.1 Actions required by Table 2.4.2.1 All previous defects and and non-conformances attended to and All previous defects non-conformances attended to and recorded recorded Summarised actions PassPassFail FailN/A N/A Verify water supply stopstop valvevalve No. No. Verify water supply 1.10b1.10b position indicators checked position indicators checked Verify each valve monitor indicates No. 1.10c1.10c at CIEVerify each valve monitor indicates checked No. at CIE checked Record and and verify system pressure gauge readings before Record verify system pressure gauge readings before 1.11 1.11 alarm function test test (record in table below) Record results of actions alarm function (record in table below) alarm function test test and and verify timetime of operation ofhere. Conduct alarm function verify of operation of Where results are 1.121.12 Conduct gong(s) (record in table below) more complex or need to gong(s) (record in table below) No. No. cater for multiple systems or 1.131.13 Verify alarm signal operation Verify alarm signal operation checked checked components, record results in Check control valvevalve assembly is unobstructed from1.1 corresponding 1.1 Check control assembly is unobstructed service schedules 1.2 1.2 Check sparespare sprinklers and and spanner are available Check sprinklers spanner are available in the relevant standard. 1.3 1.3Record Check signage for damage, legibility and and location Check signage for damage, legibility location here as pass, fail or 1.4 Check fire brigade booster connection is operational 1.4 Check fire brigade booster connection is operational not applicable. 1.6 1.6 / / Unique number and barcode assigned to each logbook form. ÌCB-AA10000101FÎ «LB2A Part1 1» CB-AA10000101 Customer Service: 13 15 98 SiteSite Name Name 1.5 1.5 Record service provider details here, using a stamp or handwriting. Books with pre-printed company information available soon. Check mainmain stopstop valves and and alarm No. No. Check valves alarm cockscocks are open, secured and and labelled are open, secured labelled checked checked Check pump starting devices are open No. No. Check pump starting devices are open and and secured checked secured checked specified sections below. 1.141.14 Check operation of strobe indicators Check operation of strobe indicators 1.151.15 Record and and verify system pressure gauge readings after Record verify system pressure gauge readings after alarm function test test (record in table below) alarm function (record in table below) Check foamfoam concentrate levels Check concentrate levels 1.7 1.7 Check pressure switches Check pressure switches 1.8 1.8 Check alarm signalling equipment (ASE)(ASE) Check alarm signalling equipment 1.191.19 1.9 1.9 Check sprinkler system interface status Check sprinkler system interface status TestTest automatic and and manual pump checked automatic manual pump No. of No.devices of devices checked devices in accordance withwith Auto 1.161.16 & & starting starting devices in accordance Manual Auto Manual 1.131.13 and and 1.171.17 of Table 3.4.1.3.4.1. 1.171.17 itemitem of Table Record results in pumpset logbook. Record results in pumpset logbook. water supply stopstop valves are are Verify water supply valves 1.10a1.10a Verify openopen and and secured secured No. No. checked checked Alarm function testtest results Alarm function results No. 1No. 1 No. 2No. 2 No. 3No. 3 No. 4No. 4 No. 5No. 5 No. 6No. 6 No. 7No. 7 No. 8No. 8 No. 9No. 9 No. 10 No. 10 No. 11 No. 11 No. 12 No. 12 Installation pressure before test test – 1.11 Installation pressure before – 1.11 kPa kPa TimeTime to operation of alarm gonggong – 1.12b to operation of alarm – 1.12b SecsSecs Installation pressure after test test – 1.15 Installation pressure after – 1.15 kPa kPa Pressure readings 1.151.15 Location 1 1Location 2 2Location 3 3Location 4 4 Pressure readings Location Location Location Location Below StopStop ValveValve Below kPa kPa Associated / Connected Associated / Connected Equipment Service Completed Equipment Service Completed Yes YesNo NoN/A N/A If NoIforNoN/A, indicate reason below or N/A, indicate reason below Monthly pumpset Monthly pumpset Record defects, Monthly water storage tanktank (Item(Item 1.18)1.18) repairs, notes or Monthly water storage recommendations Monthly CIE Monthly CIE here. (Requires corresponding action Activity / System Failures No. No. Defect TypeTypeDescription / Corrective Action Required or Repairs Completed Activity / System Failures ItemItem Defect Description / Corrective Action Required or Repairs Completed statement item & Comments & Comments number and defect Defect TypeType Identified type.) Defect Identified Water Supply 1 1 Water Supply kPa kPa Water Supply 2 2 Water Supply kPa kPa Notes section that can link the primary service record to additional Notes Pages in which to record additional defects, repairs, notes or recommendations. 1 – 1Critical Defect – Critical Defect 2 – 2Non Critical Defect – Non Critical Defect 3 – 3Non Conformance – Non Conformance 4 – 4Recommendations – Recommendations Record here if routine service of associated equipment has been completed where a system relies on other systems or equipment to perform correctly. Declaration that the system or equipment has been serviced in accordance with the respective standard. Includes a disclaimer that completion of routine service is not confirmation that neither the fire protection system or equipment nor the building is fully compliant with all applicable building and fire safety legislation. Record technician Further information Further information details here (name, recorded on notes pagepage recorded on notes signature and service date).I hereby certify thatthat the the above system has has been routinely serviced in accordance withwith AS1851-2012 andand I hereby certify above system been routinely serviced in accordance AS1851-2012 QUEENSLAND thatthat the the information on this service record is true andand correct. ThisThis record doesdoes not not inferinfer compliance withwith QUEENSLAND information on this service record is true correct. record compliance BUILDINGS ONLY BUILDINGS ONLY all applicable building andand firefire safety legislation within the the relevant jurisdiction. all applicable building safety legislation within relevant jurisdiction. Technician Technician Name Name Licence / / Licence Permit Permit Name Name Holder Holder Maintenance complies withwith QDC,QDC, MP6.1 Maintenance complies MP6.1 System is in proper working orderorder System is in proper working Signature Signature Record licence/ permit holder details here (name, licence number, licence type and FPAS number). Licence Licence No. No. DateDate Licence Licence TypeType / / / / FPASFPAS No. No. Record client DateDate / / / / details here (name, Distribution of service record copies: owner/occupier/agent = original provider = duplicate in this book = triplicate Australia 20142014LB2A V1.0V1.0 AprilApril 20142014 signature and service© FPA Distribution of service record copies: owner/occupier/agent = originalservice service provider = duplicateretained retained in this book = triplicate © FPA Australia LB2A date). Client Client Name Name LB2A_Full_FA2.indd 1 LB2A_Chubb_FA2.indd 1 Signature Signature Fire Australia 2/04/2014 2:412:39 pm pm 2/04/2014 winter 2014 | 15

© Copyright 2026