Document 182703

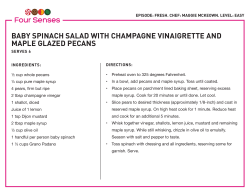

~ Material handUng made easier with special accessories Brushes,rags &. guns: How to use die simple tools of wood finishing Squeeze profits from projects with basic cost-cutting measures On a modified band saw, David Borek cuts blgleaf maple burl slabs Into hIghly prized turning blocks. His PacIfic Northwest shop Is exclusively devoted to thIs specIalty lumber. Page 8 8 WOOOSHOP NEWS . SEPTEMBER 1~ & Modified equipment, loggers' cooperation madethe difference By Bill LaBay _Wrti...uk-etuddedDMJDBteiD IoomiDIb8bjDdDaYid Borek'oobopmicbt be ~ -.. than 8D8D9i8HeYiew,but tbio fiIodsillof W88hiD,_'0 c.-II8 MouateiDr8DI8 -t.. cI.&D.a ofpi8C8that:o minored in Bolek hi.-r. ".. cla8D air aDdopara1y~ laDdocape oua-t the frODti8rW.t retbor than tba Jar.- un- CBDter of SeettleIe.. than ao miIeoaway,aDdBor.k baa the rMO~ t.. matda. HaviDcwa1kedaway hm the aDdcI.maDdoof running a hicb PI1JdI1djon c.-t..m millwork ohop,the 42-yeer~ YODken,N.Y.. 00rn Borek baaaweat8d.bartered, oaivapd, raotored,rebuilt, ~. IIeereoi,jury-ric.-d, aDd.aoa1aotreoort, openthie way t.. a ohopd88iID8d for juat ODetbiDc - omg - ~ maple burIo for woodtumen. He.- mppIioa11-8 bIcbly JWiI8d blrDiDg~ t.. ~ opeI2a)ty wood.--Iero ; - 01 aDd !be ,.- beckaDdcurly lwuber. In many ways,the opecialtyfocuaof Borak'sburl shop Mought bjm f\ill circle in his relaaonobipt.. wood. " I laad to lea", WG811" prepared -unkeen -r r' a lot I for: chaill Be;"'_" ---os, . !ilmg, I thoug hi I could .1Ib it all out. The lint lIDO otreooofmaDaciDI twOodoa8D employ. Unlike -furniture hard- pulp mill. A81n~tift, Bolek pays - aDda ..-iDc buoiD8..got t.. bjm. woods,mr leaf mapiaia oftan~ two t.. three timee what the lop -rbere werejoot too maDY ed aDd~ not for lUIiIh8rbut would nonnally fetch. Becauoebe beadocbeo:Bolek 8id. "I weon't "r pulp, whid1ia then usedt.. make . can't be on the road aUthe time, be ID8kiDI eny ~t, aDdI wun'\ hav. pa.-. To haw t.. burIa and fig- mabo periodicruno t.. pick up burla ins 8DYfua. With that mud1oae., lured s...k had t.. cxm- the kIg.. aDdlop when the quantia- make W88IouL This ia better. J can ph diI'8dIy aDd8rraII88t..lI'Udthe trip wortbwbiJa.At tbio point, 1r...t late or eerly, whJ wanL" !be materiol beforeit w..t int.. the there 8r8 no guaranteeothat Borek Borek.doddedt.. dII8!bemiBwork ~. The burIo 8r8 aoayt..apot, 8'Itt8n hia lIMIneY'owortll.aDd obop.HeaIm-d 011" theequipment butbehadt..aIIw.t. the and u.- a party t 1eI..- bjo new. L__L. ~ ..- t L- "'_0 ..., 1.--" ,. Aa a toIrDaraDd ...xId..orkar, Borek. ~ Ca1iiaruiaaUthe way up t.. He 1aomad t.. turn et age 11, and the Canadian proviu.. ofBritiah Co1m , ia t.. the ~ ma~ era) woodworkiug skiBo, it was that original enthaBiaom for bJrning thet laUDdlad tbio ..ture. "- 4.VII ~ 1,-. oiderably -than the 8Opr mapia hm tba ~ aDd North. eaot, but tIIe,'ra -1ib1y t.. yield I~ with carty or quBIad ftsure. Some aIoo fonD Jar.- haria, IQW.d.d tzavelingthe Baotem United Statee, eventual1yheadingweat t.. oettlain Auatin, Tezao.Tboachbe openeda shopt.. prod... cuotomtiJmiture. redwoodburl tableeand general wCKldwork, be WaomoD~aIiainIln dooro,windowsand other millwork for the nIatoratiouof hiatJIric~ aDdother otl'udu.- in the area,induding the otate~t..1 building. Borak'sdiMte wce often wealthy, but he oaidthey truly a~ted Tbia Soutb.D geaality, Boreksaid, aa-, -.,ht attar ". -and turDiDI -*. Boutpro..-8ing is a dirty ~, ~, and the raw supplien Borek.beard aboutsot )MJOr NVi8W8hID tb8Ir matomora. "I cheekedout what peopJawere ..yins: Borek said. ~ ~nIplaiDed that tba hlankoW8nD't oquan, or w- too tbif:k or too thin, or ~ )MJOr quality. And they ook!it by the polmdwhen it W88still wet. It's 08-soiDI t.. be 8Dbonaotdeal that way," Borekbad two t\mdamantaltaob though helaterdewloped - sen. ~ traao ~ W88in marked..t.. the aUitoda of sou. of the ---a riehe"dieote be w«bd for after be relocatedt.. the SeaWeareain 1988.Borekutab1iobedaDOdI8rohopthere,but the peopJa - thatiDdI. now Borek.'o w)Qfti. para , .-tiDI aaIda lop that wooa)d otbenoiaeSOt.. the of hie-.k ia aDUaheadofhim. "You_'t know if,w iDIIht a ~ b8i,«1ag ~, t. it, be oaId. '"nIio . a ..-DIPm80 In proc-.in, tbaroach ot..ca int.. premiumtumin, bIocbor aluoift veneer.qua)ityburl fiIUre, Bonk uau- awood that:o mo. -:...I: ---' of.-rmal ~wood "- "'-- lIE air. no mackeL on tax put and inmme their of craftamen Borek apent mlldlofbjoearly 2(M - ... - okilled 'nI.- knewthat thePadftcNorth_, &om aol ~ - D8WW~ - a little abINt the 1I8rkpatt8rnaand yean _arl" killed me, be- iIwMi &-!"mobu!iII.-liat.e!'" bepn otJI8: t8I)taIa th.-. c-.e aU the molley went tba tran8iIiIJD ... bjo new ~ cate ftIIIr8Ii wood u...t becaU8 --,~. .,-,~ pie U8iD& ~ opeoiaJ1y modifiedb&8II-David BorekbjcJeaf-pia b...1olabaInto hJ8hqpri88d ". 'otherran """*' quiJ":;:fidoIIe- turBI-. blooka.Bo""'1.- devotedhieeadreMop to Proo-;.l b1lrla-.I fipred lumberfro- North- try aDd aIoo miDo tMgJeaf aheadofbjm when he daGdedt.. plungeint.. the buoIn... of burla. Firat was findinl a oapplyof the raw material, aDd~ waogettins equippedt.. bancUeand ...t iL Thoughburl catting b--tI.-. heotWto iad & taka d8YG-~ -.;;~; in tM craftthat lOt hila ~ tunlinc. WOODSHOP NEWS. t ally anticipates a loss of about 65 percent. 'ntisrelatively low yield, and the enormous amount of specialized equipment and mmntenance required to procesa the burls, make the business an ambitious and sometimes precarious undertaking. Most of the risk and work stems from the nature of burls themselves. Many grow at the base of the b-unk, and nearly all of them have bark inclusions, high silica content, hidden rocks and other surprises that brutalize cutting edges. Borek loves the beauty of burls, but he a!JlO_pects theDl as be would a worthy adversary. Once he uses a 3,200-psi pressure washer to water-blast the raw mounds, which can measure 3'-4' acrosa and weigh over 3,000 Ibs., he uses a chain saw to cut them into halves or quarters. 'ntege more manageable sections are then slabbed, trimmed, and cut into blocks on two modified band saws. An average day's sawing will require six blade changes, Borek said, and if be's really puab~ it that count can climb to 15. Likewise, the contest between chain saw -.,d burl has each devouring the other. If he spends all day roughing the burla into sections, the tally for fresh chains can eaaily exceed two dozen. ,"",at's what keeps this going - the maintenance," Borek emphasised. "I had to learn a lot 1 waan't prepared for: chain saw upkeep and grinding, saw setting, filing. 1 thought I could sub it all out but I couldn't. ~ lint two years nearly killed me, because all the money went back into the shop." With almoet half of the business's $6,000 monthly gross income going toward blade and chmn saw mmntenance, Borek knew he had to make ROmechanges. He bought and restored an ancient band saw blade grinder, a complex mechanical assembly of pulleys, Oat leather drive bells, gears, trip levers, and guides that automatically position each tooth, grind it, then index the blade forward and sharpen the next tocKh. He bartered an antique gun for a saw chain filer and started buying chmn in bulk rolls. Bringing these operations in-house made additional demands on Borek's time, but he's gotten much faster through sheer repetition and now haa more control over his direct costs. Once the burl. are unloaded and powerwa.hed, Borek secUon. them with a chain saw to get rough blocksofa manageable size. Burled rocks and hiCh silica eontent tend to annihilate the chain'. cutUna teeth,80 Borek buy. bulk saw cham in roD. and does hi. own sharpening. .. repairs, and got the saw owner to agree to a trade. Two days later the band saw was sitting in his shop. Though both saws are maaive enough to dwarf Borek's big 6'2" frame and each has a sizable 15-hp mcKor, they weren't really designed 88 sawmill machines. Borek went to work on some m~fiC8ti0D8 to change all that. The lint maehine would be the head saw, used for cutting the rough burl sec:Qonsinto slabe. 'The cutting itself wean't the obstacle 80 much as handling the burl, holding it securely as it traveled into the blade. Cobbling together a mix of salvaged machine parts and a double reek-and-pinion track, Borek built a rolling carriage with &teel clamping doga to hold the burl in place. He then rigged a remote control relay on an articulated boom arm, 80 he could control the width of cut and the feed rate without making any adjustments on the carriage it8elf. A push- The beast, times two The biggest testimony to Bo~k's commitment and his seat-of-the-pants engineeringability is the sawingstation planted squarely in the middle of his shop. It consists of two 36" mdustrial "shake bolt. band saws, designed for cutting cedar roofing materials, which were manufactured by a now defunct Seau.le company. 'nlOUgh he also uses them to resaw the figured maple lumber fTom the logs he buys. they'~ really modified for one very specific: purpose. Borek uses them in tandem to slab burl sections, then cut the slabs into bJoclts. Though he was aIJIe to buy one of the saws used, the second belonged to a local man who said ilewasn't interested in selling. When ~k 1eerned that the man wanted a pickup !.ruck another feJlow bed for sale. he brokered a deal. He bought tile truck, made some button controlsetsup the naxt peasby indexingthe burl pest the bladein I" I increments, and a dial determines the feed rate. It's an impressive machine to watch, and it should be. Borek estimates that between the saws original cost and the substantial modifications he made, be baa almost $18,000 in- vestedin this onemachine. Oncethe slab is cut, Borek slidesit aO & a steel roller bed and sets it up at his secondband saw.With the slabeIIOWreducedto a moremanageI able size,another automaticfeedsystem wasn't necessary. Instead,Borek replacedthis saw's fixed platfonn with a sliding table that travels on precisionsteeltrack and industrisllinear bearinga The aI~t effortlessmotionof the table lets him trim the slabsquickly, and a built-in fenceand scalemakeit easier to sizethe turning blocksaccurately. I The opeetacular burl offers. SEPTEMBER 1996 9 fteure of this ro~ hed-out bowl _t-.e 9I.L..,..' ~ &0 t/ie rew8rdo 'Tha blocks air-dry for a few days, then get a wax dip to keep them &om checking. Even for this laat aimple scteP' ~rek im~oed. INlAY PHOTO Rescued from the oblivion of a mili. tary surplus wareboue, a stainless steel kettle burner that saw duty in the 1991 Persian Gulf War now baa a more peaceful mission. Borek U8M it to melt the large blocks of paraffin be uses to seal the cut burl. Oncethey'~ dipped,the blocksget sortedonto sbelvesand, finally, are ~ady to ship. The rewards of patience Bo~k's origins 88a woodturner have kept bjs enthusiasmfor burls high and his eyesharp. He'. adamant that scraps end up in the firewood pile, not in someCR)8'sorder. Small offcuta and lower-grade blocks get sold by the pound in bulk cartons, but be's elective about the better grade blocks and sells them by the board foot, not by weight. P~mium burl ~tails for about $17/bf, with wholesale pricing offered for purchases of 100 bfor mo~. "I try to cut stock I would want 88 a turner: Borak said. "I don't want to ell anything I wouldn't want to buy." Bo~~ customer. include noted turners such as David Ellsworth, Bonnie Klein, and Michael Petersen. He also wholesales large quantities of burl turning blocks and figured lumber to catalog retailers such 81 Woodcraft, Penn State Industries and Groff &. Hearne Lumber. With turning an increasinglypopular pastime,demandfor burl blanks has grownsomuch that Borakh81 had trouble keepingup by himself.He recentlytook on a partner, Ren~ Booth.and organizedthe wholesale and retail salesefforts under a new company,Maple SpecialtiesInc., offering burl blocksand micro-thin, figured maplelumber.Hsving a partner, Borakhopes,will give him moretime for equipmentmaintenance,burl and lumber cutting, and attendingto his wholesalebuyers,and it may evenallow a few stolenmomentsat the lathe. When Borek gets a bowl blank on Be. ~r, Page 11 12 ~DSHDP By Thomas NSWS . SEFnaMBER 1996 Clark r . ~ __STAFF OPINION I recently found myself scratching my head over the deaign oC a built-in desk Cor an extra room over the garage, and ended up opting Cor a construction technique that seems more .hop-built than built in. The built-in concept seemed 80 logical Cor the space. I had framed in a niche that lits into the knee wall so there would be support for the desk components on three sides. This buill-in support, I reasoned, is an economical and elegant solution to the desk problem because SO much is hidden from .ight anyway. Why not utilize alllhat slrucrural support rrom lhe walls 80 you can save the precious hardwoods Cor lhe surraces lhat show? It aeemed like a no-brainer until I sat down toligure oul precisely how to do it. Buddenly, I realized that I'd entered a realm wilh it. own language and rules. Dh, il'. simple enouKh to hang a ~t deaip The frame-and-panel construction at the sides of the knee hole would provide the tradit.ional reference. But using expoled joinery for the drawers would give it a more contemporary flavor So the problem became one of devising a means to .upport the banks of drawers, bul retaining the traditional look you get with rrame-andpanel construction - the narrow stiles and rails dividing tbe drawers. I guess I could have used plywood, but thal seemed like throwing away the original concept or econolni%ingOll materials. So, what I came up with was that the easiest way for me to carry out that look was to make up series of rrames just as if it was a rree-atandingdeak. Well, I lhoughl, at least I can use the strips along the walla instead or panels al the ends.. righl? Maybe nolo How would I do the drawer runners? I didn't want to buy hardware runners, 80 I'd need would be fewer places to screw up So Cor a buill-in desk, I senlially was able to eliminale a few panels on the back, a truly minimal savings in materials Oh sure, I didn't have to use the good cherry for the interior Crames,saving myself some money, but I did use aboullhe same amount of solid wood. Now, I'm sure there's a way to build a good built-in desk using less materials. Trouble is, my enlire reference is either solid wood, rree-standing rumiture or plywood-panel cabinel construction. The methods used ror built-in work are bound to produce a different look than what I started wi!.h as a premise. So, by trying lo reproduce my traditional rramework in a buill-in motir, I had started out from !.he wrong spot. Maybe I'll get it right next time. one on the other side of the knee hole. My concept. also had a run or shallower drawers running over t.he lhree banks and lhe knee hole and supporting t.he top. wha~ size lhe pieces had to be, and milling the stock ror them, and whelher there welv Muds in the right spots, and getting them to line wi!.h lhe runners in the opposing A Michi,an compo ny, ITW I Amp International, mallufactures pneumatic V-llaili", machine. for Join"'" mi/end comers in picture frames alld other wood a.- lib a lot leas work just making up two molV Crames. That way all the parls would be the same and there Till wmpany con be rmdJed al 37450 Elllerpri.e Court, FarmiJIgtoll HillI, MI48331. TeL' 800-322-4204. Bl.llN4AV_TO It took a lot of work to make oIabbing the burls look this 888)'. Borek built a power-feed carriage for his lead band saw, and added a boom.mounted push-but. toD control to set the cutting width and feed rate. of shelvesf)"m a waiL to position the wood runners Readers But what I had in mind was on the wall to match !.herun. three banks or fairly deep neroin lbe frame. Fro.. PO&'"'10 drawers, two on one aide and But when I lhought about The concepl is an interpretation of a t.raditional desk Thoma. Clark i. Senior Editor of Wood.hop News. : I I I I I I I I I I~ ~ 0 Address I I C ity I 0 Check (if any) .. 51 M \0 n . my ~ t a e 7- rl ~ ~ - . ~CMI- : (00-. oIlheU.S.A. - '10~ ~ ,; I E peryear.) PI8Ue - 6--lor ~ ..iW8Iy; - recipie.nta,;hosenby Presi. I dent Bill Chnton out of more 'd tial d awar than300applicants submit. I I I I I I Since 1906, Menominee Tribal Enterprises (MTE) has sold 2.25 billion bf of timber while sustaining the health and size of it. 220,000.acre forest ted to the President's Council on Sustainable Development. MTE was the only lumber producer to receive an award. This was the.first year the awards were B'ven. I I In late March. the tribe's foreat management system The Menominee miles northwest I I received Award B.ay, pine, I opment Honors for the p'residential SuStaInable Devel. during Prosram Preaident!al ceremonies I in Washington,D.C. The cer. I emony was presided over by 1200 II ~ means a lot of grunt work before the payoff. and Borek apparently needs no reminmng of the reality of his business, especially st the end of a long day. Still, as he pulls a freahly sawn block off the band saw table and lets a good look at the intense burlligure, he sounds inspired. "If you're not a patient person, you don't want to do this," he said. "But to me thia is what it's all about, working and getting to the gold." For information contact Maple Specialties Inc.! Borek Enterprises, .3306 S.E. North Bend Way, Suite 2, North Bend, WA 98045. Tel: 800-409-9663. I Menominees earn 0 36 monthsfor $29.97 I presl en -. enckI6ed the lathe and starts turnjug, it's obvious he can em. pathize with the woodwork. ars who buy from him. He watches intently as the fig. ure and abape of the piece change with the gouge's progress, looking for the details he wants to preserve in the final turning. Unless one has witnessed him wielding a chain saw with a .' har or slamming a quartered burl in place on the head saw carriage, it's a little deceptive to see how differently Borek works at the lathe It's e task that seems almost ef. (ortless by comparison, I 0 24 months for $23.97 Name ~ny From Pap 9 : 012 monthsfor $15.97 I . . =: New subscription 0 Re~~~a~ I I ! -. for the term checked: which in reality it is. Handling thoee large raw burls awyer panel - it suddenly aeemed semblies. Pleasesend my WOODSHOP NEWS I subscription S VIee President AI Gore. MTE was one of 15 award Wis., includes hemlock, hard oak, ba'.swoocl' yellow birch. fore4t, 40 of Green white maple, red maple and These woods,along with 10 other hardwood and soft. wood species, are marketed worldwide.

© Copyright 2026