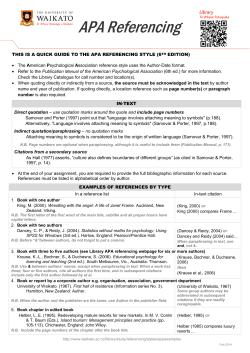

A / M 2007