071 263 2963 086 658 0055

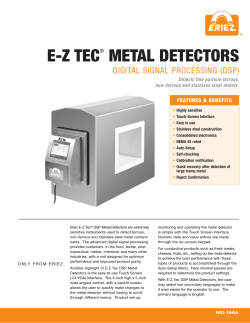

Tel: Fax: Email: Postal: CK: Vat: 071 263 2963 086 658 0055 [email protected] P.O. Box 10765, Aston Manor, 1630 2007/211803/23 4060241330 How to develop your food safety management system Welcome to our series to assist you with the development of your food safety management system. We trust that this column will be beneficial and we look forward to your comments and questions. Foreign body detection systems Last month we looked at controlling foreign bodies in food and the systems we should use to prevent this type of contamination. We looked at the use of HACCP as a tool to help identify the significant hazards in other words the hazards that could cause significant harm to the consumer and have the highest probability of occurring. These hazards need the highest level of control and in many cases we will implement a step in the process called a critical control point (CCP) to eliminate the hazard. It is usually at this step that a specialised piece of equipment is installed with the purpose of detecting and eliminating the hazard. In simple terms we install a metal detector or a sieve to remove the foreign bodies from our product. It is important to note that no system can fully guarantee to remove every contaminant and the effectiveness of the equipment will depend on the type of foreign body, the initial level of contamination and the maintenance of the equipment. Sprenger (2009) reminds us that most machines will deteriorate with age and use and constant testing of the equipment to ensure its capability. There are a variety of detection and removal systems in use such as: • Metal detection systems • X-ray systems • Sieves and filtration • Vision systems including monochromatic, colour and laser sorters • Magnets • Air or liquid separation systems • “Spotters” or sorters on a bottle lines or illuminated inspection belts/sorting tables. I am by NO means an expert on all of these systems but I can help with a few pointers and suggestions from a number of reputable sources. 1. Metal detection The BRC Metal detection guideline suggests that every company should conduct a hazard analysis for EVERY product it produces to assess the risk of metal contamination in their products (Sure I said that too….). The guide further states that if there is a risk of metal contamination a metal detector is required. The analysis of © Von Holy Consulting | January 2009 | © The Food Safety Network| Oct 2010 the process must also show the company what type of metal contamination they have e.g. ferrous, non-ferrous, stainless steel etc. A pie facility poses the risk of metal contamination from cutting blades, mixing blades, filling heads, swarf from aluminium pie trays and sieve damages. A wine bottling line would not have the same hazards as wine is passed through a series of filters which would remove the metal before bottling. No metal but glass would be a big issue – so no metal detector require in this process but another type of control as we will see later. Metal detectors should be placed in the production process so that packed and sealed product goes through the metal detector. Different metal detectors would be necessary for products that have to be packed into foil before passing through the detector. Sometimes a metal detector is used for screening raw materials but this is usually to prevent damage to processing equipment later in the process. The recommended installation configuration should always include an automatic divert system for product that is contaminated by metal with a lockable reject box for conveyor lines which can only be opened by authorised personnel. An audible and visual alarm is also recommended. A failsafe system is also required for if the reject mechanism does not work to ensure the line stops. The installation is a specialised activity and should be done by a reputable supplier in accordance with the manufacturers instructions/recommendations. Make sure you check out their references first. The sensitivity of a metal detector is influenced by the ratio of aperture size to the product size. The search head size is selected based on the product. Further influencing factors include salt content, moisture, vibration, moving metal, the proximity of other detectors, cleaning methods and changes in temperature and humidity. The orientation of the contaminant also plays a role – think of the needle in a product in the vertical position and the horizontal position. According to the BRC, metal detectors cannot be calibrated technically but the sensitivity is optimized. The sensitivity can then be verified using standard sized rods or balls of different types of metals to ensure the metal detector detects these. Further validation of the metal detector by controlled spiking of the product is also essential. A properly trained operator is a must and the correct procedure and checklist to verify the correct operation and checking of the metal detector at regular intervals. The checking interval is determined by how quickly product moves through the facility. If there was a failure of the system could you still find the previous product that passed through the detector or would it be despatched if the product is already gone, reduce the time between checks. The application of metal detectors is being extended to magnetized plastic compounds. A reusable detectable plastic cable ties, product tags and detectable ear plugs are examples. 2. X-rays These systems are used on meat lines to detect bone, stones and glass in agricultural products and to detect steel, plastics and natural rubber in processing lines. © Von Holy Consulting | January 2009 | © The Food Safety Network| Oct 2010 According to Sprenger, the greater the density of the product the easier to detect. You can even detect contaminants in plastic, card or glass packaging and this is the ideal solution for canned products – if you can afford it. One manufacturer claims detection limits of 0.3mm. An added factor is the ability of some of these machines to identify incorrect fill levels and damaged product – built in QC services. Once again a complete instruction and competent operator are essential. 3. Vision systems These systems are usually used for rejecting unsatisfactory raw materials and involve cameras measuring light reflected in monochromatic and colour sorters. If the pre-set thresh hold is reached the product is rejected. The cameras can be combined with UV or infrared the sorters can sort and reject by density. Laser sorters are used for products within a narrow colour range. These systems require regular and specialized maintenance and should not be allowed to run to failure. Vision systems also use humans to “spot” defects. Sorting lines/conveyors or spotters on a bottle washing line are some examples. Precautions such as eye testing colour blindness testing and regular rotation would be some of the “maintenance checks” you will need to put in place. Adequate lighting of the correct colour is essential as defined by SABS 049. The line speed will affect the number of spotters or inspectors as they are known in the abattoir industry. Proper training to “spot” defects is critical. When using a human “device” we need to remember that the performance checks needed are to re-check already inspected product to see if the “device” is failing to detect. This should be done by QC personnel and these checks recorded. In conclusion, as an auditor I see too FEW of these systems in use in the food industry. I see many hazard analyses that identify the need for this level of control but the answer is always “THE COST”. A number of retailers already penalize their suppliers for foreign body contamination – these “fines” can quickly justify the purchase of a metal detector or the like. In a study that was conducted on recalls involving foreign body contamination in the USA in 2007, Peariso found that the lack of proper maintenance systems, the lack of supplier control systems and the absence of a robust HACCP system were the root causes of these incidents. Even though some of the organisations had the correct detection mechanisms in place, a “temporary” concession from management to bypass these systems caused the recall. This underlines the importance of a strong food safety culture and ensuring that we don’t stop doing all the right preventive mechanism that we discussed last month just because we have a metal detector. © Von Holy Consulting | January 2009 | © The Food Safety Network| Oct 2010

© Copyright 2026