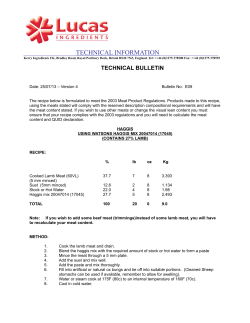

Meeting the Requirements of the 1998 Minnesota Food Code