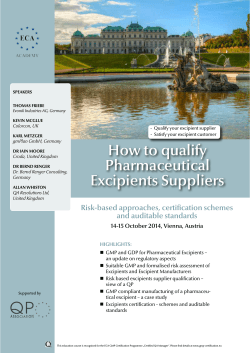

PHARMACY european INDUSTRIAL FEATURES