How to Reduce Your Chemical Hazard Footprint

How to Reduce Your Chemical Hazard Footprint Webinar Agenda What is Your Chemical Hazard Footprint? Current Issues Affecting Your Hazard Footprint Methodologies to Reduce Your Footprint Blueprint for Success 2 What is Your Chemical Hazard Footprint? • A hazard footprint consists of the environmental, health, and safety implications and costs associated with the use, management, and disposal of hazardous chemicals. 3 Aspects of Chemical Hazard Footprint Regulatory Physical Environment 4 GOALS OF CHEMICAL HAZARD FOOTPRINT REDUCTION 1. Reduce The Number, Volume, And Use Of Hazardous Chemicals 2. Identify Potential Product Substitutions 3. Better Communicate The Considerations And Impacts Of Working With Hazardous Chemicals (Increase Worker Safety) 4. Meet Regulatory Compliance and Stakeholder Initiatives 5. Reduce Corporate & Facility Risk 6. Reduce Corporate Cost Of EHS Programs (And Remediation) 5 Industry Statistics In 2008 alone, chemicals and chemical products were the source of 15,220 non-fatal occupational injuries and illnesses. In 2008, where chemicals and chemical products were the source of injury or illness in non-fatal occupational injuries resulting in days away from work, 34 percent resulted in six or more days away from work, and 10 percent resulted in 31 or more days away from work. Exposure to caustic, noxious, or allergenic substances led to 216 on-the-job fatalities in 2008. Per the Bureau of Labor Statistics 6 Regulatory Drivers - Sample North America Global Asia Pacific • OSHA – Hazard Communication Standard • CA Restriction of Hazardous Substances (RoHS)/ Waste Electrical and Electronic Equipment (WEEE) • CA Green Chemistry • CA Prop 65 • U .S. Bioterrorism Act • U .S. Chemical Assessment and Management Program (ChAMP) • Toxic Substances Control Act (TSCA ) • Canada’s Chemicals Management Plan (CMP) • Workplace Hazardous Materials Information System (WHMIS) • Globally Harmonized System (GHS) (Global) • International Council of Chemical Associations Global Product Strategy • NGO SIN (Substitute It Now) Lists • Industry Lists • China RoHS) • Industrial Safety and Health Law (ISHL) (Japan) • Poisonous and Deleterious Substances Control Law (PDSCL) (Japan) • Chemical Substances Control Law (CSCL) (Japan) • Dangerous/Toxic Materials (Taiwan) • Industrial Safety and Health Act (ISHA) (Korea) • Toxic Release Inventory (TRI) • Australian Inventory of Chemical Substances (AICS) • Hazardous Substances and New Organisms (HSNO) Act (New Zealand) European Union • European Community (EC) Regulation 178 • EU RoHS • 2007/47/EC (Phthalates) • REACH Per SAP “Product Compliance, Safety, and Stewardship for Process Industries” whitepaper 7 Globally Harmonized System • 1,000,000 chemicals • 5,000,000 businesses • 40,000,000 workers • Estimated net savings of $764 million in U.S. alone from safety and health risk reduction and productivity improvements • * Per OSHA “Facts on Aligning the Hazard Communication Standard to the GHS” 8 Primary HCS Changes Per GHS MSDS Labels MSDSs will need to be updated or re-authored to meet GHS guidelines Labels will need to be reprocessed during transition. Standardized pictograms, signal words, hazard statements will be required. Communication Training Updated safety data sheets and labels will need to be circulated and distributed to stakeholders Employees must be trained on the new content and format of SDSs and chemical labels 9 Chemical Management Evolution Strategic Chemical Data Management Unified Chemical, Inventory & Chemical Data Management Basic HazCom Compliance 10 Comparison of Approaches 1. Paper-based or web access to generic catalog 2. Limited chemical data indexing 3. No reporting 4. Separate material approval processes 5. Duplicate, outdated MSDSs 6. Little to no regulatory crossreferencing 7. Notebook updating is your responsibility 1. Web-based data and documents 2. “Hands-free” chemical data management 3. Synchronized regulatory reporting 4. Integrated material approval and chemical labeling 5. GHS-ready applications 6. Always-updated MSDSs and chemical data 7. Completely chemical visibility across all facilities 8. Audit tracking of notebook 11 Steps to Manage Your Footprint Chemical Inventory Management Material Approval Chemical Data Management M o n i t o r i n g & Communication & Reporting Training 12 Chemical Inventory Management • Elements of Proper Inventory Management Chemical Inventory Management – What – Where – How Much • Ongoing Inventory Management – Updates – Barcoding – Data Exchange-Various Systems 13 Material Approval • What are the Basic Elements of an Effective Material Approval Process? Material Approval • Include the appropriate personnel in the review cycle • Trackable • Easily modified as the work environment or personnel change • Closed Loop (notify the requestor when the request to introduce the material has been approved or denied) • Beyond Chemical ApprovalHazard Profile Technology 14 Chemical Data Management Chemical Data Management 15 Monitoring & Reporting Monitoring & Reporting • Set goals to remove specific hazard types (carcinogens, corrosives, toxic substances, aquatic hazards, etc) • Identify certain highrisk plants, chemical areas, or job functions with greater exposure • Determine regulatory impact of certain materials when reviewing hazard footprint (e.g. CA Prop 65) • Identify alternative products that have lower hazardous footprint 16 Material Regulatory Monitoring 17 Communication & Training • Definition • Methods of Addressing • Expected Results Communication & Training 18 MSDS - The Foundational Element •Hazard Classifications •Regulatory Information (components, %, don’t forget section 15) •Exposure Limits •Handling, storage, disposal •More! 19 The Business Case for Reducing Your Footprint • Elimination of chemical document administration costs via outsourcing • Lower insurance premiums or out-of-pocket workers’ compensation claims • Vendor consolidation and lower chemical inventory counts • Risk reduction for fines, frequency of employee incidents, and severity of incidents • Better public relations • It’s the right thing to do! 20 A Quantitative Approach MSDS and Chemical Management MSDS Management - Safety Binder Creation & Distribution - Safety Binder Updating (bi-annual MSDS Updates) - MSDS Archival - MSDS Management Total $ $ $ $ 6,720 21,000 1,200 28,920 $ $ $ 4,200 10,500 14,700 $ $ $ $ 750 3,000 1,500 5,250 $ 48,870 $ $ $ $ 17,824 1,747 3,095 22,667 $ 22,667 $ 71,537 ROI Chemical Inventory & HazMat Management - Physical Inventory of Chemicals (Improvement) - Inventory Management & Labelling - Chemical Inventory Management Total Regulatory Compliance & Business Reporting - Workplace Chemical Inventory Reporting - Form R Information/Reporting - Tier 1/Tier II Reporting - Chemical Inventory Management Total - TOTAL IN-HOUSE MSDS MANAGEMENT COST Risk Management Risk Management - Workman's Comp Risk Reduction - Lost Productivity Reduction - OSHA Fine Risk Reduction - Risk Management Total - TOTAL RISK REDUCTION TOTAL INTERNAL COST & RISK REDUCTION OPPORTUNITY 21 Implementation Blueprint Step 1 – Gain control of chemicals entering the workplace Step 2 – Utilize a system and/or service that provides access to the hazard footprint information found on the MSDS Step 3 – Take advantage of the tools available to assess your existing chemical hazard footprint to locate areas for improvement (and cost reductions) Step 4 – Proactively review new materials entering the workplace Step 5 – Implement an ongoing continuous improvement process that allows regular review of your chemical hazard footprint and provide the ROI necessary for meeting ongoing Corporate sustainibility initiatives. 22 For more information, contact: Scott Williams [email protected]

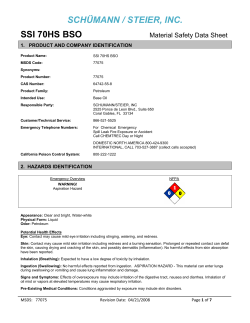

© Copyright 2026