Document 212506

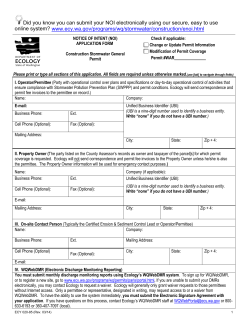

. . * I water How t hers: -8 2i/L+zL fIi U.S. Environmental Protection Agency @PA) regulations, published in November of 1990, require that industrial facilities, such as electroplating and surface finishing shops, obtain a National Pollutant Dscharge Elimination System CNPDES) permit for poinGsource stormwater discharges. These controversial regulations will generally require the development of a stormwater pollution prevention plan (SWPPP). The plan must incorporate identification of pollutant sources, identification of best management practices WIMPS) to prevent or minimize pollution of stormwater run-off, training of facility personnel, and documentation of the plan’s implementation. Stormwater management must be an integral part of facility operations if cost-effective implementation of the SWPPP is to be achieved. Management principles range from elimination of storm run-off, selection of inexpensive but effective control measures, employee training to reduce pollutant generation, and record keeping for demonstration of compliance to the SWPPP. T he controversy over the regulations has continued since their publication, fueled to a considerable extent by the lack of clear and consistent direction in EPAs permit application processes: by differences in implementation requirements between EPA and the individual states; and by very limited guidance about permit issuance and compliance. However, one factor that is emerging is that operators of regulated facilities will, at some point, have to develop a site-specific SWPPP 46 for the facility. To develop an SWPPP, the questions that an operator must consider, and the ones to be addressed here, are: To what extent is my facility regulated? What is an SWPPP and what does it require? How and by when must I prepare an SWPPP? Whatdoesan SWPPPimplyforNPDES permit compliance? Extent of Regulatory Coverage The first basic question to always consider in the managementof stormwaters at an industrial site is whether the site has regulated stormwater discharges. Under the stormwater regulations, stormwater is not regulated under the following conditions: The stormwater discharges to a municipalsanitary sewer system or a municipalcombinedsanitary-stormsewer system. There is no point-sourcedischarge(e.g., pipe; ditch; swale: or concentrated, localized flow) of industrial stormwaters. In all other cases the stormwater discharge must be regulated. If a facility has no regulated stormwater discharge, either because of one of the above reasons or merely because it has no stormwater discharge from the industrialareas of ihe facility, no permit (or permit application) is required. While considerable caution should be exercised in determining whetherastormwaterdischargeisa pointor non-point-sourcedischarge (the regulatory definition of point-sourcedischarge is extremely broad), the possibility that a permit may not even be required provides two obvious guidelines for management of stormwater discharges: . Determine whether you have a regulated stormwater discharge. If you have a regulated discharge, see if you can modify the stormwater drainage so that stormwater drainage is no longer regulated (e.g.,direct discharge of stormwaters to a city sanitary sewer after some pretreatment). Of course, contemplated modifications should be examined in regard to nonstormwater-related consequencesas well. If stormwater dischargeswill occur from the industrialareasof thefacility, then the question is whetherthe discharge is regulated as a consequence of the industrial operations or conditions at the site. One mechanism that the November 16, 1990, stormwater regulations use to identify regulateddischarges is to specify regulated industries by Standard Industrial Classification (SIC) code. (There are other mechanisms, but these are not of concern here.) Most electroplating facilities (if not all) have an SIC code of 3471. Facilities with this code (or more generally, a two-digit SIC code of 34) are currently regulated if they have stormwater discharges where material handling equipment or activities, raw materials, intermediate products, final products, waste materials, by-products, or industrial machinery are exposed to stormwater. That is, if you handle, store, or transfer materials or products in your industrialactivities at your electroplating facility in such a way that rain could fall on them and then run-off from your facility iisstoii?ivv’atei, .yoiiifacility, a iegiilated facility. This source of regulatory coverage is the light industrial coverage category, or the “exposure” criteria (corresponding to EPAs industrial category xi in the November 16,1990 regulations). Asecond regulatorycriteria, the “heavy industrycriteria”(correspondingto EPAs category i in the November 16, 1990, regulations), may also apply to an electroplating or related facility. A facility is “regulated if it is already subject to stormwatereff luent limitationsguidelines, new source performance standards, or Plating and Surface Finishing EPA on the PFCs will more clearly define About the Author ative rinsing agents vironmental impact. he fact that it does not it very attractive for ot tolerate the presprecision-cleaning cleaning of materia water retention are proved, it is likely that addit and rinsing agents will be result will be a very robust tal impact. Ll Acknowledgments The author appreciates the collective input of Petroferm, Detrex, 3M Company; and the Raytheon Waltham, MA, facility that made this article possible. Frank A. Marino is a Senior Corporate Environmental Specialist with the Raytheon Company, 141 Spring St., Lexington, MA. He has an MS in environmental studies from the University of Massachusetts Lowell, and he has taught a collegelevel course in industrial environmental managementat that university forthe last seven years. Marino, who has 13 years' experience in industrial environmental bnagement, has beentheenvironmen- 1 If the form has been removed, call AESF Headquartersfor a new one: 4071281-6441. Reference 1. U.S. EPA Memorandum, "Uses of Perfluorocarbons in Industrial Cleaning," 1-4 (1/6/93). fill out the listing form in Journal, fold it, affix a stamp, and mail it back. Vista, FL. \ / - COLD VAPORIZATION'".. . T logy Of Compliance. PROVEN FIELD IN S including: \ ACID ACTIVATORS PAINT SPRAYS ACID RECOVERY ALKALINE CLEANERS ANODIZING OPERATIONS COATING EMULSION Model STU-5000-2(5000gpd) 1 \ METALSfiCLUDE: Cadmium, Chrome, Copper, Gold, Lead, Nickel, Silver, Tin, Zi;\F Calfran International "The Zero Discharge People;' I a . BOX 269, SPRINGFIELD, MA 01101 PHONE: 413/732-3616 FAX: 413/732-924 ST COAST OFFICE PHONE/FAX: 714/497-6331 / April 1993 Free Details: Circle 115 on postpaidreader service card. 45 * <.) ’. toxic pollutant effluent standards unde 40 CFR subchapter N, and it is not ex empted as aconsequence of being regu. lated under the “exposure” criteria. The electroplating industry is subject to efflu. ent guidelines and standards in Part 412 of subchapter N of 40 CFR. Specific types of industrialactivity subject to these guidelines and standards are summa. rized in Table 1. While there are some limited exceptions to the industrial cat. egories in Table 1 (see 40 CFR Pari 413.01), most electroplating operations would fall in one or more of these categories. By virtue of the fact that pretreatment standards in the various subparts 01 Part 413 define effluent limits for toxic pollutant discharges to municipal systems, this regulatory requirementapplies to electroplating facilities in the categories of Table 1. The application of the criteria, under current regulation,can be put in the form of the following questions: Does your facility have the SIC code of 34? If so, apply the exposure criteria to determine whether a permit is required. Does your facility have an SIC code different from 34 and conduct one or more of the activities identified in Part 413 of Subchapter N? If so, a permit is required. The complicatingfactor in these questions is that in June of 1992, a federal court ruled that the EPA improperly excluded facilities in the “exposure” category from regulatory coverage by basing their regulatory coverage on whether or not there is exposure of equipment or materials to stormwater run-off. While the EPA’s exposure criteria seems logical (Why worry about stormwater run-off if there is no source of pollutants to contaminate it?), the fact remains that the courtsaid such exclusionwas nota proper application of the law. The EPA was directed by the court to address this deficiency, but has not yet promulgated a rule for doing so. When it will is unknown, and what form the rule will take is unclear, although experience would suggest the exposure principle would be eliminated or significantly limited. Until such time as a new rule on exposure is promulgated, however, the existing regulations apply, and the following stormwater management guidelines are suggested: If you want to rely on existing regulations and yourfacility is regulatedsolely because of exposure, try to modify conditions at the facility to eliminate (or April 1993 1 significantly reduce) exposure, so that a permit is not required or the area of the facility covered is small. If your facility is covered solely because of the exposure of equipment or materials to rainfall run-off, and you want to be proactive in addressing stormwater control (whether or not a permit is required now) in order to be well positioned for future regulations, consider developing an SWPPP now. Requirements for an SWPPP The regulatory-requiredelements in an SWPPP, as prescribed by the federal jeneral permit, include the following najor elements: A map of the facility indicating areas of stormwater drainage to various outfall points. Description of potential pollution sources. The minimal description consists of the elements listed in Table 2. An evaluation of possible illicit connections of non-stormwater discharges to the stormwater conveyance system. Illicitconnections are a pollutantsource, but are such a special source they are given special attention. Description of measure and controls to prevent or minimize pollution of stormwaters. Such measurements and controls are generally termed best management practices (BMPs). Categories for which measures and controls must be developed are listed in Table 3. Formation of a Pollution Prevention Team from facility staff to be responsible for developing and implementing the SWPPP. If SARA Title Ill Section 313 chemicals are handled at the site, a stormwater monitoring program will have to be instituted. Stormwater sampling will have to be conducted on a semi-annual basis. Inspection and site-compliance evaluation on a regular basis, at least once a year by facility personnel, to evaluate at least: Evidenceof pollutants enteringthe drainage system. 47 , . . How to Prepare an SWPPP Evaluation of the performance of pollution prevention measures. Identification of areas where the SWPPP should be revised to reduce discharge of pollutants. Once you know that you are or will be required to prepare an SWPPP for your facility, the following guidelines can be used to develop an SWPPP: Documentationof inspectionand compliance (with a report). Consistency with other plans, such as Spill Prevention Control and Countermeasure plans and Best Management Practices programs. Review what you will need to address in the SWPPP, either by review of specific requirementsgiven as part of a permit, or as stated in a general permit applicable to your facility. Some states have industry-specificpermitsthathave narrowly focused requirements which would limitthe rangeof thingsyou have to consider for inclusion in SWPPP. In lieu of specific permit information, use the federal general permit as a guide, because most permits will be using its requirements as a baseline. Review other facility management activities and needs and assess whether you want to address other activities besides development of an SWPPP at thesametime you preparetheSWPPP. Not only can this result in a better SWPPP, butyoucan perhapsefficiently address other facility management needs. Structure your development of the SWPPP as appropriate to this comprehensiveapproach. Forexample,you may soon have to renew some NPDES permits for process waste discharges; it might make sense to do some of the work for that permit at the same time the stormwater permit applicationwork is done. * Identify the key people who will be involvedin the development and implementation of the SWPPP. Some or all of these may be on the Pollution Prevention Team. Get them involved as early as reasonable and possible, so they understand the reasoning that goes into the SWPPP development. Gather various site, topographic, or facility maps or photos that you currently have and determinetheir usefulness for describing drainage conditions and pathways, materialshandling and storage at the site, and pollutant sources. Decide whether additional mapping is required. Generally, only limited mapping is required for the SWPPP, but there may be other mapping needs for the facility that would be usefully done as part of the SWPPP preparation. * Gather all permits, existing pollution control plans, pollution management plans, reports on past spills, and any types of enforcement actions for the facility. Reviewthe informationneeded in the SWPPP and be sure the SWPPP to be developed is consistent with the information contained in them. 1 Determine whether you have SARA 313 chemicals at your facility. If so, identify and list them, and determine where on your site they exist. Develop a stormwater sampling plan for runoff from areas that have SARA 313 chemicals. Conduct a site inspection of your facility, looking for significant or potential sources of pollutants. Table 3 lists examples of possible sources. Most inPlating and Surface Finishing 1 ' *." - 7 t. dustrial facilities will have areas where the potential for pollution of run-off waters is obviously greater than other places. If resources are limited, pollutant control should be focused on areas of greatest pollution potential. Review results of inspection and set priorities for development and implementation of best management practices; make a preliminary selection of BMPs for the identifiedsources. Conduct another inspection to finalize the selection of BMPs for the facility. Prepare a preliminary written SWPPP, addressing each regulatory requirement. Includea proposed schedule for plan implementation. The plan can be phased, but actions and controls not involvingconstructionshould be scheduled for rapid implementation. Be action-oriented in your written document. Review the proposed SWPPP with managers, to be sure that they understand the implicationsof the programparticularly the cost implications.Once the plan is developed, it must be implemented. Finalize the plan. Document the implementation of the plan on a continual basis and be prepared at all times to demonstrate, by records, logs, or things in place, that the plan is being implemented. If, during the implementation of the SWPPP, you find some things are not working or there are more cost-effective ways to implement a BMP, you can changeyourSWPPPtoreflectachange in BMPs. Just be sure to document the change and why you did it. Selecting BMPs BMPs can be source controls, hydraulic controls, or treatment controls. Source controls, such as covering workand storage areas, illicit connection removal, or spill prevention, attack the potential pollution by trying to eliminate the pollutant. Hydraulic controls, such as detention basins, modify the run-off hydrograph so that pollutant transport in run-off waters is reduced. Treatment controls, such as swales or oil-water separators, cause a change in the physical or chemical characteristics of the pollutants in the stormwaters. The order of preference in selection of controls is usuallysource controls, hydraulic controls, and treatment controls, primarily because source controls will usually be the most costeffective. The guiding principle in selection of BMPs is: try to do the simplest thing first. Other selection guidelines are: April 1993 Try to remove the needfora BMP at all. Try to modify drainage to reduce the number of outfalls, particularly if sampling is required. Consider diverting run-off to retention or detention storage facilities. Consider diverting very polluted run-off to process waste facilities for treatment. Find and eliminate illicit connections. Is it cheaper to train (frequently) personnel or spend money for hydraulicor treatment-oriented BMPs? Does it make any difference if the BMP is permanent or easily changed? Will the implementationof the BMP be easy to document? Will the BMP be easy to implement? Will the effectiveness of the BMP be easy to demonstrate? Will the BMP be readily accepted and used by employees? And always keep in mind, when selecting BMPs for your facility, that you probably are doing, already, many things that are BMPs, even though you may not have called them that. These are acceptable BMPs for your SWPPP. BMPs selected for your SWPPP do not have to be new; they can be BMPs already in place. Take credit for your prior efforts and include them in your SWPPP. 49 ~ k Deadlines and Compliance When must the SWPPP be prepared and implemented? There are several considerations. First, there are a number of phases to recognize: Plandevelopment, plan implementation, and plan compliance. Plan compliance must occur overthe duration of the permit (usually five years). In the case of the federal general permit, no compliance reports (except for possible stormwater sampling reports) must be submitted during the permit term. The SWPPP does not even have to be reviewed by EPA after it is prepared; it merely is kept on-site for possible inspection. This discretionary character of the SWPPP can be either a curse or blessing. The essential criteria for the SWPPP seem to be reasonableness, effectiveness, and regulatory completeness. If you have an actual permit, such as the federal general permit, by which you are supposedto abide, then it will specify certain deadlines for preparation and implementation. Inthe caseof the federal general permit, the SWPPP must be pre- pared by April 1,1993, and implemented by October 1, 1993. State general permits may have the same or different deadlines, so state agencies should be consultedif yourfacility is beingpermitted under a state general permit. If you have applied for an individual permit, or if yourfacility is being permitted through the EPA-prescribedgroup application process, you will not be likely to have an actual permit at the current time, in which case some best judgment must be applied about how quickly you will or will not have to develop and implement an SWPPP. Without specific directions from a regulatory agency, you have presumably no permit requirements to meet if you have made an appropriate application. Unfortunately,there is no clear regulatory guidance in regard to permits being obtained through the group application process. Some states have already decided, or may in the future decide, to stop accepting permit applications that are made using the group process, and require that permit compliance be initiated under deadlines set by the state ratherthanthe EPA, becausethatagency is taking considerable time to develop model permits for facilities in groups. Consequently, good management guidelines are: Understandthe permit process in which you are involved, what the regulations do and do not say about deadlines for this process, and just who is saying what the deadlines are. In states where the state has NPDES authority, talk to the state permitting agency to get their insight into deadlines and requirements. When in doubt about what to do, do what makes sense for controlling stormwater pollution. The nationwide implementation of stormwater permitting is currently not without ambiguities and uncertainties. Development and implementation of SWPPPs for industries such as the electroplating industry is, however, a clear necessity. Varying levels of complexity in the SWPPPs for electroplating and surface finishing facilities can be expected, but the principles for their development will generally be the same. Stormwater management should build on reasonableness, effectiveness, completeness, and demonstration of compliance of the SWPPP developed for the facility. About the Author For more information contact SPF today: 730 Burbank Street Broomfield, CO 80020 Phone: (303)438-1747 FAX: (303)438-1749 Free Details: Circle 116 on postpaidreader sewice card. 50 Dr. Michael Collins is an Associate and Senior Project Engineer with WoodwardClyde Consultants, 7600Tidwel1, Suite 600, Houston, TX 77040, with training as a civil engineer with specialities in hydraulics, hydrology and hydrodynamics. His experience includes ground and surface water quality modeling, deterministic and stochastic simulation, and non-point-sourcepollution evaluation and management. Prior to his current position, Collins was on the engineering school faculty of Southern Methodist University, where he taught and did research for nearly 20 years, in the areas of hydrology and hydraulics, and he directed the Center for Urban Water Studies for five years. Collins is widely published, with more than 80 publications and technical conference proceedings. Plating and Surface Finishing ~ ~~~ ,

© Copyright 2026