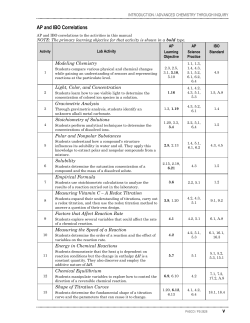

Document 261563

An Automated Sample-Processing and Titration System for the Determination of Uranium J. E. Harrar, W. G. Boyle, J. D. Breshears, C. L. Pomernacki, H. R. Brand, A. M. Kray, R. J. Sherry, and J. A. Pastrone Lawrence Livermore Laboratory, University of California, Livermore, California 9^550 ABSTRACT The system comprises a computer-controlled automatic wet chemical analyzer, and a scheme for handling all of the data generating operations associated with the assay of solid or solution samples containing uranium. The analytical measurement technique is based on the Davies-Gray/New Brunswick Laboratory method, and involves controlled-current coulometry with potentiometric endpoint detection. To increase the credibility of the analytical results and minimize the probability of processing large numbers of samples incorrectly, the analyzer includes an extensive faultmonitoring network. This guards against (a) off-normal conditions that might result in analytical errors, and (b) unsafe operating conditions. There is provision for analyzing standards along with samples, and for automatically comparing the standard results with allowable control limits. INTRODUCTION Among the numerous methods proposed for the accurate assay of uranium in nuclear materials, the titrimetric method of Davies and Gray (!_) as modified by workers at the New Brunswick Laboratory (2_), has emerged as the most selective and hence the most versatile. It has been thoroughly characterized at the New Brunswick Laboratory and elsewhere, and found to be especially applicable to uranyl nitrate solutions, samples such as aluminum-, stainlesssteel-, and Zircaloy-clad fuels, and samples containing niobium, hydrofluoric acid, and nitric acid. The original Davies-Gray method involved the reduction of U(VI) to U(IV) by Pe(II) in strong H^POn, oxidation of the excess Fe(II) with UNO3 in the presence of Mo(VI) catalyst and sulfamic acid, dilution of the solution, and then titration of the U(IV) with KpCrpOy to a visual end point. The method was improved and refined at the New Brunswick Laboratory by the addition of V(IV) to the solution to markedly speed up the attainment of equilibrium, which allowed the use of potentiometric end-point detection. The basic method has also been extended by Goldbeck and Lerner (3.) to a coulometric titration, in which the titrant is V(V), electrogenerated at constant current by the oxidation of V(IV). This procedure, * Work performed under the auspices of the U.S. Energy Research and Development Adminstration, Division of Safeguards and Security. Fall 1976 199 compared to the volumetric one, has the advantages of not requiring a titrant solution, having greater precision and lower systematic error in the measurement of the quantity of titrant, being easier to adapt to changing quantities of uranium titrated, and being more amenable to automation. Because of the large number of assay samples processed by many nuclear laboratories, there has been a continuing need for the automation of a general-purpose method such as that based on the Davies, Gray, and NBL procedures. Other benefits that usually accompany automation, such as more timely analyses, freedom from operator bias, reduced clerical time and errors, increased precision, and reduced operator intervention in the processing of radioactive samples, could also be realized. However, to achieve the maximum benefits of the automation, all operations performed on the samples, riot Just the titratlon itself, should be incorporated into the automatic system. Pour basic steps are involved in the complete analysis: sample dissolution, sample solution preparation, titratlon, and calculation and presentation of the results. All of the work done thus far has been directed toward mechanizing the last three of these steps. Progress in the automation of the Davies-Gray-NBL method thus far has included the adaptation of the volumetric potentlometric titration to a Fisher Scientific Company Titralyzer (20, Radiometer Company titration equipment (4_), and a Metrohm-Brinkmann titrator with programmable calculator control '(5.) • The coulometric titration has also been carried out with the Fisher Titralyzer (6.,2_) • AUTOMATIC URANIUM TITRATION SYSTEM The design of the automatic analysis system developed at the Lawrence Livermore Laboratory departs from previous systems in several respects. A simplified block diagram of the system is shown in Figure 1 and Figure 2 is a photograph of the system. The system is controlled by a Digital Equipment Corporation PDP-8/e minicomputer. To reduce the systematic errors in the analysis, all sample solution aliquoting is carried out on a weight basis. The two principal operations — the weighing of the solid and solution samples, and the titration of the uranium In the solutions — have been integrated so that previously entered weight information, with appropriate identification numbers, can be extracted from a computermemory file and used with the titration results in an automatic calculation of the quantity and weight concentrations of uranium in the analyzed samples. Weight information can be stored semiautomatlcally via the electronic balance or entered from the keyboard. A commercially-available sample changer (8_) having a capacity of MOO 300-ml beakers is used, together with a Mettler optical-reader electronic subsystem that reads coded labels denoting the positions of the beakers in the sample changer< 2M Nuclear Materiab Management The apparatus for delivering the pre-titration reagent solutions and discarding the waste solution is based on the use of pressurized solution containers and an appropriate valving arrangement, rather than a system of pumps. Titrations are performed by controlled-current coulometry using a specially-designed electrolysis cell and electronic modules for programming the current and measuring the electrode potentials (9.). BASIC STEPS IN OPERATION OP SYSTEM Weighing and Storage of Weights. There are three basic steps in the operation of this system: the weighing operations, the loading of the sample changer, and the analytical measurement. First, a series of weights, from which the weight concentration of uranium will be calculated, are entered into the computer memory file along with appropriate identification numbers. An example computer printout illustrating the entry format for a sample, followed by a standard is shown in Figure 3. For unknown samples, three weights are entered: the Subsample Weight, or portion of the solid sample to be analyzed, which is then dissolved in appropriate solvents; the Subsample Solution Weight, which is the solution resulting from the dissolution of the subsample; and the Subsample Solution Aliquot Weight, which is the portion of the subsample solution placed in the beaker for titration. In the case of known standard solutions, the weight of the aliquot of standard solution is first entered, the operator then enters the concentration of the standard solution, and finally the computer calculates and stores for later use only the quantity of uranium in the standard aliquot, along with its I.D. number. Loading of Sample Changer. After a group of samples and standards have been weighed and prepared for titration, the beakers are placed in the sample-changer magazines. The operator, interacting with the computer, then enters into the computer memory file the I.D. number of each subsample solution aliquot or standard quantity of uranium, along with the number of the position in the magazine into which he has placed each beaker. The input format for this operation is illustrated in Figure 4. During the operation of the sample changer, the sample identification subsystem identifies each beaker by position number as its solution is being analyzed. After the titration has been completed and the quantity of uranium found has been calculated, the computer links the quantity found viathe position number to the previously-entered I.D. number and weight information. Analysis and Data Readout. After a series of samples and standards have been weighed, loaded on the sample changer, and their position numbers indexed to the I.D. numbers, the automatic analysis system is started. After each beaker is processed, the result of the analysis is printed out, along with the previously entered weight information and information on the characteristics of the titration that may be useful for diagnostic purposes. This is illustrated in Figures 5 and 6. In the case of the standard, as shown in Figure 6, an error is calculated; this value is compared with a previously-set FalM 976 201 control tolerance, and a system shutdown will be initiated if the error is too large. Because of the positive sample identification features of this system, samples and standards can be loaded and processed in any proportion and in any order. FAULT MONITORING SYSTEM In addition to monitoring errors in the analytical results themselves, a number of other conditions of the system operation are also sensed; a summary these is given in Table I. The faultdetection system is "intelligent," i.e., if any of the fault conditions should occur, the system is programmed to give an alarm, indicate and record the fault, and shutdown, hold or carry out certain actions that depend on the nature of the fault and the point in the analytical cycle during which the fault occurred. TABLE I. Sensor Points and Off-Normal Conditions Monitored by Fault-Detection System. Spills or Leaks: in Reagent Containment System in Reagent Valve System at Sample Changer Flows: Sulfamic acid FedD-HoPOjj HNOo-Mo(VI) Diluent Reagent-Line H20 Rinse H20 Waste solution Cell Gas Pressures: Reagent Solution - Low or High Water Supply - Low or High Air Supply - Low Cell - Low or High Power Outage Digital Panel Meter Overload Titration Characteristics: Electrolysis Current Error Current-Source Voltage Limiting High Generator-Electrode Potential Quantity of Uranium over Maximum Limit Failure to Find Inflection Point in Titration Curve Control Standard Error 202 Nuclear Materials Management SYSTEM PERFORMANCE The prototype of the system was developed for use at the New Brunswick Laboratory of U.S. E.R.D.A. and Is being evaluated there. Preliminary results with uranium-metal standards, UoOg, and U02 indicate that the precision of the system is ^0.03 mg U (A.S.D.) in the range of 12-l8o mg U. Absolute accuracy based on electrical calibration of the instrumentation varies from -v-0.15 to +0.20 mg U as the quantity of uranium decreases. Types of samples tested thus far, and analyzed by the system without difficulty are 11303, UOg, UF6, U-A1, and U-stainless steel. ACKNOWLEDGMENT The encouragement, advice, and cooperation of C.D. Bingham and the personnel of the New Brunswick Laboratory during this work are gratefully acknowledged. REFERENCES (1) W. Davies and W. Gray, Talanta 11, 1203 (1964). (2) A. R. Eberle, M. W. Lerner, C. G. Goldbeck, and C. J. Rodden, Titrimetric Determination of Uranium in Product, Fuel, and Scrap Materials After Ferrous Ion Reduction in Phosphoric Acid, U.S. Atomic Energy Commission, New Brunswick Laboratory Rept. NBL-252, (1970). (3) C. G. Goldbeck and M. W. Lerner, Anal. Chem. 4JJ_, 59^ (1972). (4) L. Z. Bodnar and J. M. Scarborough, in Annual Progress Report for the Period July 1972 through June 1973» U.S. Atomic Energy Commission, New Brunswick Laboratory Rept. NBL-267 (1973), pp. 22-28. (5) J. V. Bender, Paper presented at 27th Pittsburgh Conference on Analytical Chemistry and Applied Spectroscopy, Cleveland, Ohio, March, 1976. (6) C. G. Goldbeck and M. W. Lerner, in Annual Progress Report for the Period July 1971 through July 1972, U.S. Atomic Energy Commission, New Brunswick Laboratory Rept. NBL-265 (1972), pp. 5-20. (7) C. G. Goldbeck, M. W. Lerner, and G. E. Peoples, in Reference 4, pp. 29-31. (8) Metrohm Ltd.-Brinkmann, see HJ. Keller, Neue Teknik, 14_ (2), 31 (1972). (9) J. E. Harrar and C. L. Pomernacki, Computer-Compatible Instrumentation for Automated Cdntrolled-Potential Coulometry, Fotentiometry, and Galvanostatic Measurements. Lawrence Llvermore Laboratory Rept. UCRL-78059 Preprint (1976). Fall 1976 203 FIGURES Figure 1. Block diagram of automatic uranium titration system. Figure 2. Automatic uranium titration system. Figure 3- Entry of weight data for a sample and a standard. Figure 4. Entry of sample-changer position numbers and identification numbers for a standard and two samples. Figure 5. Data readout for the analysis of an unknown sample. Figure 6. Data readout for the analysis of a standard. "Reference to a company or product name does not imply approval or recommendation of the product by the University of California or the U.S. Energy Research & Development Administration to the exclusion of others that may be suitable." 204 Nuclear Materials Management Minicomputer Keyboard Control panel and interface 1 Programmable constantcurrent source Electronic balance Water Electrode potential measurement interface subsystem Solution and gas distribution subsystem Post-titration waste distribution subsystem Figure 1. 8 Sample identification subsystem pressure regulation Block diagram of automatic uranium titration system, Figure 2. Automatic uranium titratIon system. « M Minicomputer Keyboard Control panel and interface I Programmable constantcurrent source Electrode potential measurement Sample identification subsystem Electronic balance Water pressure regulation interface subsystem Solution and gas Post-titration distribution subsystem waste distribution subsystem Figure 1. Block diagram of automatic uranium titration system. S W» DRTE ENTERED: 04-81-76 I. D. NUMBER: E2849-1-2 SUBSRMPLE WT. , GM. : 099. 32521 SUBSRMPLE SOL. WT. , CM. : 925. 21899 SUBSflMPLE SOL. flLIQUOT WT. , GM. : 919. 28549 DflTE ENTERED: 94-91-76 I. D. NUMBER: R9919 STD. flLIQUOT WT. > GM. : 999. 43429 STD. STD. CONC. , MG. URflNIUM/GM. SOLN. : 19. 352 QUflNTITV OF URflNIUM, MG. : 193. 32399 Figure 3. 5 Entry of weight data for a sample and a standard. DRTE: 84-01-76 SfiMPLE POS. N U M B E R : : 2 1 I. D. N U M B E R : R0811 DflTE: 94-01-76 S R M P L E POS. N U M B E R : : 2 2 I. D. N U M B E R : E2849-1-1 DfiTE: 94-01-76 SflMPLE POS. N U M B E R : : 23 I. D. N U M B E R : E2849-1-2 Figure 4. nu 2 V n v^ 2 u 3 U $ n Entry of sample changer position numbers and identification numbers for a standard and two samples. DATE: 04-92-76 TITRflTION PARAMETERS :N. SflMPLE POS. NUMBER: 22 I. D. NUMBER: E2849-1-1 SUBSRMPLE WT. , GM. : 000. 32521 SUBSAMPLE SOL. WT. , GM. : 925. 21390 SUBSAMPLE SOL. flLIQUOT WT. , GM. :809. 59358 MG. NORMAL URANIUM IN SflMPLE ALIQUOT= 30. 5172 GM. NORMAL URANIUM PER GM. SUBSAMPLE= 9. 24668 SMALL SAMPLE OPEN-CIRCUIT POTENTIALS, MV. =IND. ELEC. :27.91-3 GEN. ELEC. :23. 70 FINAL PRE-ENDPOINT INTERVAL POTENTIALS, MV. =IND. ELEC. :GEN. ELEC. : IND. Cl-~ ELEC. ENDPOINT POTENTIAL, MV= 93.29 25 C2= 67 E. P. -•= 261. 234 C3= 354 Figure 5. Data readout for the analysis of an unknown sample. 13.30 60S. 10 DflTE: 93-31-76 TITRflTION PflRflMETERS:N. SflMPLE POS. NUMBER: 27 I. D. NUMBER: R0005 STD. QUflNTITV OF URfiNIUM, MG. : 035.93192 MQ. NORMflL URflNIUM IN STD. flLIQUOT, MG. ERROR: 0. 0112 OPEN-CIRCUIT POTENTIflLS, MV. =IND. ELEC. :GEN. ELEC. :- 85. 9912 46.29 47. 80 FINflL PRE-ENDPOINT INTERVflL POTENT IflLS, MV. = IND. ELEC. :GEN. ELEC. : IND. ELEC. ENDPOINT POTENT IflL, MV= 100.34 Cl= 0 C2= 113 E. P. = 364. 886 C3= 457 Figure 6. Data readout for the analysis of a standard. 20.50 635. 50

© Copyright 2026