Document 262265

1 SAMPLE REPORT Extract fan bearing survey for biscuit oven No.1 Prepared for Jim Smith, Company Name, 123 High Street, Anytown, Anywhere 2 Extract fan bearing survey for biscuit oven No.1 This is a survey report for a biscuit baking oven that is gas fired and incorporates two extract fans . The survey was carried out using a thermographic camera (Fluke Ti25) to acquire the running temperatures of the motor bearings and the overall condition of the motor. The bearing condition survey was carried out using an acoustic emittion device (Holroyd MHC Memo ) . This gives the decibel level and distress levels of the bearing in running mode. The decibel level tells if the bearing is running dry or needs lubrication. The distress level tells whether the bearing has a deformity in it , such as brinelling , cracks or flat spots. In the survey report you can look at the timewave form of the acoustic analysis to ascertain the running smoothness or roughness of the bearing. Then you can listen to the bearing , as with headphones , with the WAV recordings. Lastly with the charts it is possible to keep a trending record of the condition of the bearings and see if there is any deterioration in the future needing remedial or maintenance work to be done. 3 Index Page: 1. Survey outline 2. Index 3. Survey report 4. Extract fan No.1 thermographic/timewave/sound analysis 5. Extract fan No.1 trending charts 6. Extract fan No.2 thermographic/timewave/sound analysis 7. Extract fan No.2 trending charts 8. Summary 4 Extraction fan No.1 Point 1 2 3 4 Asset No. Description MOB MIB FIB FOB Distress 7 9 Db 51 49 Comments Running within parameters Running within parameters Image/wave/sound See attached folder Extract fan No.2 Point 5 6 7 8 Asset No. Description MOB MIB FIB FOB Distress 6 11 Db 39 54 Comments Running ok Please see analysis report Image/wave/sound Asset No. Description MOB MIB FIB FOB Distress Db Comments Image/wave/sound Asset No. Description MOB MIB FIB FOB Distress Db Comments Image/wave/sound Asset No. Description MOB MIB FIB FOB Distress Db Comments Image/wave/sound Asset No. Description MOB MIB FIB FOB Distress Db Comments Image/wave/sound Asset No. Description MOB MIB FIB FOB Distress Db Comments Image/wave/sound Point 9 10 11 12 Point 13 14 15 16 Point 17 18 19 20 Point 21 22 23 24 Point 25 26 27 28 5 Extraction fan motor bearing No.1 THERMOGRAPHIC IMAGE Motor temp 60.7 MOB temp 56.4 MIB temp 66.8 TIMEWAVE AND SOUND DOUBLE CLICK ON ICON TO LISTEN R09_0049.WAV MOB R09_0050.WAV MIB COMMENTS: If you listen to the sound of the bearings by clicking on the WAV icon you will hear that the bearings give off a slightly tinny sound . This only means that the bearings could do with a slight amount of grease. As these bearings are sealed that is not possible so future monitoring is advised although the situation is not serious. 6 DISTRESS LEVEL HISTORY CHART 20/03/2013 14 12 9 10 7 8 20/03/2013 6 4 2 0 MOB MIB DECIBEL LEVEL HISTORY CHART 20/03/2013 60 51 50 49 40 30 20/03/2013 20 10 0 MOB MIB 7 Extract fan No.2 THERMOGRAPHIC IMAGE Motor temp MOB temp MIB temp 56.9 oC 48.2 oC 55.2 oC TIMEWAVE AND SOUND DOUBLE CLICK ON ICON TO LISTEN MOB MIB R09_0045.WAV R09_0046.WAV COMMENTS: The motor outboard bearing (MOB) is healthy and running well. The inboard bearing (MIB) is showing higher parameters and listening to the WAV sound and looking at the increased temp on the thermographic shows all the signs of imbalance on the fan impeller. This can be further verified with vibration analysis. 8 DISTRESS LEVEL HISTORY CHART 20/03/2013 14 12 11 10 8 6 6 20/03/2013 4 2 0 MOB MIB DECIBEL LEVEL HISTORY CHART 20/03/2013 60 54 50 40 39 30 20/03/2013 20 10 0 MOB MIB 9 SUMMARY No.1 fan motor and bearings are running well within the desired parameters although, as always, regular surveys are recommended to keep check on this situation. No.2 fan impeller shows signs of imbalance due to the fact that the inboard motor bearings are showing hotter and decibel and distress levels are higher. Further, if you listen to the WAV recording you wil hear a distinct waver in the sound. This can be further verified by having vibration analysis being done.

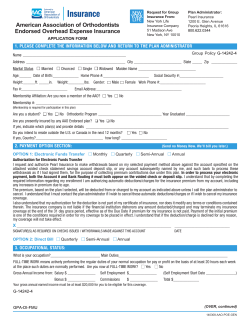

© Copyright 2026