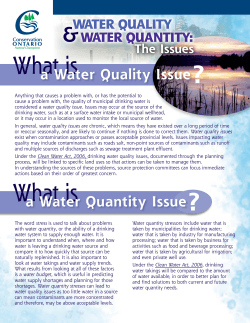

DRINKING WATER QUALITY MONITORING MANUAL