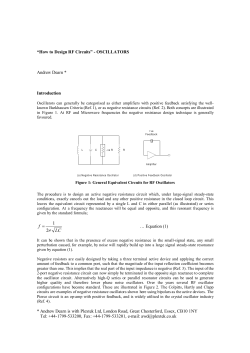

Operator's Manual 3100B High Frequency Oscillatory Ventilator