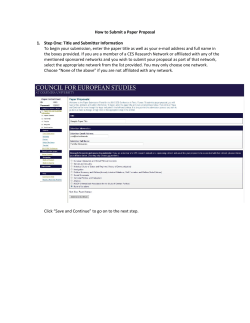

U ’ M SER