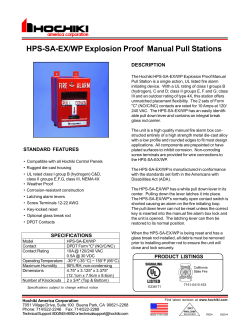

Document 310826