540-CA13 a new generation of high impact copolymer polypropylene

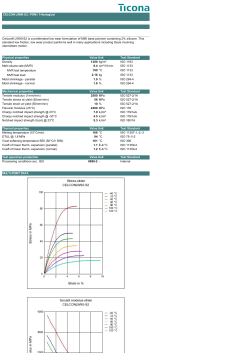

540-CA13 a new generation of high impact copolymer polypropylene 540-CA13 540-CA13 is a high impact copolymer polypropylene grade recommended for injection moulding of luggage, crates and boxes as well as for the production of compounds. This new grade offers a unique set of mechanical properties which were specifically designed to give very high levels of impact resistance at low temperatures. Product properties Properties Methods 540-CA13 New 500-NA20 Standard Units MFR 230°/2.16kg ISO 1133 13 20 g/10min Flex. Modulus ISO 178 1150 1250 MPa Tensile Strength @ yield ISO 527-1,-2 22,5 25 MPa Notched Izod @ -20°C ISO 180/1A 9,5 6 kJ/m2 Notched Izod @ -30°C ISO 180/1A 7,7 5 kJ/m2 Impact Falling Weight @ -20°C ISO 6603-2 Total Penetration Energy HDT 0,45 MPa Vicat softening point (10N) 41 26 J ISO 75/B 94 95 °C ISO 306/A50 148 150 °C For Product Data Sheet and Safety Data Sheet please visit us at www.ineos.com or contact your INEOS O&P Europe local representative or send an e-mail to [email protected] © INEOS Olefins & Polymers Europe, October 2014 540-CA13 a new generation of high impact copolymer polypropylene 120 Flexural Modulus (MPa) 100 80 540-CA13 60 IFW @ -30°C (J/mm) Competition A 40 N.Izod @ 0°C (kJ/m2) 20 0 Competition B 500-NA20 N.Izod @ -30°C (kJ/m2) N.Izod @ -20°C (kJ/m2) To satisfy the ever increasing demands of the returnable transport packaging market, the grade has been especially designed to offer: · Exceptional levels of impact performance especially at low service temperatures · Excellent creep resistance coupled with good stiffness to give superior crate stacking stability · Excellent dimensional stability and low warpage. · Increased crystallization temperature for potential reductions in mould cooling times Dimensional Stability 1,4 Shrinkage (%) 1,2 1 0,8 Perpendicular 0,6 Parallel 0,4 0,2 0 540-CA13 Competition A Competition B 500-NA20 What does 540-CA13 bring on moulded parts? · High impact strength – particularly at very low temperatures · Excellent surface finish and antistatic performance · Stacking stability · Very good dimensional stability · Low blushing · FDA approved For Product Data Sheet and Safety Data Sheet please visit us at www.ineos.com or contact your INEOS O&P Europe local representative or send an e-mail to [email protected] © INEOS Olefins & Polymers Europe, October 2014

© Copyright 2026