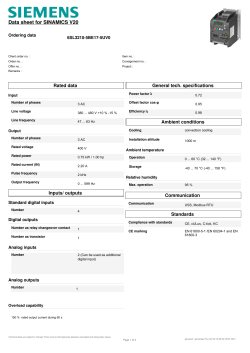

SWITCHING DEVICES August 2014