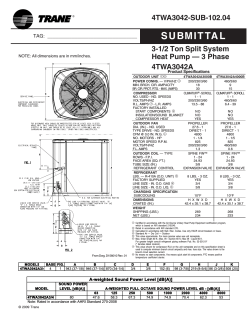

HydroBank MS Compact, Single Stage Water Source Heat Pumps