Don’t let the (herbicide resistance) O

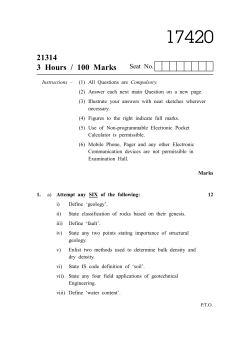

◄ PREVIOUS NEXT ► Don’t let the (herbicide resistance) cat out of the bag: US lessons OO By Jeff Werth1, David Thornby2 and Graham Charles3 “We let the cat out of the bag and it won’t go back in.” “We have been put back 20 years in terms of weed control programs that rely heavily on residuals.” “We are not farming cotton anymore, we are farming against Palmer amaranth.” “Glyphosate has now become a useful adjuvant.” R ECENTLY a group of Australian cotton growers, consultants and researchers visited parts of the cotton growing region in the US to see first-hand the problems growers are facing with herbicide resistant Palmer amaranth. The group visited several farms, researchers and trial sites to investigate how the US cotton industry is managing the issue. Below are some of the comments from US growers/consultants about their current situation: The problem In short, the problem is Palmer amaranth and glyphosate. Palmer amaranth is a weed with a tremendous ability to reproduce and share genetic material. The plant is dioecious, which means it has separate male and female plants. It therefore generally has to share genes between plants, though both male and female parts can sometimes be found on the same plant. It can produce over one million seeds per plant and large amounts of pollen. These traits have given Palmer amaranth the ability to adapt to a wide range of climates, and also to evolve resistance to a number of herbicides. Growers in the US in the late 80s and early 90s were Palmer amaranth can produce over one million seeds per plant. 16 — The Australian Cottongrower experiencing issues managing Palmer amaranth as populations were starting to develop resistance to trifluralin, atrazine, pyrithiobac-sodium and a number of ‘imi’ herbicides in cotton, corn and soybean. Then along came glyphosate-tolerant (Roundup Ready) crop technology. The ability to use glyphosate over the top of crops solved a number of issues such as soil and moisture depletion under frequent tillage, and provided excellent control of Palmer amaranth. Notable Arkansas consultant and ex-university professor Ford Baldwin said that “Roundup Ready took the thinking out of weed control” and fields in cotton and soybean crops were clean again. But after about six years growers started noticing some escapes, but for a number of reasons continued to rely solely on glyphosate. Two to three years later these patches of escapes spread across whole fields and growers were in serious trouble right across the cotton and soybean growing regions. What are they doing now? Glyphosate is no longer working on Palmer amaranth across the region, so growers are finding its management far more complex. As Palmer amaranth germinates throughout the season, growers have had to implement heavy residual herbicide programs, with residuals being applied approximately every two weeks from planting until canopy closure. The use of glufosinate-tolerant (Liberty) varieties has also increased to approximately half of crops planted. But as glufosinate is less forgiving of late applications, and Palmer amaranth grows rapidly, growers are facing challenges covering their fields in a timely manner for effective control. Between frequent residual applications and Liberty’s requirement for Spray booms with Wilmar Fabrication hooded sprayers, now a common sight on US farms in cotton growing regions. October–November 2014 ◄ PREVIOUS NEXT ► Perfect combination in cotton: POMMIER & PRESIDIO PRESIDIO 2700 is built for demanding conditions with 4WD hydrostatic transmission, 174hp Deutz 6 cylinder engine, run-dry Ace pump and aluminium boom. It raises the standard in its class! The air-bag suspension provides superb comfort and ride, with a crop clearance of 1.25m. “The cost, efficiency and simplicity of this sprayer make it second to none, and it is ideal for Australian conditions.” Joe Sandford, Kinyerrie Partnership POMMIER TR4 delivers incredible performance through design and construction techniques perfected over 30 years. The greatest advantage of POMMIER aluminium booms over steel is the reduction in weight which significantly improves performance in the field. POMMIER engineer their own profiles, using material cross-sections which are larger than what would be possible from equivalent off-the-shelf materials.Their strong rugged construction are half the weight of steel counterparts! Function and rates control are at your fingertips. In-cab HC 8500 touchscreen application controller provides the highest level of performance and application precision. Try the PRESIDIO for yourself at a Ride&Drive event near you. Visit hardi.com.au to register your interest online, or to see a video of the sprayer in action. Contact Wideland Ag Dalby - your local HARDI dealer - call Tony 0447 022 804 or Sam 0447 022 838 For additional information call HARDI Territory Manager Paul Tuohey on 0418 465 130. ◄ PREVIOUS NEXT ► residual programs used for Palmer amaranth, but there is potential for future resistance development, and the US industry will need to consider these weeds more carefully if they are to be ready when that happens. Glytol (glyphosate+glufosinate tolerance) is in its first season, and Roundup Ready ExtendflexTM (glyphosate+glufosinate+dicamba tolerance) will be introduced next year. A number of growers are waiting eagerly for its introduction and if they return to relying on the over-the-top herbicides they will face additional issues in the near future. Fortunately, companies are promoting the introduction of Extendflex and Glytol with accompanying residual herbicide programs. Weed control in non-crop areas is a further apparent difficulty for American growers. Even on farms with very clean fields, adjacent areas often had thick stands of Palmer amaranth, and the affected growers will never get control of the problem effectively until they adopt a zero-tolerance mindset in non-crop areas as well. What is our current situation? Ford Baldwin discussing Palmer amaranth management at Dow Brantley’s (blue polo shirt) farm in Arkansas. greater timeliness, growers are having to buy a substantial amount of additional machinery in order to increase their capacity to get across their fields. The number of growers using chipping to control escapes and late season germinations has also dramatically increased. It was noted that growers who maintained a diverse weed control system before glyphosate resistant Palmer amaranth appeared on their farms now have a lower weed burden, and subsequently lower chipping costs, than growers who used glyphosate alone until it became impossible to do so. The cost of weed management in cotton crops has subsequently risen from $150 to $400 per acre. This, combined with lower cotton prices, has resulted in a dramatic reduction in areas of cotton being planted. Growers are finding that cotton is the hardest crop in which to manage Palmer amaranth due to its low competitive ability earlier in the season. Research at the University of Tennessee has shown that corn planted in narrower rows can grow quickly and shade out Palmer amaranth, thus reducing the reliance on herbicides. Corn and other crops that produce robust stubble also appear to provide extra Palmer amaranth control through mulching. As a result the majority of growers who have continued to grow cotton have been those who own gins and/or are leasing country. The growers we visited made comments on what they would change if they could start again: OO “Move away from a single herbicide.” OO “Implement a residual program.” OO “Use crop rotations to rotate chemistry options available.” OO “Have a zero-tolerance to weeds in both crop and non-crop areas.” OO “Develop the capacity for timely application of herbicides.” OO “Increase water rates to ensure effective control.” Underlying concerns for the US Growers are currently so focused on Palmer amaranth, that glyphosate-resistant populations of goosegrass (crowsfoot grass), Johnson grass and barnyard grass are not being considered in the majority of fields where they appear. These weeds are likely to be managed for now by the heavy 18 — The Australian Cottongrower There are now populations of glyphosate-resistant awnless barnyard grass, fleabane, sowthistle, windmill grass and ryegrass present in cotton rotations. Fleabane and awnless barnyard grass are the most widespread in the north, and ryegrass is creating problems in the south, particularly in areas that have recently started growing cotton. Though none of these weeds have the ‘super-weed’ characteristics of Palmer amaranth, growers who are dealing with them are finding their costs of weed management rising. What can we do now? If we take into consideration the comments of US growers, there are a number of things that can be done to either prevent resistance occurring on Australian cotton farms, or manage resistance that may already be present. Research has shown that controlling survivors of herbicide application and preventing new weed seeds from entering the seed bank is the most effective option for resistance prevention and management. Using residual herbicides and strategic tillage where applicable in crop and fallow is an effective measure to minimise the numbers of plants being exposed to post-emergent herbicides. Moving away from glyphosate and adopting two non-glyphosate tactics in crop and fallow (‘2+2’) will be a successful long-term strategy. The focus of resistance management, and weed management in general, should be aimed at the seed bank. Vigilance in ensuring large cohorts that emerge are effectively controlled, preventing new seed entering the soil by controlling survivors and using residual herbicides to reduce emergences will result in driving down the seed bank for long-term benefits. The importance of farm hygiene to prevent incursions from channels, roadsides and fences into the field underpin weed management at a farm level. Keeping the thinking in weed control, and adopting a diverse weed control program instead of automatically reaching for glyphosate will result in long-term benefits. These are lessons that growers in the US have learnt the hard way. Queensland Department of Agriculture, Fisheries and Forestry, Toowoomba Innokas Intellectual Services, Upper Coomera New South Wales Department of Primary Industries, Narrabri 1 2 3 More information on weed management is available through: WEEDpak – http://www.cottoncrc.org.au/industry/Publications/Weeds Weed Smart – www.weedsmart.org.au/ October–November 2014 ◄ PREVIOUS NEXT ► ◄ PREVIOUS NEXT ► Herbicide Resistance Management Strategy for Australian cotton OO By Annabelle Guest, AGDel and Susan Maas, CRDC A COTTON grower’s 10 year son was recently heard asking his father “What’s a cultivator?” Historically the Australian cotton industry has had a strong integrated weed management system, but the move to no-till farming and extensive use of herbicide tolerant (HT) cotton varieties has seen a reduction in the diversity of weed control tactics used, with glyphosate now accounting for more than 80 per cent of all herbicide used in cotton. Unfortunately this has resulted in an increase in incidence of herbicide resistance. The Australian cotton industry has taken the first step in responding to the risk of herbicide resistance development, with the launch of the Herbicide Resistance Management Strategy (HRMS) at the Australian Cotton Conference. This strategy provides growers and consultants with a tool to be able to assess and manage their risk of resistance. Experience with conventional insecticide resistance has encouraged a proactive Susan Maas. culture to resistance issues in the Australian cotton industry. Responding to the threat now, is far easier than reacting to a crisis in the future. CRDC commissioned a project conducted by Annabelle Guest, AGDel, to facilitate the development of an industry agreed strategy to manage herbicide resistance in cotton. The strategy was initially drafted by the TIMS herbicide technical panel with the aim of raising awareness of herbicide resistance in the Australian cotton industry and providing a tool to help implement management systems that delay the timeframe to herbicide resistance development. The draft strategy was circulated widely to industry stakeholders and industry feedback addressed and incorporated prior to its ratification by the TIMS committee. It is planned that the strategy will be further developed to include a wider range of herbicide groups and incorporate other HT cotton varieties as they become available. The strategy demonstrates how various combinations of chemical and mechanical control tactics lengthen the timeframe to expected resistance development and their impact on weed seed bank levels. The strategy is based on data generated from modeling barnyard grass resistance development in glyphosate tolerant cotton where three over-the-top (OTT) glyphosate applications are made per season. Scenarios for resistance development in both back-to-back irrigated cotton and dryland cotton every second year are presented. The keys to extending glyphosate life in cotton systems are: FIGURE 1: Herbicide use in cotton Survivor control prior to seed set is a key factor in delaying resistance development. Glyphosate resistance in common sowthistle has been confirmed in northern NSW. 20 — The Australian Cottongrower CCA Market audit data shows the increasing reliance on group M. Source CRDC/CCA. October–November 2014 the way forward ◄ PREVIOUS NEXT ► Resistance Management Strategy (IRMS). The IRMS started from OO Use a range of weed control tactics in the summer fallow Cnr Buckland & Yaldwyn Sts a basic position and has matured over time with the benefit phase; Toowoomba Qld 4350 of stakeholder feedback. It is anticipated that HRMS will be over-the-top glyphosate OO Control any survivors of in-crop expanded to include more scenarios, tactics, and combinations of applications andPhone: prevent setting seed; and 07 them 4635 9872 tactics as well as mature to be relevant in a multi-herbicide-trait OO Control weeds in adjacent Fax: 07 4635field 6633areas including roads and cotton system. channels. www.excelagr.com.au Brian Moran The dependenceBrian on glyphosate in the current farming Moran 0427 722 925 How to use the HRMS system and the increasing of700 cases of glyphosate Dan Ryannumber 0427 779 resistance (Figure 1) has meant that the priority for the first Given that glyphosate resistance takes around 18 years to A DIVISION OF HRMS has been to make glyphosate resistance in HT cotton the world develop when cotton system prior to pla ✓ Construct andcropping refine seed-beds ✓ Utilising renowned John used Deerealone in an irrigated for enhanced seeding vigor metering superior seedinplacement a key focus. The HRMS will go through a similar process of system for and 14 years dryland, it is important to identify the likelihood Australian made ✓ own Incorporate pre and chemi ✓ Designed by Australian farmers todevelopment reduce downin your annual reviews for continuous improvement like the Insecticide of resistance operation. Thepost-emergence strategy and owned Dan Ryan for fast knockdown and essential weed con time and boost yields ✓ Cultivate serious weeds while preserving se ✓ Designed for dryland irrigation, contour growth and crop root systems following or Tram Trak needs ✓Aerate the soil, aiding water penetration and ✓Twin 16” disc opener with walking depth gauge retention for young plants wheels for greater reliability and accuracy Australian owned & Australian made for over 80soil years! ✓ Help control and water losses from ero ✓ Full range of planter options available Excellent product. Excellent service. whilst managing residue retention Millennium Planter Agriculture Rolling Cultivator A family owned business NEW nks lic sha Parabo g less HP for usin s fuel & les FERTILISER RIGS 4 Available for 6, 8 & 12 metre rows 4 Up to 3 tonne capacity with exceptional stability and ease of lifting 4 Low draft shank and clamp assembly for simplistic reliable operation 4 Offering an unrivalled 770mm of underframe clearance for brilliant trash flow 4 Proven stainless steel metering units for corrosion resistance 4 Variable rate technology available 4 Can apply gas at same time as fertilisers ROLLING CULTIVATORS EXCEL PENETRATOR 4 Available in 4, 6, 8 & 12 metres 4 Side busting/centre busting capabilities 4 Adaptable for gassing, dry fertiliser using Excel’s Penetrator rig mounted fertiliser boxes 4 5/8” inline sheer bolts 4 Unrivalled trash clearance 4 C onstruct and refine seed-beds prior to planting for enhanced seedling vigor 4 Incorporate pre and post-emergence chemicals for fast knockdown and essential weed control 4 Cultivate serious weeds while preserving seedling growth and crop root systems 4 Help control soil and water losses from erosion, whilst managing residue retention …the Excel Rolling Cultivator will deliver E XC E L C U LT I VAT O R CULTIPACKER 4 Revolutionary patent clean sweep assembly delivers a superior weed kill with minimum soil disturbance and minimal moisture loss STUBBLE WARRIOR 4 Plant wheat back into cotton hill 4 Double disc 4 Single disc 4 Gassing and/or fertilising 4 Large range of tooling options for cultivating, spraying and fertiliser applications 4 Crop shields to minimise plant damage and increase cultivation speed FIXED BAR UNIVERSAL RIG 4 Full cultivation 4 Bed renovator 4 Fertiliser application 4 Fallow listering rig 4 Available in 6, 8 & 12 metres 4 Reduces the amount of water required to pre-irrigate as the soil is a lot finer resulting in a more even moisture profile for better seed germination 4 Accelerates the breakdown of large clods in-field which promotes soil flow therefore trash incorporation 4 Large heavy duty rings for breaking clods from the top to the bottom of the furrow ALSO AVAILABLE: 4 Rubber Tyred Roller 4 Shielded Sprayer EXCEL ALSO STOCK A WIDE RANGE OF SPARE PARTS 74–92 Buckland Street, Toowoomba Qld 4350 PH: 07 4636 9100 A DIVISION OF GREAT WESTERN CORPORATION PTY LTD (ABN 91 064 434 475) October–November 2014 Brian Moran 0427 722 925 Graham Easey 0427 700 779 (NSW) FAX: 07 4636 9140 — www.excelagr.com.au The Australian Cottongrower — 21 ◄ PREVIOUS FIGURE 2: Percentage of area consulted on believed to contain resistant weeds NEXT ► Reducing fertiliser needs by accounting for soil microbes OO By Dennis O’Brien, USDA–ARS Information Staff CCA Survey results indicate increasing incidence of herbicide resistance in cotton farming systems. Source:CCA/CRDC. tables enable you to determine which other weed control tactics can be incorporated into your management system by providing guidance as to how much extra time they will give you until resistance develops, and demonstrating the effect they will have on the weed seed bank, which is critical to effectively managing resistance. The supporting information provides a concise summary of other key issues for weed management, such as monitoring, record keeping, timely implementation of tactics, management of non-crop areas and Come Clean, Go Clean. The strategy to manage glyphosate resistant weeds is similar to the strategy to prevent glyphosate resistance – integrate a range of different tactics throughout the weed lifecycle to rapidly deplete the soil weed seed bank, and prevent further seed set/ recruitment. This means that the HRMS is just as relevant to managing resistance weeds as it is preventing them, and can help to inform a weed management plan. The HRMS is not intended to be prescriptive, and is aimed to be an industry mechanism for communicating the herbicide resistance risks from different tactics. It has been designed to present the risk related to a range of tactic combinations, to allow growers and consultants to make their own, informed decisions. The strategy is supported by a number of existing industry resources such as Weedpak, cotton production manual, and the cotton pest management guide that are available from CottonInfo or from www.mybmp.com.au, with other resources under development. Additional information is also available at http://www.glyphosateresistance.org.au, and www.weedsmart.org.au 22 — The Australian Cottongrower F ARMERS face a balancing act when deciding how much fertiliser to apply. Applying too much wastes money and adds to nutrient runoff problems. Applying too little reduces yields. Agricultural Research Service scientists in Temple, Texas, have found a way to help get it just right, maximising profits, minimising costs, and saving water bodies from unwanted nutrient runoff. They have developed a test that accurately portrays soil health by determining the levels of naturally occurring nitrogen and other nutrients. Traditional methods for determining fertiliser needs are based on soil tests developed in the 1960s, which measure the amount of nitrate in the soil. But these tests don’t account for the contributions of soil microbes. The microbes play a key role because they mineralise organic nitrogen and phosphate and make them more available to the crop. As a result, farmers often apply more fertiliser than the plants actually need, adding to their costs and causing unnecessary nutrient runoff. “The problem is that conventional tools are not measuring the right soil characteristics. They test for inorganic nitrogen in the form of nitrate, but that’s just one form of nitrogen available to the plant,” says Richard Haney, a soil scientist with the ARS Grassland, Soil, and Water Research Laboratory in Temple. Richard has developed a more integrated approach. Known as the ‘Soil Health Tool’ or ‘Richard test’ in commercial laboratories, it involves drying and rewetting soil and analysing it in ways that account for microbial activity and measure both nitrate and ammonium, plus an organic form of nitrogen. It also measures organic carbon and other nutrients, in part by replicating some of the natural processes that occur in a field. The drying and rewetting mimics what happens in the field before and after a rain. Nutrients and other compounds are extracted from the soil samples with both a water-based solution and a solution known as ‘H3A,’ which has the organic acids that plant roots use to acquire nutrients from the soil. Growers who use the process receive a spreadsheet that shows the amounts of nitrogen, phosphorus, and potassium available to plants, based on results extracted by both the water- and H3A-based solutions. Results also include measurements of waterOctober–November 2014 ◄ PREVIOUS NEXT ► Stabilise your soil nitrogen with FertiCoatthe ultimate solution for nitrogen retention. Call today to find out how. Th ng e ul timate f ertilizer co a t i Perfect for granular coating, mixing with UAN for stability and liquid soil injection. Ian Leonard Specialist Agronomist North QLD 0419 757 863 [email protected] Johan Prinsloo Specialist Agronomist NSW, Vic 0488 911 981 [email protected] N U T R I O L O G Y * *the science of growing 03 5133 9118 omnia.com.au ◄ PREVIOUS soluble organic carbon, water-soluble organic nitrogen, and soil microbial activity, and they provide a calculation of soil health and the ratio of carbon to nitrogen (a key in how much organic nitrogen is released). Organic carbon and organic nitrogen are natural byproducts of microorganisms breaking down the soil. Growers can use the results to determine fertiliser needs. Savings for farmers The Soil Health Tool works for any crop produced with nitrogen or other nutrient fertilisers. Richard has made it available to commercial and university soil-testing laboratories, worked with farmers to promote it, and published several papers detailing its mechanics. The research is funded in part by the Texas State Soil and Water Conservation Board and the US Department NEXT ► of Agriculture’s Natural Resources Conservation Service. This enhanced soil-testing process is now offered by laboratories in Maine, Nebraska, and Ohio. It adds to the time and costs for a soil test, but farmers have learned that in the long run it saves on fertiliser costs. David Brandt, who farms 1200 acres in Carroll, Ohio, started using Richard’s system three years ago to estimate the amounts of nitrogen he needed to apply to his corn, soybeans, and wheat fields. He also used it to estimate his phosphorus and potash fertiliser needs. “I estimate that it’s saved us at least 25 per cent in nutrient costs,” he says. “The readings were more accurate than other soil tests we had run, and we either maintained or increased our yields.” On average, fertiliser costs are reduced by about $10 to $15 per acre by adopting the system, Richard says. With less fertiliser being applied, there is also less nutrient runoff into rivers and bays. “This means that less of the nutrients are going into the Gulf of Mexico, Chesapeake Bay, and other waterways, where they have been contributing to algae blooms year after year,” Richard says. Works well with no-till, cover crops An ARS technician applies an organic fertiliser source on plots in a study to optimise application rates of organic and inorganic fertilisers. The study is part of efforts to evaluate a new ARS-developed tool for soil testing that can be used to help growers reduce fertiliser use without decreasing yields. (Photo: Daren Harmel) Another problem with conventional soil tests is that they are based on tilled systems used from the 1940s through the 1960s, so they often fall short in providing estimates in cover-crop and no-till systems, which create entirely different soil profiles. Richard’s system is able to measure the effects of cover crops and no-till practices. “We can develop a soil health calculation and suggest a cover crop mix,” Richard says. David found that the results helped him understand the contributions made by his cover crops. “We knew they were helping, but we never understood why. This new information gave us a better understanding of what was going on in terms of nutrients in the soil,” David says. He used the information to adjust his mix of cover crops and get a better ratio of carbon and nitrogen, a critical factor in soil health. “It’s helped us to pick the right cover crops to utilise in the field,” he says. In a four-year field study conducted with Daren Harmel, research leader of the laboratory in Temple, Richard evaluated the enhanced soil-testing method in fields of wheat, corn, oats, and grain sorghum at nine sites in Texas. They applied fertiliser at traditional rates or at the amounts dictated by the Richard soil tests, and they left some plots unfertilised. They planted and harvested on the same dates at each site and kept track of fertiliser costs, crop prices, and overall profits. They found that the enhanced method reduced fertiliser use by 30 to 50 per cent and reduced fertiliser costs by up to 39 per cent. The enhanced method had little effect on corn production profits, but increased profits 7 to 18 per cent in wheat, oat, and sorghum fields. The results were published in the Open Journal of Soil Science in June 2013. “We’re asking farmers to think about what they’re putting on the soil and whether it is necessary. It involves a new way of thinking, but fertiliser costs are rising, so the idea is attracting more interest,” Richard says. This research is part of Climate Change, Soils, and Emissions, an ARS national program (#212) described at www.nps.ars.usda.gov. ARS scientists have developed a testing process that accurately measures naturally occurring nitrogen and other nutrients in soil. (Photo: Peggy Greb) 24 — The Australian Cottongrower Richard L. Haney is with the USDA-ARS Grassland, Soil, and Water Research Laboratory, 808 East Blackland Rd., Temple, TX 76502; (254) 770-6503. “Reducing Fertiliser Needs by Accounting for Soil Microbes” was published in the July 2014 issue of Agricultural Research magazine. October–November 2014

© Copyright 2026