Document 354857

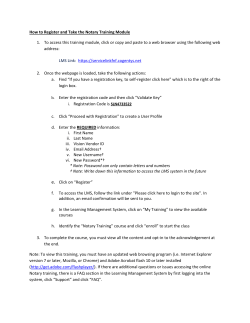

L. T. TROLANILJ. A. BALL, AND J. M. ANDREWS. r . LIQUiD TREATMENT OF CINEMATOGRAPHIC FILMS. APPLICATION FILED SEPT. 1. 1921. 1,435,76é2. Patented M, 1922. 2 SHEETS-SHEET I. 71v677f0r W jeomfd 12 ) ,s; L. T. TROLAND, J. A. BALL, AND J. M. ANDREWS.~~ LIQUID TREATMENT OF CINEMATOGRAPHIC FILMS. APPLICATION FILED SEPT. l. 1921. 1,435,764. Patented NOV. 14, 1922. 2 SHEETS—-—SHEET 2. ' _ 157067771074 b€0na7t57T 103827;” ' 9mg; 745.325’. % . 7. S1‘ 1,435,764 ltd, 1922. . A ‘is: D STATES PATENT OFFICE. ‘2?. 'I‘ROLAND, OF MALDEN, AND JOSEPH A. BALL AND JARVIS M. ANDREWS, TQLLASTON, MASSACHUSETTS, ASSIGNORS TO KALMUS, COM‘STOCK & WESCOTT, J., OF BOSTON, MASSACHUSETTS, A CORPORATION OF MASSACHUSETTS. LIIQUID TREATMENT OF CINEMATOGRAPHIC FILMS. Application ?led September 1, 1921. Serial No. 497,590. surface tension, we have discovered that it iii met may concern: . sown that we, LEONARD T. Tno is not only possible but highly practicable. In one aspect the invention involves main 65 .i. BALL, and JARvrs M. AN of the United States of tainingr the ?lm substantially flat and there restraining it from contacting with the zston, Massachusetts, respec liquid on its upper side and, where the ?lm counties of Middlesex, Nor-' iis supported by floating, preventing it from ‘elk, respectively, and State of sinking, by making the ?lm multi-ply. For .esidents of Maiden, Wollas 10 ~ ‘, have invented new and use vaphic Films, of which the fol LLA in 15 60 example, if two ?lms are properly secured oveiients in Liquid Treatment of together back-to-back with the coatings on ‘ eci?cation. oion relates to the liquid treat the outer sides, the resulting double ?lm will have less tendency to curl and buckle, even when only one side is wet, presumably for 65 photographic ?lms, particularly the same reason that a multi-ply board or w ic ?lms, and speci?cally to cardboard has less tendency to Warp and 'o one In curl than a single ply 'piece. In another aspect the invention consists in making the film water-repellent at the 70 or pictures representing one sides, preferably from the extreme edges 20 ‘ are carried on one side of the ‘ iemental series representing inwardly to lines extending longitudinally of'the ?lm slightly inside the sprocket holes. aspect is carried on the other One way of rendering the marginal portions of the ?lm water-repellent is to make the 75 celluloid support bare and clean throughout iii’erently as, for example, by such portions. This is preferably accom~ ' L, it is frequently desirable to 'iosite sides of the ?lm sepa 25 de a reddish color and the plished by dissolving off the unexposed gela tine emulsion and thoroughly washing the of the invention is to provide ?lm, thus leaving the celluloid perfectly 80 no. apparatus for treating one bare and clean outside the lateral edges of n independently of the other side the images which are slightly inside the rows-of sprocket holes. The unexposed por tions may be dissolved off without affecting _ at oi" the ?lm. Another object is to the images ‘between the rows of sprocket ‘iCli'Z-y and uniformity, without in ' e ?lm, and without affecting the 85 a, method and means for automati~ holes by ?rst hardening the gelatine ‘ ,ring a ?lm to normal position in throughout the exposed image spaces in ‘ at the ?lm tends to submerge on. known manner. The marginal portions of ' e result of a wavy edge such as have. . vo the present invention the sad along the surface of a body of such manner that it is supported the ?lm may be rendered even more liquid repellent by a coating which is not readily acid wax. , ' In order to illustrate the invention, one Y the iiquid without the aid or" any concrete embodiment is shown in the accom 7 supports, thereby avoiding the maintaining the liquid at a de? 45 panying drawings, in which,—~ has heretofore been considered c and other photographic ?lms, - the liquid has a relatively low 95 Fig. 1 is a side elevation of a complete. nits predetermined level relatively to the machine; Fig. ‘2 is a section on the line 2-2 of supports and also avoiding friction and ' of ‘the ?lm by the supports. Fig. 1: in the case of the thin and tenu such as are used in treating cine 90 wet by aqueous solutions, such as stearic Fig. 3 is a plan, viewed from line 3-3 of 100 Fig. l of a portion of the drying chamber showing the drying-air feed-pipe incross section; v. ‘ ‘ F ig.4 is an enlarged sectional view ofthe wear/ea La liquid trough, showing a ?lm ?oating upon may be supportedat intervals upon legs, or 68 the surface of the liquid within the trough; as shown in Fig. 4 it may be stamped from ' 10 15 Fig. 5 is a view similar to Fig. 4 showing a single sheet of metal. At one end of the the action of the ?lm and the liquid when troughs 23 and 24 are the triangular sup ports 26, one being located upon each side of the former becomes displaced; Fig. 6 is a longitudinal sectional view of the troughs as shown in enlarged scale in the liquid trough and general assembly of Fig. 6. These~ triangular supports are con the lower portion of the apparatus, the cen nected together by a rod 27 upon which is tral portion of the trough being cut away; mounted guide roller 28 similar in construc Fig. 7 is a detail section of line 7—~7 of tion'to guide rollers 16. At the apex of the Fig. 6, showing surface liquid removing triangular support are registering holes 29 serving as bearings for a shaft 30 forming means; Fig. 8 is a sectional view on the line 8-8 a portion of the carriage 31 which comprises of Fig. 1, showing in elevation the means side arms 32 connected by rods 33 upon 'for drawing the ?lm through the machine; which are rollers 34 and 35. In'order to Fig. 9 is a sectional view on the line‘ 9—~9 hold the carriage 31 in adjusted position the of Fig. 6, showing. in elevation the devices triangular supports are provided with bind 70 75 80 for applying the liquid repelling substance ing screws acting upon the shaft 30. 20 At the opposite end of the treatment tank to the edges of the ?lm; Fig. 10 is a detail vertical sectionalyiew are brackets 36 extending upwardly from through one ofthe devices shown in Fig. 9; the base 11. These brackets are connected and ' _ Fig. 11 is an enlarged cross section of a 85 by rods 37 and 38 upon which are mounted respectively plain roller 39 and guide roller ?lm such as above described (in which S 40. 25 Supported between rods 37 and 38 by and S’ are the two celluloid strips cemented means of attachment members 41 is a block together and R and R’ are the images car 42 shown in detail in Figs. 6 and'7. This 99 ried by the respective strips). bloci: acts as a means for removing the iiquid from the ?lm as the latter is-' The speci?c embodiment ofthe invention 30 chosen for purpose of illustration comprises a-base 11 to which are fastened U-shaped supporting uprights 12 connected by eros' members 13. These upright and cross ' bers are preferably made in one ‘1319i Upon the cross members 13 is supported an 35 40 elongated drying chamber 14 enclosed on the top, bottom and sides and open at the ends. Within the drying chamber and mounted in U-shaped supports 15 are rollers shoulders 16 consisting 18 ofof greater a central diameter drum 17 .ian the drum and beyond these guide ?anges 19 of still greater diameter. When the rim is fed rem the treatment trough. The means removing the excess liquid comprises -_“-"isve1‘se nozzle 43 fast at the lower por 95 tion. the block and allowing space through in the block for the passage of the ted ?lm above the nozzle. The nozzle s elongated slot 44 directed at an angle of approximately 45° toward the ?lm as 100 issues from the treatment trough. A pipe connects the nozzle with any suitable source of compressed air. The portion of the block 42 directly above the ?lm has a hollow‘ chamber 46 shown in Fig. 7 with openings into the recess in which the ?lm through the drying chamber after the liquid travels directly above the sprocket holes in treatment the edges of the film restv upon the the ?lm. Threaded into the chamber 46 is 105 a pipe 47 to which there is a connection ?lm cannot contact with the drum 17. At from a suction pump. The blast of air from one end of the drying chamber is pipe 20 the slot in the nozzle below the block coop through which warm air is forced into the erates with the suction means above the ?lm drying chamber through the side opening .1. to completely remove all liquid from the 113 45 shoulders 18 so that the moist face of the 50 sprocket holes of the ?lm, and also sweep is Supported a broad U~shaped upon the trough base 11 23 by shown biocirs in the lower portion of the ?lm which has been 115 cross-section in Fig.2. Within the trough treated clear of surface‘liquid. Mechanism of the general character above 23 is mounted the elongate shallow trough 24 for the liquid treatment of the ?lm (Fig. described for removing surface liquid from 55 4). The trough 23 serves as a means for a ?lm is claimed in the application of Daniel taking care of accidental ‘over?ow from F- Comstock, Serial No. 497,703 ?led on even 120 trough 24, pipe 23’ (Fig. 6) being‘ arranged date herewith. to carry away this over?ow. The trough 24 Suitable means for applying a liquid re has upwardly ?aring or diverging sides 25 pelling substance to the edges of the ?lm 60 which extend above the level at which the are shown in detail in Figs. 9 and 10. The liquid is constantly maintained. The dis substance applied by this device is stearic tance between the sides 25 at the level of acid wax, although other substances. e. g. the liquid is slightly greater than the width para??n. may be used. Removably clamped. of the ?lm A to‘ be treated. The trough24 to the side arms 32 of the carriage 31 by 125 ' 1 $35,704. ‘ of set screws 48 are bracket arms 49 of the liquid,threaded upwardly under roller ‘ g inwardly and over the edges of 39 through the recess in the surface liquid re in‘ proximity to roll 34. The outer moving block 42 under guide roller 40, up bracket arms 49 support tubes 50 through a slot in the drying chamber 14 over . ng pistons 51 urged downwardly by the guide rollers 16, throughout the length sp 'ngs' 5:2, the tension of the latter being of the drying chamber over the sprocket 70 it by hand screws 53. A stick of wax wheels 57, the sprocket teeth being regis olaccd in‘ the lower end of the tube 50 tered in the sprocket holes of the ?hn, and and ed in frictional contact with the edges down around an empty ?lm reel upon the 10" of the ‘film by the spring-pressed piston 51. extremity of shaft 69, the takeup reel being ' ,ilication of Wax' or the like is par driven by a belt (not shown) over pulleys _ L, ‘desirable prior to treating the 65——71 or 66-—72. Since it is impossible to second'side of a ?lm as the tendency for arrange for the slight variation in proportion the‘, PM id’to flow over the top is sometimes between the speeds of shafts 57 and 69 in if the upper surface has already reeling up the ?lm, a provision is made for 161 I slip” between the driven member 70 and right-‘hand end of the device as. shaft 69, comprising'arrangin the driven ~ in Fig. 1, and supported above the member 70 loosely upon sha t 69- but in ' ted.‘ ' “i l’ hymeinbcrs similar to supports 12, so’;vi spring-pressed frictional engagement with his 56 iipon which is mounted thel the collar'73. 20'" 75" as ‘ drawing the ?lm through the _ A cardinal feature of the invention con machi- . This means is shown in detail in sists in the upwardly ?aring sides of the F 6 and comprises a main shaft 57 sup liquid trough and the slight clearance be in bearings 59 and provided with tween the edges of the ?lm and the sides of t wheels 58 which cooperate with the the trough when the film is ?oating nor 90 '. t holes on the- sides of the ?lm. mally. If the liquid creeps over the edge of 25 ., 57 has keyed upon its central por the ?lm, as a result of curling or buckling, thereby submerging one side of the ?lm, the upon a shaft '62 mounted transversely submerged edge engages the inclined, side ' 57' and below the same. Shaft 62 and by virtue of the inclination the other n through pulley wheel_63 from any side is caused to ride up the opposite inclined iie source of power. Upon the end of side, the ?lm assuming aposition such as T opposite to the .end of the sprocket shown in Fig. 5. Owing to the surface ten wheels, ‘is the driving member 64 comprising sion acting on the tipped-up side the ?lm is a pulley wheel 65 and a smaller pulley either restored to normal position or re wheel 66. , Suspended below table 56 is a strained from being submerged except inthe bracket support 67 having an elongated immediate region of the curl or buckle. In forming the relief images the mar bearing68 for a shaft 69 arranged in paral lei relation to shaft 57. Shaft 69 has a ginal portions of the gelatine or other col a. worm gear 60 meshing with a worm projecting end directly below sprocket loid material are completely removed in the. 57 over which a ?lm reel is adapted hot-water etching bath, the! marginal por to be placed, upon which ‘the ?lm, after tions being unexposed. Thus the gelatine 109. 105 being treated and dried, is adapted to be or other colloid material in which the im wound. In order to turn the drum at a. ages are formed terminate short of the mar .15 proper speed to take up the ?lm, the op ginal edges of the ?lm and indeed is con?ned posits end of shaft 69 is provided with to the space between the series of marginal ‘ driven member 70 comprising smaller pulley registering openings (Figs. 3 and 4). This is' wheel 71 directly below pulley wheel 65 and important in coloring the relief images inas pulley “.72 directly below‘ pulley 66. Driven much as pigment solution can be applied to 56 member 70 is loose upon shaft 69 but is one side with little or no tendency to creep 115 held hy springs 74 in frictional contact with around the edges of the ?lm to the opposite dish '73 keyed’ to shaft 69. The tension of side by virtue of bare celluloid margins. ‘ 355 '74 is regulated by collar 75 l ‘ position on shaft 69 by so operation of the device is l in , '. of ?lm is placed upon the bracket t 77 which is suspended from the base ‘ . ?lm in ‘this reel‘is threaded‘ up through an opening'in the base 11 “7e claim: 1. The method of treating a roll of’photoé graphic ?lm which comprises moving the 12!) ?lm over a body of liquid in surface contact out therewith the major and supporting part of thatthe portion ?lm throughl contact-y - P1 ing with the liquid solely by the liquid. 7 guide roller 27, then upwardly over 2. The method of treating a roll of photo-7 v under the wax ends 54, over roller graphic ?lm comprising extending a long‘ “ en downward the length of the section of the ?lm along the surface'of a t trough 24, the film resting upon liquid so that the ?lm is supported solely by ice of the liquid and being supported, the liquid which wets the lower surface of ' The ?lm is drawn along the surface. the ?lm only. , 130 The method of treating a roll of photo 12. The step in the method of treating, graphic ?lm comprising extending a long photographic ?lms which comprises ?oating section of the ?lm along the surface of a the same upon a thin and tenuous ?lm-stain-l liquid so that the ?lm is supported solely ing ?uid. 13. In apparatus for treating photo by the liquid which wets the lower surface of the ?lm only and continuously drawing graphic ?lms, a long narrow trough having ‘ ‘i the ?lm ‘forwardly along the surface of the diverging sides and adapted to contain liq 10 uid, guiding means for the ?lm at each end of the trough whereby a section of the ?lm may rest within the trough and be support ing applying a liquid repellent substance to ed by the liquid, means for removing the the edges of the ?lm and then ?oating the excess liquid from the ?lm as the latter is sues from the trough comprising ?uid pres— ?lm upon a liquid. . i 5. The method of treating ?lms compris sure and ?uid suction means, a drying cham ingapplying a liquid repellent substance to ber above said trough and means for contin liquid while the ?lm continues to be sup ported by the liquid. _ 4c. The method of treating ?lms, compris 70 75 80 the edges of the ?lm, ?oating the ?lm upon uously conducting the ?lm along the trough, a liquid, and moving the ?lm forward while, past the surface liquid removing means and through the drying chamber. so supported by the liquid. _ 14:. ‘n apparatus for treating phot0~ 6. The method of treating ?lms compris ing applying a liquid repellent substance to graphic ?lms, a long narrow ‘trough having 85 the edges 01’ the ?lm, floating the ?lm upon diverging sides and adapted to contain liq a liquid, moving the ?lm. forward while so uid, guiding means for the ?lm at each end supported, removing surface liquid from the of: the trough whereby a section of the ?lm ?lm, and then drying the ?lm. _ may rest within the trough and be supported by the liquid. means for applying a water 90 7. The method of‘treating the lower su_r~_ 25 face of photographic ?lm with a liquld repelling substance to both edges of the ?lm in suchinanner as to prevent access of the betoreit enters the trough, and means for liquid to the other side which comprises ap progressively conducting the ?lm under the plying to theedges of the ?lm a substance applying means and along the trough. 15. In apparatus for treating photo 95. '30 which will prevent the liquid from wetting the ?lm and then passing the ?lm along the graphic ?lms, a long narrow trough having diverging sides and adapted to contain liq surface of the liquid. ‘ 8. The method of treating the lower sur uid, guiding means for the ?lm at each end face of a photographic ?lm with a liquid in the trough whereby a section of the ?lm such manner as to prevent access of the may rest within the trough and be supported 100 liquid to the other side which comprises ap by the liquid, means for applying a water plying to the edges of the ?lm a substance repelling substance to both edges of the ?lm which will prevent the liquid from wetting before it enters the trough, a drying cham the ?lm and then passing the ?lm along the ber above said trough and means for con-_ surface of the liquid, the ?lm being sup tinuously conducting the ?lm under the ap ported solely by the liquid. 105 plying ‘means along the trough and through v ‘ 9. The‘ method of preparing an elongate the drying chamber. 16. In ' apparatus for treating photo Q. strip of photographic ?lm which comprises joining a plurality of ?lms together to form graphic ?lms, a long narrow trough having a multi-ply ?lm, and then passing the ?lm diverging sides and adapted to contain liq. lengthwise over and in contact with-the sur uid, guiding means for the ?lm at each end face of a body of liquid, whereby the ?lm is of the trough whereby a vsection of the ?lm 'maintained relatively ?at and is restrained may rest within the trough and be supported from contacting; with the liquid on its up by the liquid, means for applying a water Kill per side by virtue of its multi-ply character. repelling substance to both edges of the ?lm 10. The method of preparing an elongate before it enters the trough. all strip of photographic ?lm which comprises lili " joining two coated ?lms baclr-to-back to form a symmetrically double ?lm and float ing the ?lm lengthwise over and in contact with the surface of a body of liquid, where by the ?lm is maintained relatively ?at and is thereby restrained ‘From contacting with the liquid on its upper side by virtue of its symmetrically double character. ll. The step in the method (it treatingr 110;.» 115 17. In apparatus for treating photo-’ graphic ?lms, a liquid trough having up wardly diverging sides, the distance between. said sides at the liquid level being slightly 120 greater than the Width of the ?lm to be treated, and means for moving the ?lm lon— gitudinally of the trough. 18. In apparatus for treating photo~ graphic films, a liquid trough having di 125 verging sides, the distance between said ‘sides mated photographic films which comprises at the level of the liquid being slightly floating the same upon a thin fluid medium greater than the width of the ?lm, and capable of changing the color of the coating means for passing the ?lm along the surface upon the ?lm. of the liquid in the trough so that the ?lm 130 ' 1,435,764 is normally supported solely by the liquid. strip of photographic ?lm having a row of 19. In apparatus for treating rolls of pho images supported on a water-repellent sup tographic ?lms, a trough adapted to contain port which comprises moving the ?lm liquid, ?lm guiding means arranged to guide lengthwise over and in contact with the sur the ?lm to and from the surface of the liq 30 face of a body of liquid with the marginal uid, and means for applying a liquid repel portions of the ?lm bared. ' ling substance to the edges of the ?lm before 24. The method of‘treating an elongate it contacts with the liquid, thereby to insure strip of photographic ?lm having a coating its floating. 10 15 of gelatine or the like on at least one side 35 20. The method of treating ?lms which thereof, said coating terminating short of comprises rendering the marginal portions the marginal edges of the ?lm, which com of the ?lm water-repellent and then ?oating prises passing the ?lm over a body of liquid with the other side in contact with the liquid. the ?lm upon a ‘liquid. 21. The method of treating photographic 25. The method of treating an elongate ?lm having a coating of gelatine or the like strip of photographic ?lm having a coat on at least one side, such coating terminating ing of gelatine or the like on at least one 40 short of the marginal ed es of the ?lm side thereof which comprises removing the which comprises wetting t e other side 0 coating from the marginal portions of the ?lm and then passing the ?lm over a body 45 the ?lm. 22. The method of treating photographic of liquid with the other side in contact with 20 ' ' ?lm having a coating of gelatine or the like the liquid. on at least one side which comprises remov Signed by us at Boston, Massachusetts, ing the coating from the marginal portions this 30th day of August, 1921. of the ?lm and then wetting the other side of the ?lm. . 23. The method of treating an elongate LEONARD T. TROLAND. JOSEPH A. BALL. JARVIS M. ANDREWS.

© Copyright 2026