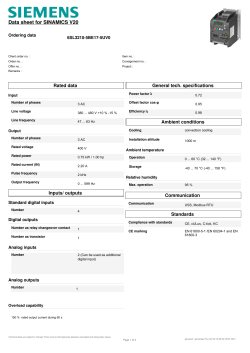

sinamics s Safety Integrated SINAMICS S120