Document 363258

Feb. 16, 1954

c. c. SMITH

2,669,166

METHOD OF MAKING ASBESTOS-CEMENT SHEETS

Filed Aug. 16, 1949

‘

2 Sheeis—Sheet 1

IN VEN TOR.

Feb. 16, 1954

2,669,166

C. C. SMITH

METHOD OF MAKING ASBESTOS-CEMENT SHEETS

Filed Aug. 16, 1949

2 Sheets-Sheet 2

INVENTOR.

BY

I

Patented Feb. 16, \1954

2,669,166‘

UNITED-‘STATES PATENT OFFICE

METHOD OF‘MAKING ASBESTOS-CEMENT

'

SHEETS

‘

4

Charles Carter Smith, Mobile, Ala., assignor to

‘The Ruberoid 00., New'York, N. Y., a corpo

ration of New Jersey

‘Application. August 16, 1949, Serial No. 110,564

‘1 Claim. (Cl. 92-40)

1

.

, This invention relates to a method of making I

asbestos-cement sheets, and more particularly to

,a continuous method of making laminated as

;bestos-cement sheets.

-

the same ?nished thickness than that made by

the conventional methods.

The invention will appear more fully from the

following description thereof, reference being

. .-.One method of manufacture of asbestos-cement

had to the accompanying drawings, in which:

sheets now extensively used is the Hatschek

method. According to that method a pulp or

slurry of Portland or hydraulic cement and as

bestos ?bers is formed in one or more cylinder

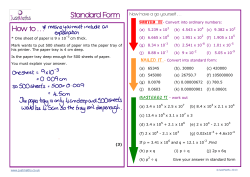

.Fig. 1 is a perspective view of one form of ap

paratus, suitable for use in conjunction with a

vats or tanks and is picked up on an endless belt

Hatschek machine, in carying out my invention;

Fig. 2 is a top plan view of that apparatus; ;

Fig. 3 is a diagrammatic view in elevation of

or band, usually made of felt, by which it is car

one form of complete apparatus, including a con

ried to an accumulator drum or roll where it is

ventional Hatschek machine;

wound, a'nurnber of times, until the desired thick

Fig. 4 is a schematic top plan view of one form

,of hopper for use in applying the intermediate

ness of laminated material has been obtained.

_

vThe material is then slit, stripped from the drum, ,j' layer or ?ller of dry mix; and,

and laid out ?at. The apparatus used in carry

ing out that method is known in the art as a

“Hatschek machine,” and is quite expensive. '

1 The Hatschek process is subject to several ob

jection's and disadvantages, among others, that

it is intermittent in that when the laminated ma

terialhas been formed to the desired sheet thick

ness it must be stripped from the accumulator

drum;' and, ‘that the sheets so formed are lim

‘ited in length to the circumference of the ac- _

cumulator drum.

-

One object of my invention is to provide a

continuous method of making laminated asbestos

cement sheets that permits of; use of thepresent

Hatschek machines.

Another object of the invention is to provide

a method of making laminated asbestos-cement

sheets of indeterminate lengths.

A further object of the invention is to increase

the rate of production of the sheets.

A still further object is to decrease the cost

Fig. 5 is a section in elevation of the hopper

taken on the line 5-5 of Fig. 4.

,

. Referring now to the drawings, l0 indicates the

vats of the Hatschek or “wet” machine, usually

three in number. Each vat contains a cylinder

screen II by which the asbestos-cement pulp or

slurry is deposited on the lower contacting sur

face of the endless belt l2. The thickness of the

'web 13 formed on the belt is, in general, deter

mined by the number of vats used. The web is

carried by the belt over the conventional suction

box l4 and under the accumulator drum or roll I5.

In the practice of my invention the drum [5

of the Hatschek machineis not used to wind the

web, in the manner in which it usually functions,

but is used‘solel'y to feed the web on to the con

veyor 16. If desired, the accumulator drum may

be replaced by a feed roll.

The conveyor 16 carries the web under and in

, contact with a rotary slitter I‘! that severs the web

into two parts or sheets I3a and l3b of equal

width. The sheet l3a. is carried downwardly on

to the horizontal conveyor l 8, while the sheet I3!)

and handling required.

is carried sidewise on the conveyors l9 and into

According to the present invention a laminated

sheet isformed by sandwiching a layer of a dry 40 superposition with the sheet 13a. In the progress

of the sheet 13a it passes under a hopper 20 by

mixture of cement and ?bers between two con

which a layer 2| of dry mix of the desired thick

tinuous webs of asbestos-cement to produce a

ness is deposited upon the upper surface of the

composite laminated sheet consisting of two outer

sheet l3a. The dry mix consists preferably of a

layers and an intermediate layer or ?ller, the

three layers preferably being of substantially the 45 mixture of Portland cement and ground asbestos

cement waste in suitable proportions. Substan

same average thickness. The sheet so made may

tially equal parts of cement and waste have been

be cut to form sidings, roo?ng shingles, or other

found to give satisfactory results. The mix may

products, which products may be textured and,

be applied by any conventional vibrating screen

if desired, faced with granules, in the usual man

ner. The sheet is usually made so that when 50 22. Where it is desired to make a tapered prod

pressed its thickness would be approximately

uct the screen may be wider along one edge of

0.150", each layer being about 0.050" thick. It

the sheet than along the other, as seen in Fig. 4,

so that as the sheet travels under the hopper the

is to be understood, however, that these dimen

sions are merely illustrative. The product made

thickness of the mix deposited on the surface will

by the practice of my invention is cheaper for

gradually reduce in thickness from one edge to

of manufacture by reducing the amount of labor

2,669,166

3

4

.

wards the other. The moisture contained in the

sheet may be su?icient to hydrate the dry cement

mix, but if not the dry mix after application may

at its ends, as indicated in Figs. 1 and 2 or the

drawings, to trim the edges of the web l3. The

wet scrap cut from the edges may be returned to

the vats HI, or it may be dried, set and ground

be sprayed with water.

While for the sake of economy I prefer to use

a single web l3 of asbestos-cement and split it

into twbi?héets “Rwanda 3b, itfiislwlthinithe _scope

of my "invention to ‘start with ‘two separately

formed sheets if desired. The latter procedure,

however, is much more expensive as it requires

for use in making the dry mix.

The upper roll

of the pair of press rolls 24 may be plain or it

may have-a textured suriareefin‘imitationyof wood

ilt'exture or .otherHdesign?to'giVe the'upp'er surface

of the pressedv composite sheet a textured- ap

vqiearance.

,

Moreover, for best results itis important tha't’the

~WhatiI-claimds;

_ A method of making a laminated product which

lie 1 that " ‘the ‘two sheets, "after ? having "been ksevered

der sheet while the cementl’o'f ethe’sheetds‘still

use of two Hatschek machines tinsteadwof‘one.

consists in continuously forming and longitudi

two outer asbestos-cement layers be of exactly

the same thickness. That resultiidllowsiriatufal-ly Y wally T‘i’ee’ding-ea imo'ist web of unset asbestos

from splitting a single weblong'ltudin'ally ‘into ."I‘5 cement, ?continuously slitting the web longitudi

‘nailly as’it ‘is Ted‘to‘ form two homogeneous sheets

‘two sheets but is difficult to attain to the required

tofisuhstantiailymniform width, continuously and

degree when the two sheets are ‘Separately-£01311“;

simultaneously feeding the two sheets longitudi

In the particular apparatus illustratedin the

nally'o'ne above the other at the same rate of

drawings the sheet l3b passes upwards an'ddown

wards in its path of travel toward the sheet 13a. 20 speed, directing the upper of the two sheets lat

‘éera‘illyfateankangle‘i into‘:parallelism=-withithe1dther,

Whisvismerely an ‘expedient “to ‘provide "space éhe

depositing ea idry mix~of Thy'drau‘l-i'c ‘cement and

tween the sheets for the fl'iopperi-ZIJ. 'TheTform'of

‘asbestos i?ber upon-lithe: upper surface or them‘ith'el'apparatus is immaterial, 'the1‘essentia1 feature

longitudinally ifrom v‘a single :web ‘or separately "25 “moist and unset: ‘before ‘it i is brought'hinto?contact

‘*wit-h‘th'e upper ‘sheewsuperposinglthe= uppereshe'et

"termed, '- are "continuously ‘progressed so that ‘one

*o?the sheets 'is-su'perposed, ‘smoothly and v?atly,

"pressingith'e'compositeiproduct.

fsaid “faced ‘surface of the ‘lower sheet,

.

-uponitheiotlrer’affteri‘thedayereof'dry mix3‘has-ibee'n ‘on

.applie'd'tothe latter.

_ The ‘composite isheet‘imay ‘then \ be ‘passed under L 30

mermmewcaea =in the‘?le of ‘this patent

?'a"hoppe‘r1‘2%‘by‘which}if ‘desired-a 'facing'of-grou't,

or of neat cement and granules, maybe‘applied

é"for" the’purpos'e v‘of-‘decorating or ornamenting' the

LYmatefiall,"after whichiitipasses between 'pl‘ess‘rolls

24, and is ?nally cult‘v‘byithei-rotaryhutter 25, 1or "v

~5Oth€1‘”ciitting instrumentality, "into " pieces or ‘the

size and shape of ‘the ‘r?nishedjproduct. The'cut '

cpieces ‘are "thentstacke'd and permitted to "set in

'fthje‘ usual‘ manner.

'In “the ‘practice "of ‘the ‘ method ‘the

sheets

{are ‘fed "continuously "and "simultaneously ‘at ‘the

same ‘rate of ‘speed so "as ‘to "avoid “tearing "or

‘bucklingbf the‘ sheets when they’arebroughtinto

"superposition. In some‘iinstanc'es itmaybeffound

iin'g >moti'on

it travels "from "slitt'er ’“IT “to the

ipoint-"where' it comes 'into superposition"withwhe

"sheet vlita‘so as’toiassurethat the"two‘-‘sheets'*will

meet ‘in exact-parallelism. ‘ The r611 vthat " carries

r't'hefrotary fsli'tter H may in'addition'i‘cariycutters i

‘UNITED z'szmres ‘PATENTS

,‘Nmnber

(Name

Date

© Copyright 2026